Patents

Literature

48results about How to "Eliminate composition segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-battery 8021 soft packaging aluminum foil and production method thereof

ActiveCN106191544AReduce hydrogen contentImprove sealingJackets/cases materialsMetallurgyIngot casting

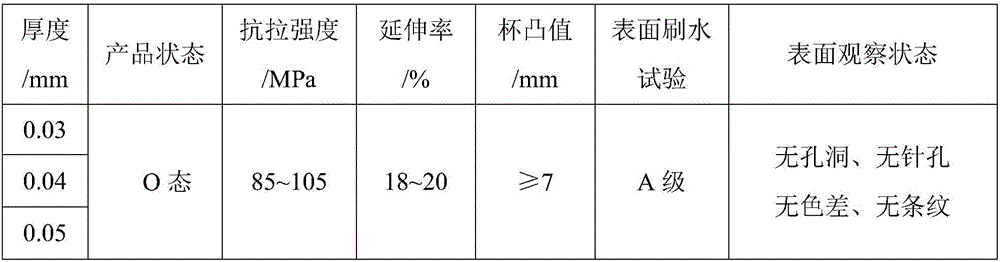

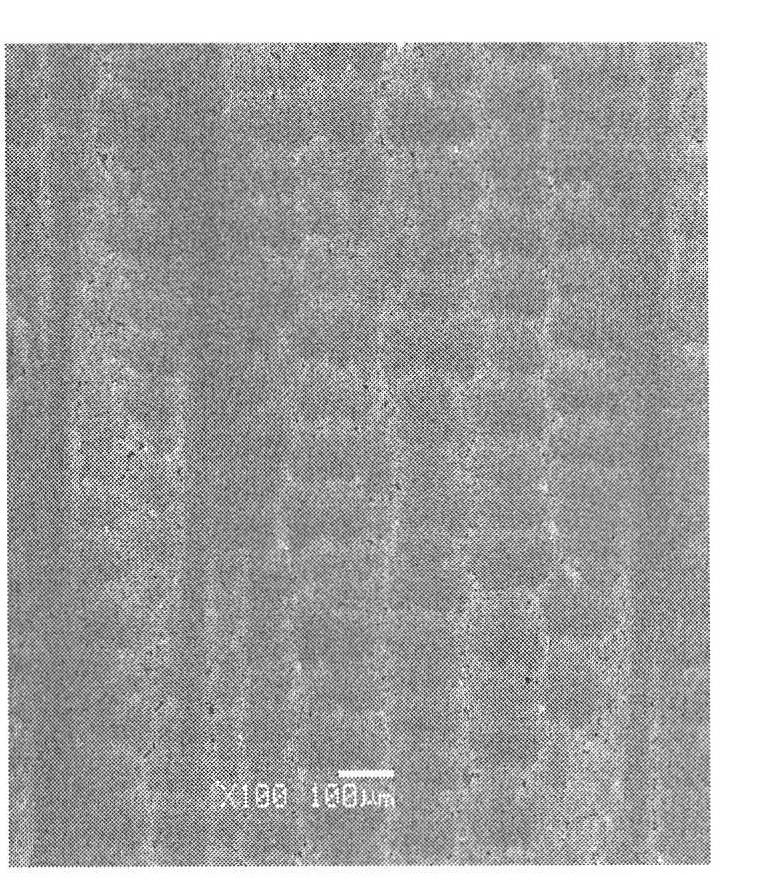

The invention discloses lithium-battery 8021 soft packaging aluminum foil and a production method thereof. Aluminum alloy containing Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al is smelted and subjected to ingot casting, then an ingot is subjected to surface milling and soaking treatment; and the lithium-battery 8021 soft packaging aluminum foil is obtained after the steps of hot rolling, cold rolling, annealing, foil rolling, roll combining, combined roll annealing and roll dividing. The lithium-battery 8021 soft packaging aluminum foil prepared through the good technological process is a finished product in the O state, the ductility reaches 18-20%, the cupping value is larger than or equal to 7 mm, and the fracture resistance, stamping resistance and the like of the soft packaging aluminum foil are effectively improved. The aluminum foil has no holes or pinholes completely, so that a lithium battery soft package prepared from the aluminum foil has good airtightness and is free of liquid leakage and safe to use. The lithium-battery 8021 soft packaging aluminum foil has good social and economical benefits and broad application prospects.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

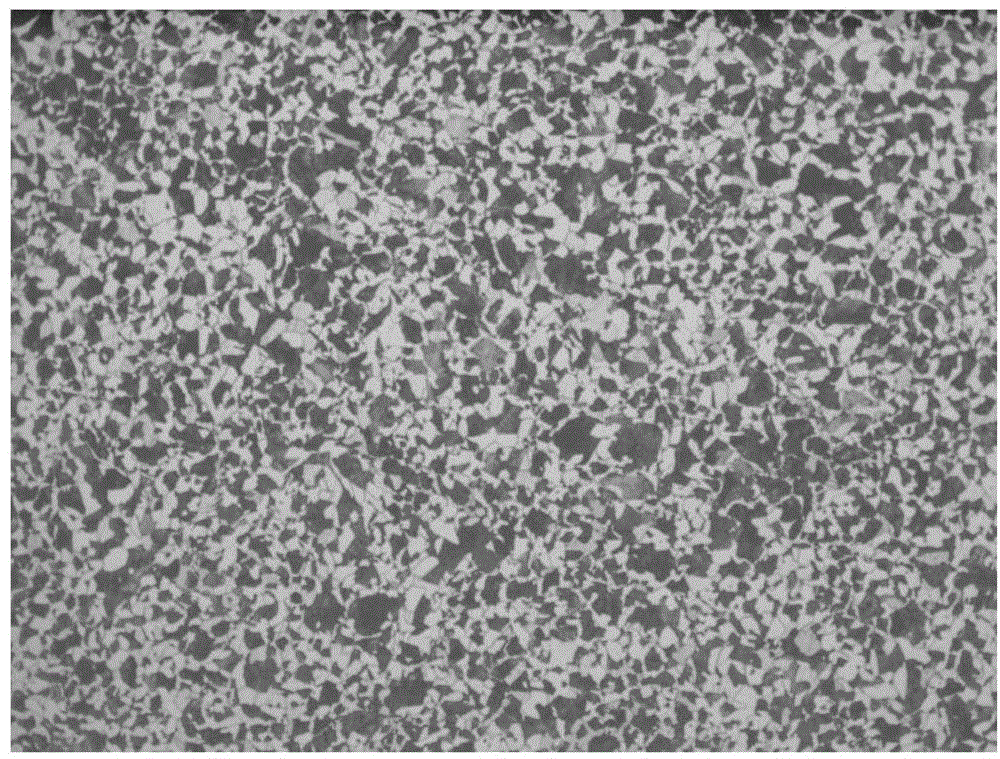

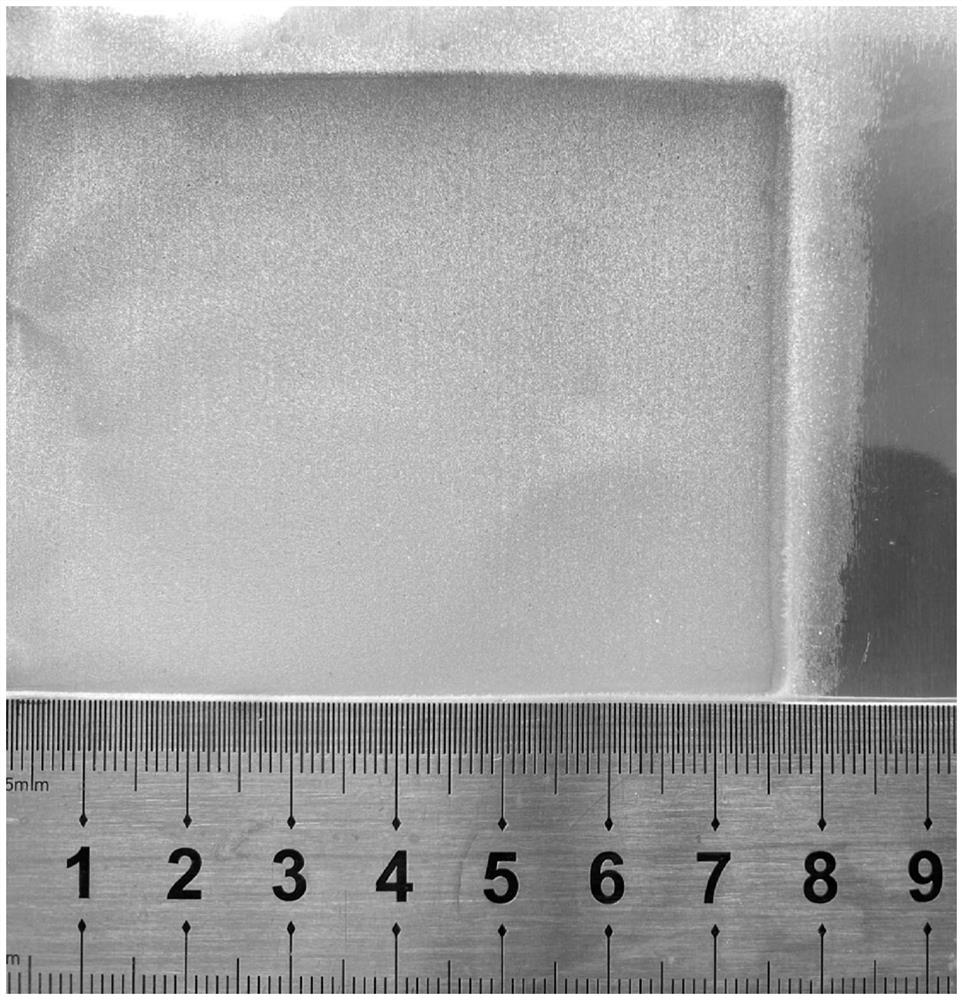

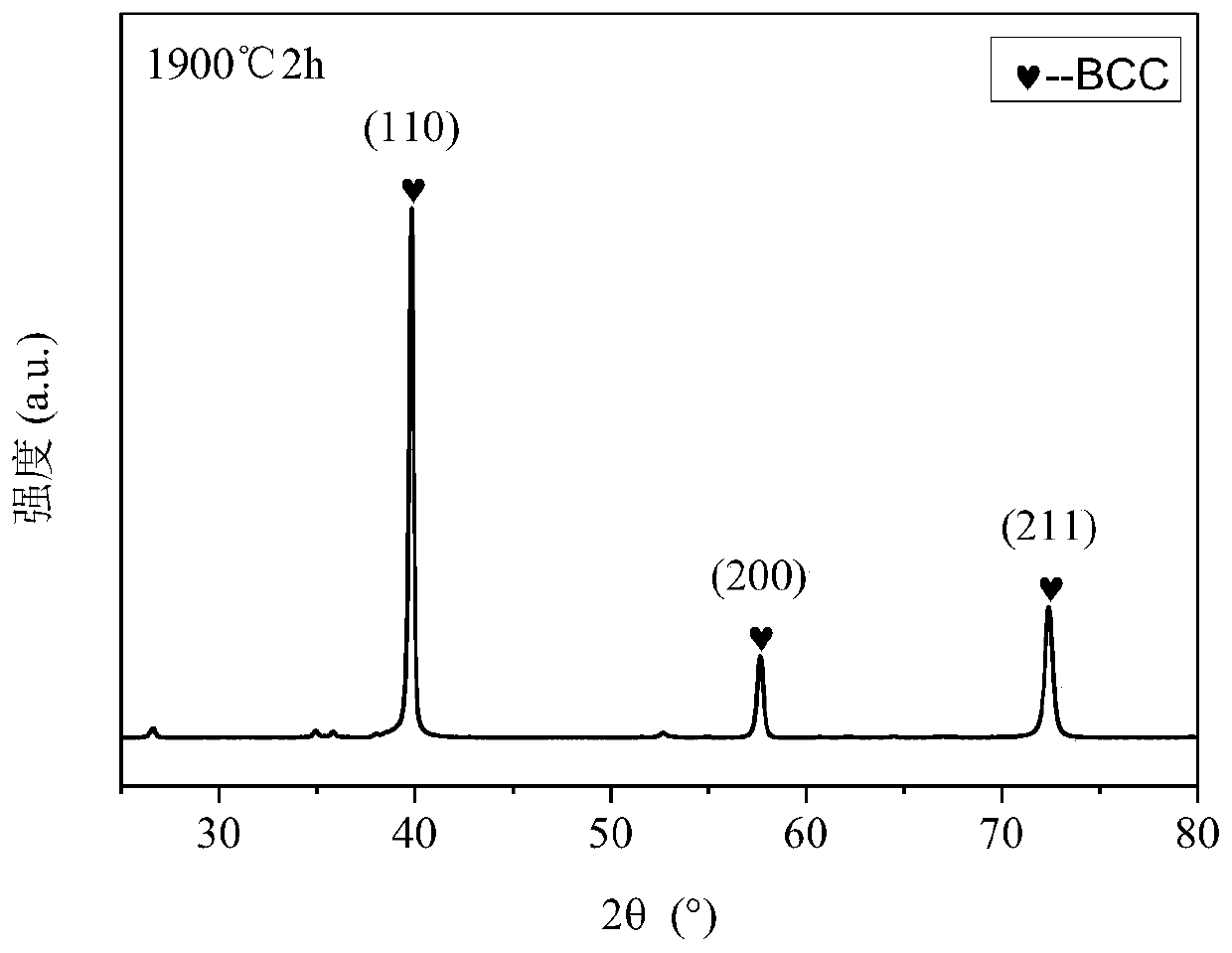

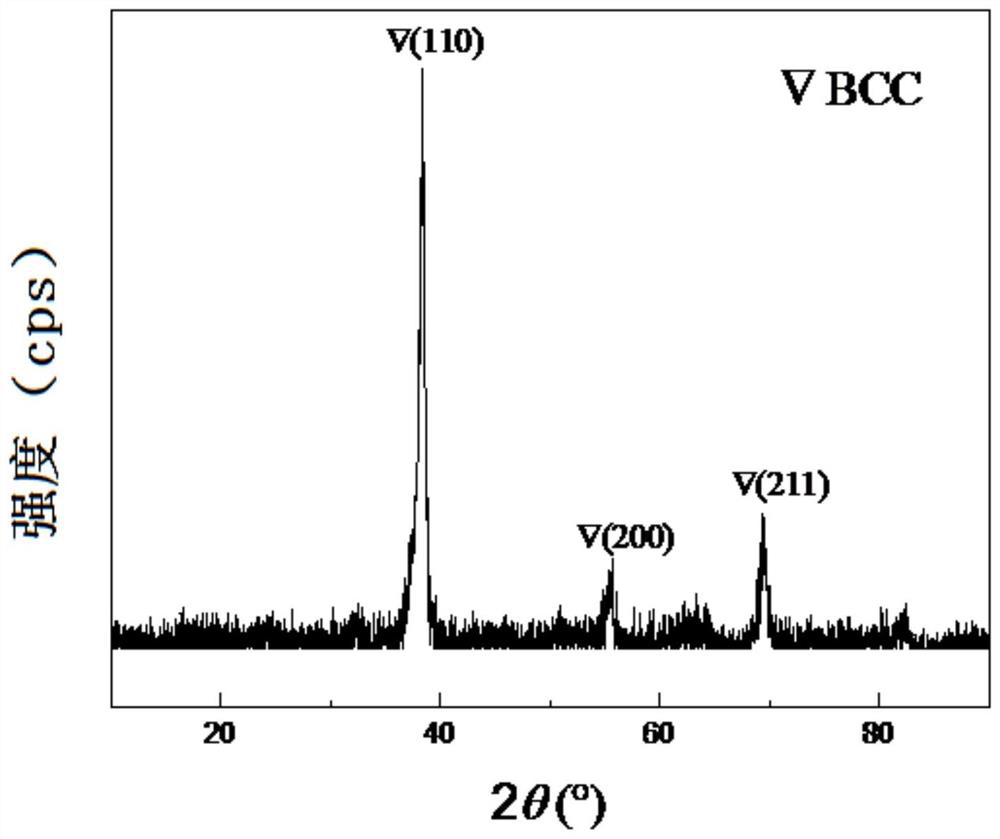

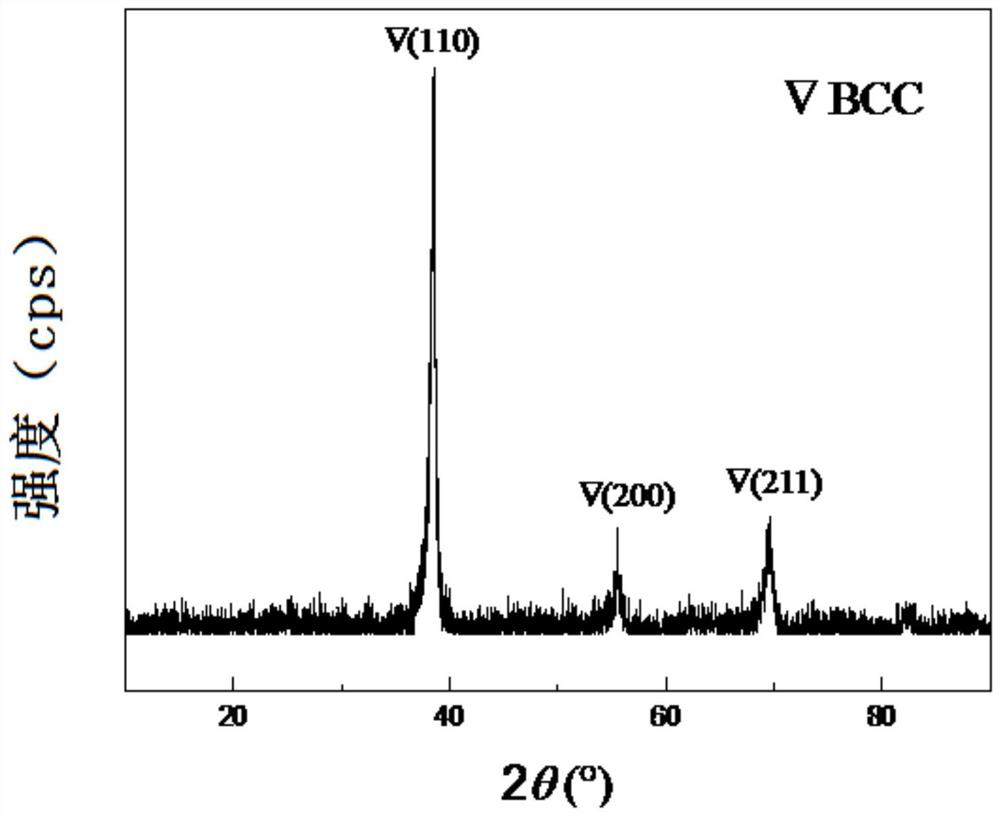

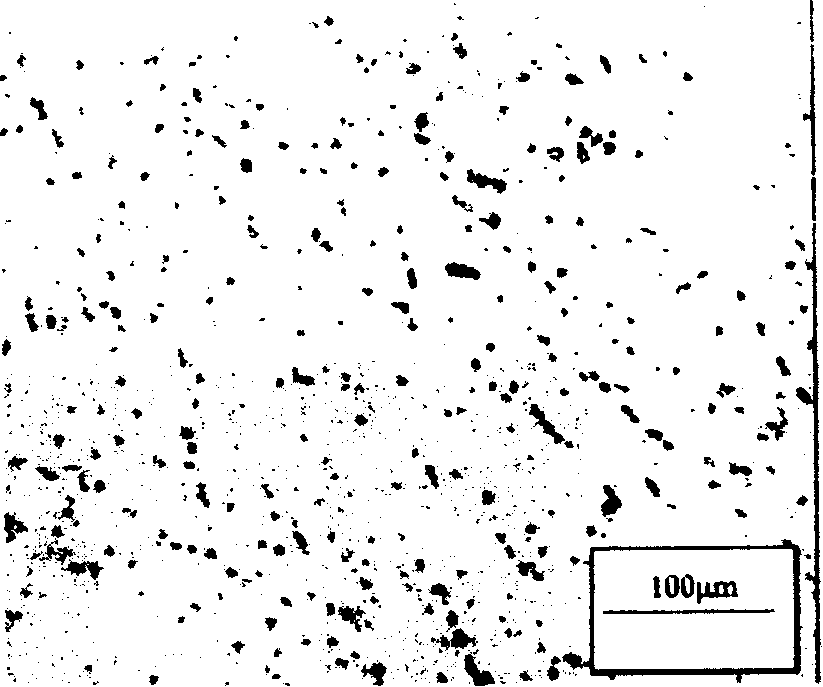

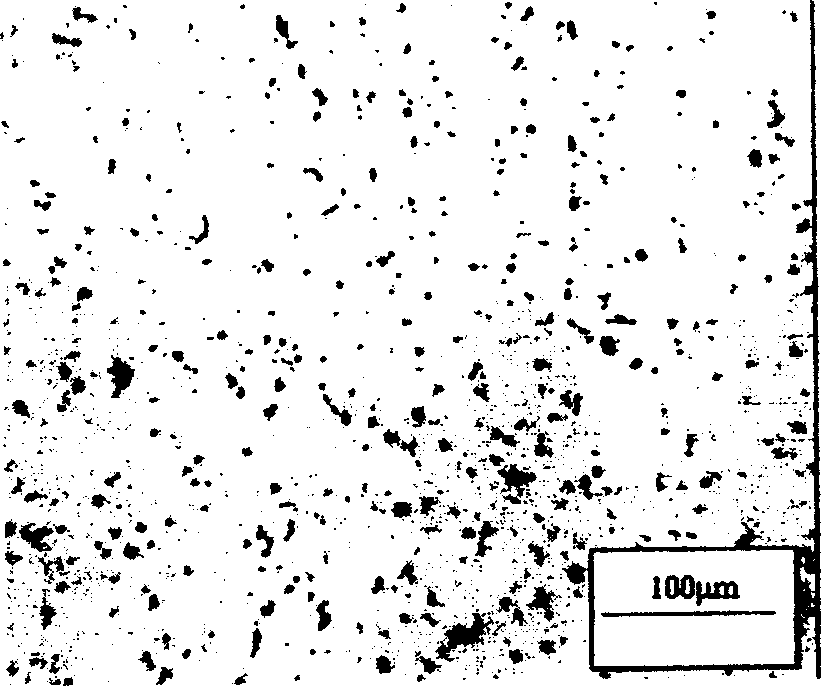

NbMoTaW high-entropy alloy, and preparation method thereof

InactiveCN106167870AImprove performanceEliminate composition segregationHigh entropy alloysSolid solution

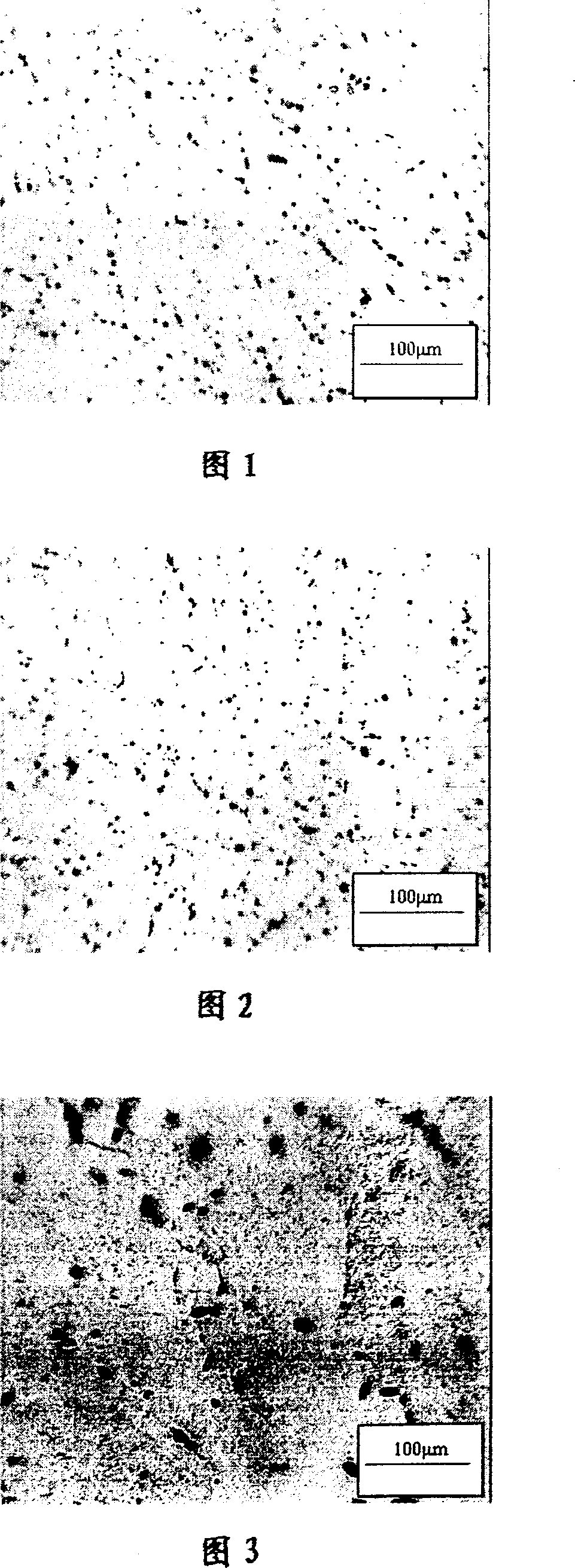

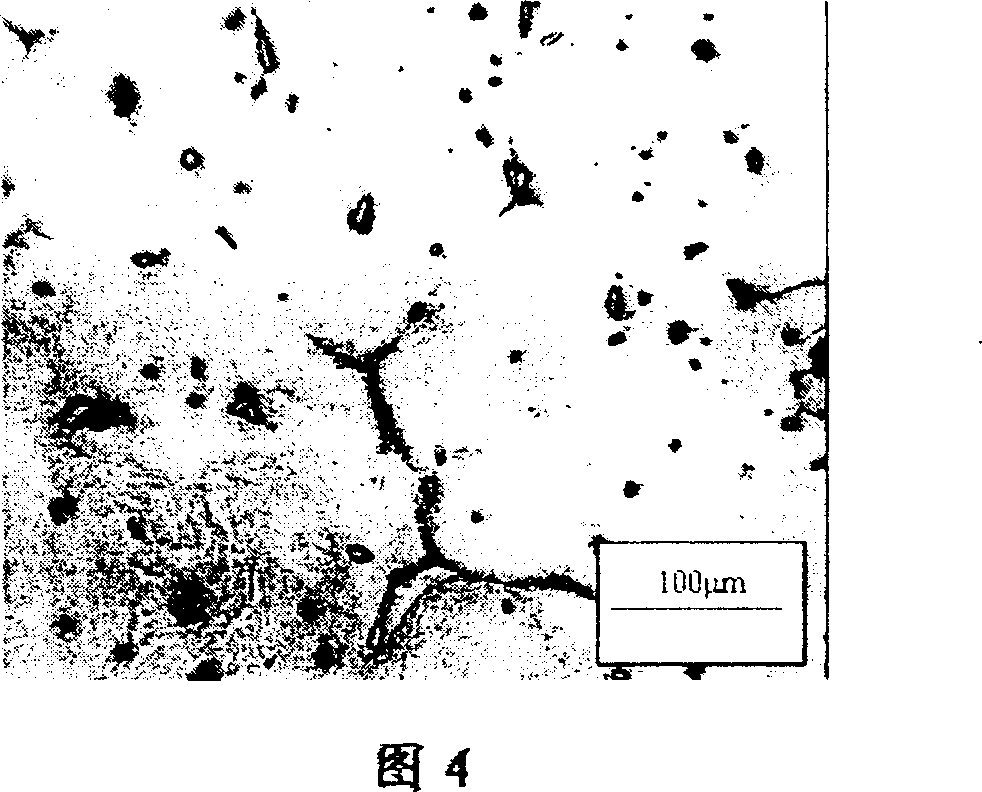

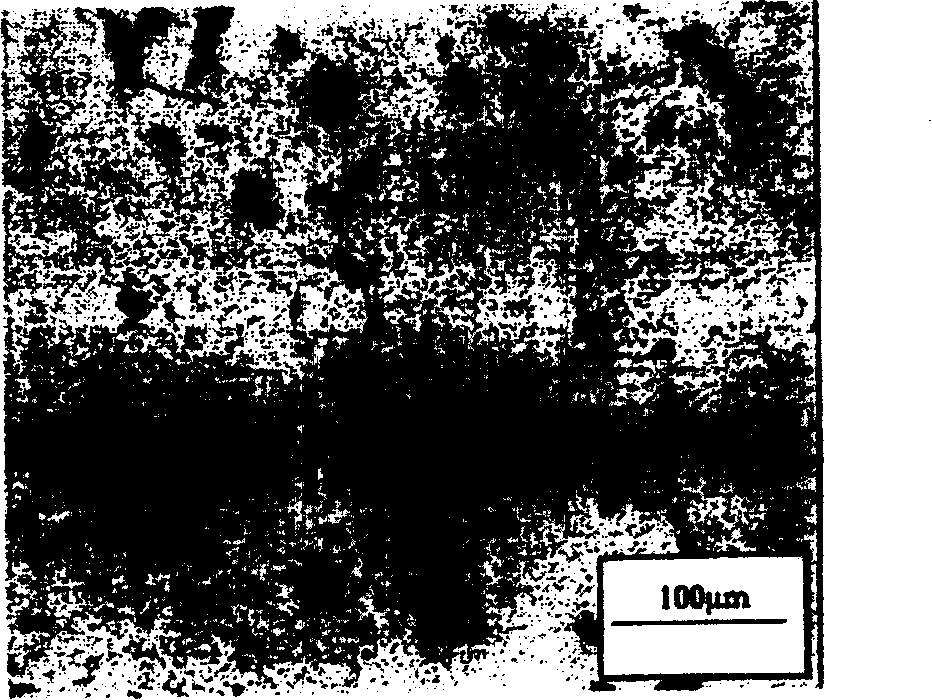

The invention belongs to the technical field of high-entropy alloy, and discloses a NbMoTaW high-entropy alloy, and a preparation method thereof. According to the preparation method, mechanical alloying and spark plasma sintering are combined for forming, alloying of Nb, Mo, Ta, and W which are high in melting points is realized at solid states, heating to the melting points is not necessary, block materials with excellent performance can be obtained via only one time of solid phase sintering ( the sintering temperature is 1600 DEG C or lower), a difficult problem that the melting temperature (>2900 DEG C) of smelting method is high is solved, processing temperature is reduced greatly, and technology is simplified. According to the microscopic structure of the NbMoTaW high-entropy alloy, dispersion distribution of a granular second phase in an isometric crystal substrate is observed, both the substrate phase and the second phase are BCC solid solution, the substrate average particle size is smaller than 6<mu>m, the second phase average particle size is smaller than 4<mu>m, the material crystal particles are small, the structure is uniform, no dendritic segregation is caused, and strength and hardness are high.

Owner:SOUTH CHINA UNIV OF TECH

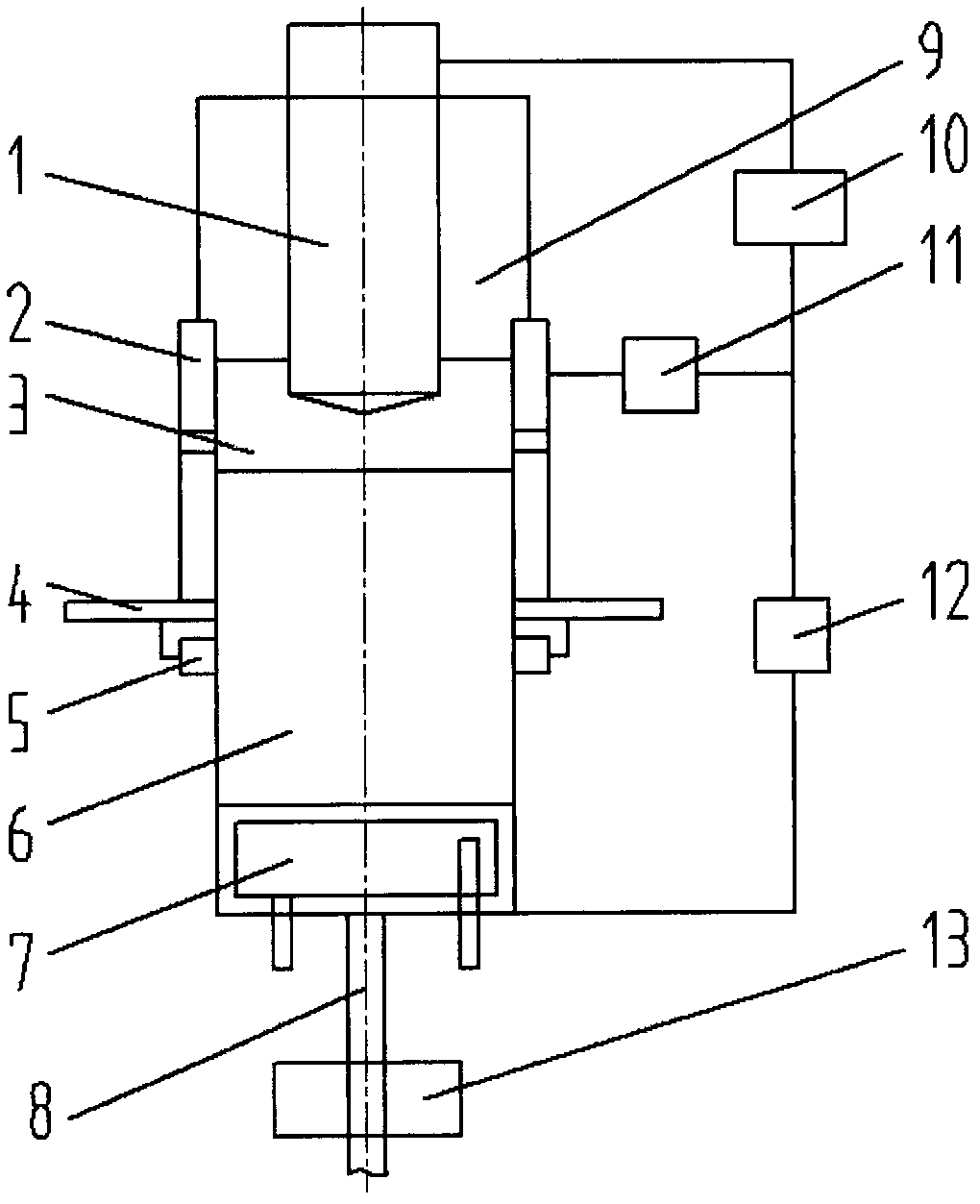

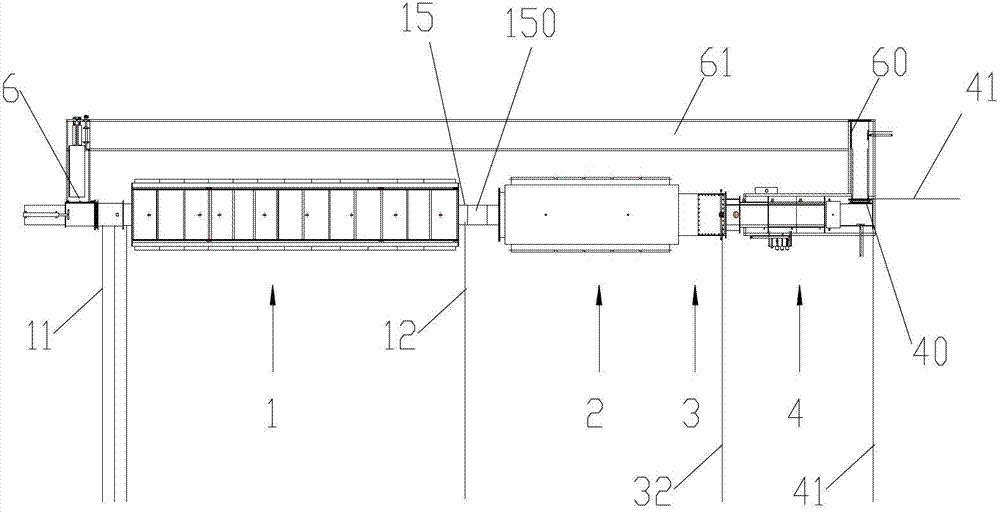

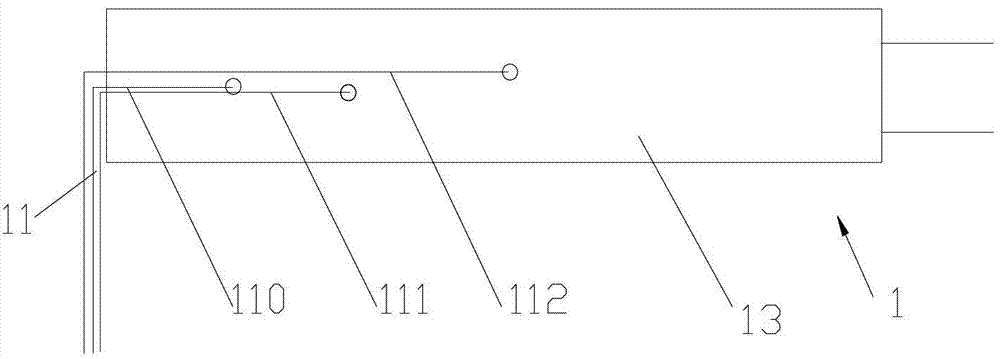

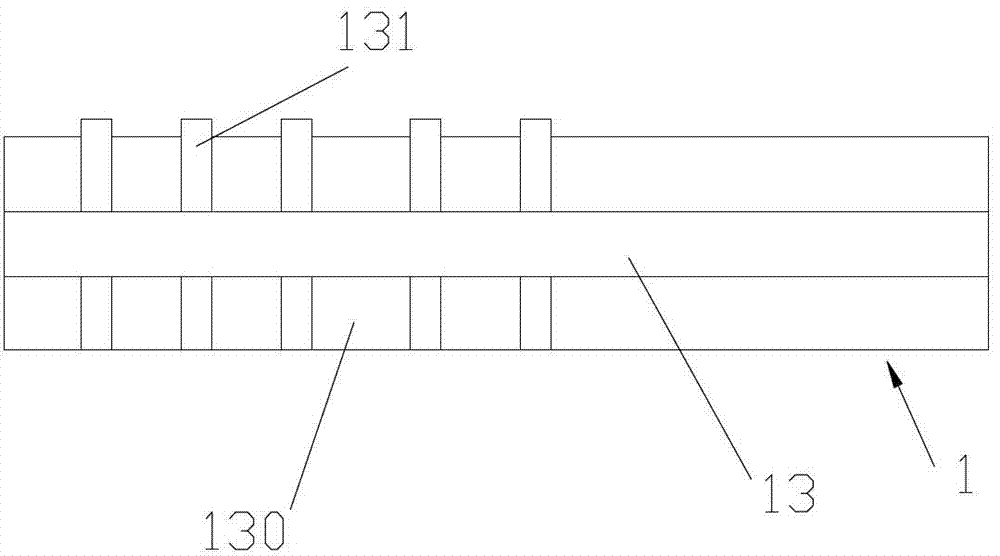

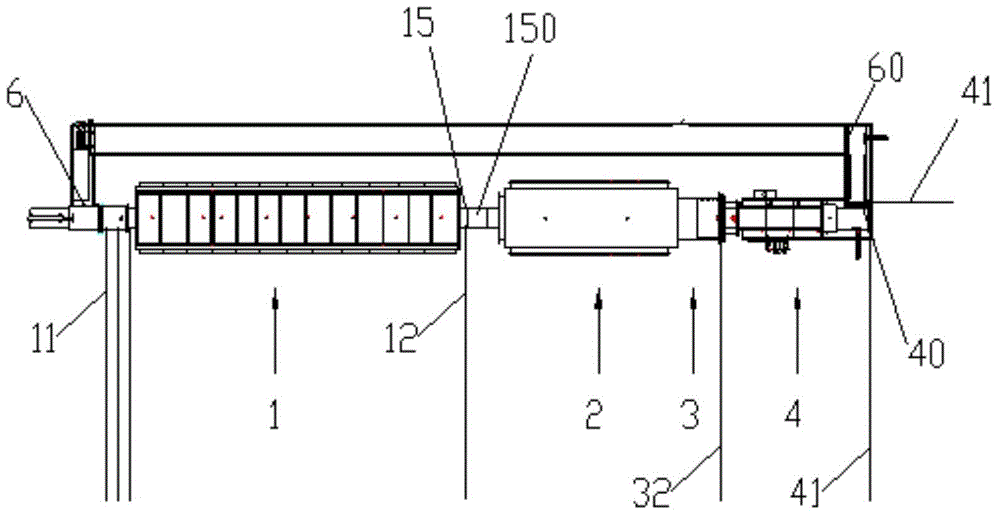

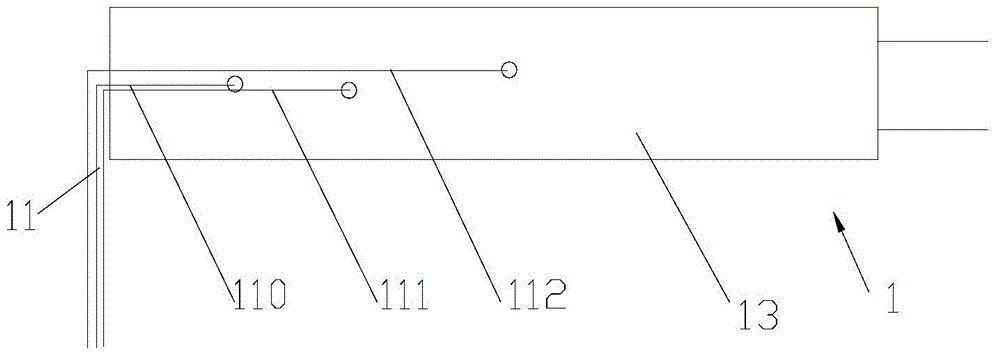

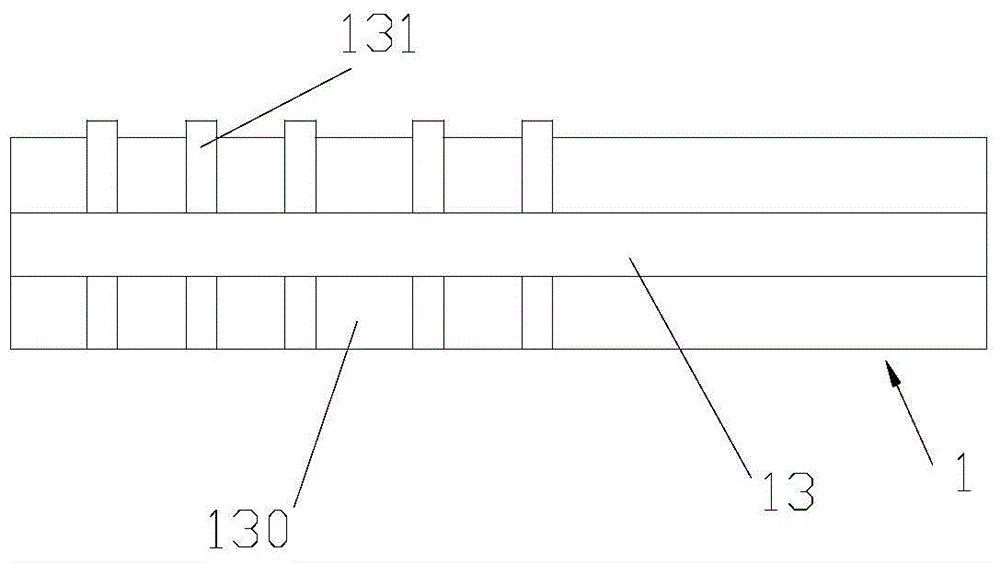

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

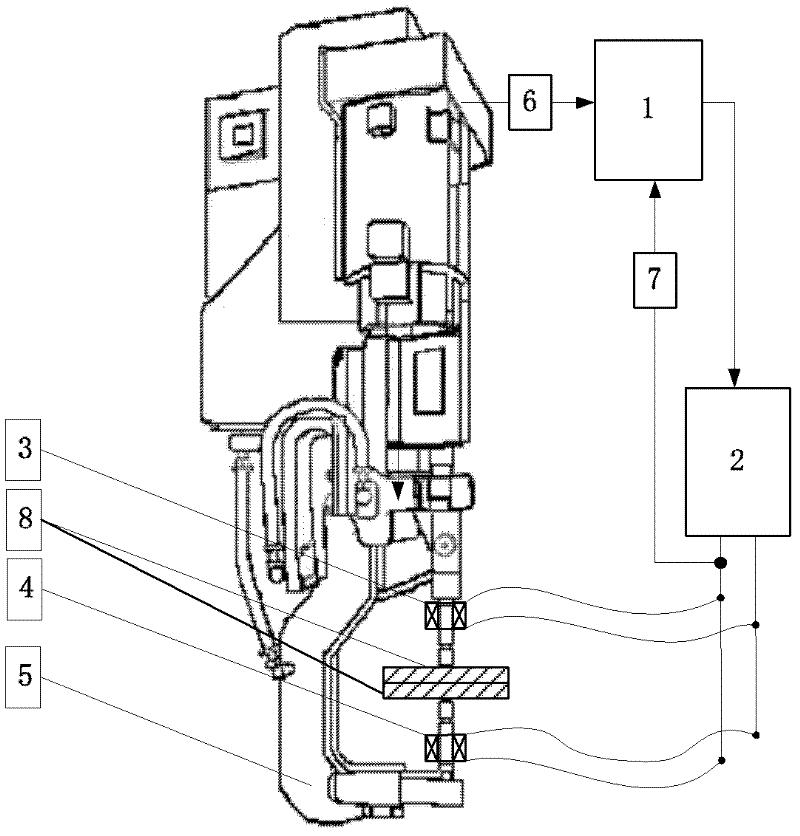

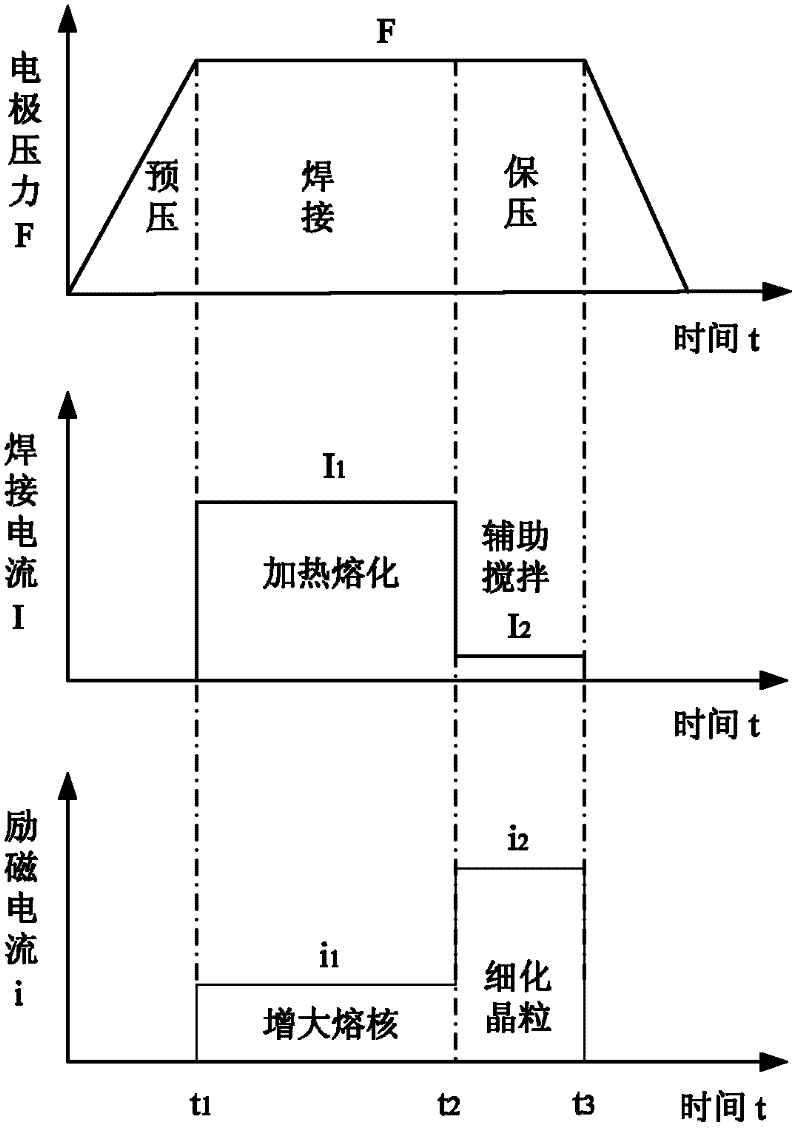

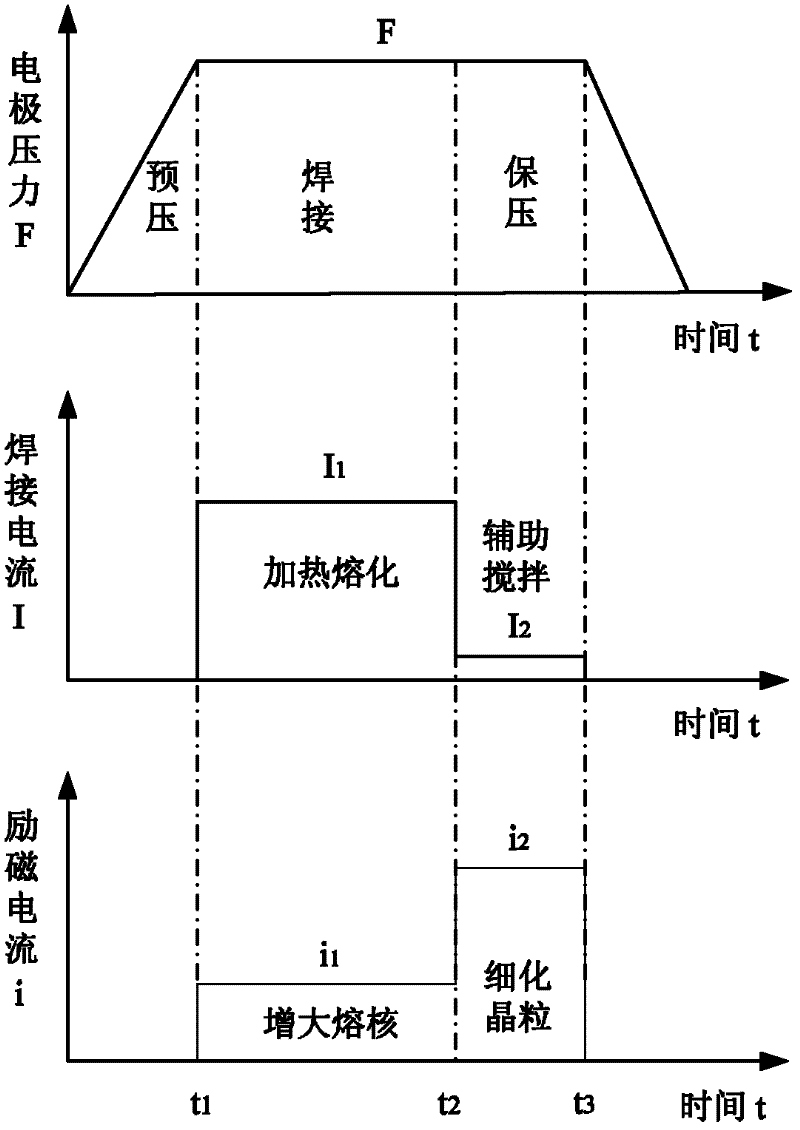

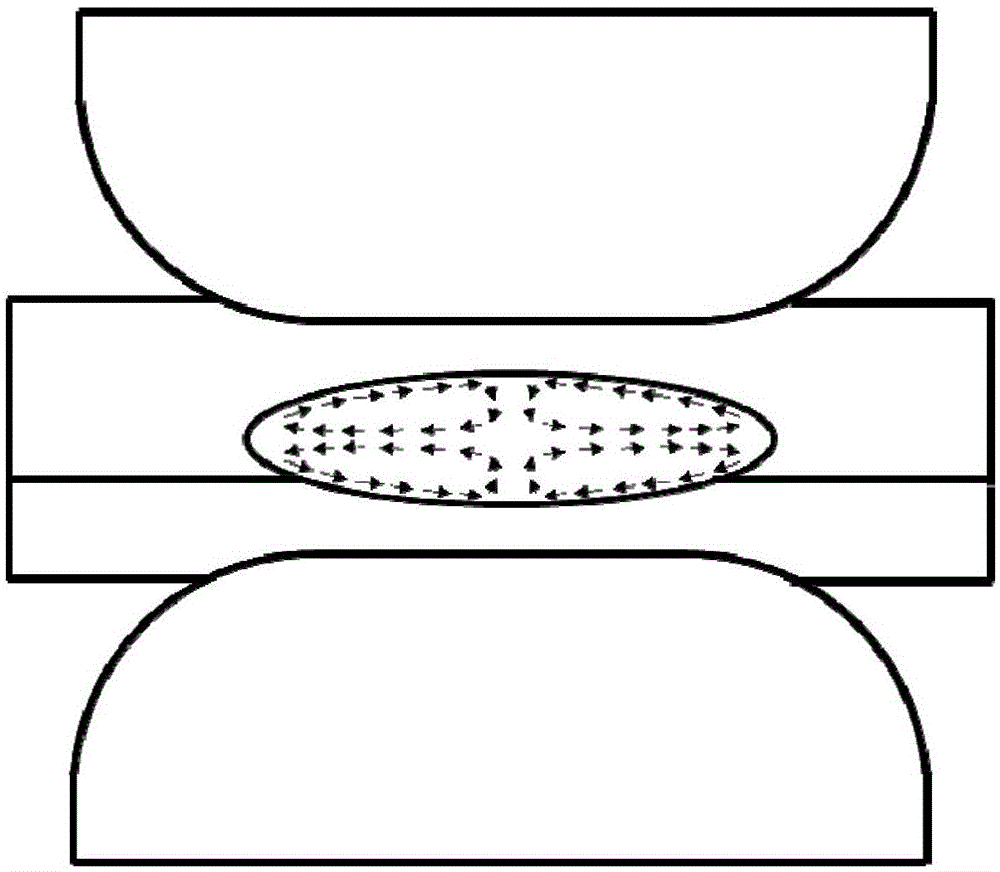

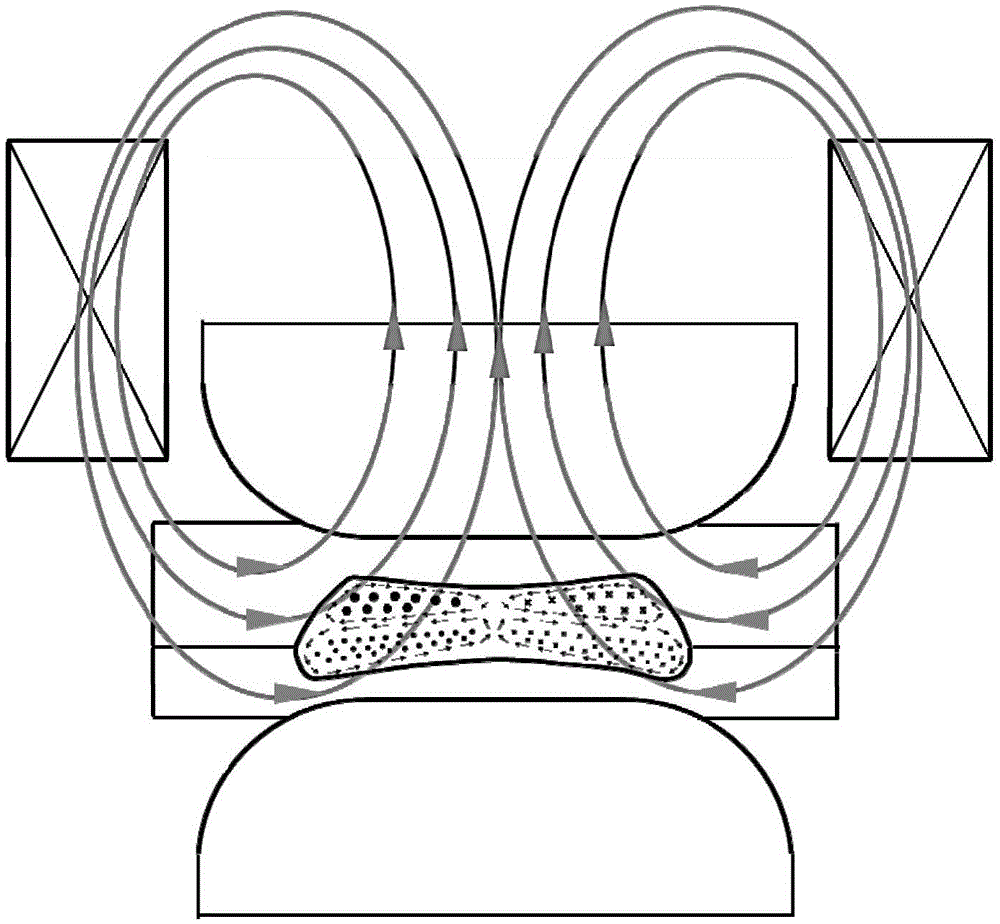

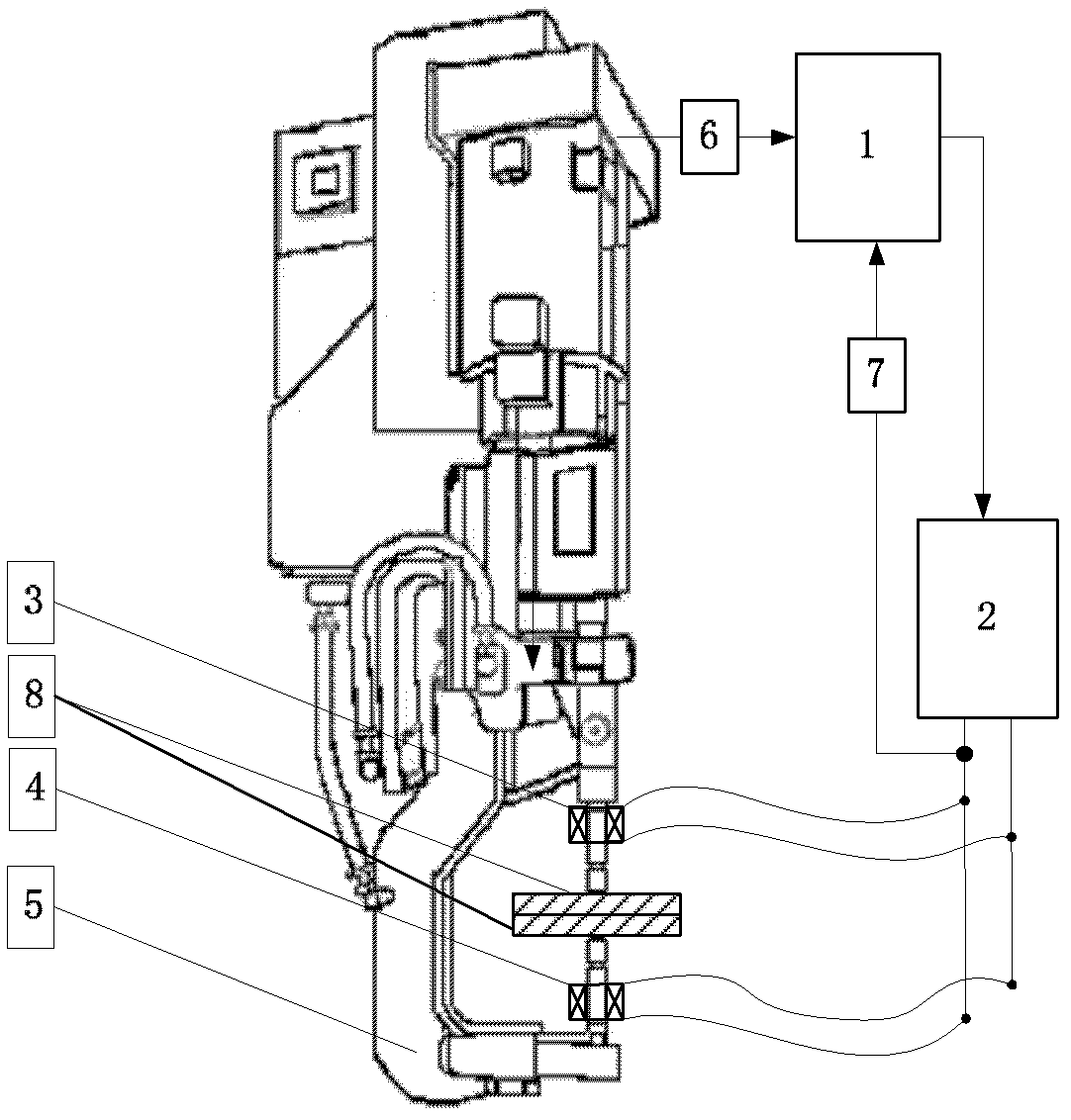

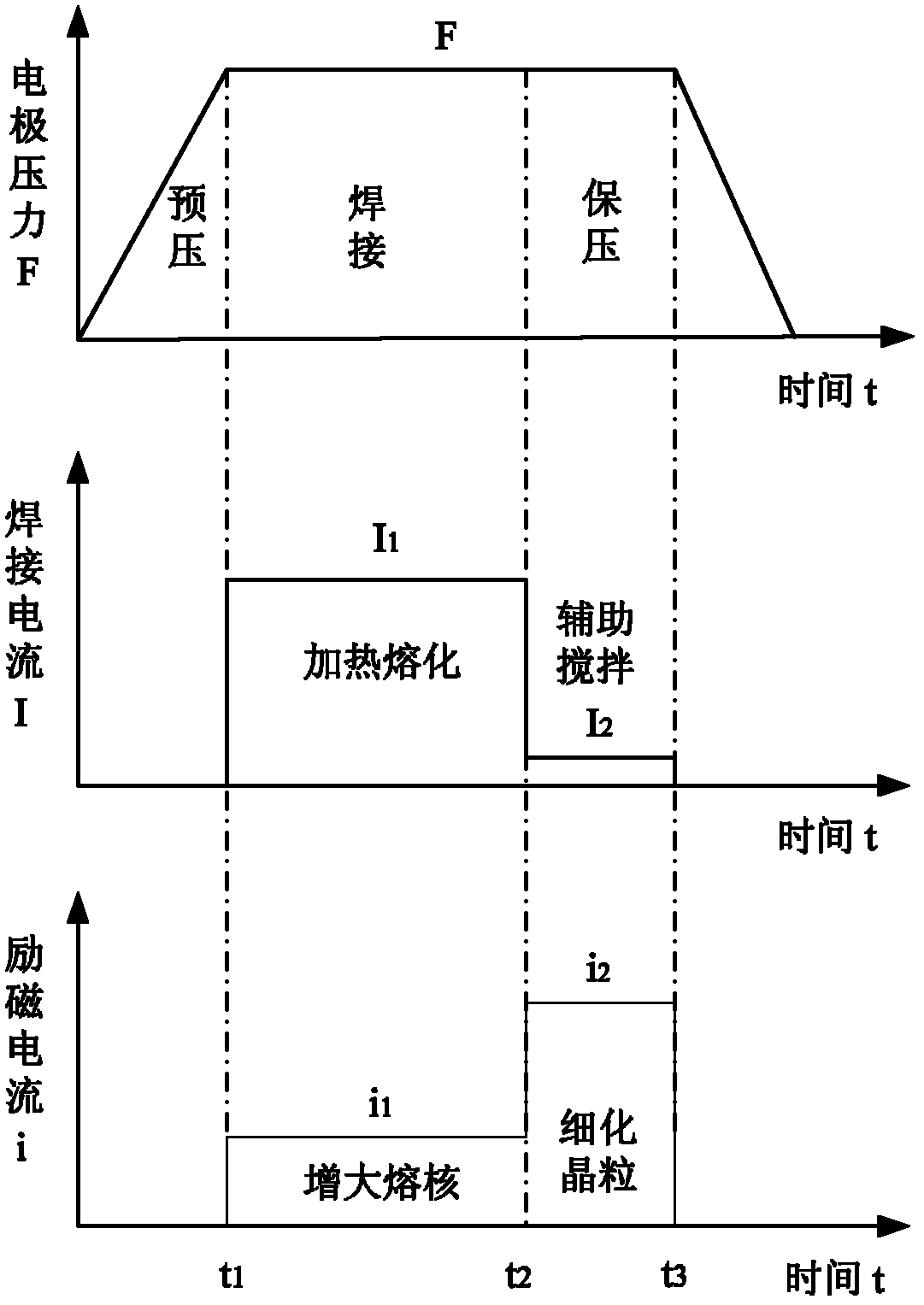

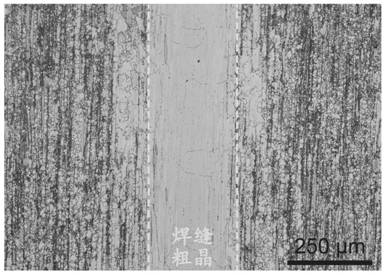

A magnetron resistance spot welding method and device

ActiveCN102267002AImprove welding qualityIncrease the number of equiaxed crystalsWelding electric supplyPower flowControl system

The invention relates to a magnetic control resistance spot-welding method and a magnetic control resistance spot-welding device. The method comprises the following steps that: 1) when a magnetic control system is in a startup state or a reset state, a synchronization system continuously detects switching-on and switching-off as well as the intensity of welding current of a resistance spot-welding gun through a first current sensor and judges whether the resistance spot-welding gun has current or not; if the resistance spot-welding gun has the current, a step 3) is executed; and otherwise, a step 2) is executed; 2) the synchronization system sends a switching-off digital signal 00 to a power conversion device to keep the switching-off state of the power conversion device, and returns to the step 1), and the like. The device comprises the synchronization system, the power conversion device, an upper excitation winding, a lower excitation winding, the resistance spot-welding gun, the first current sensor and a second current sensor. Compared with the prior art, the method and the device have the advantages that: an external magnetic field and the welding current can be controlled coordinately, the comprehensive mechanical performance of a resistance spot-welding head can be improved effectively, the applicability range is wide, and the like.

Owner:SHANGHAI JIAO TONG UNIV

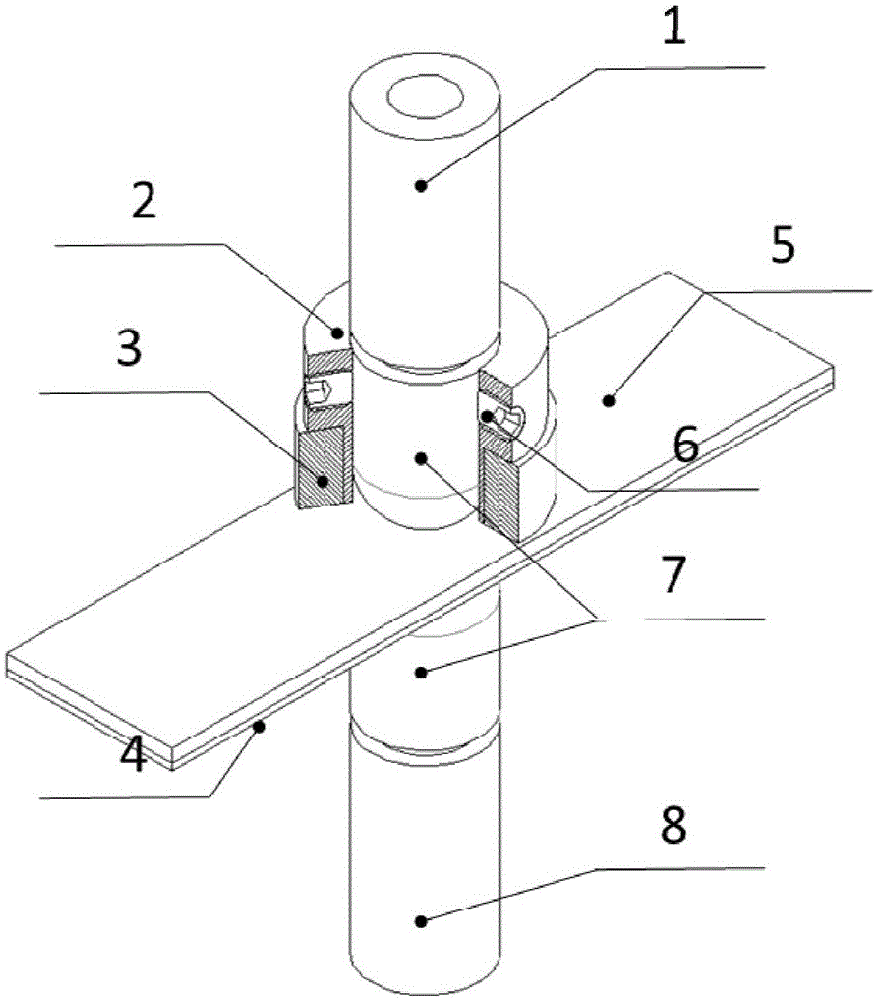

Welding nuclear deviation control device and method for resistance spot welding

InactiveCN105081545AEasy to assemble and disassembleLow application costWelding/soldering/cutting articlesMetal working apparatusEngineeringMechanical property

The invention discloses a welding nuclear deviation control device and method for resistance spot welding. The welding nuclear deviation control device comprises a pair of electrode stems which are arranged on the outer sides of two plates to be welded respectively. An annular permanent magnet is arranged outside the electrode stem on any side. The annular permanent magnets are insulated from the electrode stems. The annular permanent magnets are arranged on the sides, with high specific resistance, of the two plates to be welded or on the sides, with large thicknesses, of the plates. According to the welding nuclear deviation control device and method, assembly and disassembly are convenient, and large-scale transformation over a production line is not needed; the externally-arranged annular permanent magnets can be used repeatedly, and thus application cost is low, and the device and method can be used for welding in a narrow space; magnetic field stirring is conducted during welding, in this way, welding nuclear deviation is weakened, crystal particles are refined and the directionality of the crystal particles is improved through the stirring action, composition segregation is eliminated, and the mechanical property of a spot-welded joint is further improved.

Owner:SHANGHAI JIAO TONG UNIV

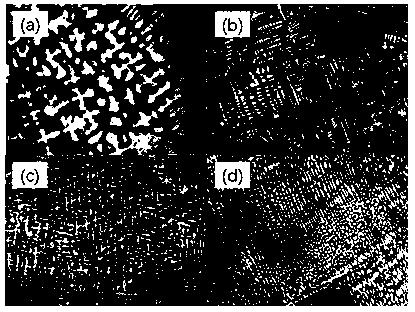

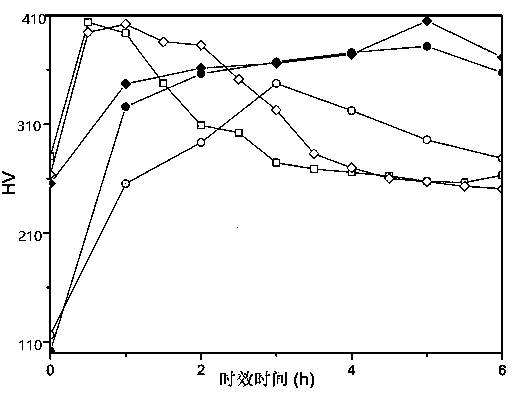

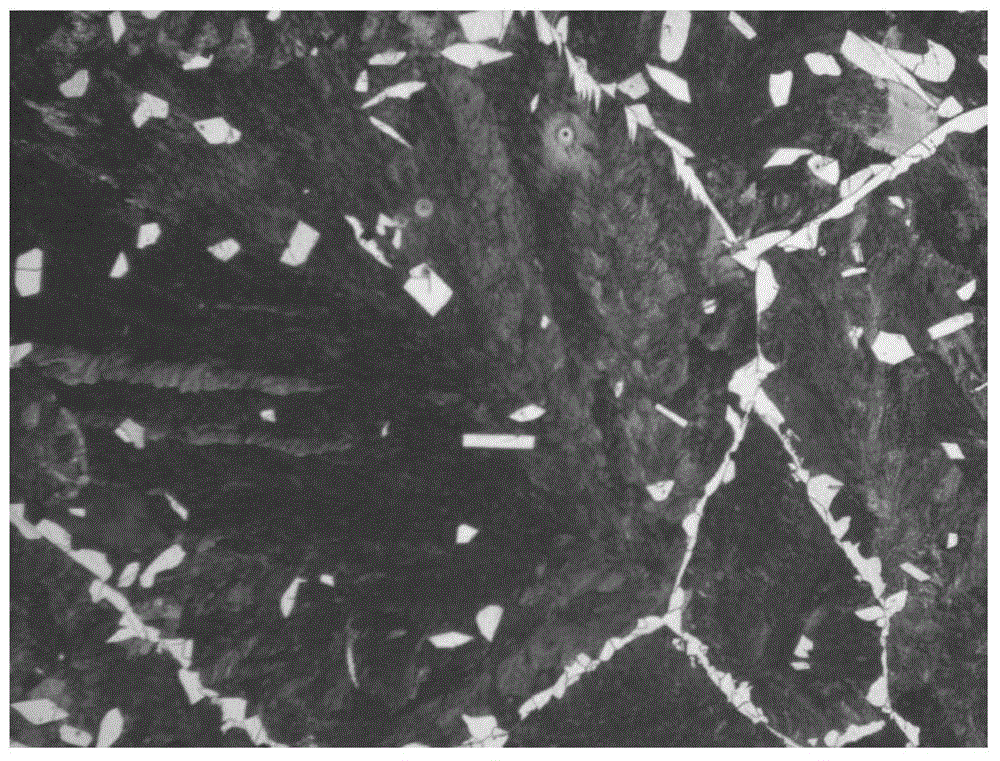

Regulation and preparation method of LPSO phase in Mg-Gd-Er-Zn-Zr alloy

The invention discloses a regulation and preparation method of a LPSO phase in an Mg-Gd-Er-Zn-Zr alloy, and belongs to the technical field of heat treatment. The Mg-Gd-Er-Zn-Zr alloy is heated up to the medium temperature of 300-350 DEG C in a heat treatment furnace; the temperature is kept for 15-60 minutes; the quenching is performed by hot water of 70 DEG C; then, the Mg-Gd-Er-Zn-Zr alloy is heated up to the high temperature of 480-520 DEG C; the temperature is kept for 3-8 hours; the quenching is performed by the hot water of 70 DEG C; and finally, the Mg-Gd-Er-Zn-Zr alloy is heated up to the secondary-high temperature of 400-460 DEG C; the temperature is kept for 12-50 hours; and the quenching is performed by the hot water of 70 DEG C. The method not only can control the volume fraction and one-dimensional dimension of the LPSO phase in the alloy, but also can effectively eliminate the component segregation of the casting alloy. Through the control process, the volume fraction of the LPSO phase is 3.2-45.67%, the range of the one-dimensional dimension is 25-120 microns, the component segregation and thick primary tissues of the casting alloy can be obviously eliminated, and the mechanical performance of the alloy is obviously improved.

Owner:BEIJING UNIV OF TECH

Method for processing magnesium alloy

A magnesium alloy processing method comprises the following steps: (1) smelting a magnesium alloy, pouring into a constant-temperature furnace containing a SF6 / CO2 protection gas to maintain the temperature of the molten alloy at 620 to 580 DEG C for 10 to 15 min; (2) electromagnetically stirring, and pressing the slurry material obtained in the step (1) by a mixture gas containing SF6 and CO2 with 0.2 to 0.3 atmospheric pressure into a cavity with a temperature of 240 to 260 DEG C for filling a mold with a temperature of 250 to 280 DEG C at a speed of 0.2 to 0.6 Kg / s for 0.2 to 0.4 min; and (3) compressing to 100 to 150 MPa and relieving the pressure when a cast is solidified. By combining semi-solid state and high-pressure solidification means, the inventive method can effectively thin magnesium alloy part tissue and eliminate air holes, porosity, component segregation and hot tearing susceptibility by twice nucleation in the solidification process. The mechanical property of the magnesium parts formed by the method is significantly improved in comparison with conventional die-casting process, and subsequent heat aging treatment can be carried out.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Homogenization heat treatment method of aluminum alloy ingot casting for pop-top can body

The invention discloses an aluminum alloy cast ingot uniform heat treatment method of tin pot body, which comprises the following steps: (1)making mass percent of alloy as 0.20 Si, 0.52 Fe, 0.18 Cu, 1.02 Mn and 1.23 Mg; setting the other single element not bigger than 0.05 and major total not bigger than 0.15; making the surplus as Al; casting the tin pot body with aluminum alloy; proceeding high-temperature uniform treatment in propulsion heating furnace with cooling device; controlling the temperature at 550-620 deg.c and keeping temperature time at 12-24h; forced-cooling to 460-500 deg.c with cooling speed at 20-60 deg.c / h; (2) controlling heat treatment of evolution phase in the same heating furnace; controlling the temperature at 450-500 deg.c and time at 6-12 h. This invention provides support for high quality production of AA3104 aluminum alloy sheet.

Owner:中铝西南铝板带有限公司

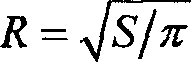

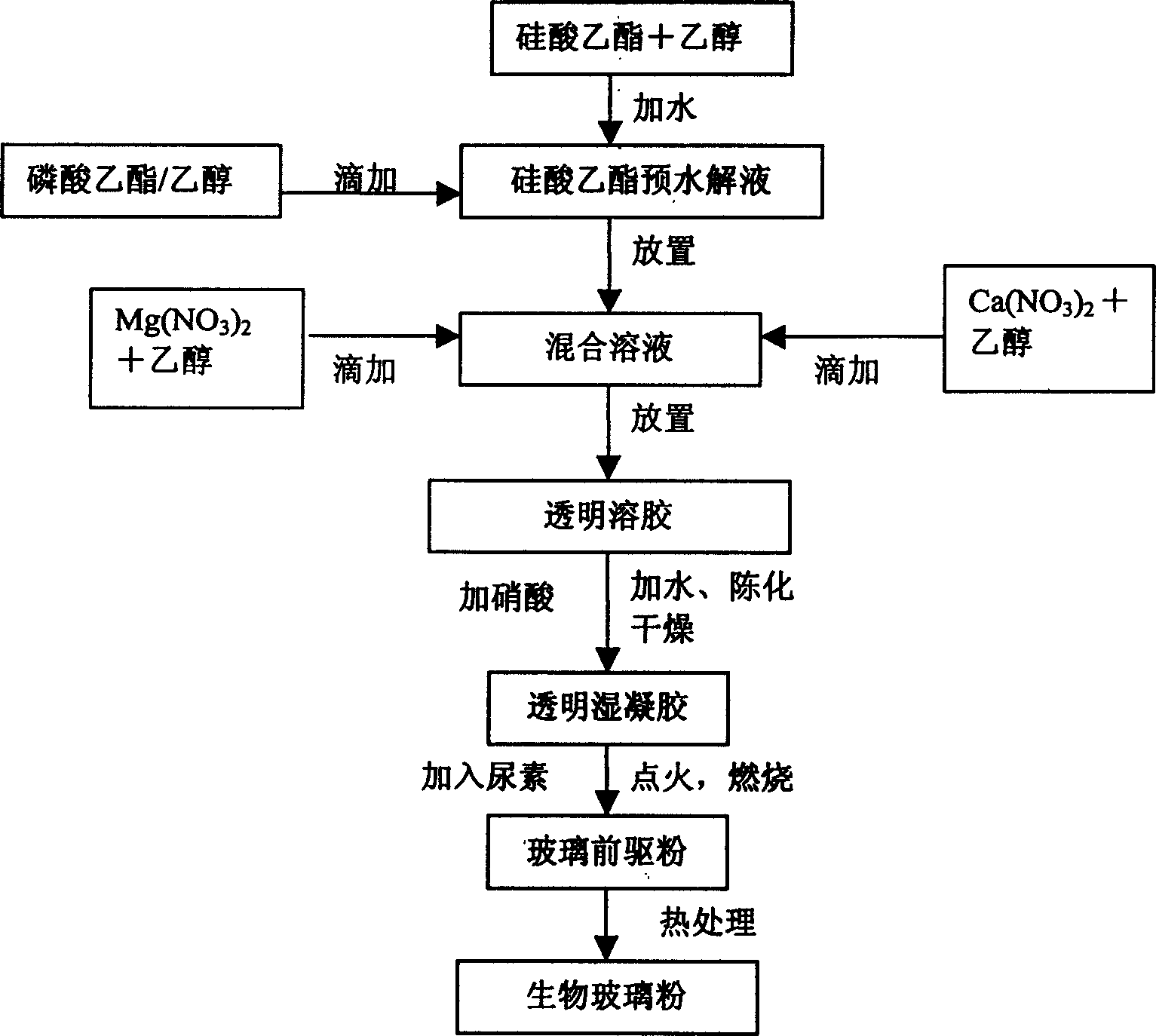

Method for synthesizing high pure superfine biological glass powder

InactiveCN1587149AAvoid preferential hydrolysisNot prone to hard agglomerationGlass shaping apparatusDevitrificationImpurity

The present invention relates to method of synthesizing high purity superfine biological glass powder, and features that after hydrolyzing ethyl silicate for 0.5-1 hr, ethyl phosphate, ethanol solution of calcium nitrate and ethanol solution of magnesium nitrate are dropped successively into the hydrolyzed ethyl silicate liquid and deionized water and nitric acid are then added to regulate pH value to 0.5-2; the mixed liquid is aged and mixed with urea in the same volume, and the mixture is ignited to burn to obtain glass powder precursor; and the precursor is heated to obtain superfine biological glass powder. The simple process can eliminate devitrification, component segregation and crucible pollution, and has short production period, less introduced impurity and less hard powder aggregation.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

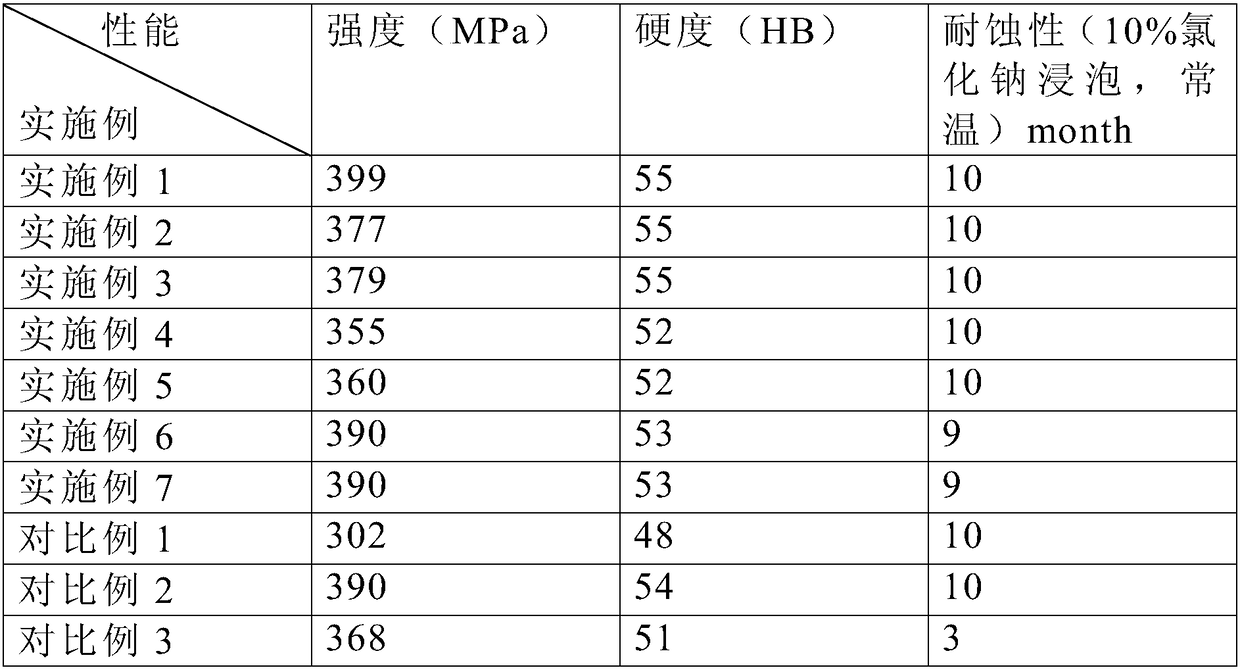

Preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

The invention relates to a preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The Cu-Ni-Sn multi-element alloy is obtained through vacuum induction melting or covering protection type non-vacuum smelting. In the casting forming process, electromagnetic stirring is applied until alloy liquid is complete solidified, and then the as-cast alloy is subjected to homogenization annealing, hot rolling and cogging, solid solution treatment, cold deformation, spinodal decomposition and other processes. The preparation method of the Cu-Ni-Sn alloy is capable ofrefining crystalline grains, reducing dendritic spacing and eliminating alloy microscopic and macroscopic structure and component segregation, provides implementation conditions for follow-up alloy plastic processing, spinodal decomposition and other processes, and has the beneficial effects that energy is saved, the production efficiency is improved, the service life of the alloy is prolonged, and the production cost is reduced.

Owner:JIANGYIN SANLING METAL PROD

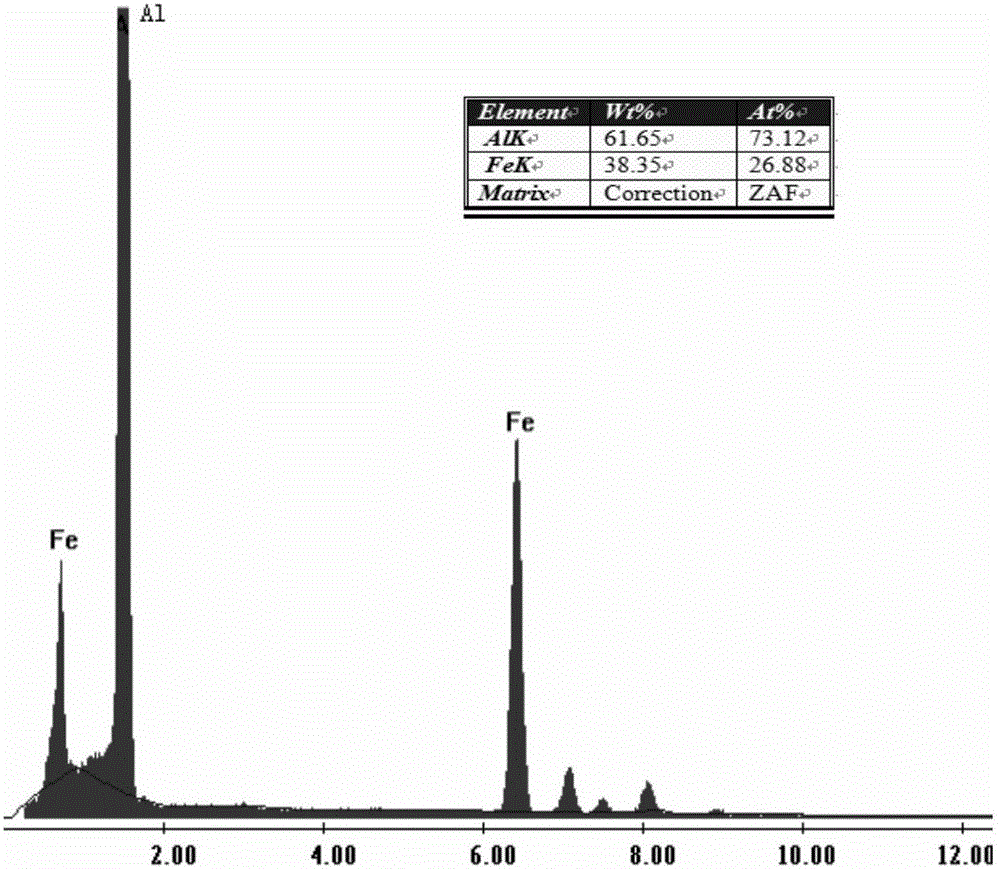

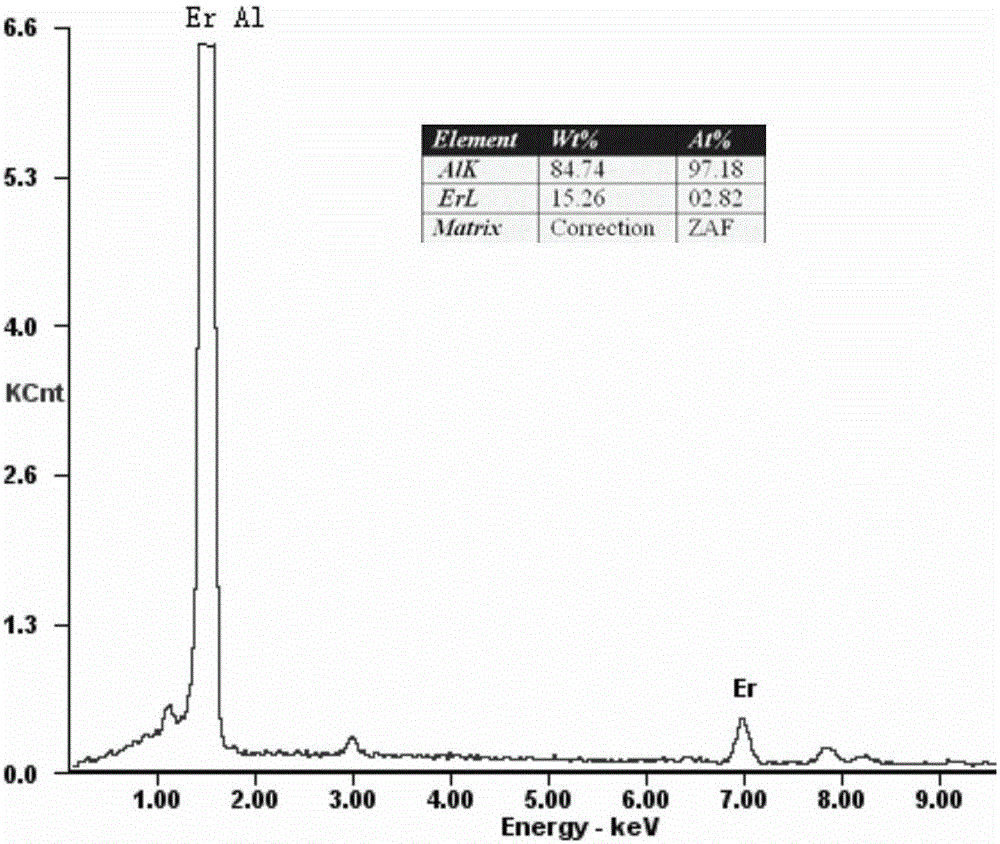

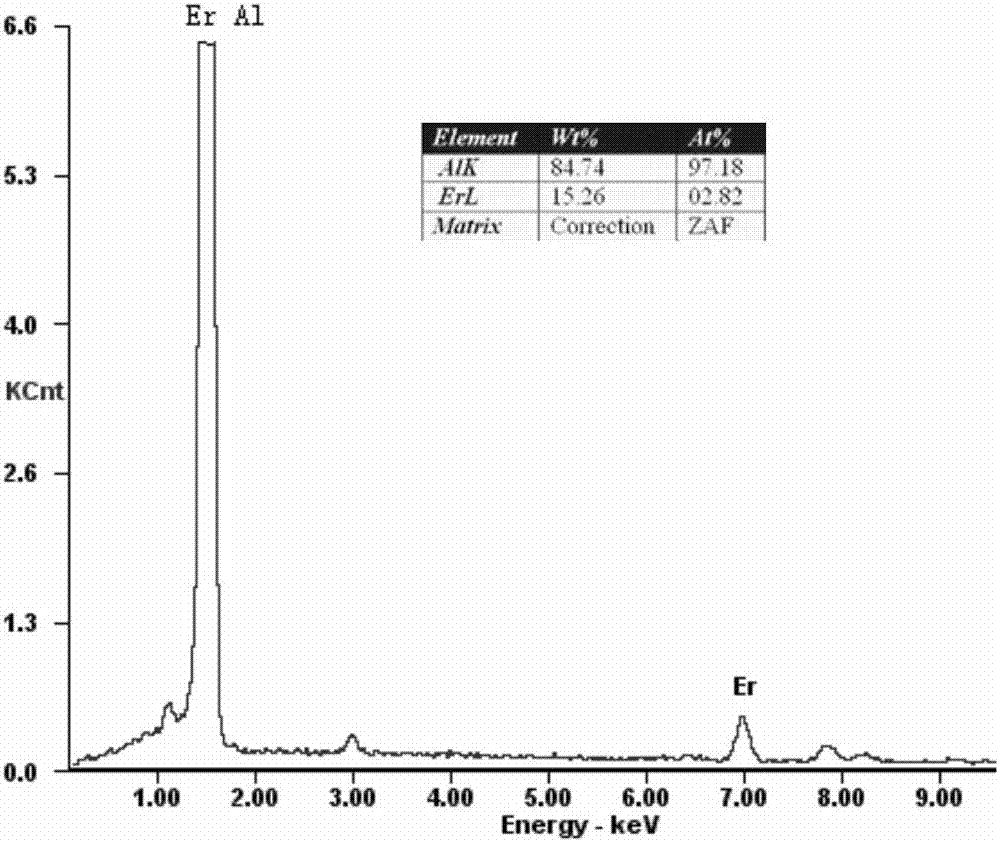

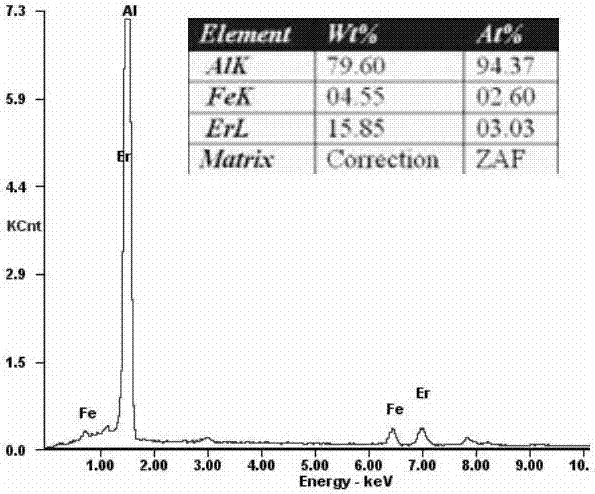

Light high-conductivity and heat-resistant aluminum conductor and preparation method thereof

ActiveCN105734353AImprove conductivityOo fullConductive materialMetal/alloy conductorsElectricityHeat resistance

The invention discloses a light high-conductivity and heat-resistant aluminum conductor and a preparation method thereof. The aluminum conductor is composed of, by weight, 0.035-0.06% of B, 0.1-0.2% of Zr, 0.1-0.3% of Er, inevitable impurities and the balance Al. The technological process comprises the steps of smelting, on-the-spot fast component analyzing, refining, rapid cooling casting, blank annealing, extruding and drawing. The added B element has the refining and modifying effects and mainly has the effect of promoting supersaturated solid solutions containing Zr and Er to separate out Al3(Er and Zr) ternary composite phases; the Al3(Er and Zr) composite phases are nano particles which are coherent with a matrix and have shell-core structures, are dispersed in the aluminum matrix and can greatly improve the electricity conductivity and the heat resistance of the aluminum conductor; the density of obtained monofilaments is smaller than or equal to 2.71 g / cm<3>, the electricity conductivity of the monofilaments is greater than or equal to 62%IACS, the short-time heat-resistance temperature of the monofilaments reaches 230 DEG C, the long-term heat-resistance temperature of the monofilaments reaches 210 DEG C, and the tensile strength of the monofilaments is greater than or equal to 165 MPa; the economic benefits are remarkable, the energy is greatly saved, and the environmental friendliness is high.

Owner:CENT SOUTH UNIV

Heat treatment process method for EA1N-material urban rail car axle

InactiveCN104404224AEliminate composition segregationHigh strengthFurnace typesHeat treatment furnacesAustenite grainPearlite

The invention discloses a heat treatment process method for an EA1N-material urban rail car axle; the heat treatment process method includes the steps of two times of normalizing and one time of tempering, wherein the heat preservation temperature of first normalizing is 850-880 DEG C, and the heat preservation time is 3-4 h; the temperature of second normalizing is 810-820 DEG C, and the heat preservation time is 3-4 h; the content of C in the steel type is 0.32-0.40%, the upper limits of the contents of Si, Mn, P, S, Cr, Cu, Mo, Ni and V are respectively 0.50, 1.20, 0.020, 0.020, 0.30, 0.30, 0.08, 0.30 and 0.06, and the balance is Fe and inevitable impurities. By the first normalizing, the car axle austenite is homogenized, the material organization and composition segregation is eliminated, and uniform organization morphology is obtained; and through the second normalizing, the car axle is austenitized at the temperature, fine austenite crystal grains are formed, after the car axle is cooled, fine ferrite and pearlite organizations are obtained, so as to achieve relatively high strength and toughness.

Owner:CRRC YANGTZE CO LTD

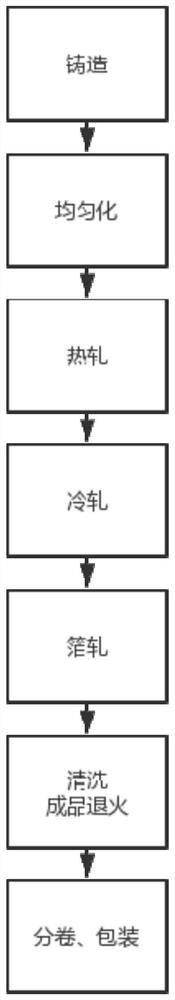

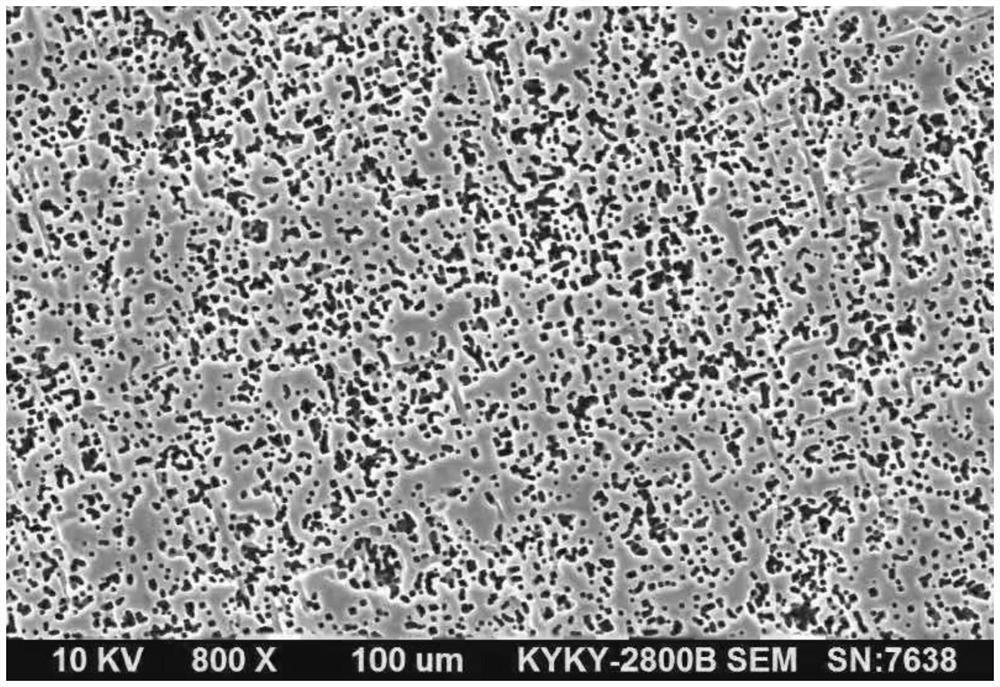

Low-voltage electronic aluminum foil for capacitor and preparation process thereof

ActiveCN113235023ARemove bulkyAvoid bulkyLiquid surface applicatorsTemperature control deviceMetallurgyLow voltage

The invention discloses a low-voltage electronic aluminum foil for a capacitor and a preparation process thereof. The low-voltage electronic aluminum foil for the capacitor, which is uniform in grain size, good in corrosion effect, high in capacity and short in production period, can be obtained through the process steps of casting, homogenizing, hot rolling, cold rolling, intermediate annealing, foil rolling, finished product annealing, coil dividing, packaging and the like.

Owner:广西正润新材料科技有限公司

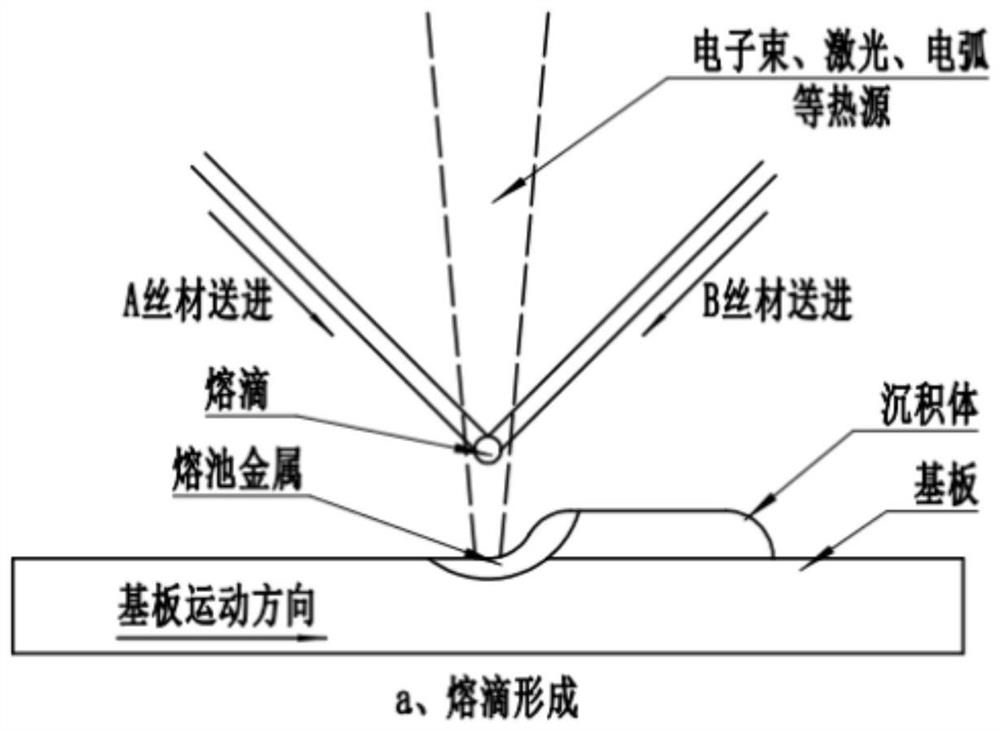

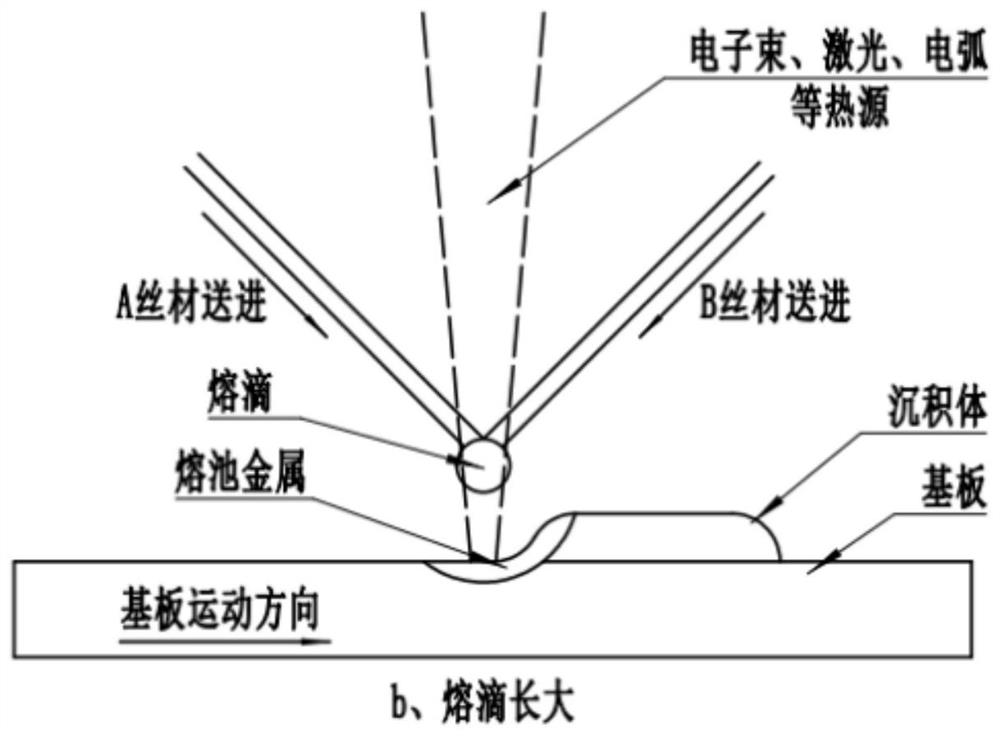

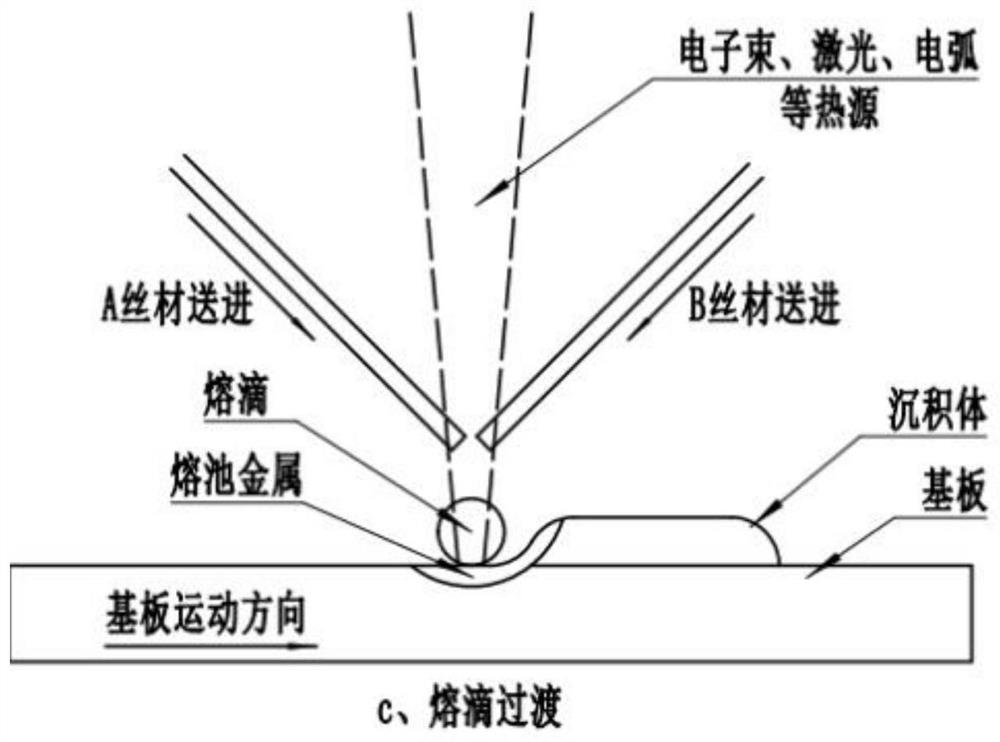

Preparation method of multi-component new alloy and component gradient alloy material part

ActiveCN112935470AIncrease profitImprove forming efficiencyArc welding apparatusElectron beam welding apparatusInhomogeneous materialAlloy

The invention provides a preparation method of a multi-component new alloy and a component gradient alloy material part. Material-forming integration is achieved, and intermediate steps are reduced. According to the method, heterogeneous materials with variable components, gradient and the like are easily realized; compared with powder, wires are used, the material utilization rate is high, and the forming efficiency is high; the wires made of two or more different materials are sequentially melted according to physical characteristics under the effect of a heat source to form a molten drop, then the molten drop is transited to a base body, all components can be uniformly mixed, component segregation can be reduced or even eliminated, the uniformity of a new alloy material in the forming process can be effectively controlled, the stability of the molten drop transition form is higher, and the probability of forming defects is effectively reduced.

Owner:浙江智熔增材制造技术有限公司

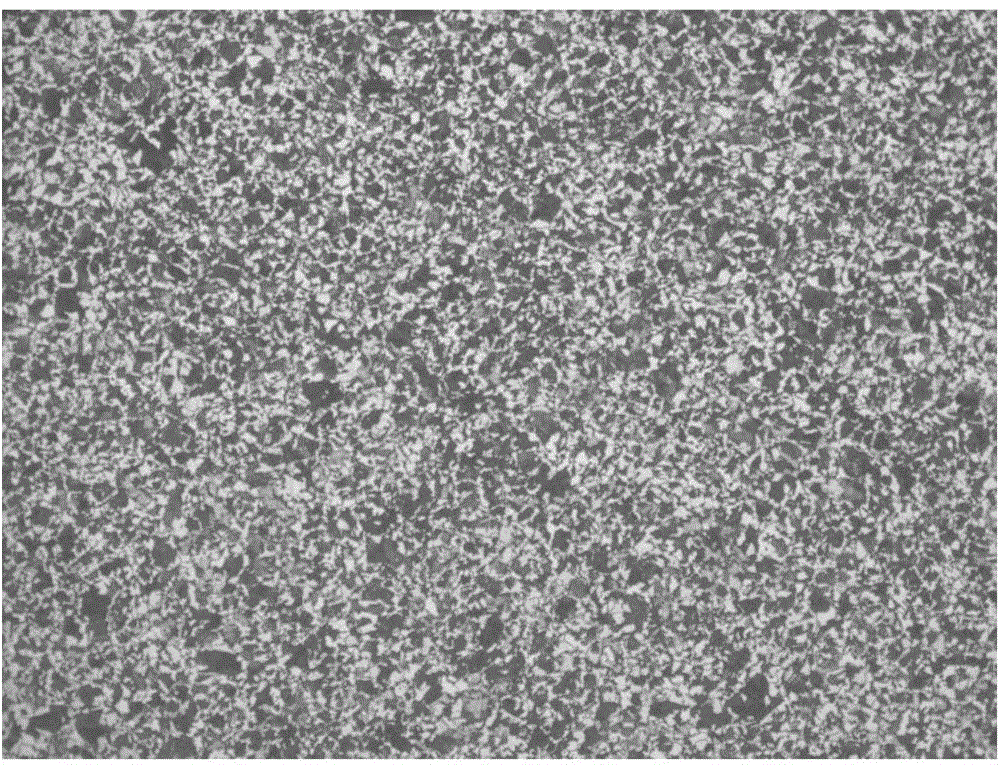

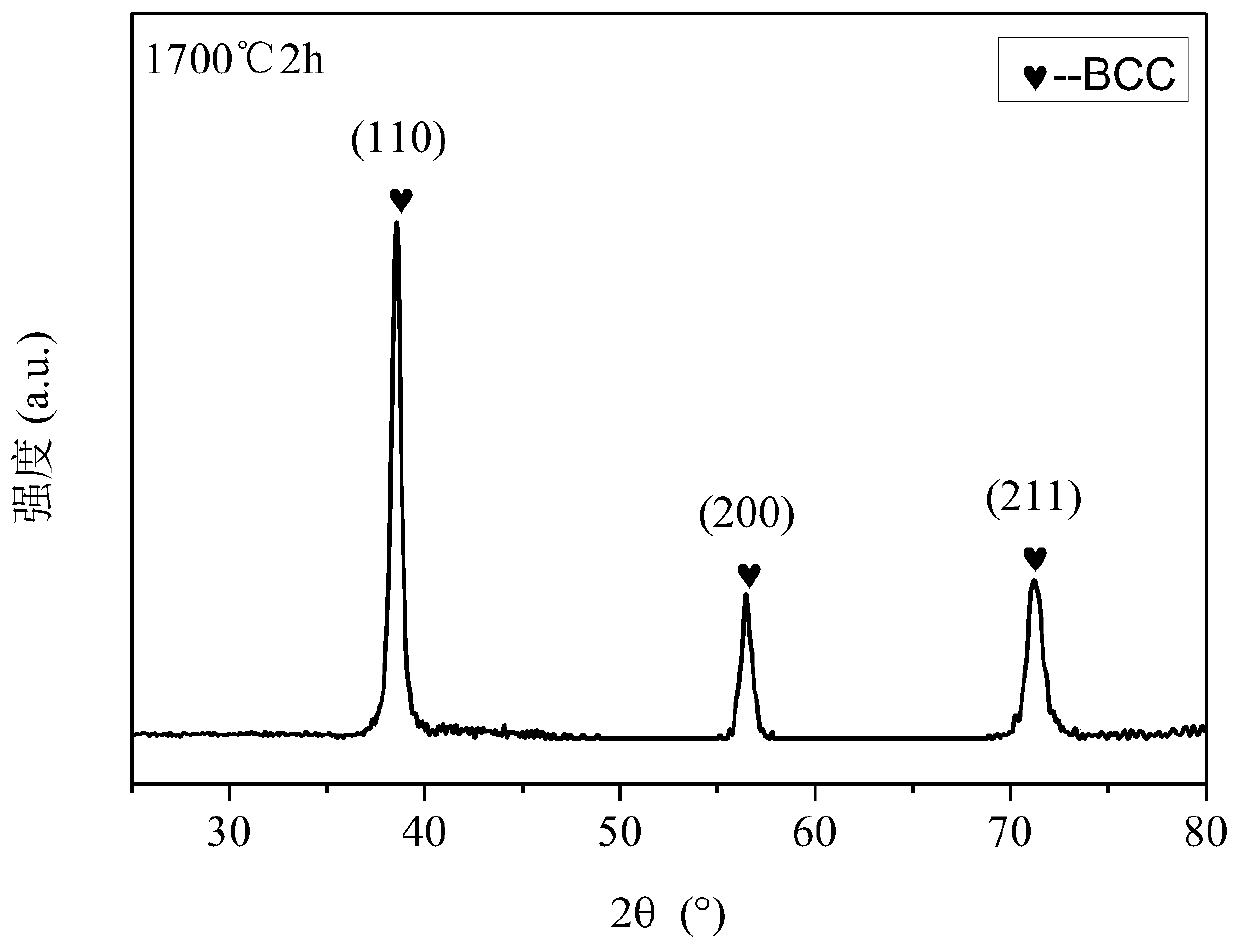

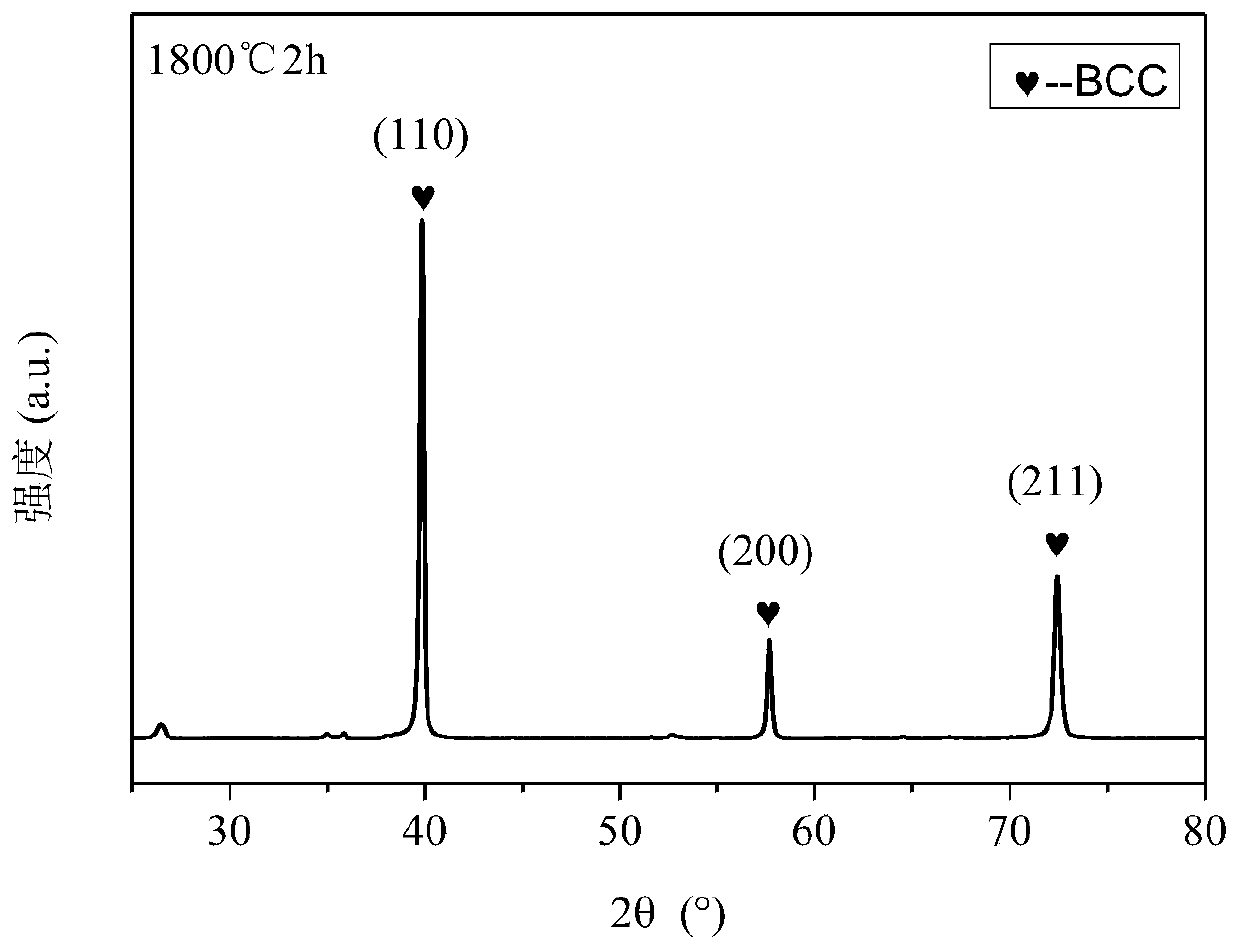

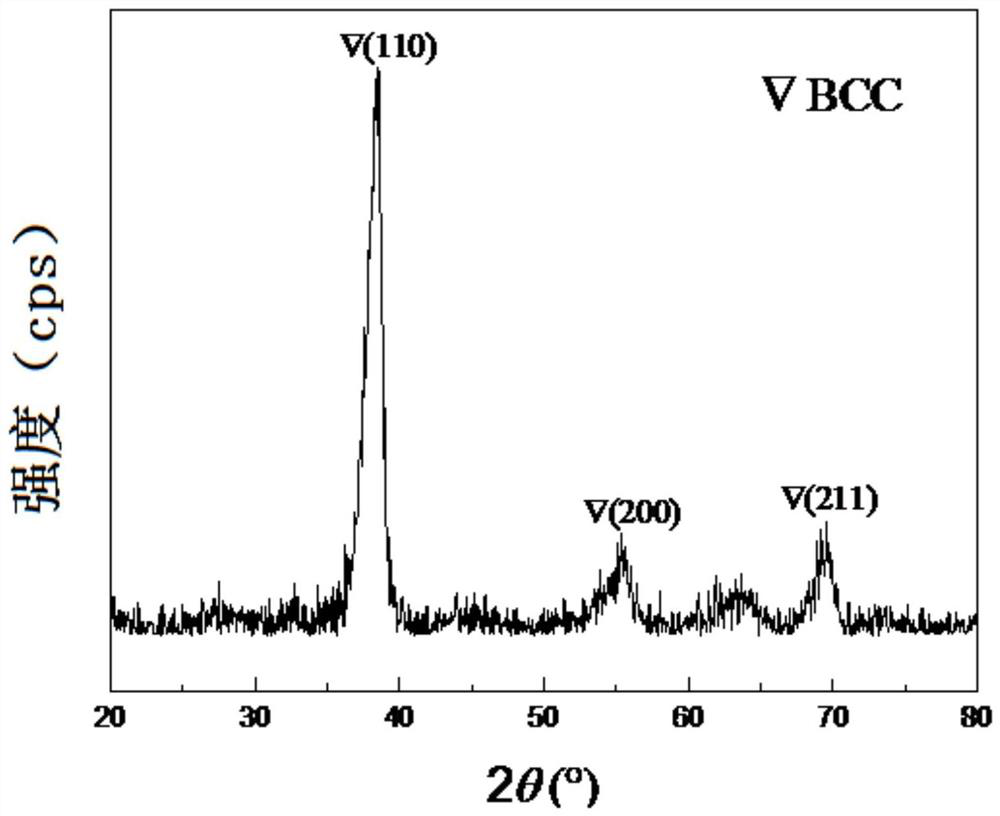

Preparation method of VNbMoTaW high-entropy alloy

ActiveCN111411249ASimple preparation processReduce the chance of oxidationHigh entropy alloysMelting Point Temperature

The invention discloses a preparation method of a VNbMoTaW high-entropy alloy. The preparation method of the VNbMoTaW high-entropy alloy comprises the following steps that simple substance powder of W, Mo, V, Nb and Ta are mixed by adopting a mechanical alloying method firstly, ball milling is carried out without adding a ball milling medium to obtain single-phase or double-phase single-body centripetal cubic structure VNbMoTaW high-entropy alloy powder, then hot-pressing sintering is adopted, the pressure ranges from 30 MPa to 50 MPa, the heating rate ranges from 5 DEG C / min to 15 DEG C / min,the heat preservation temperature ranges from 1700 DEG C to 1900 DEG C, and the VNbMoTaW high-entropy alloy block with the single-phase single-body centripetal cubic structure and the density larger than 99.5% is obtained. The preparation method of the VNbMoTaW high-entropy alloy is simple in process, a block material with good performance can be obtained without being heated to the melting pointtemperature, the processing temperature is effectively reduced, the preparation cost is lower, and a very high industrial application value is achieved.

Owner:NAT UNIV OF DEFENSE TECH

Heat treatment method for improving high-niobium reinforcing type monocrystal high temp alloy use property

InactiveCN1502717AEliminate grain boundariesEliminate composition segregationPolycrystalline material growthAfter-treatment detailsNiobiumSingle crystal superalloy

The present invention discloses a heat treatment method for improving usability of high niobium strengthened monocrystal high-temp. alloy, and said method includes the following steps: 1). high-temp. homogenization treatment: placing sample in 1140-1170 deg.C temp. environment, heat-insulating for 5-30 hr. to eliminate harmful phase and niobium segregation, and cooling; and 2). conventional ageing treatment to separate out strengthening phase so as to obtain the invented product.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

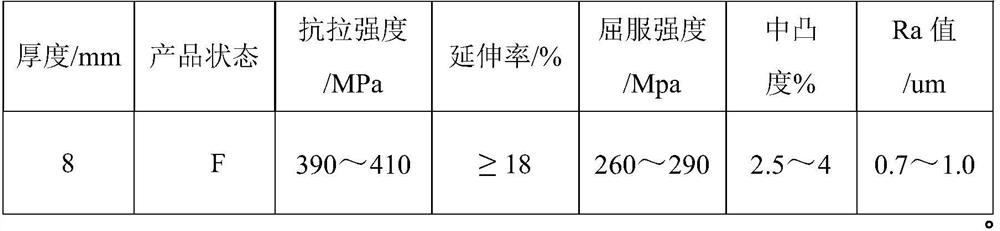

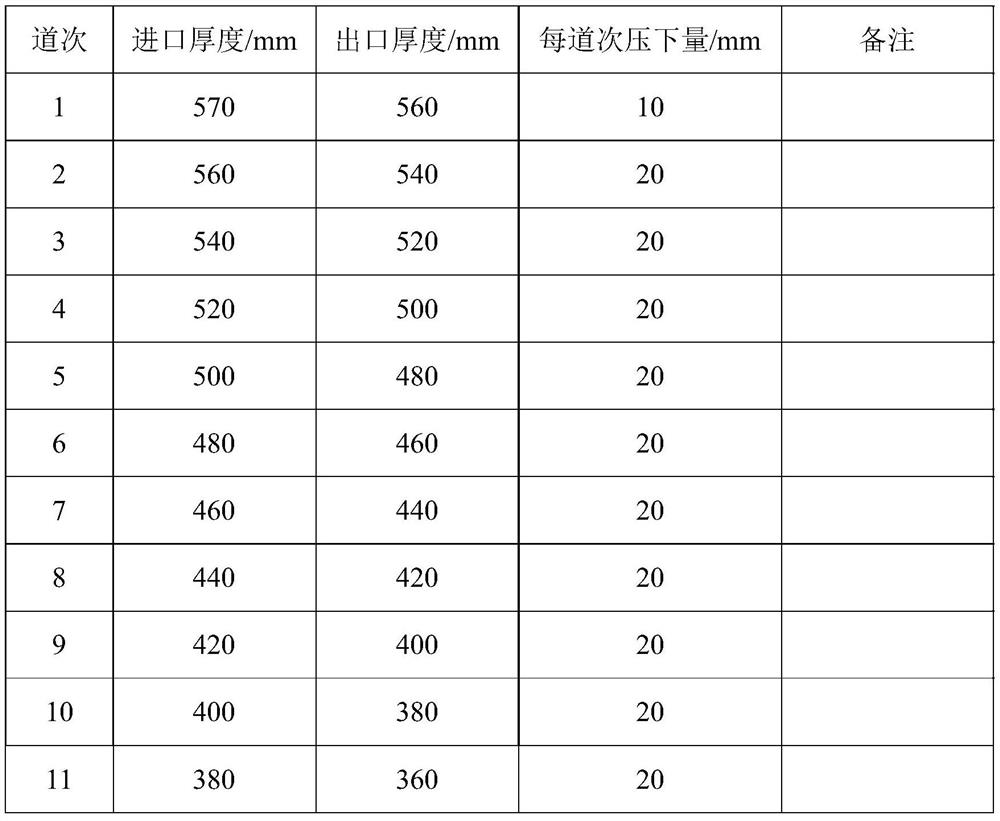

5A12 aluminum alloy hot-rolled blank and production method thereof

The invention discloses a 5A12 aluminum alloy hot-rolled blank and a production method thereof. According to the method, pure aluminum ingots and pure magnesium ingots are used as raw materials for burdening and smelting, obtained alloy liquid is refined, standing is conducted after refining, the alloy liquid obtained after standing is cast, and an aluminum alloy cast ingot is obtained; the obtained 5A12 aluminum alloy cast ingot is subjected to three-stage homogenization treatment; then the surface of the cast ingot is milled, and treatment is conducted by adopting an acetic acid water-air combined impurity removal method after surface milling; and the treated cast ingot is sequentially subjected to homogeneous heating, hot rough rolling and hot finish rolling, and finally the 5A12 aluminum alloy hot-rolled blank with the product thickness being 8 mm is obtained. By means of the method, the large-specification 5A12 aluminum alloy hot-rolled plate blank with the width of 1200 mm-1700 mm can be obtained, and the product has the advantages of being good in surface quality, high in strength, good in plasticity, free of air holes and shrinkage cavities in the blank and the like; and the problems that the requirement for equipment is high and the hot rolling technology is complex in existing large-specification 5A12 aluminum alloy plate production are solved.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD +1

Thick working layer roller outer layer centrifugal casting and molding method

The invention discloses a thick working layer roller outer layer centrifugal casting and molding method. Variable-speed casting is adopted in the method, and the whole outer layer is changed from simultaneous solidification to layer-by-layer solidification. The specific casting method comprises the steps that molten iron of the whole outer layer is subjected to continuous casting in sequence according to the rapid-slow-rapid mode, 20% of the total amount of molten iron is cast at first, and the casting speed is controlled to be 5+ / -0.5 t / min; the casting speed is decreased, 50% of the total amount of molten iron is cast, and the casting speed is controlled to be 2+ / -0.5 t / min; the speed is increased, 30% of the total amount of molten iron is cast, and the casting speed is controlled to be 7+ / -0.5 t / min; an outer layer molding agent is added in the centrifugal casting process, and the adding amount is 0.5% of the total weight of molten iron. The whole outer layer is cast at different casting speeds, the defects of slag inclusion and looseness caused by low temperature of molten iron in the later casting period are eliminated, the composition segregation problem caused by long time of solidification in a mold is eliminated, the molding time is shortened, the molding inoculation fade phenomenon is eliminated, and the outer layer is good in hardness uniformity.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Robot big cover plate and preparation process thereof

The invention discloses a robot big cover plate and a preparation process thereof, and belongs to the technical field of a metal material. The big cover plate is prepared from the following raw material ingredients in percentage: 0.4 to 0.8 percent of Fe, 0.5 to 0.7 percent of Si, 0.02 to 0.04 percent of Ti, 0.05 to 0.09 percent of Mg, 0.01 to 0.03 percent of Be and the balance of Al and impurities. The Be in the raw materials is an excellent metal additive, has low density and has the intensity being 4 times of that of steel. The light weight and high intensity of the Be are used, so that thealuminum alloy has good physical performance; the mechanical performance of the aluminum alloy is enhanced; meanwhile, the oxygen affinity of the Be is used for reducing impurity oxygen in the aluminum alloy. The chemical properties of the Ti per se is stable; the embrittlement increase risk of the Fe on the alloy is eliminated; meanwhile, the preferential solidification characteristics of the Feare utilized so that a solidification core is formed; the mechanical property of the aluminum alloy is enhanced. Meanwhile, crystal grains are refined through the progressive normalizing processing and the uniform annealing process; the ingredient aliquation in the alloy can be eliminated. In addition, a nanometer stage carbon film is formed on the surface of the alloy; the intensity is high; theanti-corrosion performance of the aluminum alloy is greatly enhanced.

Owner:NINGBO HUAYUAN JINGTE METAL PROD CO LTD

Magnetic control resistance spot-welding method

ActiveCN102267002BIncrease the number ofImprove mechanical propertiesWelding electric supplyElectrical resistance and conductanceControl system

The invention relates to a magnetic control resistance spot-welding method and a magnetic control resistance spot-welding device. The method comprises the following steps that: 1) when a magnetic control system is in a startup state or a reset state, a synchronization system continuously detects switching-on and switching-off as well as the intensity of welding current of a resistance spot-welding gun through a first current sensor and judges whether the resistance spot-welding gun has current or not; if the resistance spot-welding gun has the current, a step 3) is executed; and otherwise, a step 2) is executed; 2) the synchronization system sends a switching-off digital signal 00 to a power conversion device to keep the switching-off state of the power conversion device, and returns to the step 1), and the like. The device comprises the synchronization system, the power conversion device, an upper excitation winding, a lower excitation winding, the resistance spot-welding gun, the first current sensor and a second current sensor. Compared with the prior art, the method and the device have the advantages that: an external magnetic field and the welding current can be controlled coordinately, the comprehensive mechanical performance of a resistance spot-welding head can be improved effectively, the applicability range is wide, and the like.

Owner:SHANGHAI JIAO TONG UNIV

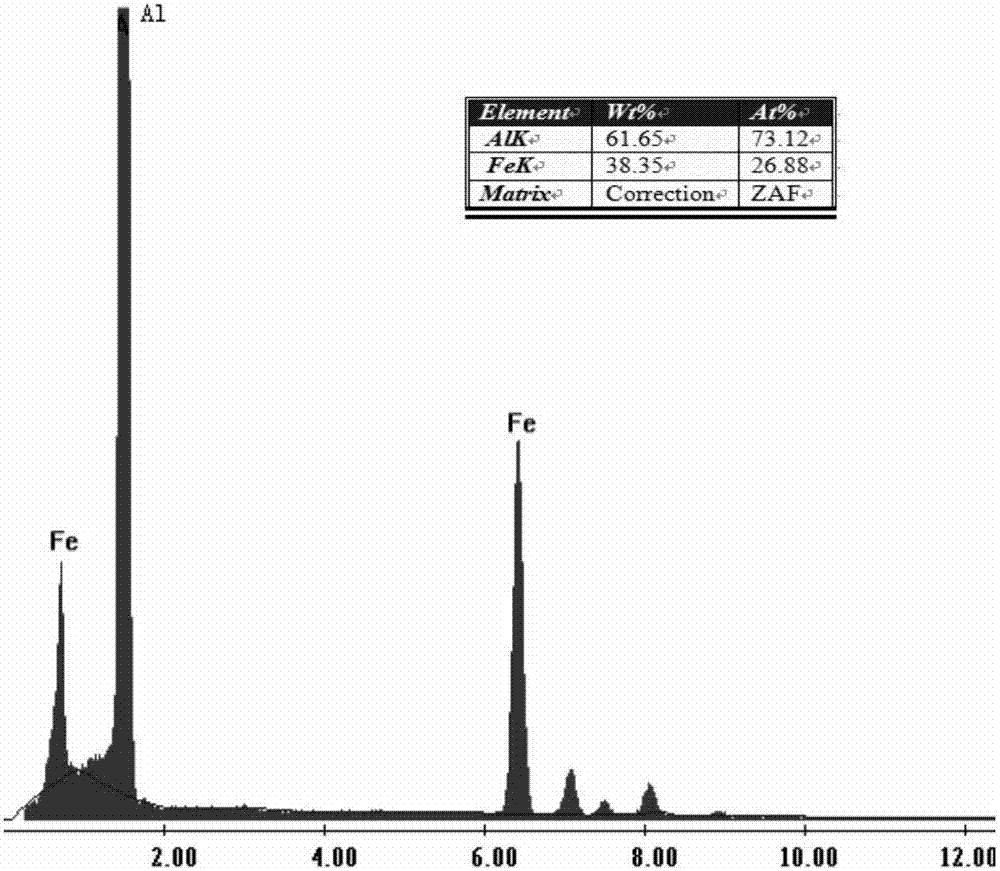

Preparation method of nbzrtita refractory high-entropy alloy powder and nbzrtita refractory high-entropy alloy powder

The invention discloses an NbZrTiTa refractory high-entropy alloy powder preparation method and NbZrTiTa refractory high-entropy alloy powder. The NbZrTiTa refractory high-entropy alloy powder preparation method comprises the following steps of mixing raw materials, namely, Nb, Zr, Ti and Ta elementary powder; then adding absolute ethyl alcohol and / or normal heptane; and carrying out high energy ball milling to obtain the NbZrTiTa refractory high-entropy alloy powder with a single-phase BCC structure. The preparation method provided by the invention is simple in steps, can be quantitively andrepetitively operated, and high in powder yield; and the prepared NbZrTiTa refractory high-entropy alloy powder is uniform in structure and element distribution, fine in grain size, and is of the single-phase body-centered cubic (BCC) structure.

Owner:NAT UNIV OF DEFENSE TECH

Production method of zinc-antimony alloy

InactiveCN104480332ASolve the speed problemSolve the problem of serious oxidationZinc metalZinc alloys

The invention provides a production method of zinc-antimony alloy. The production method of zinc-antimony alloy comprises the following steps: adding zinc metal into a melting pot, melting zinc by utilizing an electrical heating pot body, after zinc is molten, covering the surface of the molten zinc with charcoal powder, warming to 640-660 DEG C, adding antimony metal, and ingoting after the antimony metal is fully molten to form zinc-antimony intermediate alloy; according to volume of the melting pot, calculating amounts of the zinc metal and the zinc-antimony intermediate alloy which are needed to be added, adding the zinc metal into the melting pot, after the zinc metal is molten, warming to 510-530 DEG C, then adding the zinc-antimony intermediate alloy, and ingoting after the zinc-antimony intermediate alloy is fully molten, so as to generate the zinc-antimony alloy. The production method of the zinc-antimony alloy has the advantages that a secondary smelting method is adopted, the problems that smelting speed is low and oxidation is serve in a zinc-antimony alloy production process are solved, and the problem of composition segregation is also solved as the smelting speed is high when the zinc-antimony alloy product is produced, so that the production method of the zinc-antimony alloy is applicable to being applied in the field of zinc alloys.

Owner:HULUDAO ZINC IND CO LTD

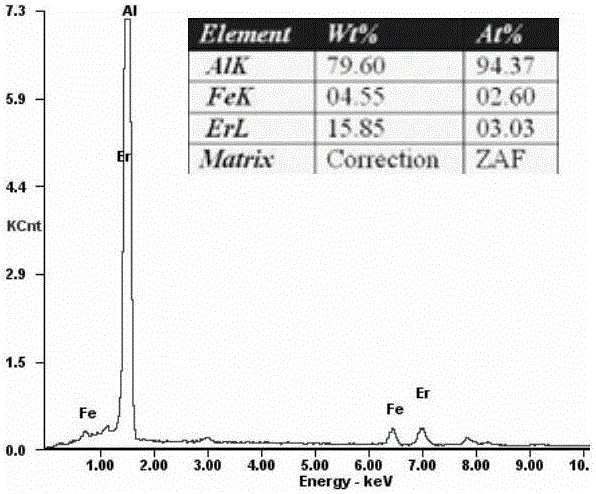

A light-weight high-conductivity heat-resistant aluminum wire and its preparation method

ActiveCN105734353BGreat influence on conductivityImprove conductivityConductive materialMetal/alloy conductorsAdditive ingredientVolumetric Mass Density

A light-weight high-conductivity and heat-resistant aluminum wire and its preparation method, the material components include B: 0.035-0.06wt.%, 0.1-0.2wt.% Zr, 0.1-0.3wt.% Er, unavoidable impurities and the balance Al , The technological process is smelting, rapid component analysis before the furnace, refining, rapid cooling casting, billet annealing, extrusion, and drawing. In addition to refining and modifying, the B element added in the invention mainly plays the role of promoting the precipitation of Al3(Er, Zr) ternary composite phase in the supersaturated solid solution containing Zr and Er. The Al3(Er, Zr) composite phase is nanoparticles coherent with the matrix and having a core-shell structure, dispersed in the aluminum matrix, and can greatly improve the electrical conductivity and heat resistance of the aluminum wire. The monofilament density obtained is less than or equal to 2.71g / cm3, the electrical conductivity at 20°C is greater than or equal to 62% IACS, the short-term heat-resistant temperature is as high as 230°C, the long-term heat-resistant temperature is as high as 210°C, and the tensile strength is greater than or equal to 165MPa. The economic benefits and the significance of energy saving and environmental protection.

Owner:CENT SOUTH UNIV

Method for manufacturing rotating shuttle through injection molding method

ActiveCN102962462AEliminate composition segregationGood consistency of sintering shrinkageTurbinesOther manufacturing equipments/toolsIron powderAlloy

The invention discloses a method for manufacturing a rotating shuttle through an injection molding method. The rotating shuttle adopts the following alloy material: Fe2NiMo, FeCrMo or FeCr; and the manufacturing method of the rotating shuttle comprises the following steps: firstly, performing segregation-free mixing on raw material alloy powder, secondly, performing alloying treatment on the raw material alloy powder, thirdly, grinding and screening the raw material alloy powder, fourthly, performing feed preparation on the raw material alloy powder, fifthly, performing injection molding on feed, and sixthly, sintering a molded rotating shuttle. The method has the advantages that a product raw material formula is improved, iron powder spherical powder produced through a carbonyl process is taken as main raw material, composition segregation and unnecessary internal impurities are eliminated, and the sintering and shrinkage uniformity of the product is good.

Owner:ZHEJIANG YIHUO TECH

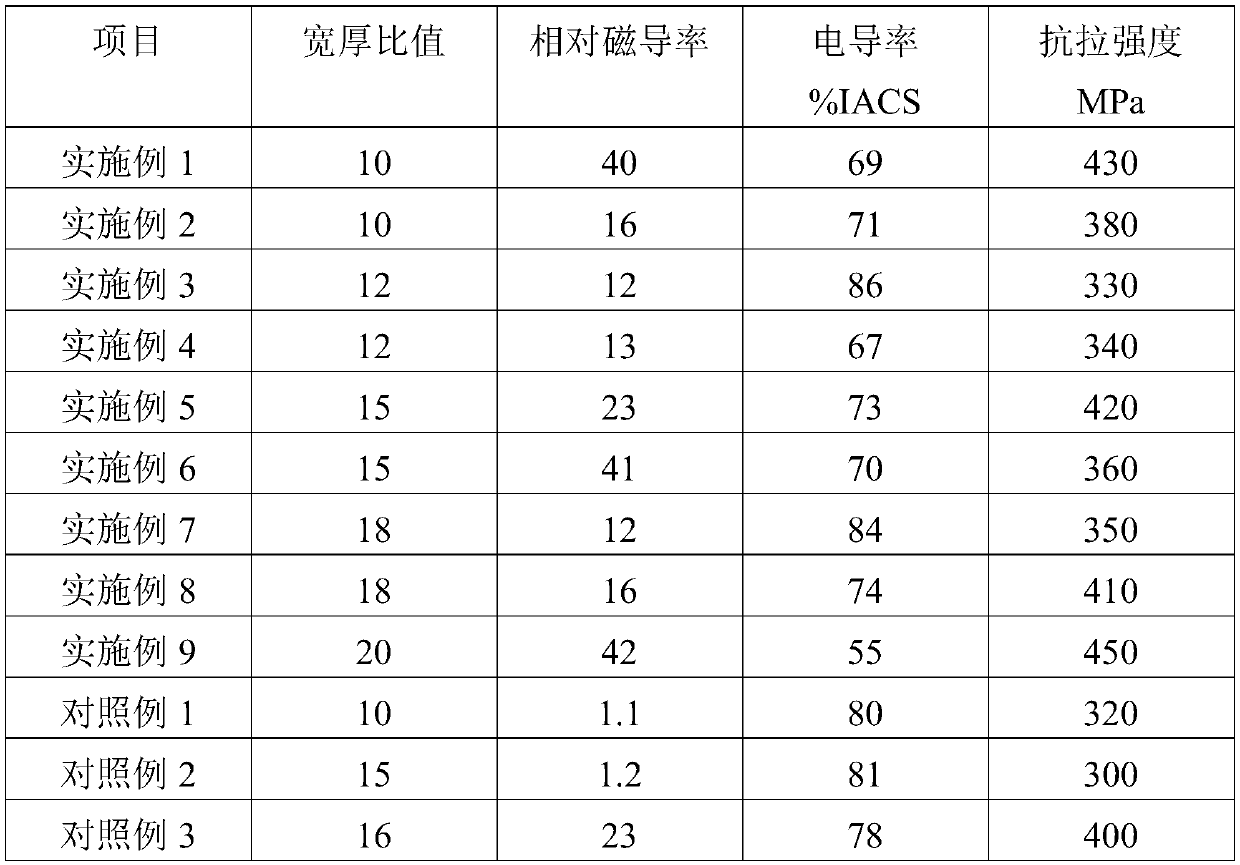

Tantalum-containing copper alloy wire/strip and preparation method thereof

ActiveCN111118320AImprove magnetic permeabilityHigh strengthUltimate tensile strengthContinuous caster

The invention provides a tantalum-containing copper alloy wire / strip comprising the following components of, by mass, 0.01%-1.0% of tantalum, 0.01%-1.0% of silver, 0.01%-0.5% of iron, and the balancecopper. The invention further provides a preparation method of the tantalum-containing copper alloy wire / strip. A continuous casting machine conducts high-temperature treatment on copper-tantalum intermediate alloy, silver, copper-iron intermediate alloy and copper, drawing casting is conducted after cooling, then repeated drawing is conducted, after micro machining, continuous heat treatment is conducted through annealing equipment, the tantalum-containing copper alloy wire is obtained, and the tantalum-containing copper alloy strip of the needed specifications is obtained through rolling ofa double-roller rolling mill. With adding of the tantalum, magnetoconductivity of the copper alloy is improved effectively, the strength of the copper alloy is improved through adding of the silver, good electroconductibility of the copper alloy wire / strip is ensured, magnetoconductivity of the copper alloy can be further enhanced through the iron element in the copper alloy, and the copper alloymaterial has good magnetoconductivity, electroconductibility and strength through the element combination of tantalum, silver, iron and copper.

Owner:HENAN POLYTECHNIC UNIV +2

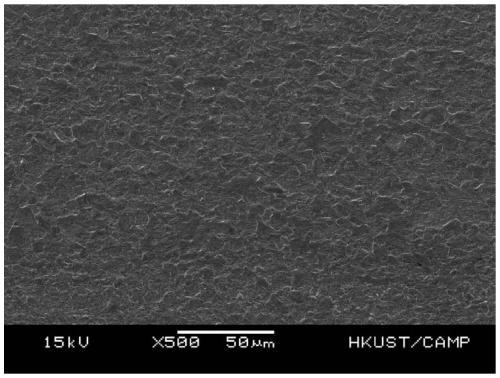

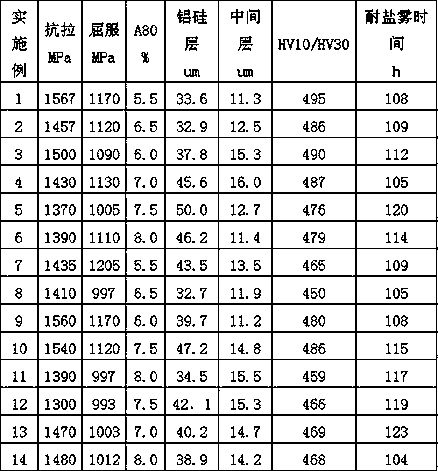

Method of producing plating high-strength components through high-temperature hot stamping

The invention discloses a method of producing plating high-strength components through high-temperature hot stamping. The method comprises the processes of heating and mold inlet stamping, and is characterized in that in the heating process, when the thickness of a plating steel plate is 0.6-1.45mm, the heating temperature is 935-960 DEG C, and the total heating time is 5.5-10min; when the thickness of the plating steel plate is greater than 1.45mm and smaller than or equal to 3.0mm, the heating temperature is 945-970 DEG C, and the total heating time is 5-11min; the plating steel plate is heated in the front 1.0-2.0 minutes until the temperature is greater than or equal to 600 DEG C; and in the mold inlet stamping process, the mold inlet temperature of the plating strip steel is 755-780 DEG C, and the mold outlet temperature is smaller than or equal to 250 DEG C; and after clamping, a mold is cooled to 400 DEG C or below in 7s. According to the high-strength parts and components produced by the method disclosed by the invention, the yield strength is 950-1300MPa, the tensile strength is 1250-1600MPa, the elongation rate A80 is 5.0-8.5%, after hot stamping, the thickness of an aluminum silicon plating is 30-50um, the thickness of the middle layer is 16um or below, and time for resisting red rust except 20mm of a notch part is 96 hours or above; the production difficulty and theproduction cost are reduced; and the production cost of the integral hot-stamped high-strength parts and components is reduced.

Owner:TANGSHAN IRON & STEEL GROUP +1

Method for manufacturing rotating shuttle door wrench by utilizing flow temperature-pressure molding method

The invention discloses a method for manufacturing a rotating shuttle door wrench by utilizing flow temperature-pressure molding method. According to the invention, the rotating shuttle door wrench is made of an alloy material namely Fe2NiMo, FeCrMo or FrCr. The method for manufacturing the rotating shuttle door wrench comprises the following steps of: (1) producing raw material alloy powder by utilizing an atomization method; (2) adding nano fine powder and a bonding agent containing a surfactant and plasticizer into the raw material alloy powder to carry out mixing and granulating, wherein the raw material alloy nano fine powder is alloy powder formed by alloyed related alloy materials; (3) carrying out mold pressing and molding on the rotating shuttle door wrench by adopting a flow temperature-pressure molding process; (4) degreasing and sintering in a sintering furnace; and (5) carrying out surface reshaping treatment to obtain the needed size. According to the method, Fe2NiMo, FeCrMo or FrCr is used as the raw material so that component segregation and unnecessary inner impurities are eliminated; and the sintering and contracting consistency of a product is good.

Owner:ZHEJIANG YIHUO TECH

Centrifugal casting and inoculation method of roll outer layer

The invention discloses a thick working layer roller outer layer centrifugal casting and molding method. Variable-speed casting is adopted in the method, and the whole outer layer is changed from simultaneous solidification to layer-by-layer solidification. The specific casting method comprises the steps that molten iron of the whole outer layer is subjected to continuous casting in sequence according to the rapid-slow-rapid mode, 20% of the total amount of molten iron is cast at first, and the casting speed is controlled to be 5+ / -0.5 t / min; the casting speed is decreased, 50% of the total amount of molten iron is cast, and the casting speed is controlled to be 2+ / -0.5 t / min; the speed is increased, 30% of the total amount of molten iron is cast, and the casting speed is controlled to be 7+ / -0.5 t / min; an outer layer molding agent is added in the centrifugal casting process, and the adding amount is 0.5% of the total weight of molten iron. The whole outer layer is cast at different casting speeds, the defects of slag inclusion and looseness caused by low temperature of molten iron in the later casting period are eliminated, the composition segregation problem caused by long time of solidification in a mold is eliminated, the molding time is shortened, the molding inoculation fade phenomenon is eliminated, and the outer layer is good in hardness uniformity.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

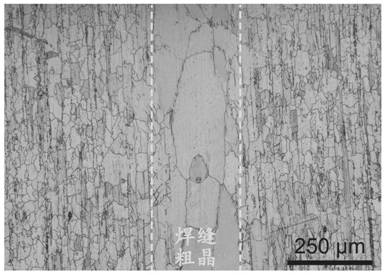

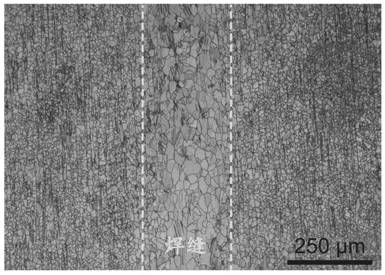

A Processing Technology for Suppressing Coarse Grain in Weld of Magnesium Alloy Profiles

ActiveCN113930699BEliminate composition segregationImprove the extrusion effectSolution treatmentIngot

A processing technology for suppressing the coarse grain of the weld seam of a magnesium alloy profile, comprising the following steps: preparing a magnesium alloy ingot, homogenizing treatment, peeling treatment, extrusion treatment, pre-stretching at room temperature, solution treatment, quenching treatment, drawing Stretch correction, artificial aging treatment, etc. This processing technology can effectively control the generation of coarse grains in the weld seam during the extrusion and heat treatment of magnesium alloy profiles, and the performance indicators of the final product are higher than the standard requirements.

Owner:SHANDONG UNIV

Homogenization heat treatment method of aluminum alloy ingot casting for pop-top can body

ActiveCN100408715CReduce solubilityAccelerated Diffusion Eliminates Compositional SegregationIngot castingThin slab

The invention discloses an aluminum alloy cast ingot uniform heat treatment method of tin pot body, which comprises the following steps: (1)making mass percent of alloy as 0.20 Si, 0.52 Fe, 0.18 Cu, 1.02 Mn and 1.23 Mg; setting the other single element not bigger than 0.05 and major total not bigger than 0.15; making the surplus as Al; casting the tin pot body with aluminum alloy; proceeding high-temperature uniform treatment in propulsion heating furnace with cooling device; controlling the temperature at 550-620 deg.c and keeping temperature time at 12-24h; forced-cooling to 460-500 deg.c with cooling speed at 20-60 deg.c / h; (2) controlling heat treatment of evolution phase in the same heating furnace; controlling the temperature at 450-500 deg.c and time at 6-12 h. This invention provides support for high quality production of AA3104 aluminum alloy sheet.

Owner:中铝西南铝板带有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com