Tantalum-containing copper alloy wire/strip and preparation method thereof

A technology of copper alloy wire and copper alloy, which is applied in the field of alloy strip manufacturing, can solve problems such as difficulty in uniform dissolution of tantalum and difficulty in strip processing, and achieve the effects of good magnetic permeability, uniform distribution of alloy components, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

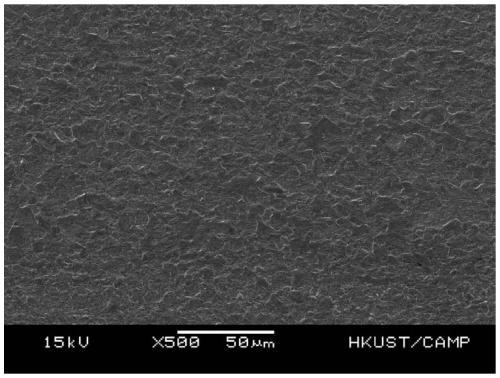

Image

Examples

preparation example Construction

[0045] In order to further understand the tantalum-containing copper alloy wire / strip of the present invention, the present invention also provides a method for preparing the tantalum-containing copper alloy wire / strip, the preparation method comprising the following steps:

[0046] S1, weigh copper-tantalum master alloy, silver, copper-iron master alloy and copper according to the ratio of raw materials, place them in a continuous casting machine filled with protective gas for high-temperature treatment, stir the alloy melt after the alloy is completely melted, and then let it stand , after being cooled by cooling water, drawing casting is carried out to obtain a continuously cast tantalum-containing copper alloy rod;

[0047] In a specific embodiment of the present invention, the preparation method of the copper-tantalum master alloy in step S1 is as follows: grind copper and tantalum into powder, mix them uniformly according to the mass ratio of 19:1, and then press the unif...

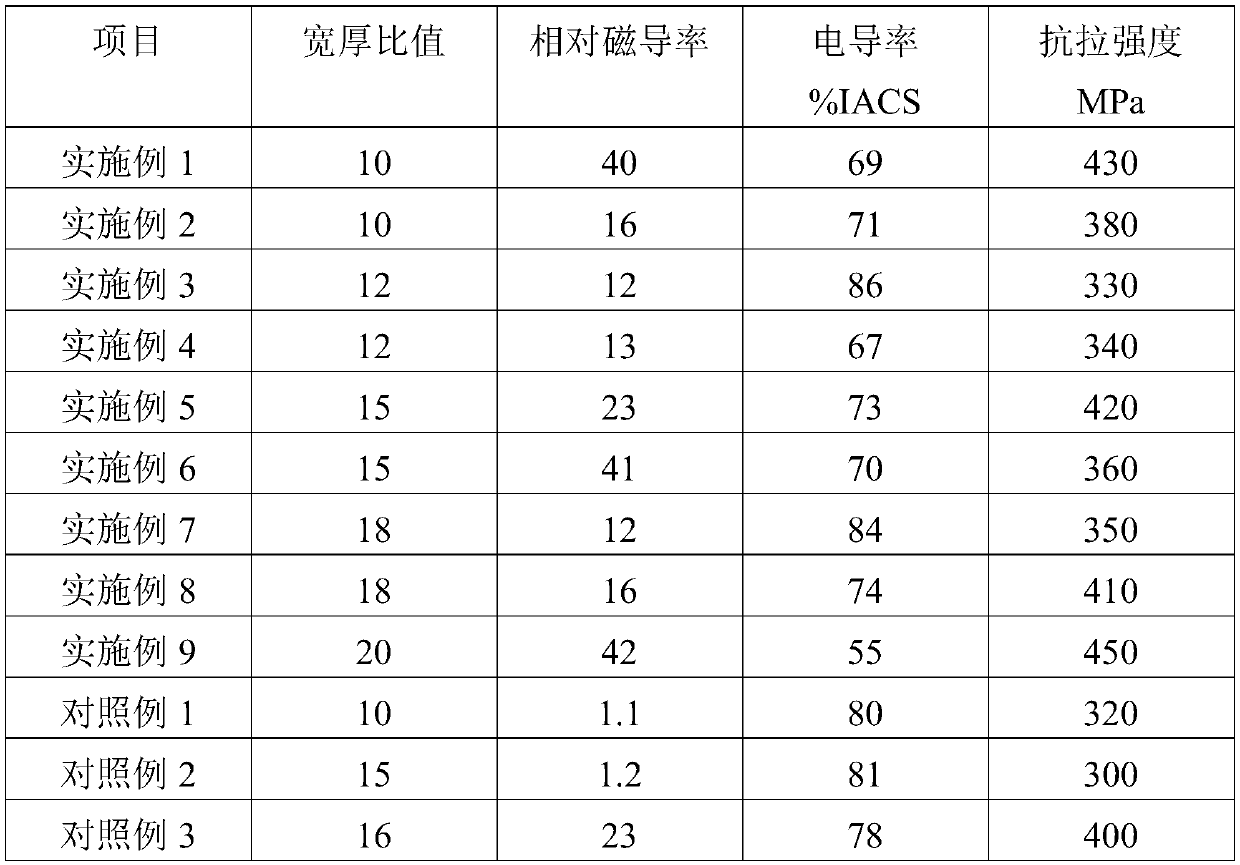

Embodiment 1

[0063] A tantalum-containing copper alloy wire / strip provided in this embodiment, the tantalum-containing copper alloy wire / strip includes the following components in mass percentage: tantalum: 0.8%, silver: 0.8%, iron: 0.02%, and the balance is copper.

[0064] A preparation method of a tantalum-containing copper alloy wire / ribbon provided in this embodiment comprises the following steps:

[0065] S1, weigh 1600g of copper-tantalum master alloy, 80g of silver, 40g of copper-iron master alloy and 8280g of copper, and place them in the graphite crucible of the vacuum intermediate frequency continuous casting machine with vertical structure. Vacuumize, and start to heat up when the vacuum degree is higher than 5.0Pa. After the temperature rises to 600°C, stop vacuuming and fill the vacuum intermediate frequency continuous casting machine with argon or nitrogen protective gas until the vacuum degree is 1.1MPa, and then heat up to Stir the alloy melt after the alloy is completely...

Embodiment 2

[0076] A tantalum-containing copper alloy wire / strip provided in this embodiment, the tantalum-containing copper alloy wire / strip includes the following components in mass percentage: tantalum: 0.4%, silver: 0.1%, iron: 0.02%, and the balance is copper.

[0077] In the preparation method of a tantalum-containing copper alloy wire / ribbon provided in this embodiment, in step S1, 800 g of copper-tantalum master alloy, 10 g of silver, 40 g of copper-iron master alloy and 9150 g of copper are weighed. Other methods and steps are the same as those in Embodiment 1, and will not be repeated here.

[0078] The magnetic permeability, electrical conductivity and strength of the tantalum-containing copper alloy wire / ribbon prepared in this example were tested, and the test standard and method were the same as those in Example 1.

[0079] The tantalum-containing copper alloy wire / ribbon prepared in this example has a width-to-thickness ratio of 10.

[0080] By testing the magnetic permea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com