Homogenization heat treatment method of aluminum alloy ingot casting for pop-top can body

A technology of aluminum alloy ingot and heat treatment method, which is applied in the field of heat treatment of aluminum alloy ingot, can solve problems such as leaky tank, thick, broken, etc., and achieve the effects of eliminating composition segregation, significant size reduction, and diffusion elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the present invention, the homogenization process of AA3104 aluminum alloy is adopted, and the alloy composition is (wt%): Si: 0.20, Fe: 0.52, Cu: 0.18, Mn: 1.02, Mg: 1.23; other elements are not more than 0.05 individually, and the sum is not Greater than 0.15; the balance is Al.

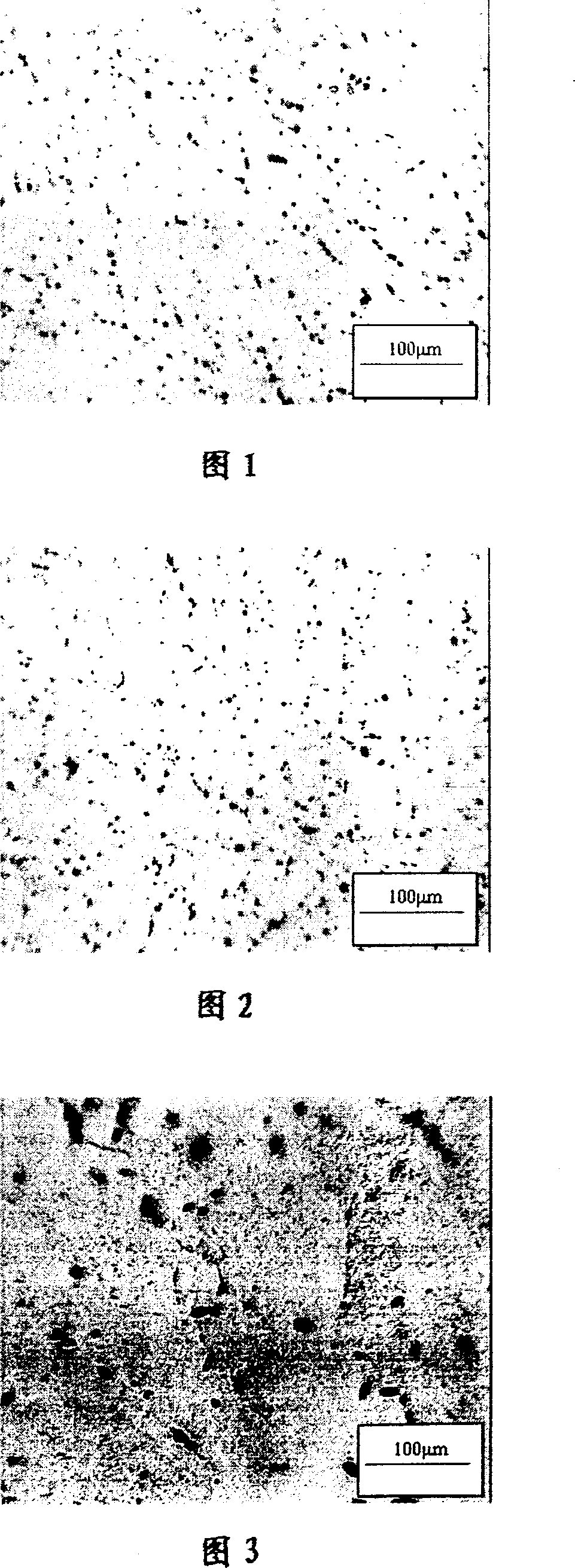

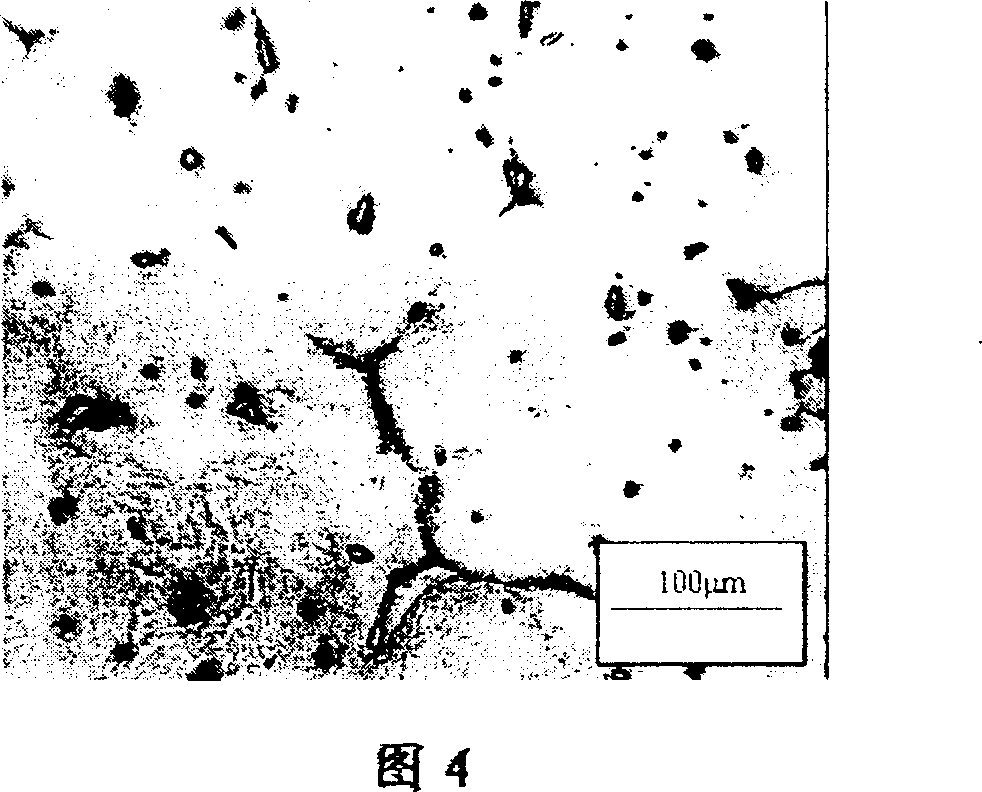

[0014] The ingots used are smelted in the same melting time, semi-continuous casting in the same casting time, face milling, and different homogenization treatments and heat treatments for controlling precipitated phases are carried out in a pusher heating furnace with a cooling device. The precipitated phase size in the embodiment of the adopted high temperature homogenization and controlled cooling is shown in Table 1, wherein the particle size is according to the equivalent circle radius, i.e. R = S / π to calculate, S is The area occupied by particles in a metallographic photograph.

[0015] Example numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com