5A12 aluminum alloy hot-rolled blank and production method thereof

A production method, 5A12 technology, applied in the field of 5A12 aluminum alloy hot-rolled billet and its production, can solve the problems of not being able to apply large-sized parts and weldments, and small-sized parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

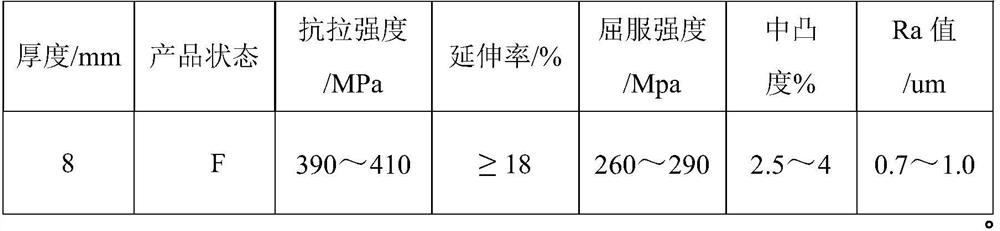

[0039] The 5A12 aluminum alloy hot-rolled blank of the present invention is represented by mass percentage, and the aluminum alloy hot-rolled blank contains the following alloy elements:

[0040]Si 0.201%, Cu 0.031%, Mg 8.802%, Zn 0.101%, Mn 0.702%, Ti 0.101%, Ni 0.060%, Fe 0.150%, other impurities 0.030%, and the balance is Al.

Embodiment 2

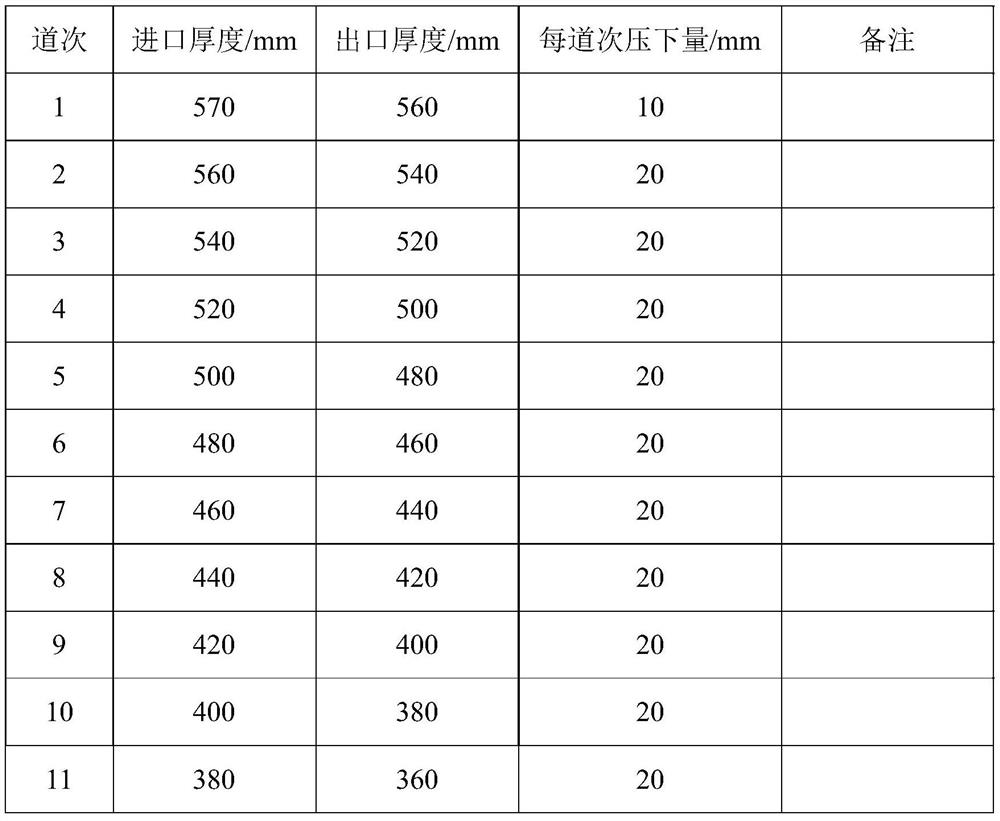

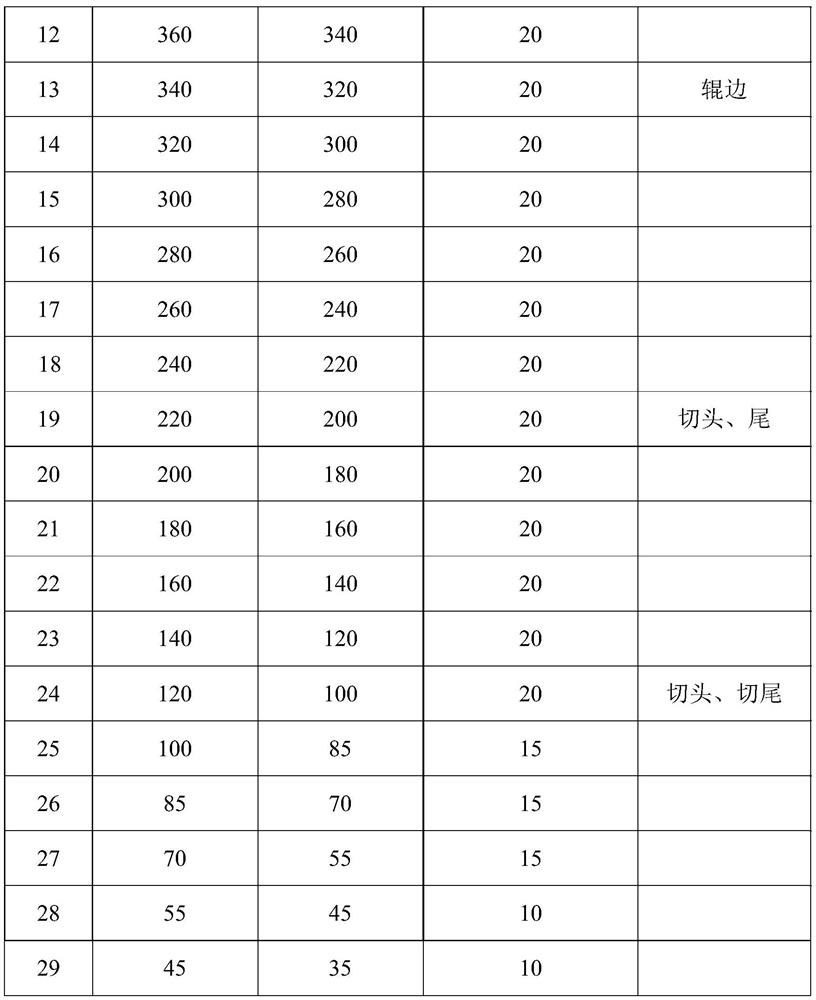

[0042] The production method of the 5A12 aluminum alloy hot-rolled blank described in Example 1 of the present invention, the detailed steps of the production method are as follows:

[0043] a. Melting: Use pure aluminum ingots and pure magnesium ingots as raw materials for batch smelting. During the smelting process, control the smelting temperature to 730-750°C, and the smelting holding time is 25 minutes; add intermediate alloys Al-20Si, Al-50Cu, Al during the smelting process -20Mn, Al-5Ni and Al-5Ti-B are batched, and the batching temperature is 730-740 ° C, so that the composition of the alloy liquid obtained by smelting meets the alloy element composition of the billet described in Example 1;

[0044] b. Refining: Refining the alloy liquid obtained in step a. During the refining process, the temperature is controlled at 720-725° C., and the refining time is 30 minutes; after refining, it is left to stand for 30 minutes;

[0045] c. Casting: cast the alloy liquid obtaine...

Embodiment 3

[0065] The 5A12 aluminum alloy hot-rolled blank of the present invention is represented by mass percentage, and the aluminum alloy hot-rolled blank contains the following alloy elements:

[0066] Si 0.221%, Cu 0.022%, Mg 8.668%, Zn 0.113%, Mn 0.689%, Ti 0.088%, Ni 0.051%, Fe 0.110%, other impurities 0.030%, and the balance is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com