Preparation method of nbzrtita refractory high-entropy alloy powder and nbzrtita refractory high-entropy alloy powder

A high-entropy alloy and powder technology, which is applied in the field of high-entropy alloys, can solve the problems of high heating temperature, low diffusion coefficient, and difficult process, and achieve the effect of improving powder output rate, reducing cold welding, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of NbZrTiTa high entropy alloy powder, adopts mechanical alloying method, comprises following technological conditions:

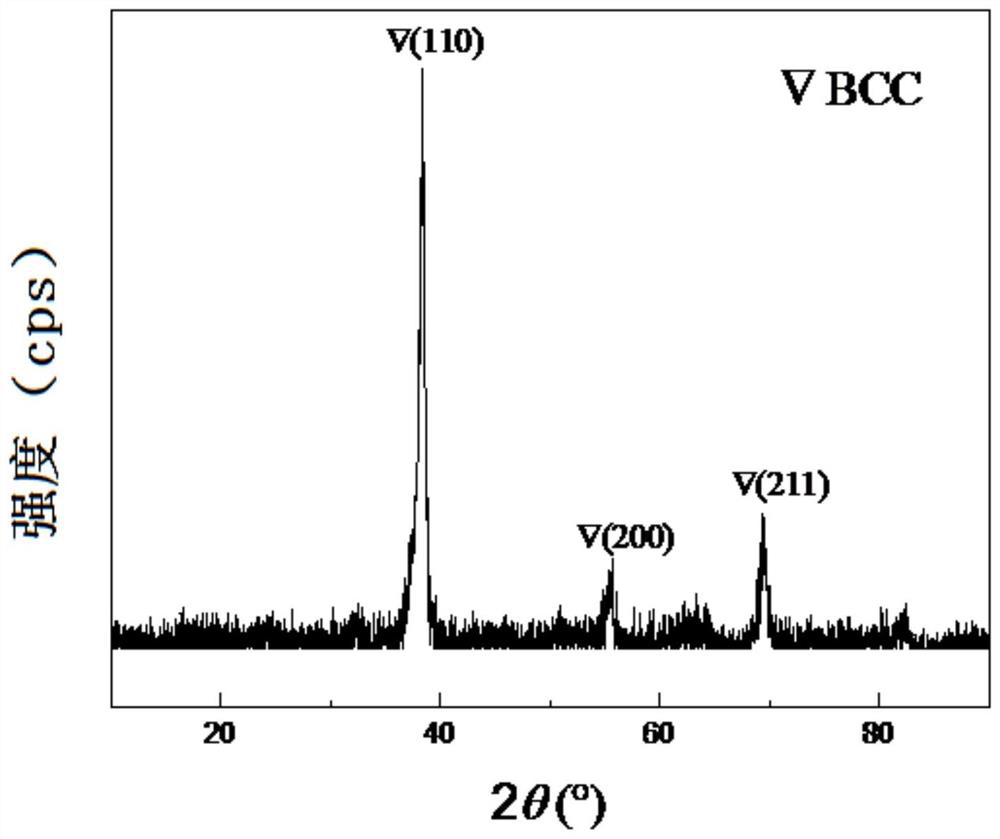

[0043] 50 g of equal atomic ratio mixed powders of Nb, Zr, Ti, and Ta four kinds of elemental powders were used as raw materials, mixed, and ball milled in a ball mill tank of a planetary high-energy ball mill. The material of the tank body and the balls are all stainless steel. The ball mill tank is evacuated and filled with high-purity argon (99.99%) as a protective atmosphere, and 0.15g (0.3%) of absolute ethanol is added as a ball mill medium. During the ball milling process, the ball-to-material ratio was 10:1, and the rotational speed was 300r / min. After 50 hours of ball milling, the NbZrTiTa alloy powder was taken out, and the powder had transformed into a single-phase BCC solid solution. During the process of high-energy ball milling, the mixed powder is gradually alloyed, and finally the alloy powder with single-...

Embodiment 2

[0046] A kind of preparation method of NbZrTiTa high entropy alloy powder, adopts mechanical alloying method, comprises following technological conditions:

[0047] The composition and content of raw material powder, equipment, ball-to-material ratio, rotating speed are all the same as embodiment 1, and ball milling medium is 15g (30%) dehydrated alcohol, and ball milling time is 75h.

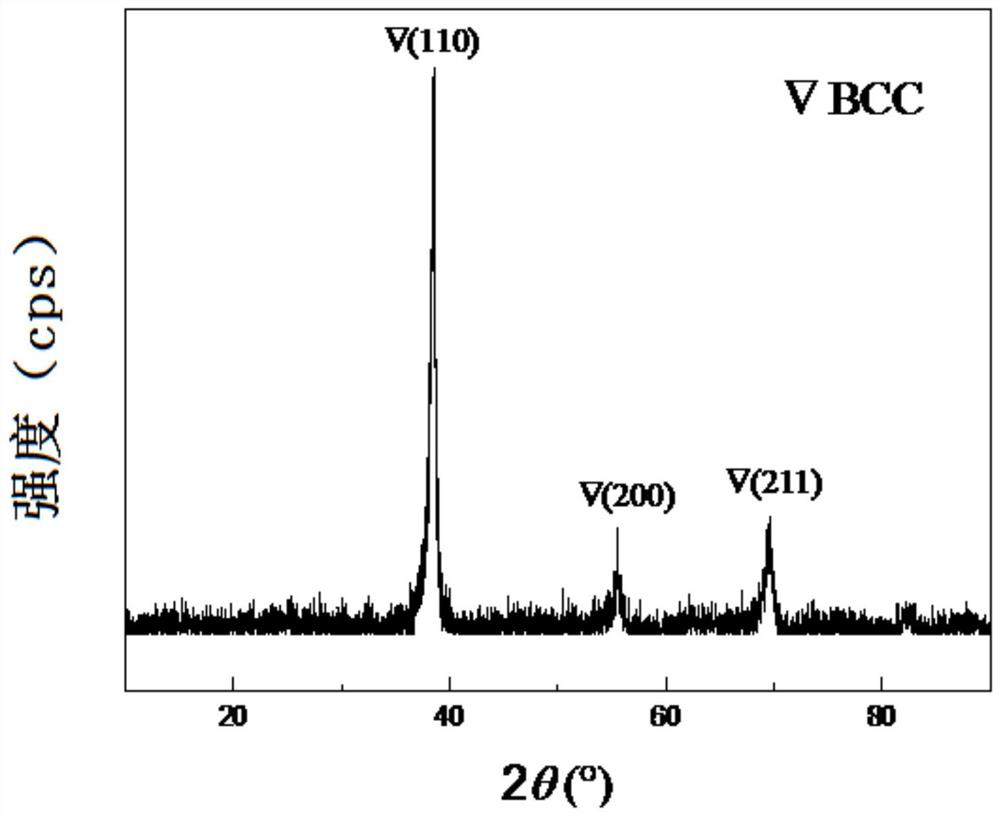

[0048] Equiatomic ratio NbZrTiTa high-entropy alloy powders were obtained after ball milling, and the XRD results were as follows: figure 2 As shown, it appears as a single-phase BCC solid solution. In this embodiment, the mixing of raw materials, high energy ball milling and sampling of samples are all carried out under an inert atmosphere.

Embodiment 3

[0050] A kind of preparation method of NbZrTiTa high entropy alloy powder, adopts mechanical alloying method, comprises following technological conditions:

[0051] The composition and content of the raw powder, equipment, ball-to-material ratio, and rotating speed are all the same as in Example 1, the ball milling medium is 0.15g (0.3%) n-heptane, and the ball milling time is 40h.

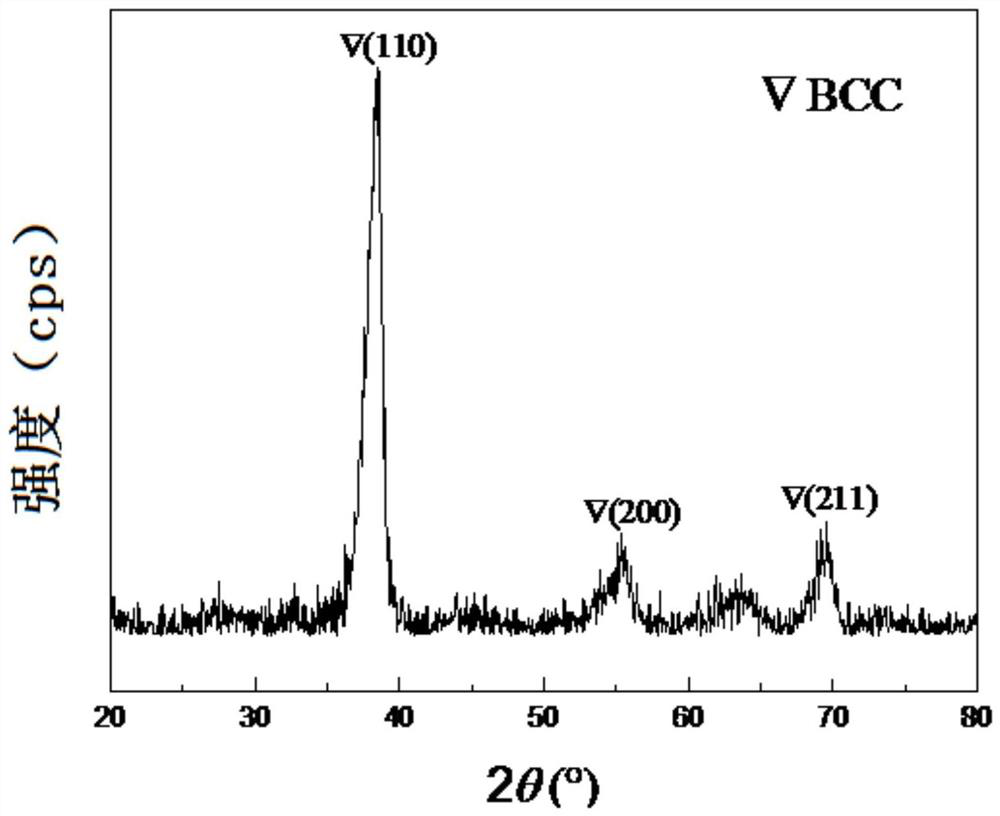

[0052] Equiatomic ratio NbZrTiTa high-entropy alloy powders were obtained after ball milling, and the XRD results were as follows: image 3 As shown, it appears as a single-phase BCC solid solution. In this embodiment, the mixing of raw materials, high energy ball milling and sampling of samples are all carried out under an inert atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com