Welding nuclear deviation control device and method for resistance spot welding

A technology of offset control and resistance, which is applied in the direction of resistance welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of reducing the penetration depth of the weld nugget and the effective nugget diameter, and achieves convenient assembly and disassembly , low application cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

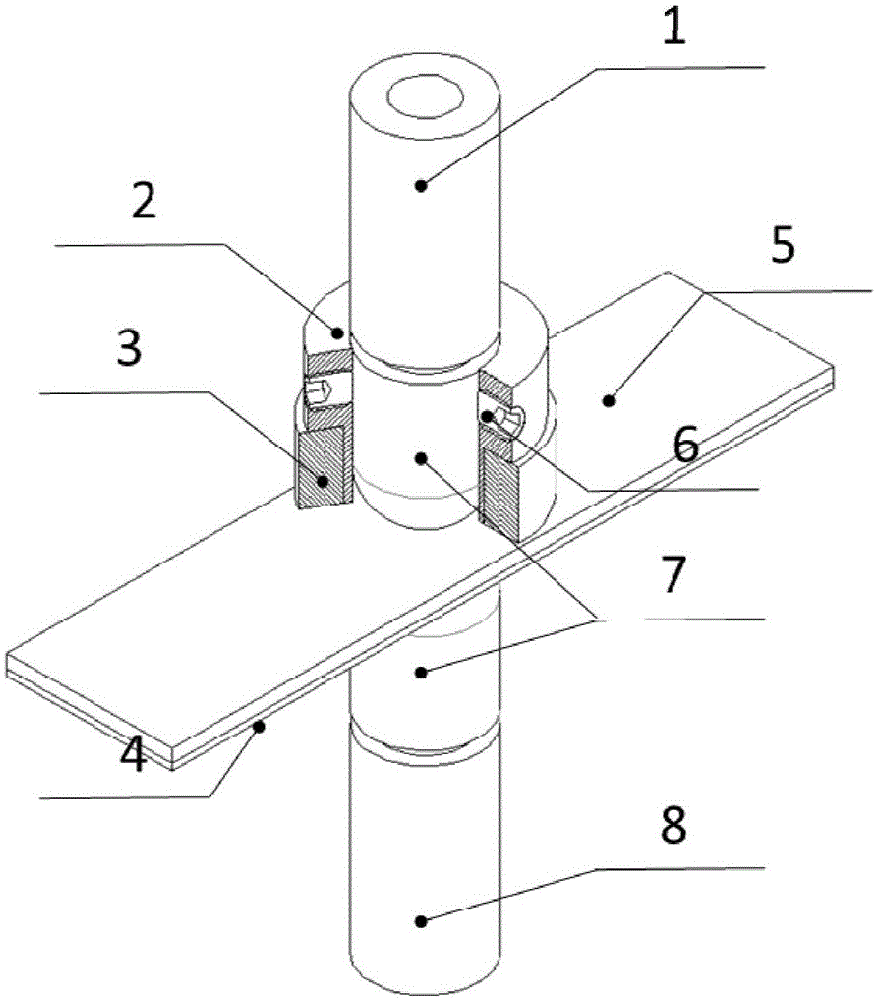

[0043] Such as figure 1 As shown, this embodiment includes: a ring-shaped permanent magnet 3, an insulating sleeve 2, an upper electrode rod 1 with an electrode cap 7 arranged sequentially on the thicker plate 5 from the outside to the inside, and an upper electrode rod 1 with an electrode cap 7 located under the thinner plate 4. The lower electrode rod 8 of the electrode cap 7, wherein: the annular permanent magnet 3 is coaxially socketed with the insulating sleeve 2, and the insulating sleeve 2 and the upper electrode rod 1 are fixedly connected by a positioning screw 6.

[0044] The outer diameters of the upper electrode rod 1 and the lower motor rod 8 are both 16mm.

[0045] The electrode cap 7 is a spherical flat electrode cap with an outer diameter of 16 mm and an end diameter of 5 mm.

[0046] The ring-shaped permanent magnet 3 has a magnetization direction perpendicular to the upper and lower plates; the ring-shaped permanent magnet 3 is a hollow cylinder with an inne...

Embodiment 2

[0064] The nugget shifting device of this embodiment is the same as that of Embodiment 1.

[0065] The upper plate 5 in this embodiment is 1.5mm austenitic stainless steel 301L, the lower plate 4 to be welded is 1.2mm duplex steel DP590; the electrode pressure is 3.5kN; the preloading time is 200ms, the welding time is 200ms, and The time is 100ms; the welding current is 5.5kA.

[0066] Other steps in this embodiment are the same as in Embodiment 1.

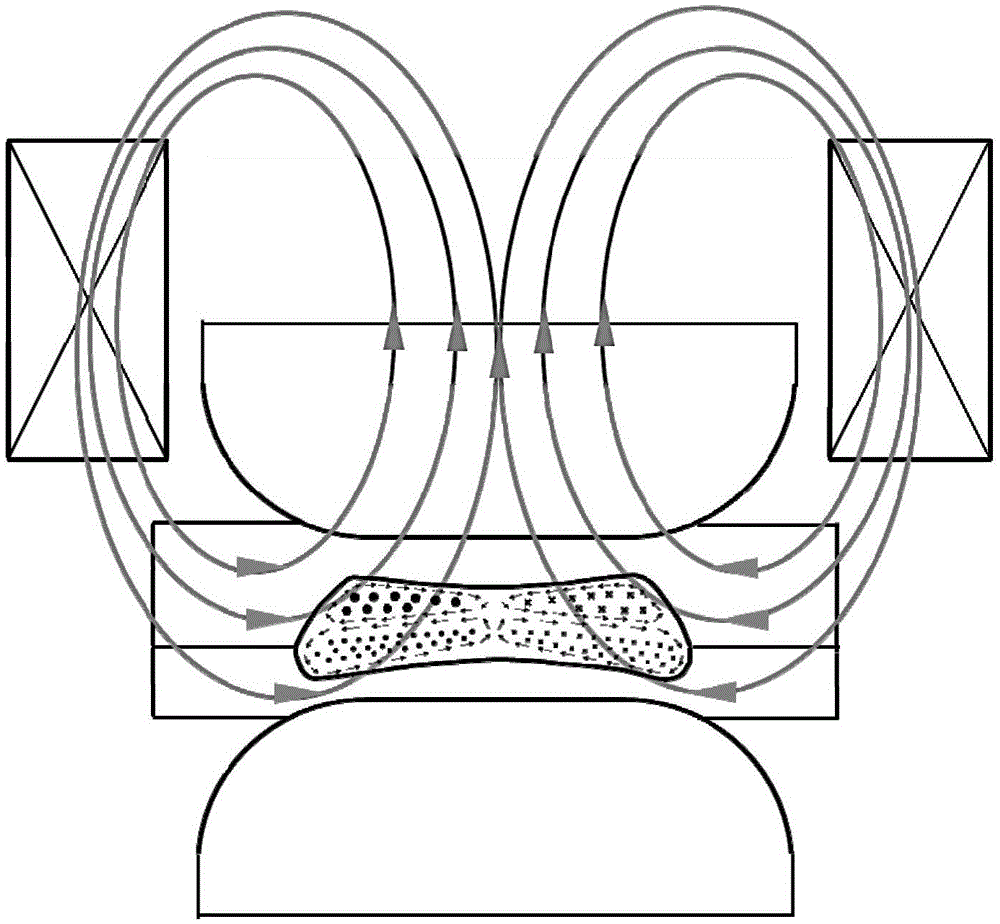

[0067] Such as Figure 8 As shown, the metallographic nugget evaluation standard after welding was tested, and the test results are listed in Table 2 below. The results show that the penetration depth of the low-resistivity side of the unilateral magnetron resistance spot welding is 0.375mm, the diameter of the nugget at the joint surface is 4.46mm, and the angle of the nugget at the low-resistivity side of the weak side is 32.3°; while the same welding Under the parameters, the traditional resistance spot welding with no exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| End diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com