A magnetron resistance spot welding method and device

A technology of magnetron resistance and power conversion device, which is applied in resistance welding equipment, welding power source, welding equipment and other directions to achieve the effect of saving cost, wide application range and improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

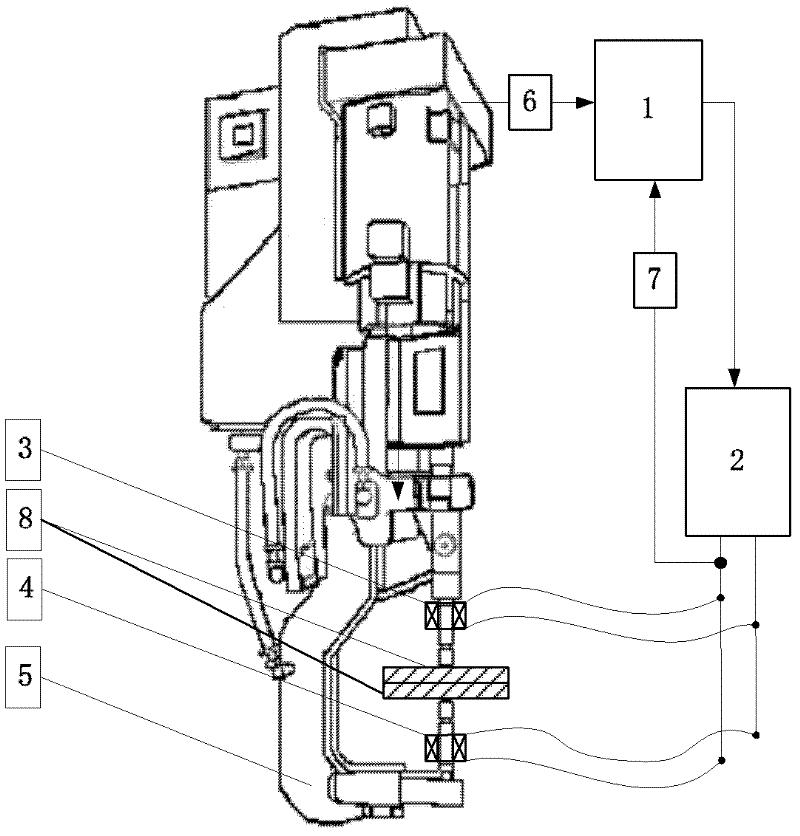

[0040] The hardware structure of the present invention includes a synchronization system 1 , a power conversion device 2 , an upper excitation coil 3 , a lower excitation coil 4 , a resistance spot welding torch 5 , a first current sensor 6 , a second current sensor 7 , and a workpiece 8 to be welded. Wherein: the input end of synchronous system 1 is connected with resistance spot welding torch 5 by the first current sensor 6, and the input end of synchronous system 1 is connected with upper exciting coil 3, lower exciting coil 4 respectively by the second current sensor 7; Synchronous system 1 The output terminal of is connected with the input terminal of the power conversion device 2 to transmit the electromagnetic stirring synchronous control signal and the excitation coil protection signal. The upper excitation coil 3 and the lower excitation coil 4 are respectively fixed at the upper and lower electrodes of the resistance spot welding torch 5; the drive input terminals and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com