Method of producing plating high-strength components through high-temperature hot stamping

A coating and warming technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems affecting processing and assembly, increasing production difficulty, and easy deformation of parts, so as to reduce production difficulty, eliminate defects, and produce speed-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

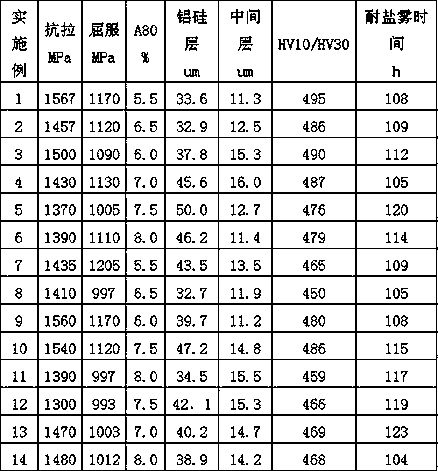

[0014] Embodiment 1-14: The method for producing high-strength parts with a coating layer by high-temperature hot stamping adopts the following specific processes.

[0015] (1) The material of the coated steel plate used in each embodiment is 22MnB5, the coating is aluminum-silicon coating, and the coating code is AS150; the thickness of the part (coated steel plate) before hot stamping is 0.6-3.0mm. The main components of the aluminum-silicon coating are (wt): Si 8.0-11.0%, Fe 1.5-3.0%, Cu 0.5-1.5%, and the rest are aluminum and its impurity elements. See Table 1 for the thickness of the coated steel sheets in each embodiment and the main components of the coating.

[0016] Table 1: Thickness of coated steel sheet and main composition of coating

[0017]

[0018] (2) The hot stamping process includes heating and die stamping processes; the heating process: when the thickness of the coated steel sheet is 0.6 to 1.45mm, the heating temperature is 935 to 960°C, and the total heating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com