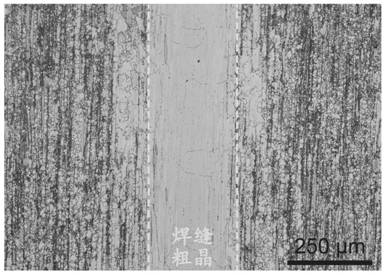

A Processing Technology for Suppressing Coarse Grain in Weld of Magnesium Alloy Profiles

A processing technology and magnesium alloy technology, which is applied in the field of weld coarse grain control in the extrusion and heat treatment of magnesium alloy profiles, can solve the problem of less research on weld coarse grains, the effect of coarse grains is not obvious, and the coarse grains of magnesium alloy profiles The organization is difficult to realize and other problems, so as to improve the effect of aging treatment, avoid the generation of coarse grain of weld seam, and shorten the effect of aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A processing technology for suppressing coarse grains of magnesium alloy profile welds, the specific steps are as follows:

[0046] (1) Prepare an ordinary commercial ZK60 magnesium alloy ingot with a size of Ф120×400mm.

[0047] (2) The magnesium alloy ingot is subjected to homogenization treatment, the temperature of the homogenization treatment is 410°C, and the holding time is 24h.

[0048] (3) peeling the magnesium alloy ingot obtained in step (2). When peeling, the surface processing amount is 1mm, and the surface roughness Ra≤23μm.

[0049] (4) extruding the magnesium alloy ingot obtained in step (3) to obtain a magnesium alloy extrusion profile, the temperature of the cast rod is 350°C, the temperature of the die is 380°C, the temperature of the extrusion cylinder is 360°C, and the extrusion speed is 5mm / s. In addition, liquid nitrogen was used to cool the extrusion die during extrusion, and the outlet pressure of the liquid nitrogen was 0.5 MPa.

[0050] (...

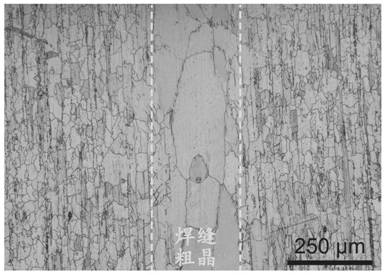

Embodiment 2

[0056] A processing technology for suppressing coarse grains of magnesium alloy profile welds, the specific steps are as follows:

[0057] (1) Prepare an ordinary commercial ZK60 magnesium alloy ingot with a size of Ф120×400mm.

[0058] (2) The magnesium alloy ingot is subjected to homogenization treatment, the temperature of the homogenization treatment is 380°C, and the holding time is 24h.

[0059] (3) peeling the magnesium alloy ingot obtained in step (2). When peeling, the surface processing amount is 6mm, and the surface roughness Ra≤23μm.

[0060] (4) extruding the magnesium alloy ingot obtained in step (3) to obtain a magnesium alloy extrusion profile, the temperature of the cast rod is 250°C, the temperature of the die is 280°C, the temperature of the extrusion cylinder is 260°C, and the extrusion speed is 0.5 mm / s. In addition, liquid nitrogen was used to cool the extrusion die during extrusion, and the outlet pressure of the liquid nitrogen was 0.6 MPa.

[0061]...

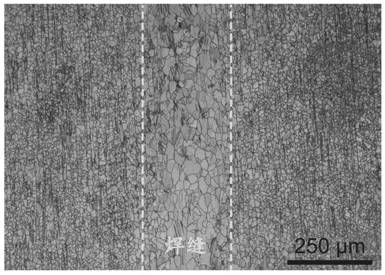

Embodiment 3

[0067] A processing technology for suppressing coarse grains of magnesium alloy profile welds, the specific steps are as follows:

[0068] (1) Prepare an ordinary commercial ZK60 magnesium alloy ingot with a size of Ф120×400mm.

[0069] (2) The magnesium alloy ingot is subjected to homogenization treatment, the temperature of the homogenization treatment is 400° C., and the holding time is 20h.

[0070] (3) peeling the magnesium alloy ingot obtained in step (2). When peeling, the surface processing amount is 4mm, and the surface roughness Ra≤23μm.

[0071] (4) subjecting the magnesium alloy ingot obtained in step (3) to extrusion treatment to obtain a magnesium alloy extrusion profile, the temperature of the casting rod is 300°C, the temperature of the die is 320°C, the temperature of the extrusion cylinder is 300°C, and the extrusion speed is 2mm / s. In addition, liquid nitrogen was used to cool the extrusion die during extrusion, and the outlet pressure of the liquid nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com