Low-voltage electronic aluminum foil for capacitor and preparation process thereof

An electronic aluminum foil and preparation process technology, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of short production cycle and shorten production cycle, and achieve the effect of less residue, elimination of uneven structure, and improvement of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

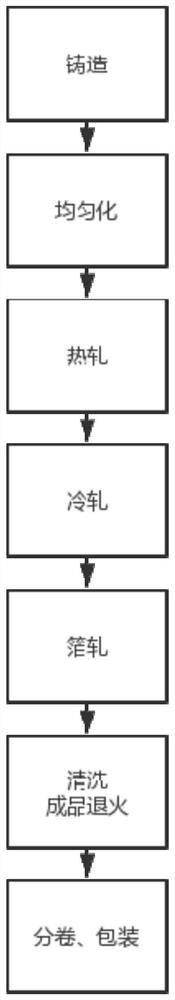

[0051] Preparation process of low voltage electron aluminum foil with a capacitor, including the following steps:

[0052] 1) Cast: The raw material of high-pure aluminum solution is smelted, insulated, refined and standing, using semi-continuous casting to produce flat ingots, casting temperature 710 ° C, rapid cooling to form flat ingots;

[0053] 2) Homogenization: The molded flat ingot obtained by the upper step is homogenized by annealing furnace, homogenizing temperature 590 ° C, homogenizing time 19 h, and homogenized after air cooling to room temperature;

[0054] 3) Hot rolling: The flat ingot after homogenization of the upper step is made of hot rolling treatment, the hot rolling temperature is 520 ° C, the final rolling temperature is 250 ° C, and the heat rolling thickness is 5.5 mm. Roll material;

[0055] 4) Cold rolling: The upper step is obtained by a hot rolled web for cold rolling treatment, and the cold rolling speed is 450 m / min to obtain a cold rolled coil h...

Embodiment 2

[0065] Preparation process of low voltage electron aluminum foil with a capacitor, including the following steps:

[0066] 1) Cast: High-pure aluminum-coated raw materials After smelting, holding, refining and standing, using semi-continuous casting production of flat ingots, casting temperature 685 ° C, rapid cooling of the formed flat ingot;

[0067] 2) Uniformity: The molded flat ingot obtained by the upper step is homogenized by an annealing furnace, the homogenization temperature is 550 ° C, the homogenization time is 15 h, and the homogeneration is holested to room temperature;

[0068] 3) Hot rolling: The flat ingot after homogenization of the upper step is made of hot rolling treatment, the hot rolling temperature is 500 ° C, the final rolling temperature is 300 ° C, resulting in a hot rolling with a hot rolling thickness of 5 mm. Coil;

[0069] 4) Cold rolling: The upper step is obtained by a hot rolled web for cold rolling treatment, and the cold rolling speed is 200 m / ...

Embodiment 3

[0079] Preparation process of low voltage electron aluminum foil with a capacitor, including the following steps:

[0080] 1) Casting: High-pure aluminum-coated raw materials After smelting, holding, refining, and standing, semi-continuous casting is used to produce flat ingots, casting temperature 720 ° C, rapidly cooling the formation flat ingot;

[0081] 2) Homogenization: The molded flat ingot obtained by the upper step is homogenized by an annealing furnace, the homogenization temperature is 600 ° C, the homogenization time is 25h, and the homogeneration is holested to room temperature;

[0082] 3) Hot rolling: The flat ingot after homogenization of the upper step is made of hot rolling treatment, the hot rolling temperature is 550 ° C, the final rolling temperature is 350 ° C, resulting in a hot rolled thickness of 7 mm. Coil;

[0083] 4) Cold rolling: The upper step is obtained by the hot rolled web for cold rolling treatment, the cold rolling speed is 600 m / min, resultin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com