Preparation method of VNbMoTaW high-entropy alloy

A high-entropy alloy and body-centered cubic technology, which is applied in the field of high-entropy alloys, can solve the problems of deteriorating the mechanical properties of alloys, increasing personnel injuries, and adjusting the cooling speed, so as to simplify the alloy preparation process, eliminate component segregation, and reduce processing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of the VNbMoTaW high-entropy alloy of the present invention, comprising the following steps:

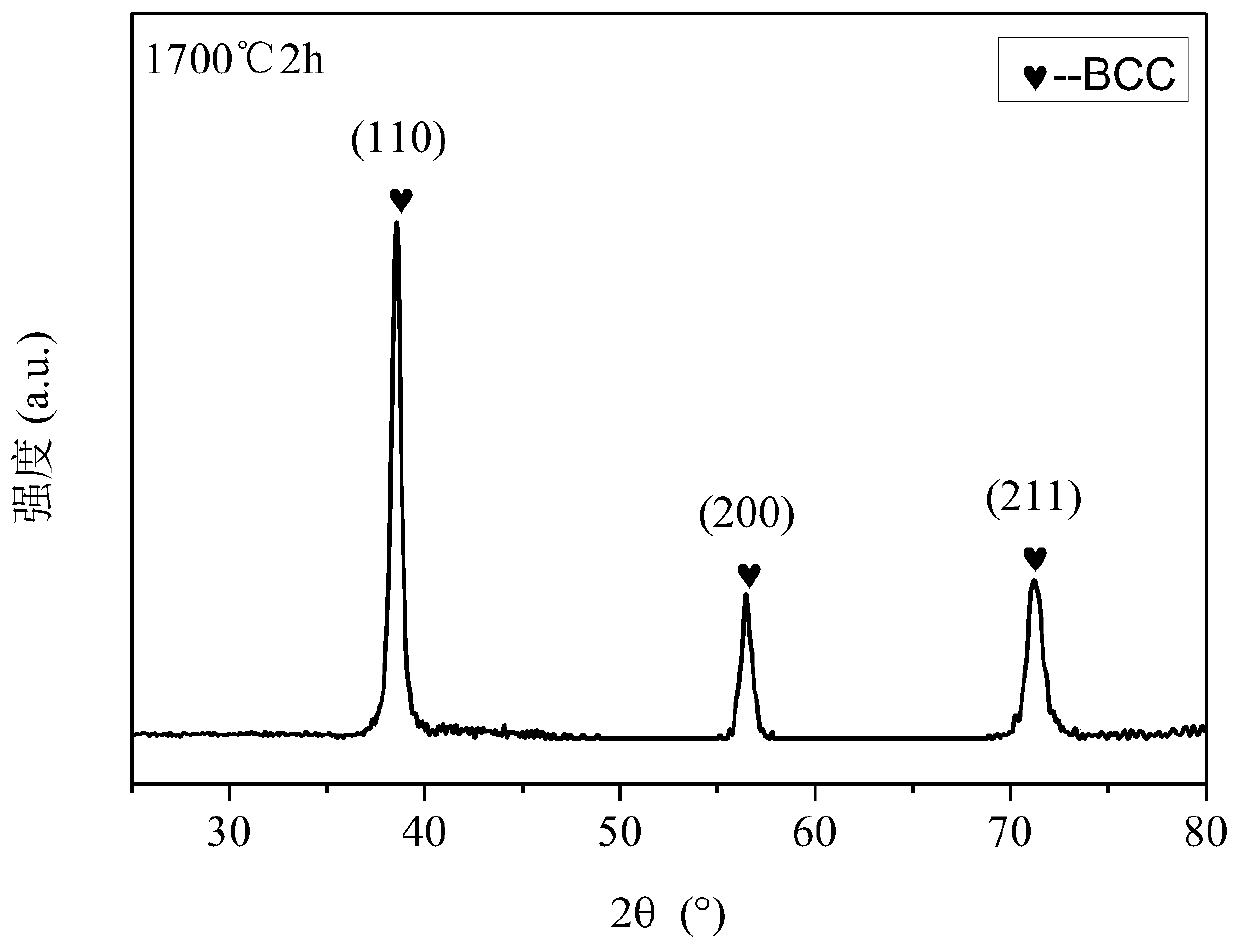

[0035] (1) Mechanical alloying method: 50 g of equiatomic ratio mixed powders of W, Mo, V, Nb, and Ta five kinds of elemental powders were used as raw materials, and ball milled in a ball mill tank of a planetary high-energy ball mill. The material of the tank body and the grinding balls are all WC carbide, and the inside of the ball mill tank is evacuated and filled with high-purity argon (99.99%) as a protective atmosphere. During the ball milling process, the ball-to-material ratio was 10:1, and the rotational speed was 300 r / min. After 15 hours of ball milling, the VNbMoTaW high-entropy alloy powder with equiatomic ratio was obtained. The VNbMoTaW alloy powder was taken out and detected by XRD. At this time, the powder had transformed into a two-phase BCC solid solution.

[0036] (2) Put the VNbMoTaW alloy powder into a graphite mold (isostatically pr...

Embodiment 2

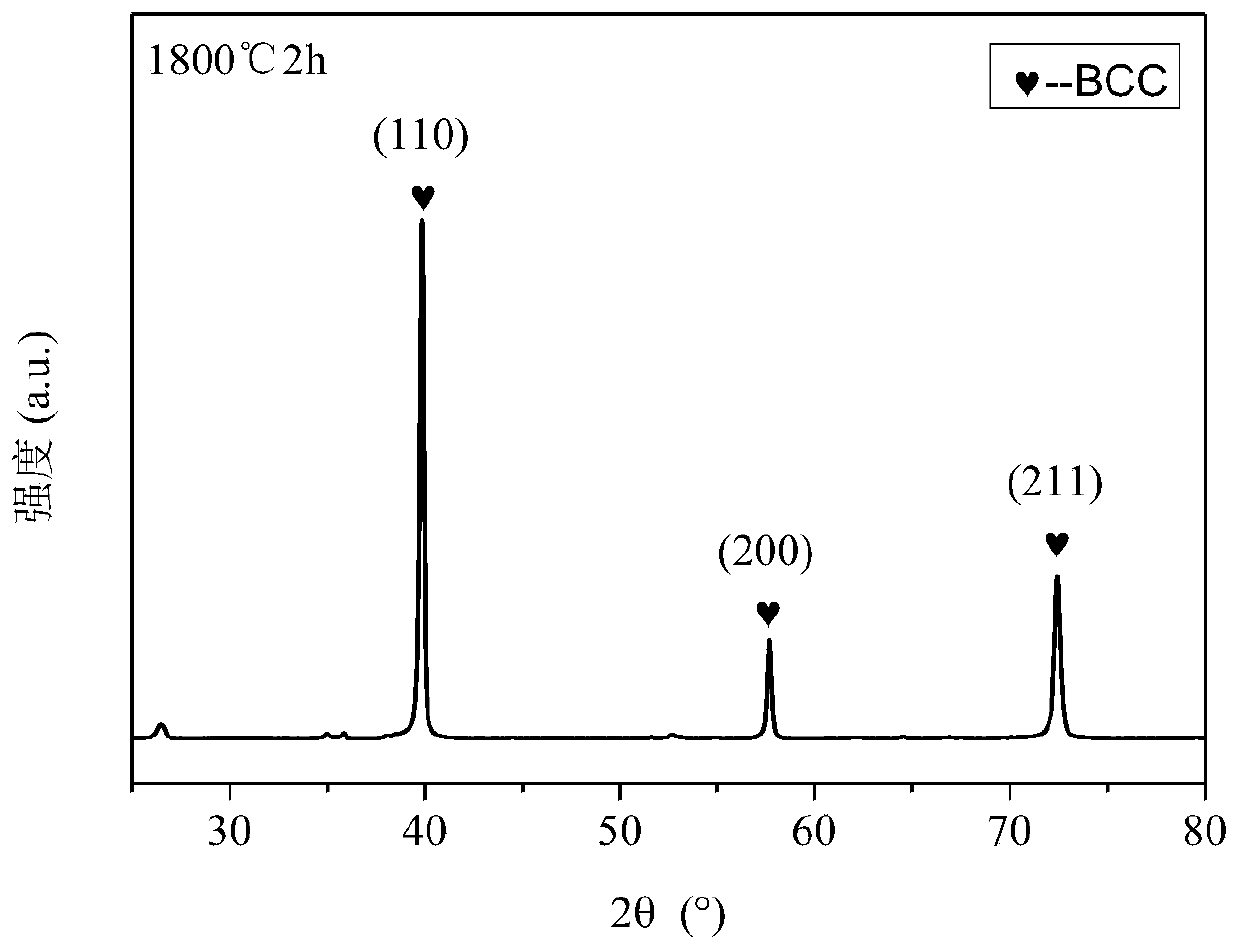

[0038] A preparation method of the VNbMoTaW high-entropy alloy of the present invention, the preparation process is basically the same as that of Example 1, the only difference is: in step (1), the ball milling time is 20h; in step (2), the pressure is 40MPa, and the heating rate is 10°C / min, the holding temperature is 1800°C.

[0039] Equiatomic VNbMoTaW high-entropy alloy powders were obtained after ball milling, and their XRD results showed that they were two-phase BCC solid solutions. VNbMoTaW high-entropy alloy bulk with a density of 99.7%, such as figure 2 As shown, its XRD results show that it is a single-phase BCC solid solution.

Embodiment 3

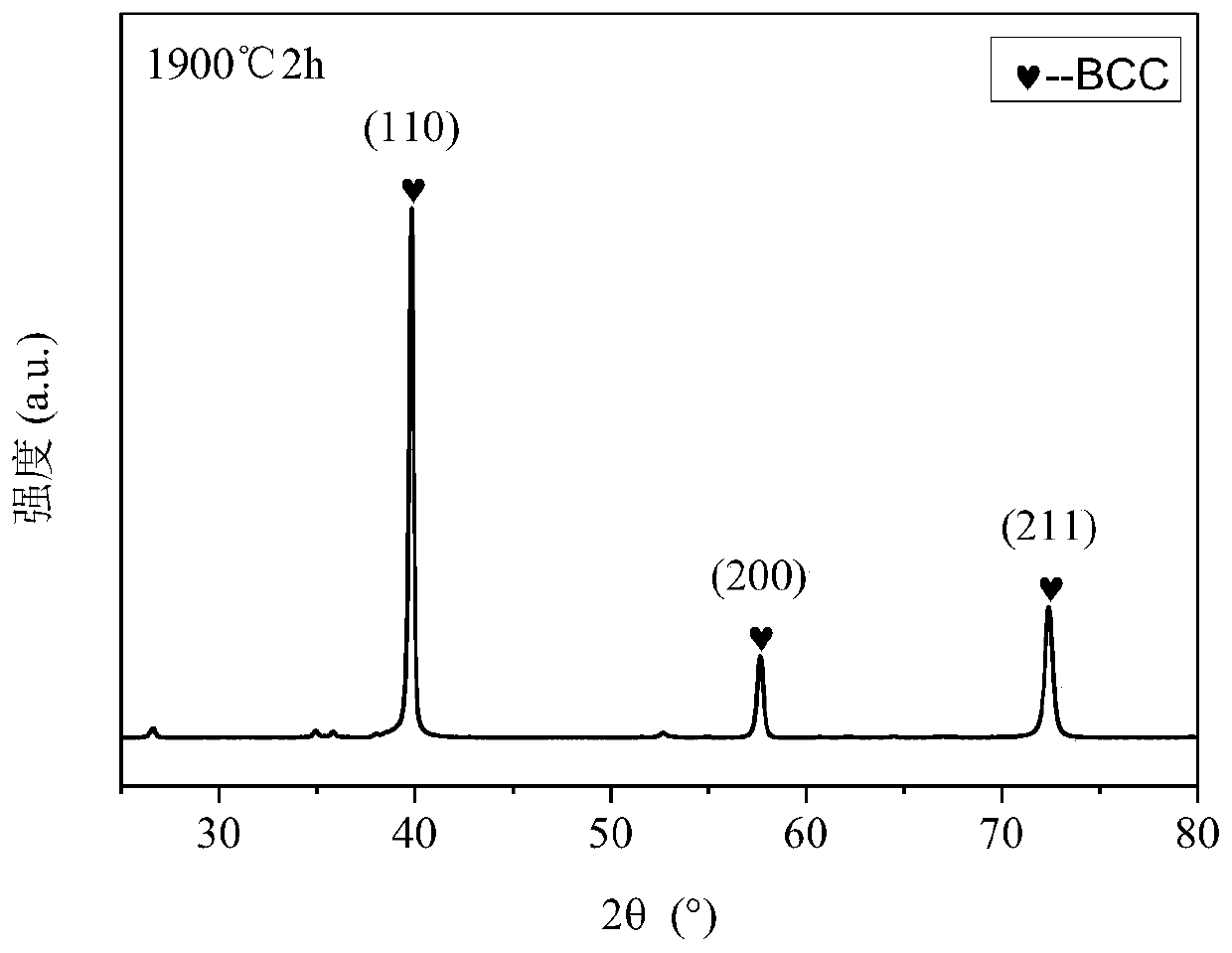

[0041] A preparation method of the VNbMoTaW high-entropy alloy of the present invention, the preparation process is basically the same as that of Example 1, the only difference is: in step (1), the ball milling time is 30h; in step (2), the pressure is 30MPa, and the heating rate is 5°C / min, the holding temperature is 1900°C.

[0042] Equiatomic VNbMoTaW high-entropy alloy powders were obtained after ball milling, and their XRD results showed that they were two-phase BCC solid solutions. VNbMoTaW high-entropy alloy bulk with a density of 99.6%, such as image 3 As shown, its XRD results show that it is a single-phase BCC solid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com