Heat treatment process method for EA1N-material urban rail car axle

A process method and urban rail technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as efficiency decline, cost increase, and waste of electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

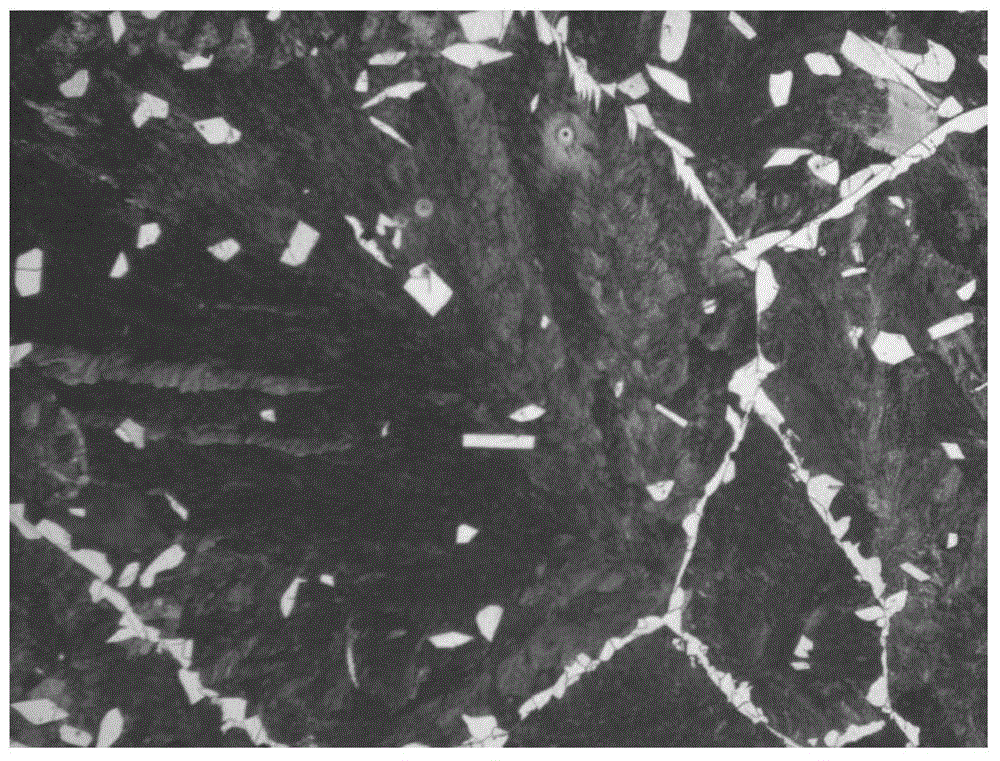

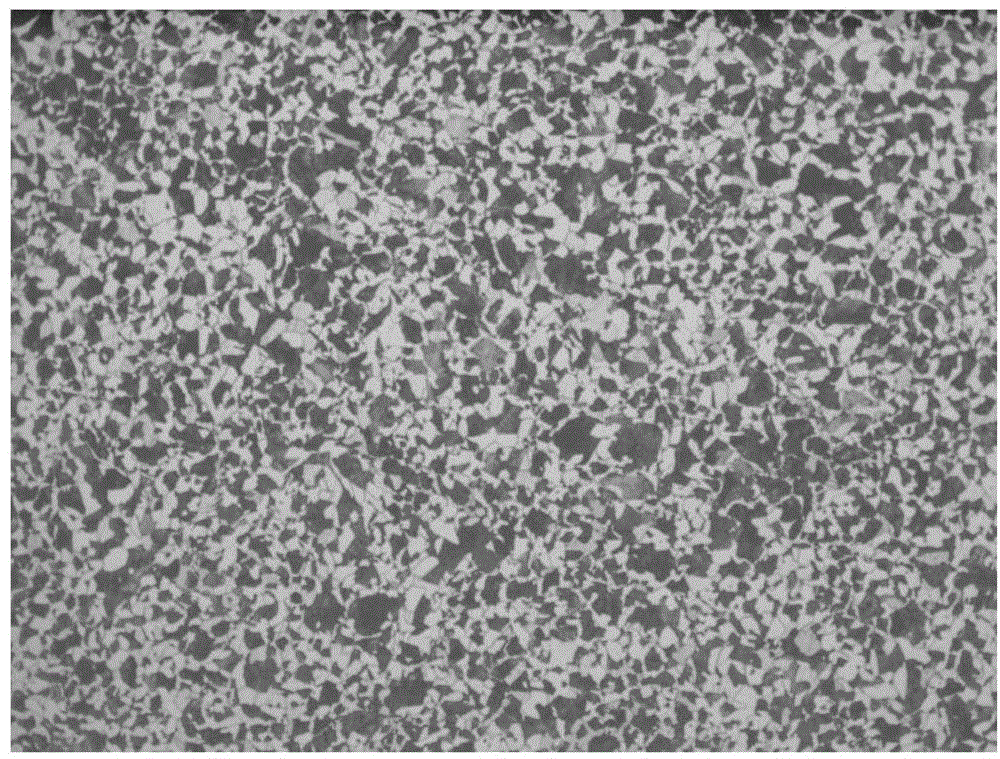

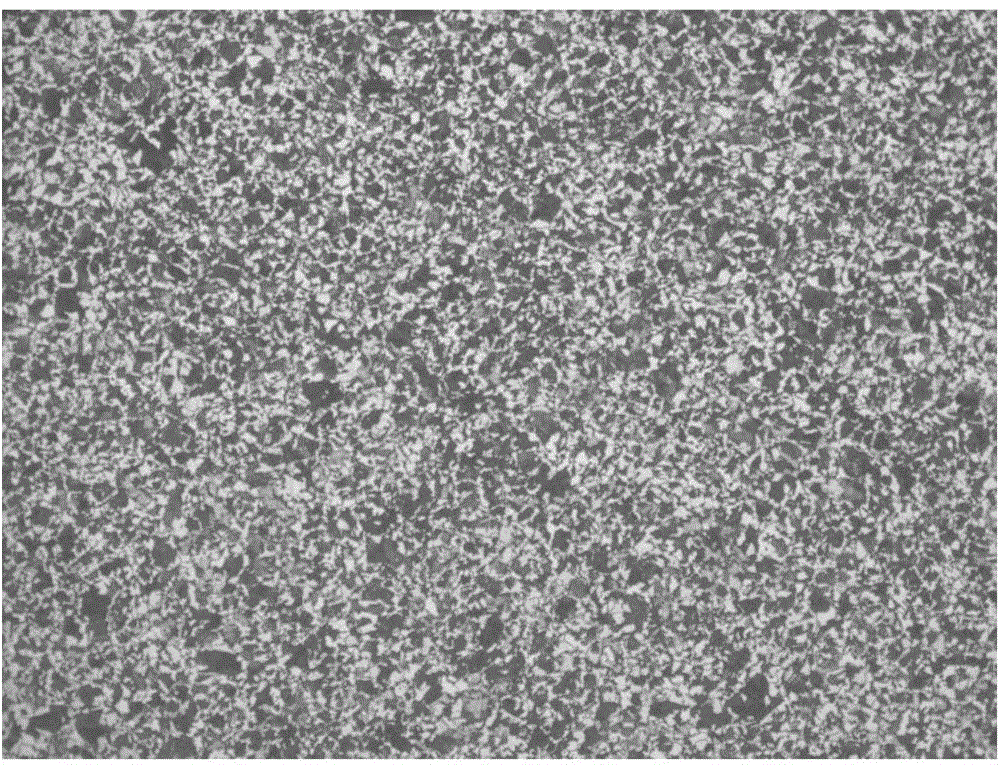

[0015] The present invention will be described in further detail below in conjunction with the specific implementation of the accompanying drawings.

[0016] Equipment and heat treatment process in the specific embodiment of the present invention are as follows respectively:

[0017] 1. Equipment:

[0018] The heat treatment process equipment is a hanging chain heat treatment production line.

[0019] 2. Heat treatment process:

[0020] 1) The temperature of the first normalizing is 850-880°C, after 3-4 hours of heat preservation, the furnace is air-cooled, and the air-cooling is below 500°C for the second normalizing;

[0021] 2) The temperature of the second normalizing is 810-820°C. After holding the heat for 3-4 hours, it is air-cooled, and the air-cooled temperature is below 250°C for tempering;

[0022] 3) Tempering temperature is 540°C, keep warm for 2.5 to 3.5 hours, take out the furnace and air cool.

[0023] In each specific embodiment, the content of C in the bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com