In-situ nanometer reinforced aluminum alloy for lightweight automobile anti-collision beam and preparation method

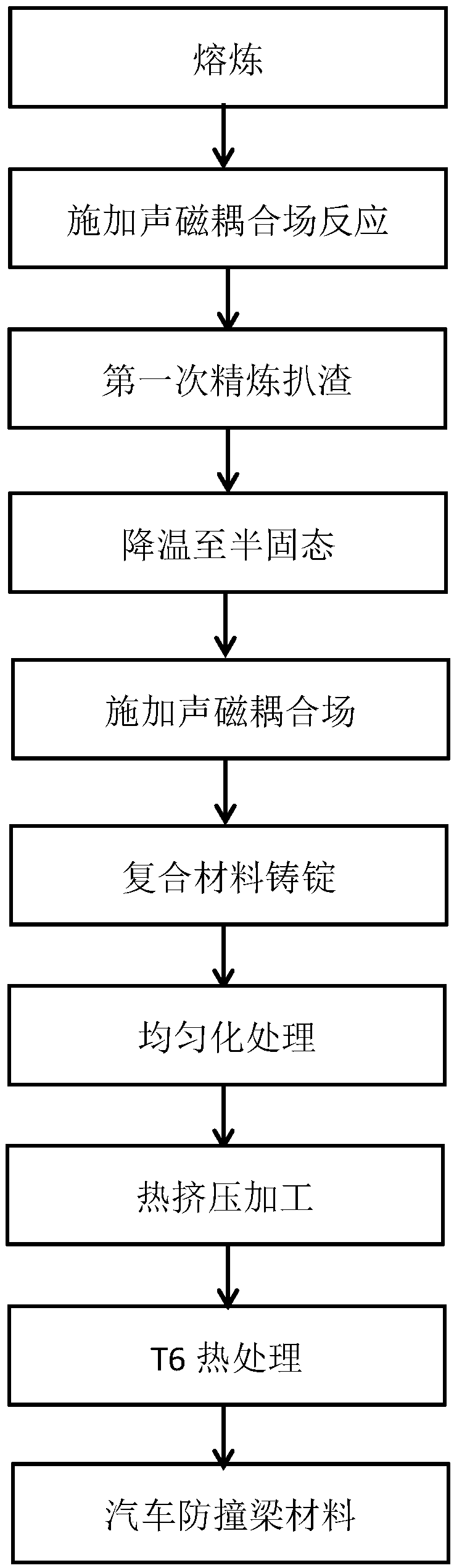

A technology of anti-collision beams and aluminum alloys, which is applied in the field of in-situ nano-strengthened aluminum alloys for lightweight automobile anti-collision beams and its preparation. It can solve the problem of complex extrusion process temperature and procedures, which are not suitable for industrialized batch and continuous production, and it is difficult to get rid of strong plasticity inversion. To achieve the effect of improving the impact energy absorption effect, promoting dynamic recrystallization, and increasing the nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

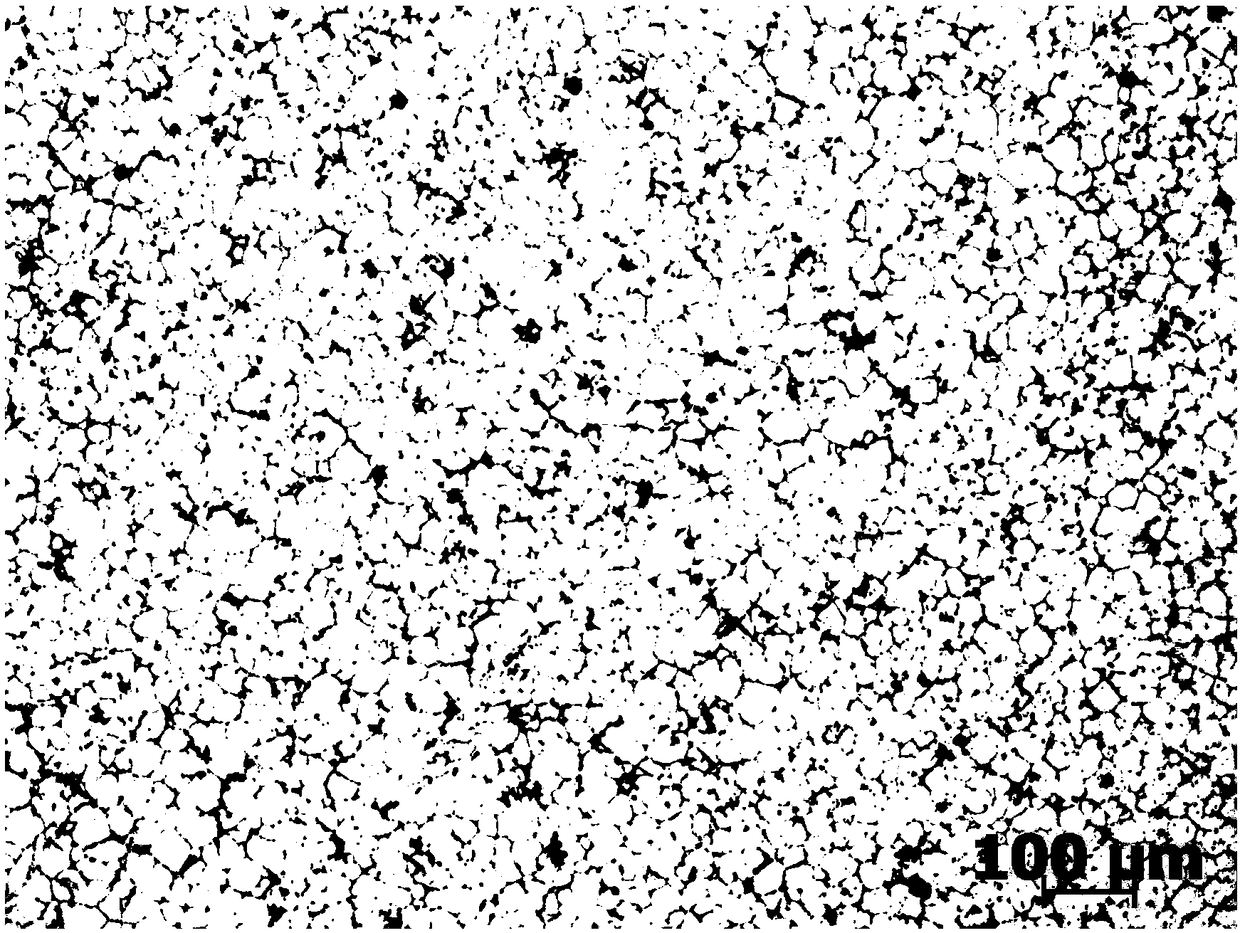

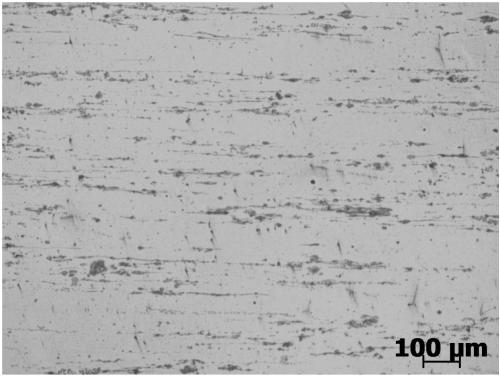

[0025](1) Aluminum alloy casting: Put 1Kg of aluminum alloy into a high-purity graphite crucible to melt at 780°C and keep it warm for 10 minutes, then raise the temperature of the melt to 870°C, and add in batches the dry-treated and wrapped with high-purity aluminum foil The reaction powder (particle size is less than 100 μm, the quality of zirconium carbonate is 38g, potassium fluoroborate is 69g, potassium fluorotitanate 75g) enters the melt, and the combined device of low-frequency magnetic field and high-energy ultrasonic field is turned on at the same time (magnetic field: frequency 5Hz, magnetic force Current 50A; ultrasonic: power 800W, frequency 15kHz) react for 20min, remove the scum on the surface of the melt after the reaction and spray hexachloroethane into the solution for refining; then put it into a resistance furnace to lower the temperature to 660°C and Keep warm, start the combined device of high-frequency pulsed magnetic field and high-energy ultrasonic fie...

Embodiment 2

[0030] The preparation method is basically the same as in Example 1, except that the reactants are different in quality. The quality of zirconium carbonate is 77g, potassium fluoroborate is 138g, and potassium fluorotitanate is 142g. 2 +2vol%TiB 2 +2vol%Al 2 o 3 ) aluminum matrix composite cast rod.

Embodiment 3

[0032] The preparation method is basically the same as in Example 1, except that the reactants are different in quality, the quality of zirconium carbonate is 115g, potassium fluoroborate is 206g, potassium fluorotitanate is 210g and the reaction is obtained (3vol% ZrB 2 +3vol%TiB 2 +3vol%Al 2 o 3 ) aluminum matrix composite cast rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com