A kind of single crystal lithium ion battery ternary electrode material precursor, electrode material and its preparation method and application

A lithium-ion battery, ternary electrode technology, applied in battery electrodes, positive electrodes, electrical components, etc., can solve problems such as uneven force, increased production costs, and impact on material cycle performance, and achieves simple methods and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the above-mentioned ternary electrode material precursor of the single crystal lithium ion battery, comprising the following steps:

[0030] A) sintering after mixing the transition metal hydroxide and the cosolvent to obtain a sintered product;

[0031] B) under airtight, high temperature and high pressure conditions, after mixing the sintered product, air bubble material and dispersant, adding bubble filling material, so that high-pressure air bubbles enter the air bubble material, to obtain a precursor of a single crystal lithium ion battery ternary electrode material .

[0032] In the invention, the transition metal hydroxide and the cosolvent are first mixed and then sintered to obtain a sintered product.

[0033] Wherein, the transition metal hydroxide is selected from one or more of hydroxides of manganese, cobalt, and nickel elements.

[0034] The co-solvent contains one or more of boron-containing co...

Embodiment 1

[0060] 1. Put Ni 0.8 mn 0.1 co 0.1 (OH) 2 After mixing evenly with boric acid at a molar ratio of 1:0.001, sinter at 400°C for 6 hours to obtain transition metal oxides with fully grown primary particles;

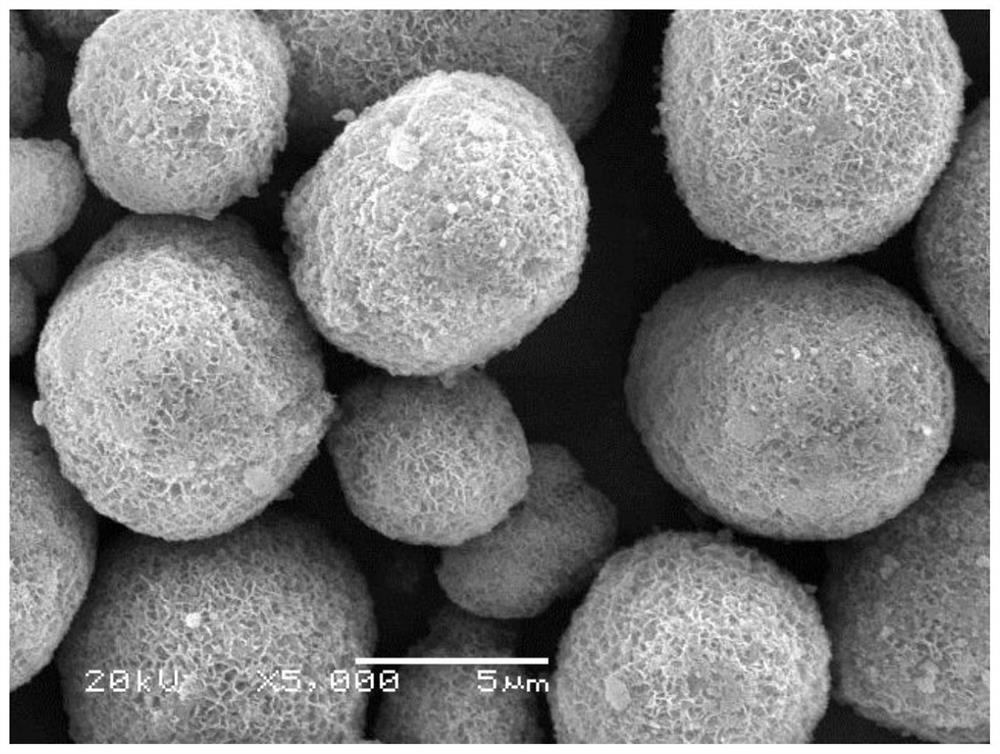

[0061] see figure 1 , figure 1 for Ni 0.8 mn 0.1 co 0.1 (OH) 2 SEM image, where, Ni 0.8 mn 0.1 co 0.1 (OH) 2 The median size of the particle size is 8-15 μm, and the particle size of the primary particle is 0.01-0.05 μm.

[0062] 2. Mix the product of step 1 with polyacrylamide and water evenly according to the molar ratio of 1:0.002:0.02, heat it to 150°C in a closed container, fill it with high-pressure carbon dioxide gas, and obtain high-pressure carbon dioxide bubbles distributed inside after cooling The ternary material precursor of ;

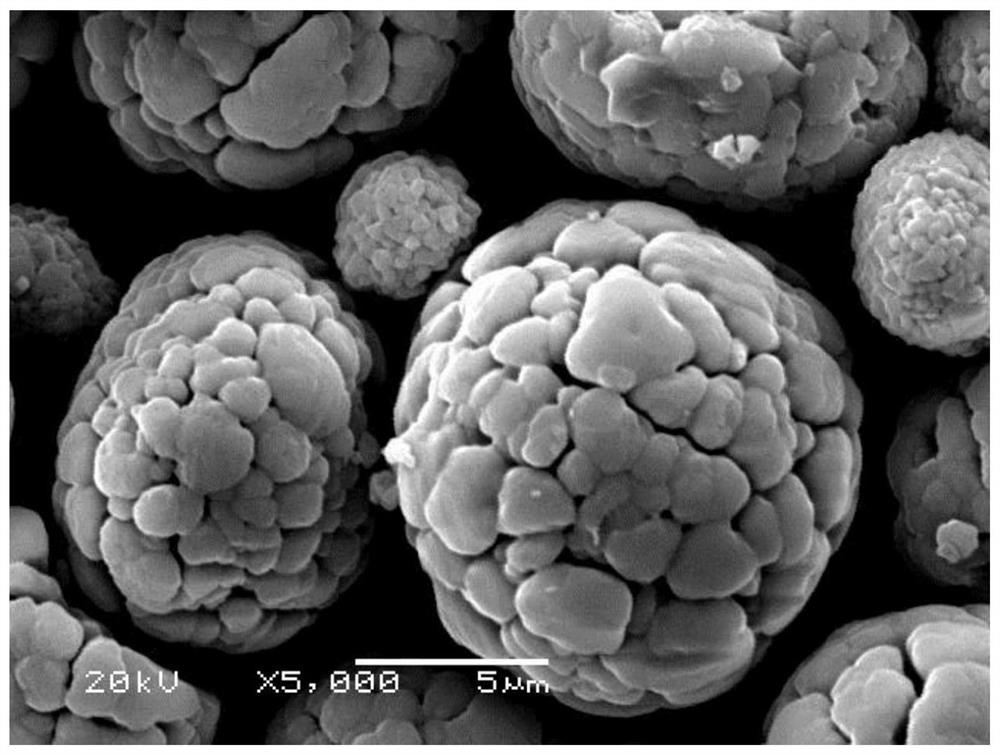

[0063] see figure 2 , figure 2 It is an SEM image of a ternary material precursor with high-pressure carbon dioxide bubbles distributed inside, wherein the median particle size of the ternary material precursor with hi...

Embodiment 2

[0073] 1. Put Ni 0.6 mn 0.2 co 0.2 (OH) 2 After mixing evenly with sodium borate at a molar ratio of 1:0.0015, sinter at 300°C for 4 hours to obtain transition metal oxides with fully grown primary particles;

[0074] 2. Mix the product of step 1 with glucose, sucrose, and water according to the molar ratio of 1:0.005:0.002:0.001, heat it to 180°C in a closed container, fill it with high-pressure carbon dioxide gas, and obtain the surface of high-pressure carbon dioxide bubbles after cooling Coated ternary material precursor;

[0075] 3. After the ternary material precursor and lithium hydroxide are mixed evenly according to the molar ratio of 1:1, they are sintered at 810°C for 16 hours in an oxygen atmosphere to obtain large-grain single crystal LiNi 0.6 mn 0.2 co 0.2 o 2 Lithium-ion battery cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com