Patents

Literature

118results about How to "Will not cause cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

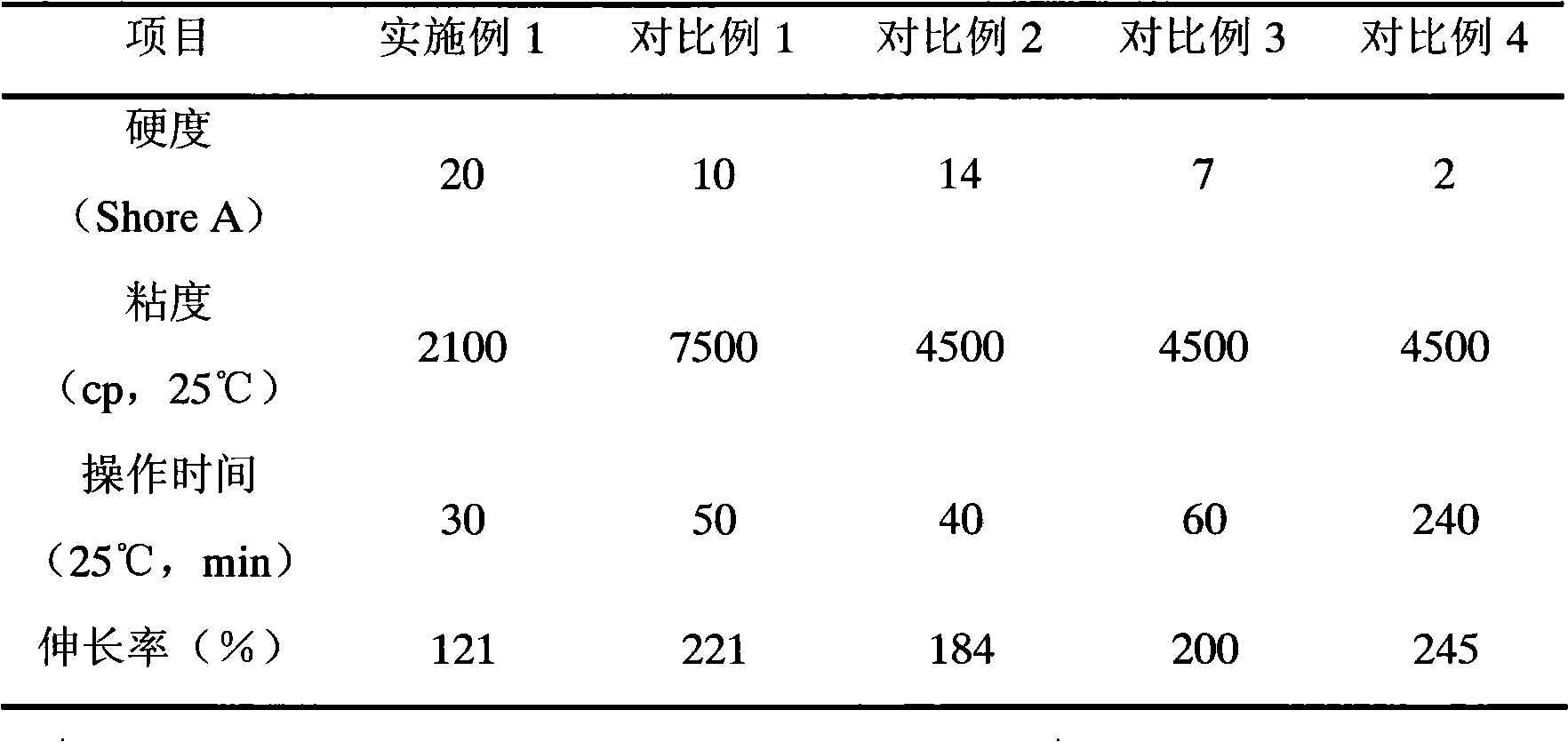

Low-hardness high-flexibility double-component condensed type organic silicon potting adhesive composition

InactiveCN101565600AGood waterproof and moisture-proof performanceImprove vulcanization effectNon-macromolecular adhesive additivesOther chemical processesPliabilityChemistry

The invention mainly relates to potting adhesive, in particular to a low-hardness and high-flexibility double-component condensed type organic silicon potting adhesive composition suitable for potting a light emitting diode (LED) display screen module. The composition comprises a component A and a component B, wherein the component A comprises a basic polymer, a filling material, a plasticizing agent and a deep curing agent; and the component B comprises a cross-linking agent, a tackifier and a catalyst. The component A and the component B are mixed according to designed proportion to have a cross-linking reaction so as to realize the effects of potting the LED display screen module, preventing adhesive layer cracking during repeatedly bending and folding LED tubes and providing excellent waterproof and dampproof properties.

Owner:GUANGZHOU HUITIAN FINE CHEM

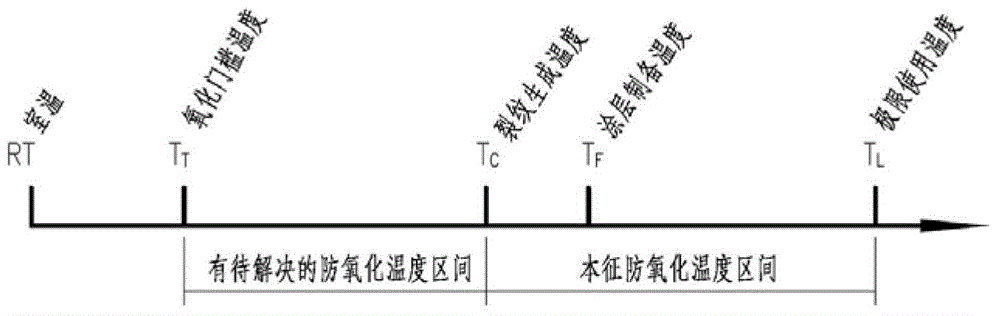

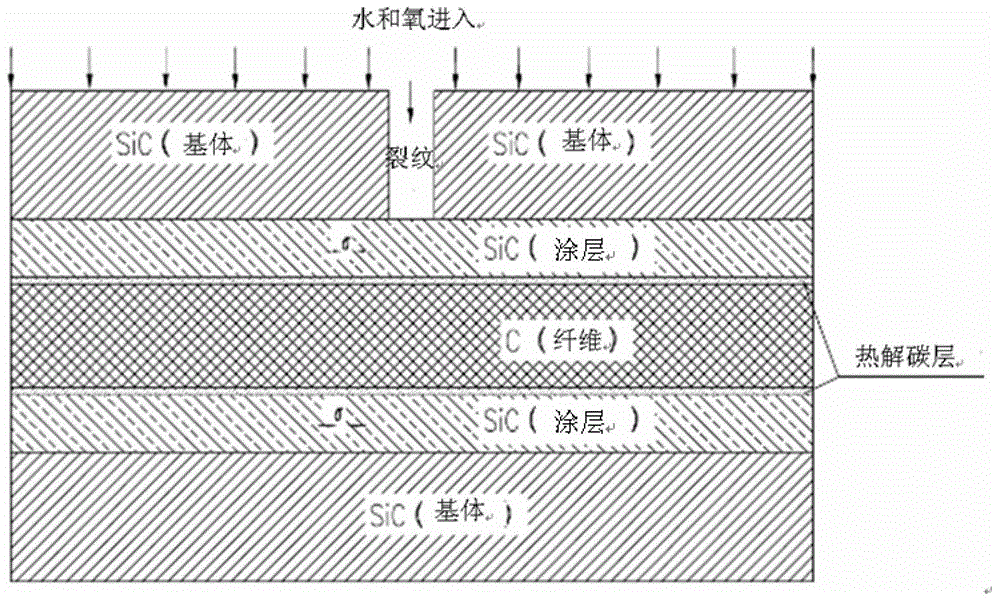

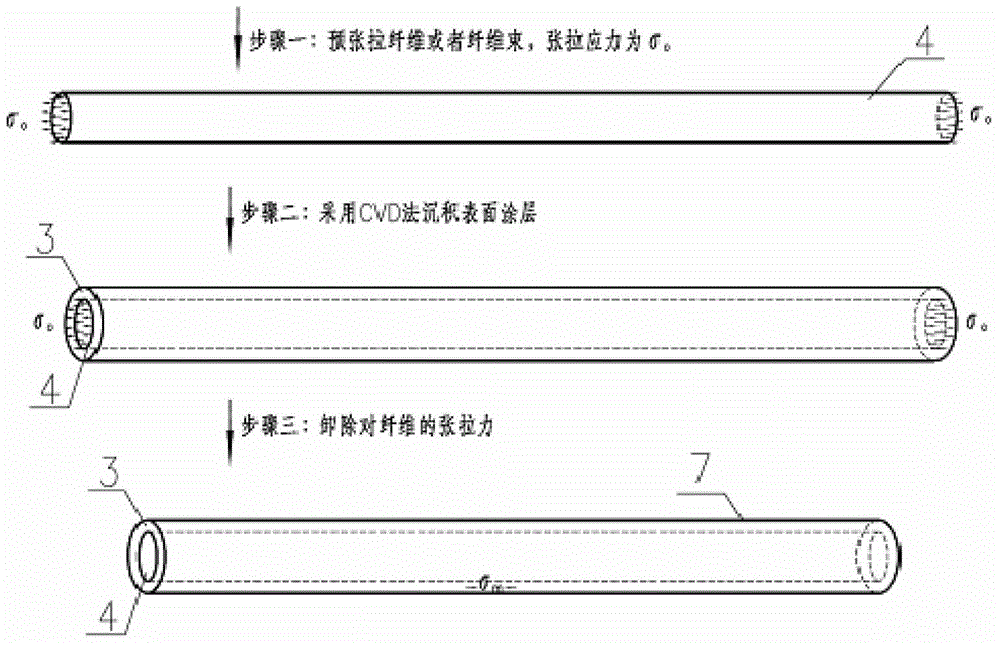

Preparation method of crack-free coating fiber

The invention relates to a preparation method of a crack-free coating fiber, and belongs to the technical field of preparation of a composite material. After initial tensile stress sigma o is exerted to continuous single fibers or fiber bundles, an anti-oxidation coating is evenly deposited on the surface by using a CVD (chemical vapor deposition) method and the like under the condition of tensile stress; the initial tensile stress sigma o is unloaded under the condition that the initial tensile stress is greater than or equal to the crack generating temperature TC of the coating after deposition is ended; the anti-oxidation coating is integrally cooled to room temperature after the initial tensile stress sigma o is unloaded, so as to obtain the crack-free coating fiber. By adopting the preparation method, a thermal stress crack caused by mismatching of thermal expansion of the fiber and the coating is avoided; a channel of an oxidizing medium is cut off; the fiber is prevented from being oxidized; anti-oxidation protection of a full-temperature section is achieved. Thus, the integrality, the safety and the reliability of the composite material are improved; the preparation method is suitable for preparation of heat-resistant, anti-oxidation and high-temperature creep-resistant reinforced composites. Therefore, the preparation method is continuous and simple in preparation technology, and convenient to industrially produce.

Owner:CENT SOUTH UNIV

Conductive silver paste for Low-temperature sintered LTCC

ActiveCN110047611AImprove performanceStrong adhesionNon-conductive material with dispersed conductive materialSilver pasteConductive paste

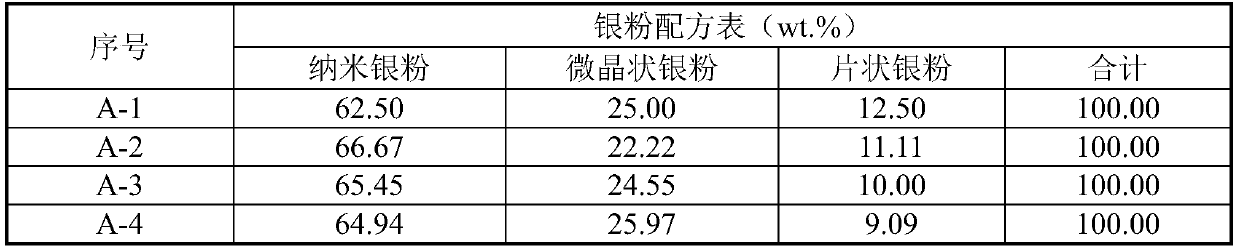

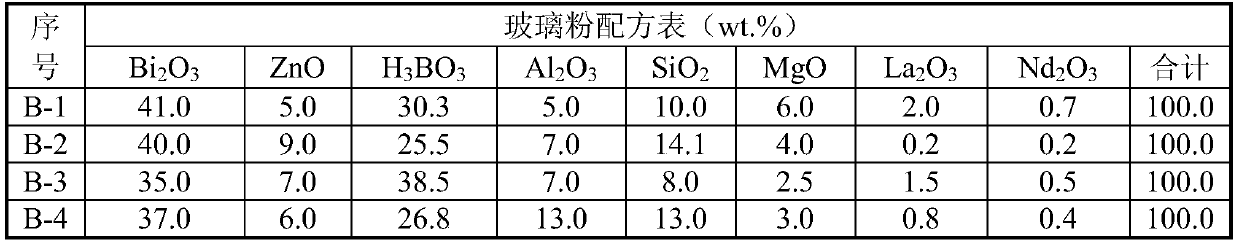

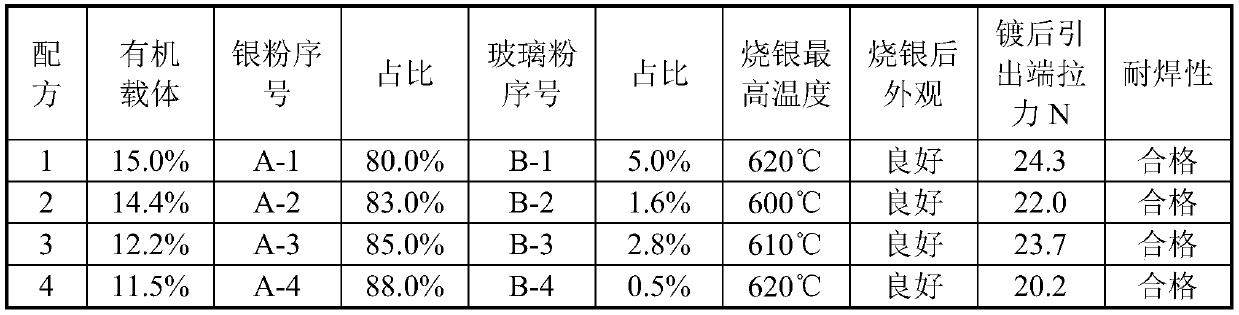

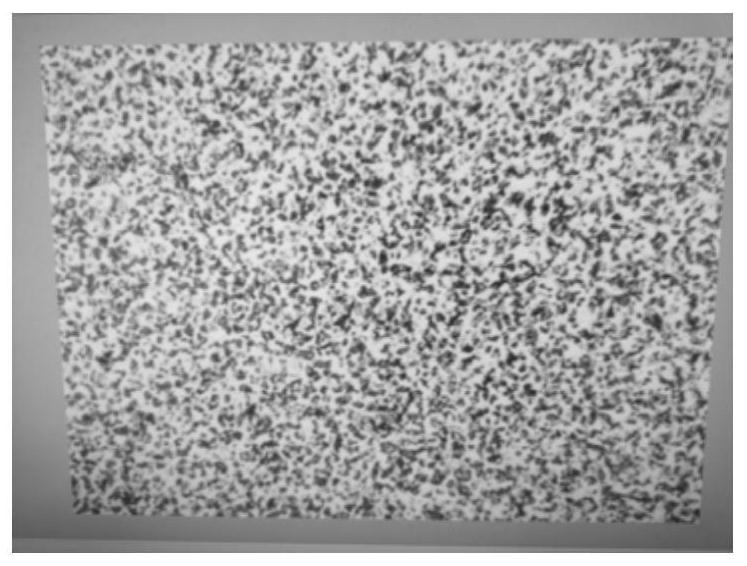

The invention discloses conductive silver paste for low-temperature sintered LTCC. The conductive silver paste comprises 80.0-88.0wt% of silver powder, 0.2-5.0wt% of glass powder and 7.0-19.8wt% of organic carrier, wherein the silver powder comprises nanometer silver powder, microcrystal-shaped silver powder and sheet-shaped silver powder, the weight ratio of the nanometer silver powder and the microcrystal-shaped silver powder is (2.5-3.0):1, the weight ratio of the nanometer silver powder and the microcrystal-shaped silver powder and the sheet-shaped silver powder is (7.0-10):1, and the glass powder comprises Bi2O3, ZnO, SiO2, H3BO3, Al2O3, MgO, La2O3 and Nd2O3. The conductive paste does not contain lead and has excellent performance, the sintering temperature is 600-650 DEG C, the sintered LTCC product has excellent adhesion and favorable silver layer compactness, and the problem that Dupont paste and seld-made LTCC ceramic material sintering are not matched is solved.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

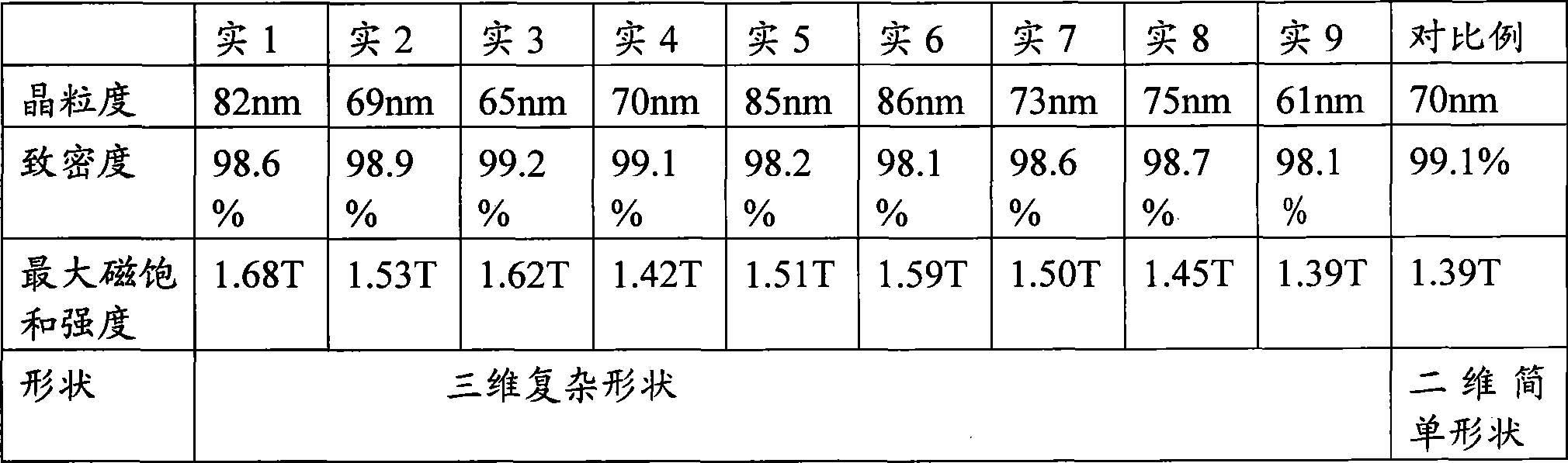

Preparation method of nano-crystal soft magnetic alloy elements

ActiveCN101456075APromote expansionReduce internal stressInorganic material magnetismMicrowaveAdhesive

The invention discloses a method for preparing a nano-crystalline soft magnetic alloy component, which comprises the following steps: (1) putting powder of each component of nano-crystalline alloy elements into a ball mill jar, and milling the powder for 15 to 50 hours under protective atmosphere of inert gas to obtain nano-crystalline alloy powder; (2) adding adhesive into the nano-crystalline alloy powder prepared in step (1) to carry out injection molding to obtain a soft magnetic alloy blank; and (3) extracting and degreasing the soft magnetic alloy blank prepared in step (2), and then placing the treated soft magnetic alloy blank into a microwave smelting device to be sintered so as to obtain the nano-crystalline soft magnetic alloy component. The method for preparing the nano-crystalline soft magnetic alloy component is not only suitable for large-scale industrialized production, but also prepares products with complex and various shapes, and has the advantages of high magnetic conductivity, high saturated magnetic induction density, low coercive force, low loss and high stability.

Owner:BYD CO LTD

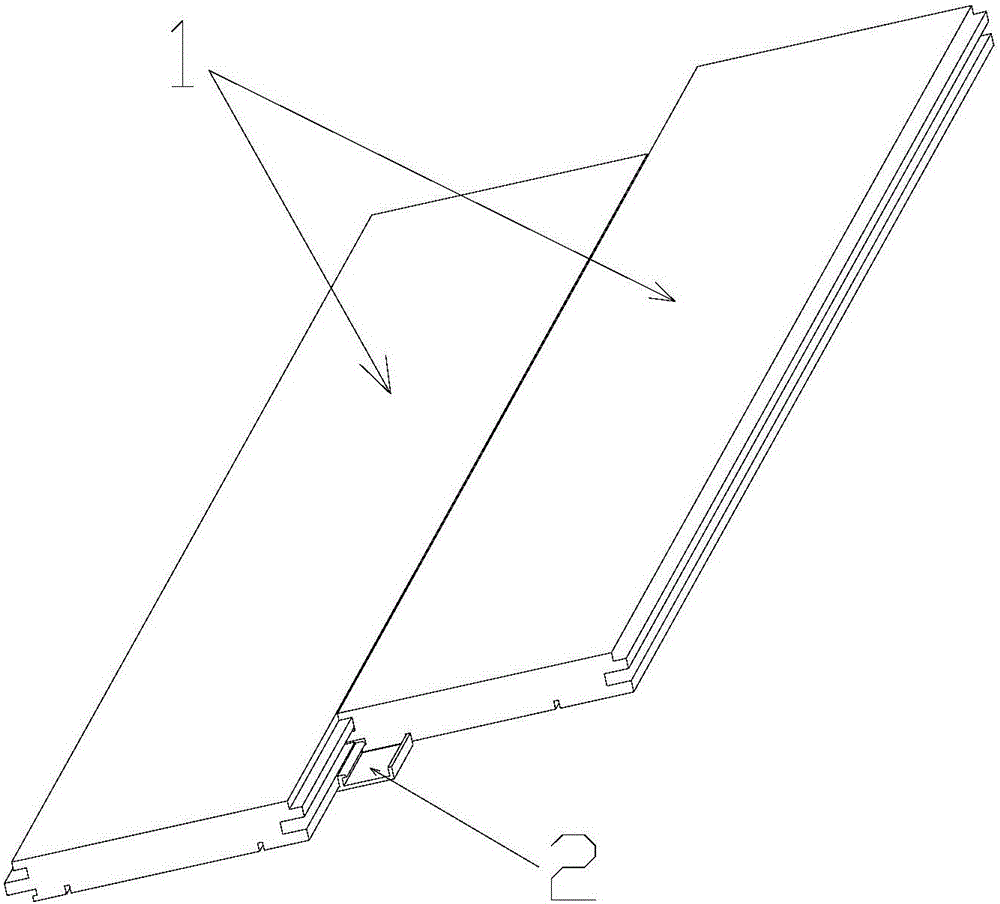

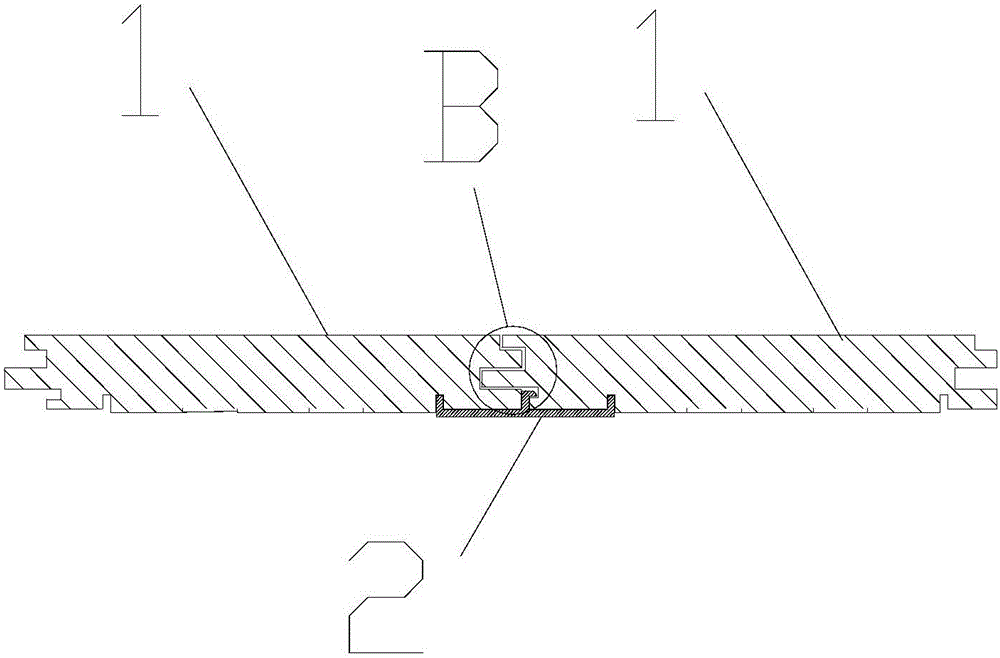

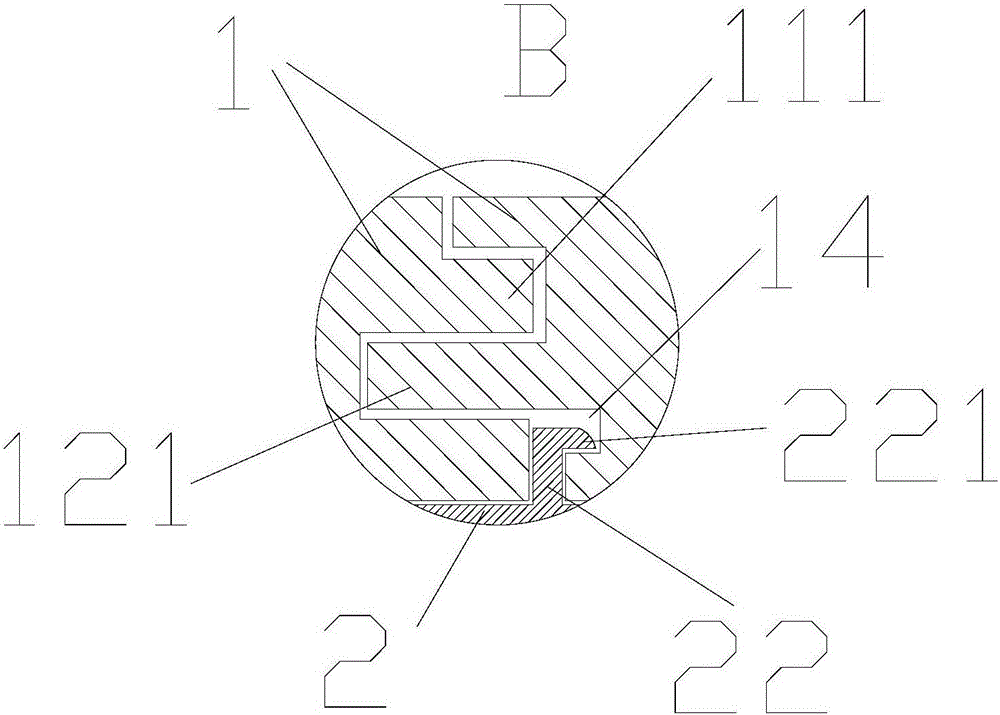

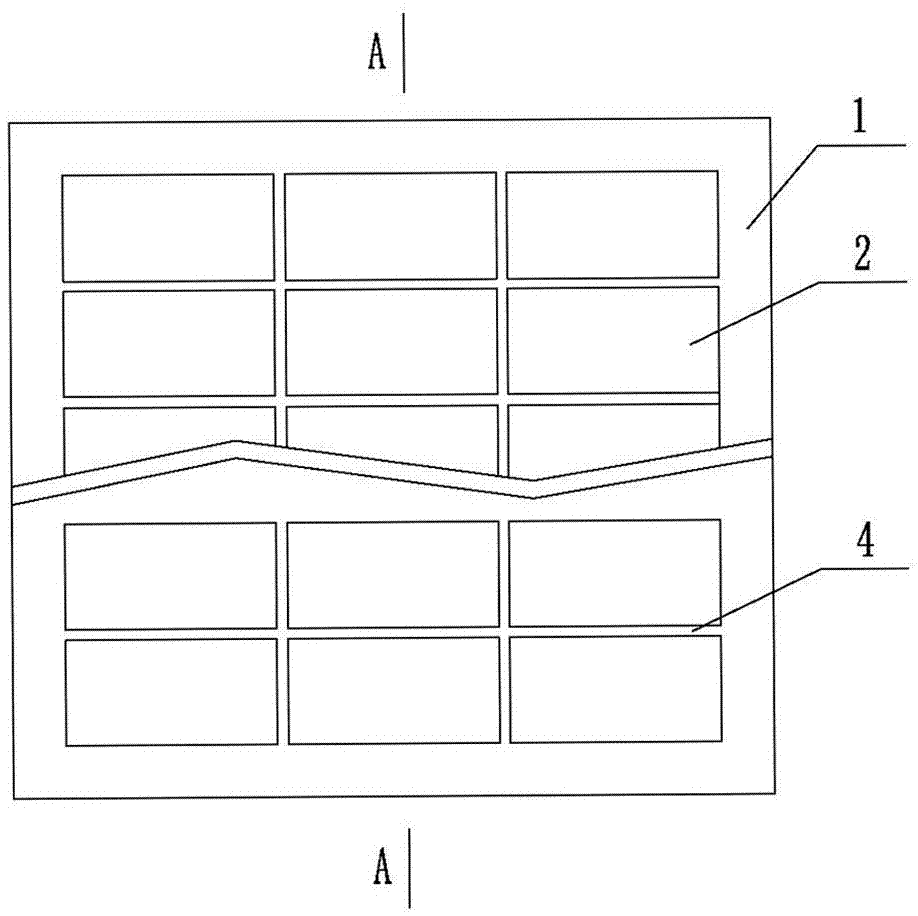

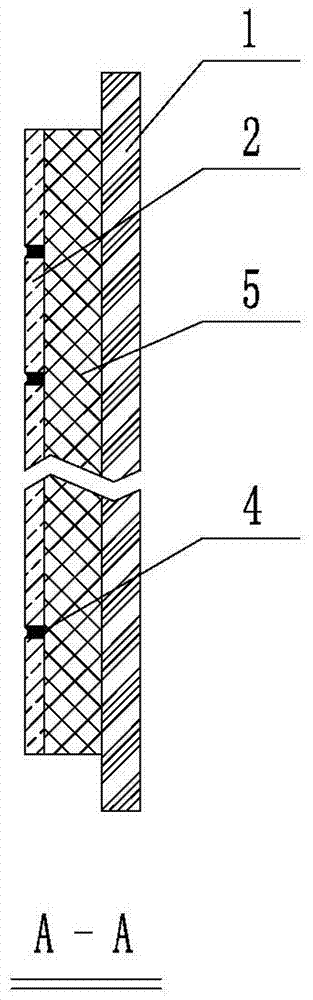

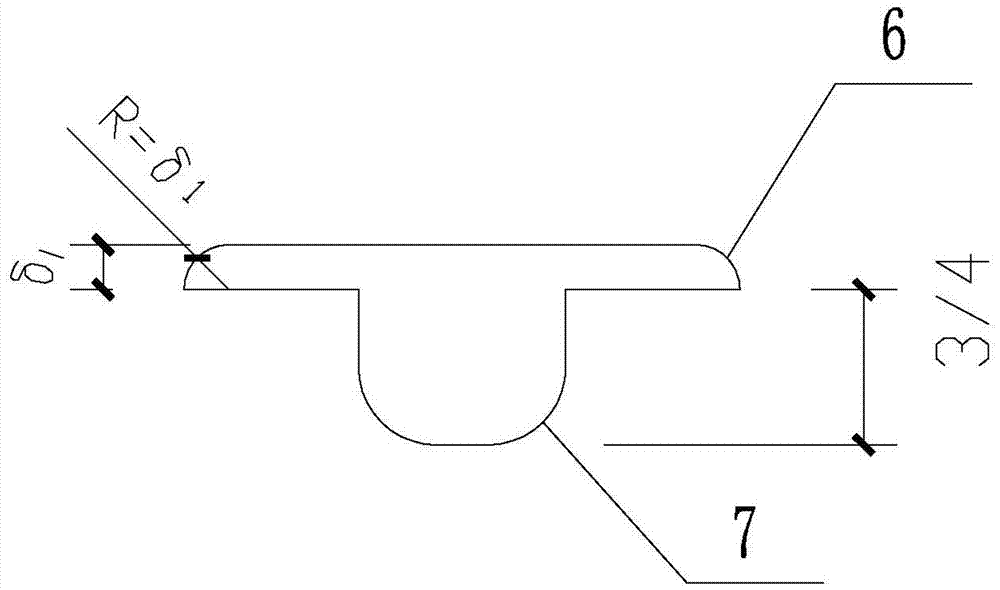

Compound buckled wood floors

The invention discloses compound buckled wood floors which comprise wood floor bodies and buckle pieces, wherein a first rabbet and a second rabbet are respectively arranged on two opposite sides of each wood floor body; after two adjacent wood floor bodies are connected with each other through the first rabbets and the second rabbets, the wood floor bodies can move in the length direction or the width direction; sliding chutes parallel to the edges of the wood floor bodies are respectively formed in two opposite sides on the back surfaces; the buckle pieces are mounted on the back surfaces of the wood floor bodies; parallel sliding rails are arranged on two sides of the buckle pieces and are matched with the sliding chutes; central boards parallel to the sliding rails are further arranged in the middles of the buckle pieces and are positioned between every two adjacent wood floor bodies. According to the compound buckled wood floors, by the adoption of a structure that the buckle pieces are matched with the wood floor bodies, the wood floor bodies cannot be damaged and can be assembled, disassembled and reused conveniently; two adjacent wood floor bodies are plugged through the rabbets and then are fixedly connected through the buckle pieces. The buckle pieces transmit fixed acting force of the wood floor bodies to the middle parts, so that cracking of the edge parts of the wood floor bodies can be effectively avoided.

Owner:BAROQUE WOOD IND ZHONGSHAN CO LTD

Preparation method for ceramic binder used for rapid synthesis of CBN abrasive tools by microwave method

The invention relates to a preparation method for a ceramic binder used for rapid synthesis of CBN abrasive tools by a microwave method, belonging to the field of preparation of binders. The preparation method comprises the following steps: a, by mass, weighing 45 to 70% of silica acid or silicon dioxide, 3 to 10% of aluminium hydroxide or aluminium oxide, 5 to 15% of anhydrous sodium carbonate or sodium oxide and 5 to 20% of boric acid or diboron trioxide, carrying out uniform mixing and grinding, and carrying out sieving with a 200-to-300-mesh sieve so as to prepare a mixed material; b, melting the mixed material prepared in the step a and then carrying out water quenching, wherein melting conditions are as follows: carrying out heating to 1300 to 1500 DEG C with a rate of 10 DEG C / min and then carrying out melting for 2 to 5 h; c, drying a product prepared in the step b at 100 to 150 DEG C for 4 to 8 h, then carrying out grinding, and carrying out sieving with the 200-to-300-mesh sieve so as to prepare a basic ceramic binder; and d, subjecting the basic ceramic binder prepared in the step c to pressing molding into a blank with a presser, and carrying out sintering with a microwave sintering furnace so as to prepare the ceramic binder. The method provided by the invention has the characteristics of low reaction temperature, short reaction time, low production cost, energy conservation, etc., and is easy to realize industrial production.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Composite precoated sand and its prepn process

InactiveCN1526491AImprove stabilityImprove high temperature resistanceFoundry mouldsFoundry coresMaterials scienceCoating

The present invention provides one new kind of pre-coated sand including coke grains in the quantity of 2-6 % of sand weight. The present invention also provides the making process of the pre-coated sand, including a coke grain and sand coating step. The pre-coated sand may be used to make sand core for obtaining casting with compact and smooth surface.

Owner:罗丙太

Multiple head small diameter long screw drilling wall forming machine

InactiveCN1900430AImprove adaptabilityGuarantee the pile qualityDamsArtificial islandsPower unitDrill bit

The present invention relates to a multithread minor diameter long auger drilling wall forming machine. Said invention adopts portal shaped piledriver side-by-side set at least auger stems, lower end set drill, top connected with spacer, spacer slip connection with portal shaped piledriver, spacer set rotating power unit, auger stem connected with rotating power unit, auger stem being hollow in middle part, connected with concrete delivery pipe, guideway set below the chassis. Said invention solves uneven soil stirring, weak intensity, inefficiency etc shortage.

Owner:HOHAI UNIV

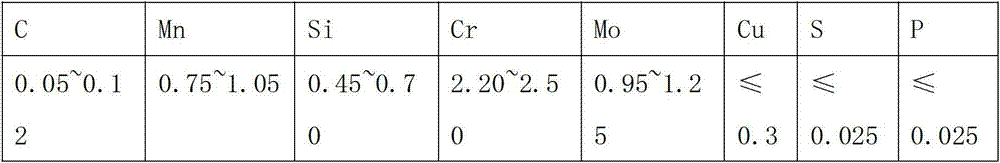

T/P91 steel electrode and manufacturing method thereof

InactiveCN103111774AArc stabilizationReduced chance of splashingWelding/cutting media/materialsSoldering mediaNiobiumWeight coefficient

The invention discloses a T / P91 steel electrode manufacturing method. An R40 welding wire is used as a core wire. Medical powder comprises, by weight percentage, marble 31-35, fluorite 26-29, titanium dioxide 4-7, quartz 1-2, mica 1-2, chromium metal 13-15, atomization nickel powder 1-2, ferrotitanium 7-9, ferromolybdenum 1-2, ferroniobium 0.5-1, ferrovanadium 1-2, and vanadium-nitrogen alloy 1-2. After the powder is mixed in a drying mode, water glass is added according to a ratio of 3:1 and is mixed with the powder in a wet mode, and suppression is carried out after uniform stirring is carried out. Electrode coating weight coefficient is controlled to be 0.95-1.0, cracking of a coating after being dried is avoided, the compression environmental temperature is over 20 DEG C, the products are placed into a drying box after being dried for 3 hours, and is dried for 2 hours when temperature is 100 DEG C, 125 DEG C per hour is risen into 450 DEG C, and then furnace cooling of the products is carried out after being warmed for two hours. The steel electrode is good in welding process performance, little in splatter, low in smoke amount, and attractive in appearance of weld. All the performances can reach foreign imported similar steel electrode technological level. Production cost is greatly reduced.

Owner:天津诚信达金属检测技术有限公司

Welded mold shell casting process for gypsum composite polymer viscous mortar

ActiveCN108115088AImprove adhesionWill not cause crackingFoundry mouldsFoundry coresWaxRoom temperature

The invention discloses a welded mold shell casting process for gypsum composite polymer viscous mortar. The welded mold shell casting process specifically comprises the following steps: preparing a wax mold, removing grease on the surface of the wax mold, putting into a coating to coat the surface of the wax mold by a layer of the coating, further coating the surface of the wax mold with a layerof composite colloid, and drying at a room temperature; putting the wax mold into gypsum slurry, and slowly rotating till the surface of the wax mold is adhered to a layer of the gypsum slurry; slowlyputting the wax mold into polymer viscous mortar, rotating at a slow speed till the surface of the wax mold is coated by a layer of the mortar, taking out the wax mold, curing in a curing agent solution immediately, further putting the wax mold into the gypsum slurry, so as to feed the gypsum slurry into a polymer mortar shell formed on the surface of the wax mold. As three layers, namely a gypsum layer, a polymer mortar layer and a gypsum layer, are arranged in sequence from inside to outside of the wax mold shell, a mold shell is relatively high in strength and is not liable to crack due tothe support and adhesion functions of the polymer mortar layer.

Owner:青田保俐铸造有限公司

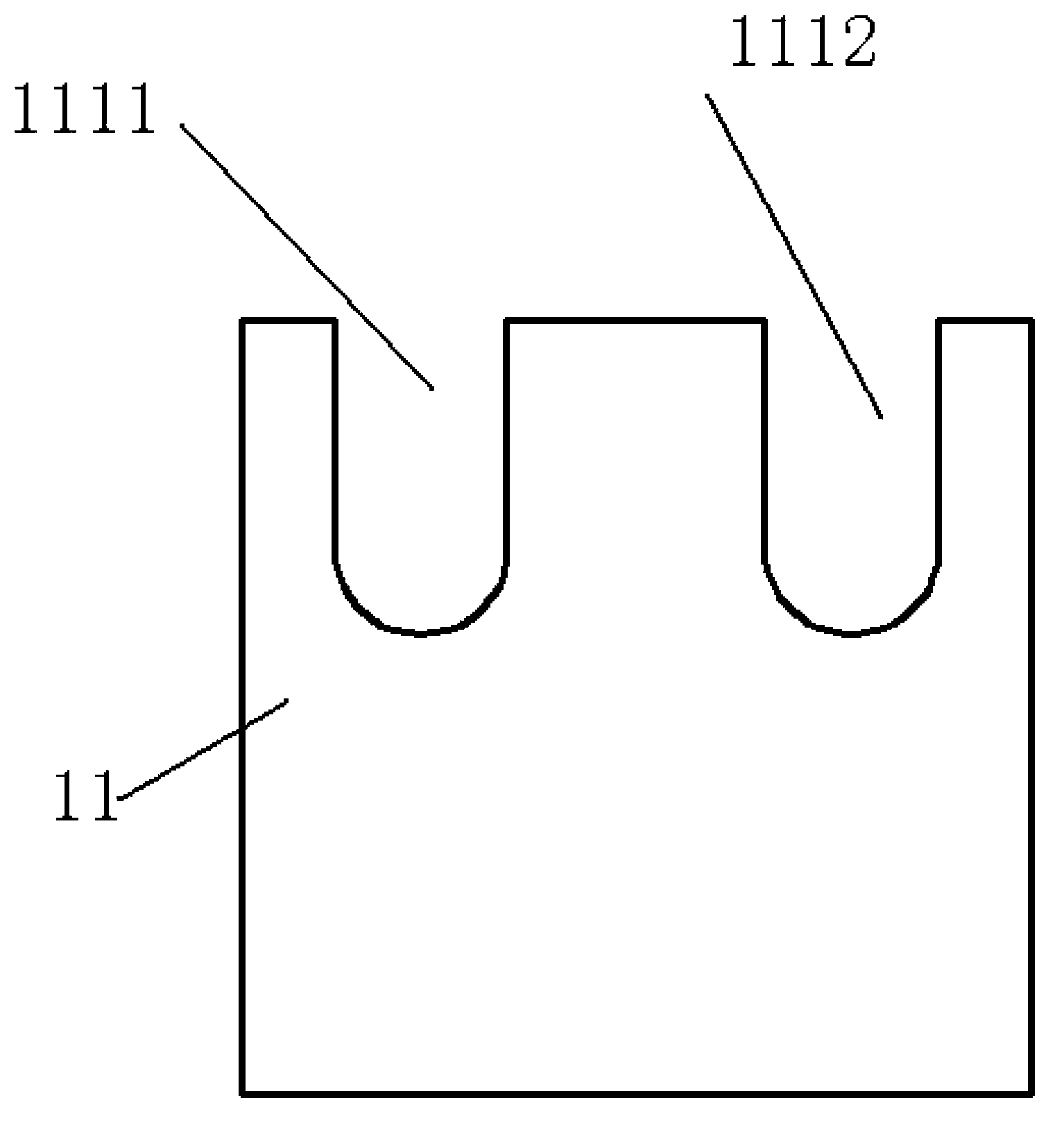

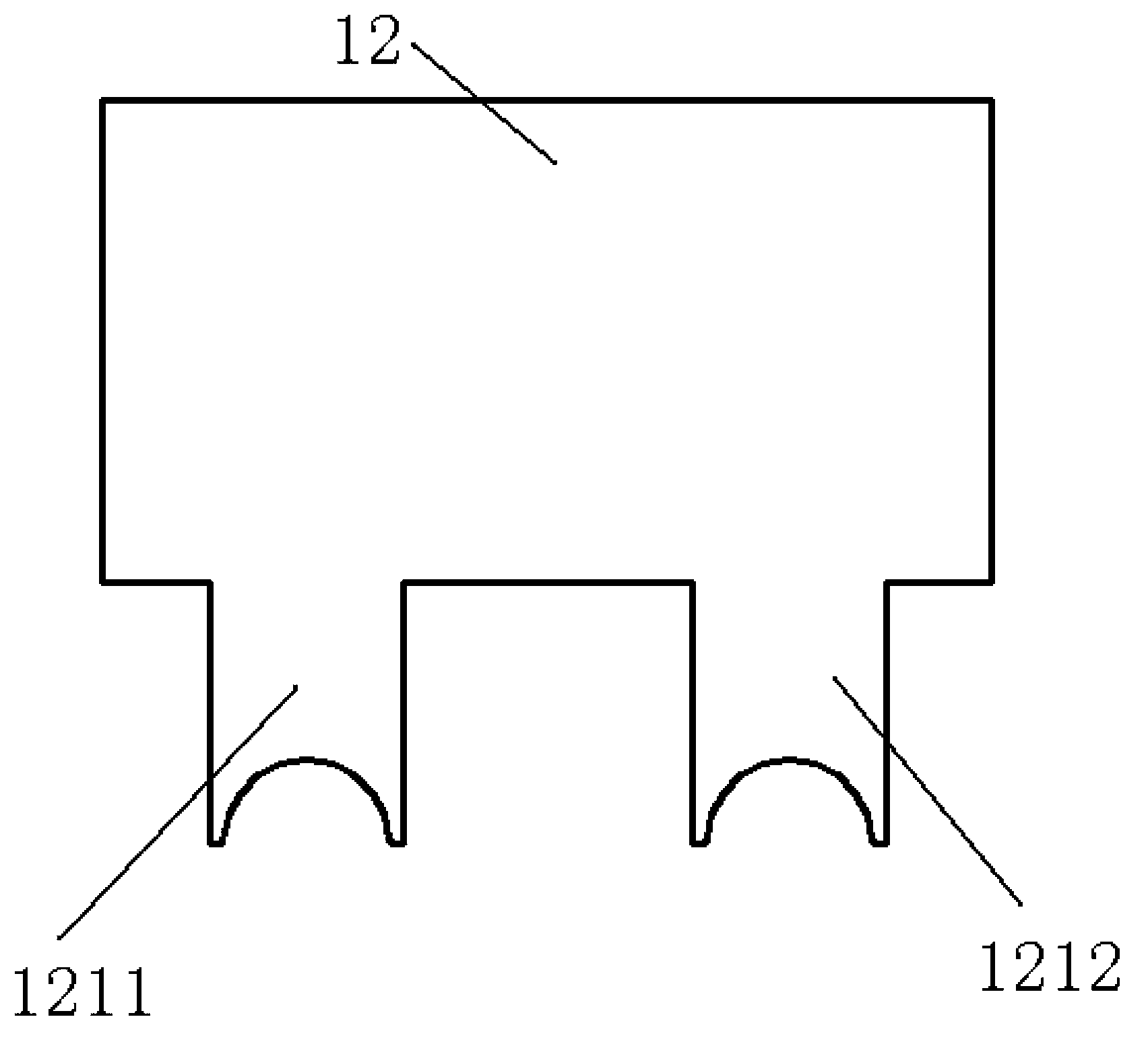

Clamp for hydraulic pipe expansion and fin distributing method of clamp

The invention provides a clamp for hydraulic pipe expansion and a fin distributing method of the clamp. The clamp comprises a lower mold and an upper mold. The lower mold is provided with at least one groove, the bottom of the groove is arc, and the groove is in a U shape. The lower mold is provided with a plurality of fin distributing grooves used for the fins to be placed, and the fin distributing grooves penetrate through the side wall of the groove. At least one protrusion is arranged on the upper mold, the top of the protrusion is arc and matched with the groove in shape. The clamp is simple in structure and convenient to use, the clamp is used for hydraulic pipe expansion, due to the fact that pipe expansion is limited within a set range, partial unevenness, thinning, deformation, crack and damage can not happen, and the yield reaches 98%.

Owner:CHANGZHOU QUNXING REFRIGERATION EQUIP

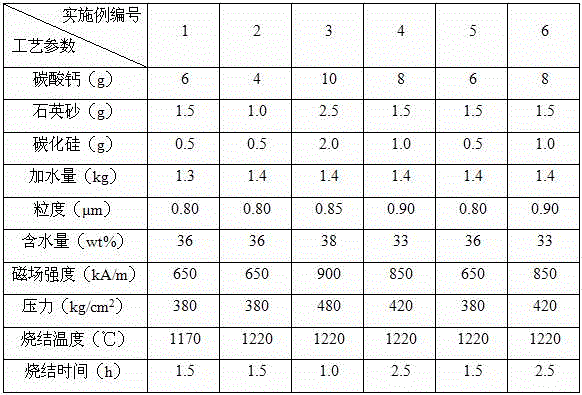

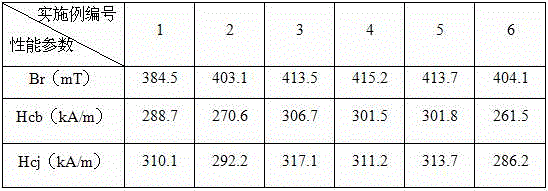

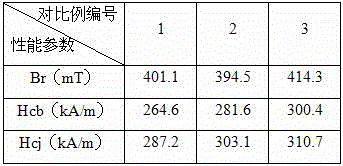

Additive and method for improving performance of permanent magnetic ferrite

The invention discloses an additive and method for improving the performance of permanent magnetic ferrite. The additive is composed of calcium carbonate, quartz sand, and silicon carbide. The method comprises the following steps: (1) adding a permanent magnetic ferrite pre-sintered material into a ball mill, at the same time, adding the additive, then adding water, and carrying out ball-milling to obtain permanent magnetic ferrite slurry; (2) filtering the permanent magnetic ferrite slurry to obtain permanent magnetic ferrite filtered slurry; (3) filling the permanent magnetic ferrite filtered slurry into a mould, and pressing the permanent magnetic ferrite filtered slurry under a pressure of 350 to 500 kg / cm2 and a magnetic field strength of 450 to 950 kA / m so as to obtain a permanent magnetic ferrite blank; (4) sintering the obtained permanent magnetic ferrite blank for 0.5 to 3.0 hours at a temperature of 1150 to 1250 DEG C to obtain permanent magnetic ferrite. The additive cost is low, the raw material resources are wide, pricy additives such as rare earth elements, cobalt oxide, and the like are not needed; compared with the prior art, the magnetic performance of the obtained permanent magnetic ferrite is more excellent, and the performance to cost ratio is higher.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

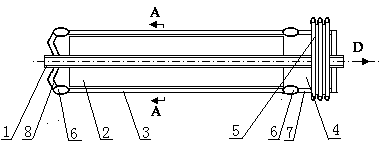

Vacuum light-condensing through high-temperature heat collecting pipe

InactiveCN103697611AGood light transmissionImprove the heat absorption effectSolar heating energySolar heat devicesHeat conductingEngineering

The invention relates to a vacuum light-condensing through high-temperature heat collecting pipe which comprises an outer pipe, an inner pipe and a light-condensing reflector. The vacuum light-condensing through high-temperature heat collecting pipe is characterized in that the outer pipe is a glass pipe, the coaxially-arranged inner pipe is a heat-absorbing heat conducting pipe, a metal end cap capable of axially deforming is arranged at one end of the outer pipe, a sealing head containing a valve-enabling metal pipe is arranged at the other end of the outer pipe, the metal end cap and the sealing head are hermetically connected with the end portion of the outer pipe to form a vacuum sealed cavity, two ends of the heat-absorbing heat conducting pipe extend out of the vacuum sealed cavity, the light-condensing reflector is positioned in the vacuum sealed cavity, and a focal point of the light-condensing reflector is positioned on the central axis of the heat-absorbing heat conducting pipe.

Owner:NANJING CHENGYUAN SOLAR HEATING +1

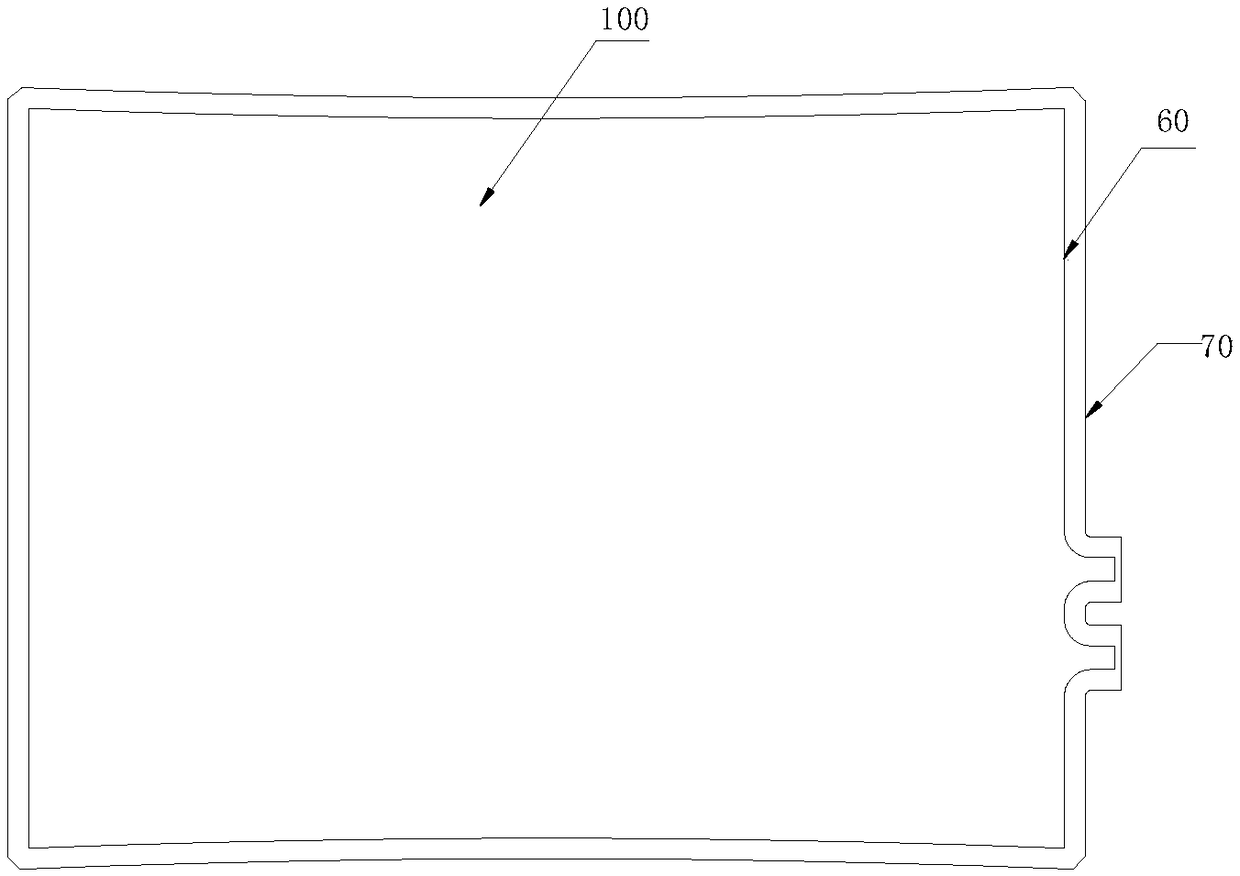

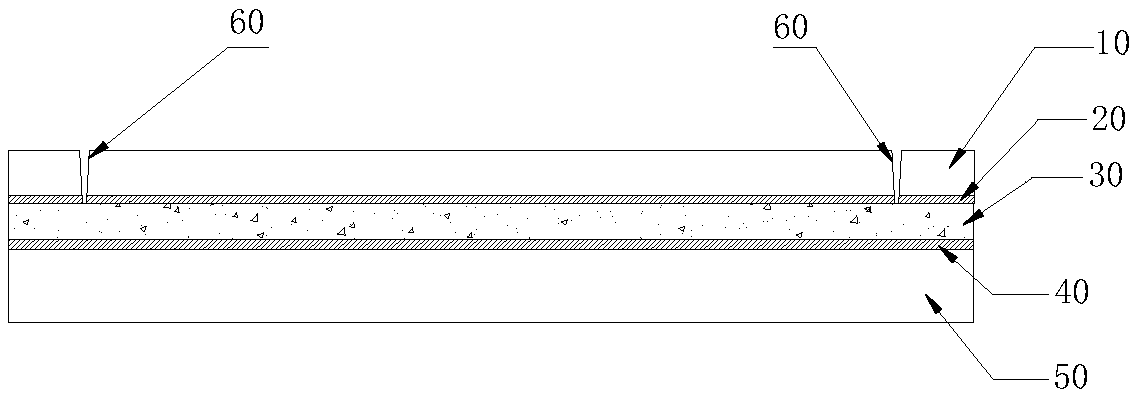

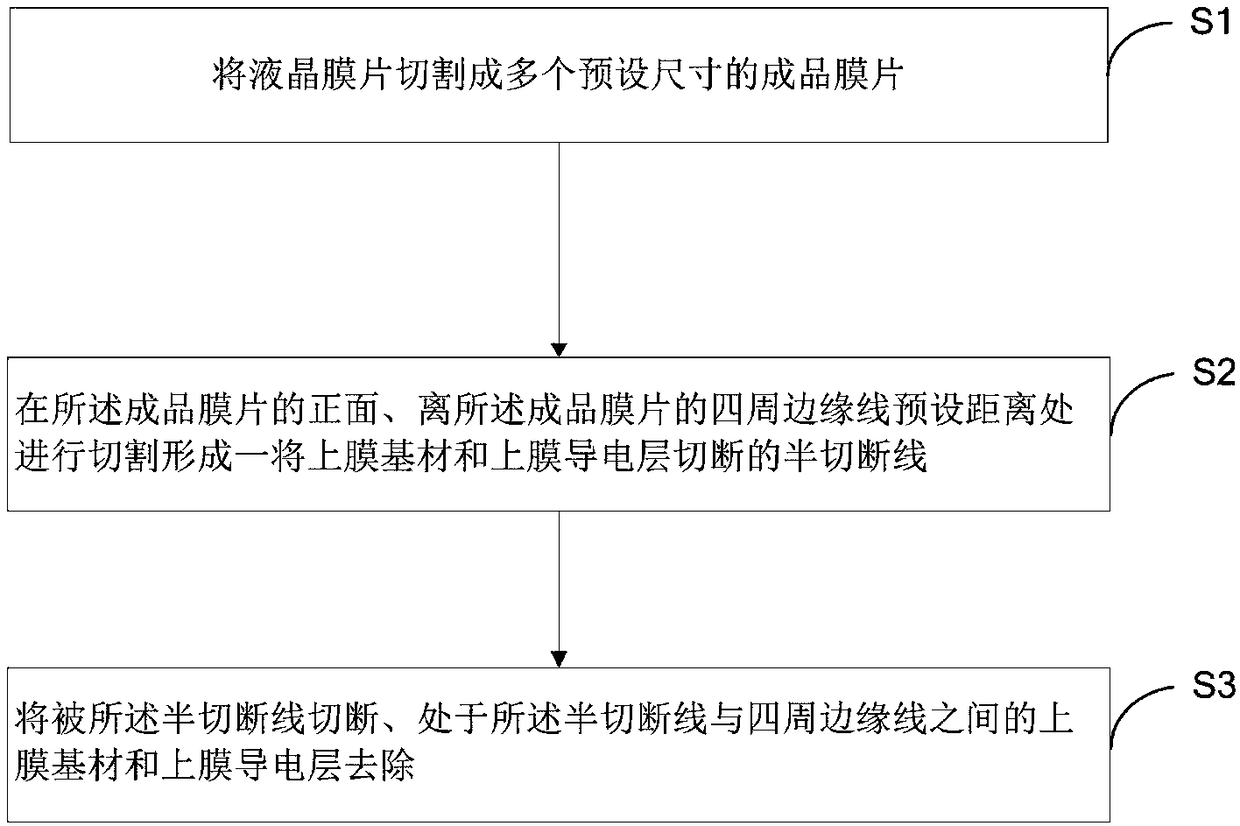

Liquid crystal diaphragm cutting method and finished liquid crystal diaphragm

PendingCN109407383AWill not cause crackingBlock flowNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a liquid crystal diaphragm cutting method and a finished liquid crystal diaphragm. The liquid crystal diaphragm cutting method comprises the steps that S1, a liquid crystal diaphragm is cut into multiple finished diaphragms of preset sizes; S2, cutting is carried out to form semi-cutoff lines on the portions, with a preset distance, from the edges of the peripheries of thefinished diaphragms, and the semi-cutoff lines cut off upper film conductive layers on the finished diaphragms. The liquid crystal diaphragm cutting method has the advantages that after the liquid crystal diaphragm is cut into the finished diaphragms of the preset sizes, re-cutting is carried out to form semi-cutoff lines on the portions, with a preset distance, from the edges of the peripheries of the finished diaphragms, the semi-cutoff lines cut off the upper film conductive layers on the finished diaphragms so that the voltage of the upper film conductive layers cannot reach the edge of the liquid crystal diaphragm, and the upper film conductive layers and lower film conductive layers do not short-circuit; the semi-cutoff lines formed by re-cutting the finished diaphragms can block theflow of liquid crystal, so that the liquid crystal around the diaphragm can be fixed, thereby not causing cracking of the diaphragm.

Owner:深圳做真科研有限公司

Preparation method of nano-ceramic binder

ActiveCN107935556AHeating evenlyWill not cause crackingAbrasion apparatusClaywaresTalcMicrowave sintering

The invention belongs to the field of binder preparation, and relates to a preparation method of a nano-ceramic binder. The preparation method comprises the following steps: a) taking the raw materials by mass percentage: 30-50% of talcum, 10-20% of kaolin, 15-20% of boron glass, 8-10% of fluorite, and 20-25% of quartz powder, grinding the raw materials and sieving the raw materials through a sieve being 200-300 in meshes to prepare a mixture material; b) pressing and smelting the mixture material, and performing water-quenching on the mixture material; c) drying the product in the step b), adding nano vanadium nitride / chromium nitride modifier, grinding the product and sieving the product to obtain a basic ceramic binder; and d) pressing the basic ceramic binder in the step c) to form abonder blank by a press, and sintering the bonder blank in a microwave sintering oven to prepare the ceramic bonder. The method is low in reaction time and short in reaction time, is low in productioncost, saves energy, and is easy to carry out industrially.

Owner:临颍德卡特新材料有限公司

Damp-proof anticorrosive adhesive for corrugated cartons

InactiveCN105907333APromote oxidationPrevent hardeningNon-macromolecular adhesive additivesStarch adhesivesAdhesiveCarton

The invention discloses damp-proof anticorrosive adhesive for corrugated cartons. The damp-proof anticorrosive adhesive comprises, by weight, 30-42 parts of corn starch, 15-20 parts of glutinous rice amylopectin, 5-8 parts of potassium sulfate, 10-15.5 parts of sodium hydroxide, 10-15.5 parts of sodium carbonate, 22-35 parts of crataegolic acid, 45-55 parts of water and 14-24 parts of modified oxidizing agents. The damp-proof anticorrosive adhesive has the advantages that the damp-proof anticorrosive adhesive is transparent and is excellent in oxidation property, chelated-state copolymers can be formed after the damp-proof anticorrosive adhesive is oxidized in air, and accordingly the adhesive property can be strengthened; the damp-proof anticorrosive adhesive can be prevented from being diffused when in contact with carton boards, and accordingly hardening of the carton boards can be prevented; the damp-proof anticorrosive adhesive is good in damp-proof property and corrosion resistance, cannot fail when in contact with water, plates can be prevented from being corroded when the damp-proof anticorrosion adhesive is in contact with salt and alkali, and adhesion openings of the cartons can be prevented from cracking.

Owner:ANHUI FENGHUANGSONG PACKAGING

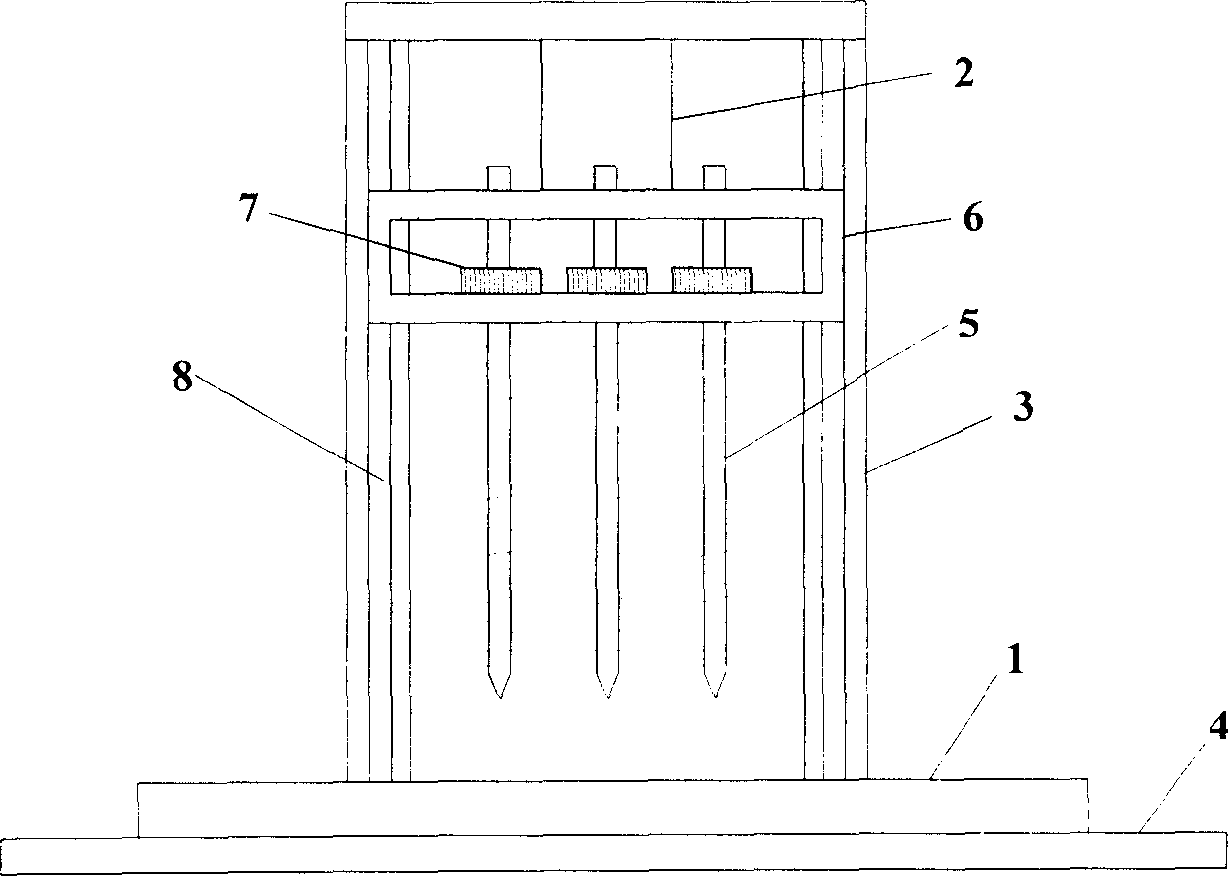

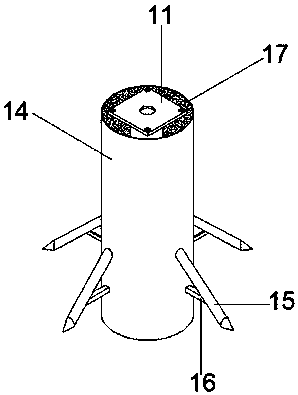

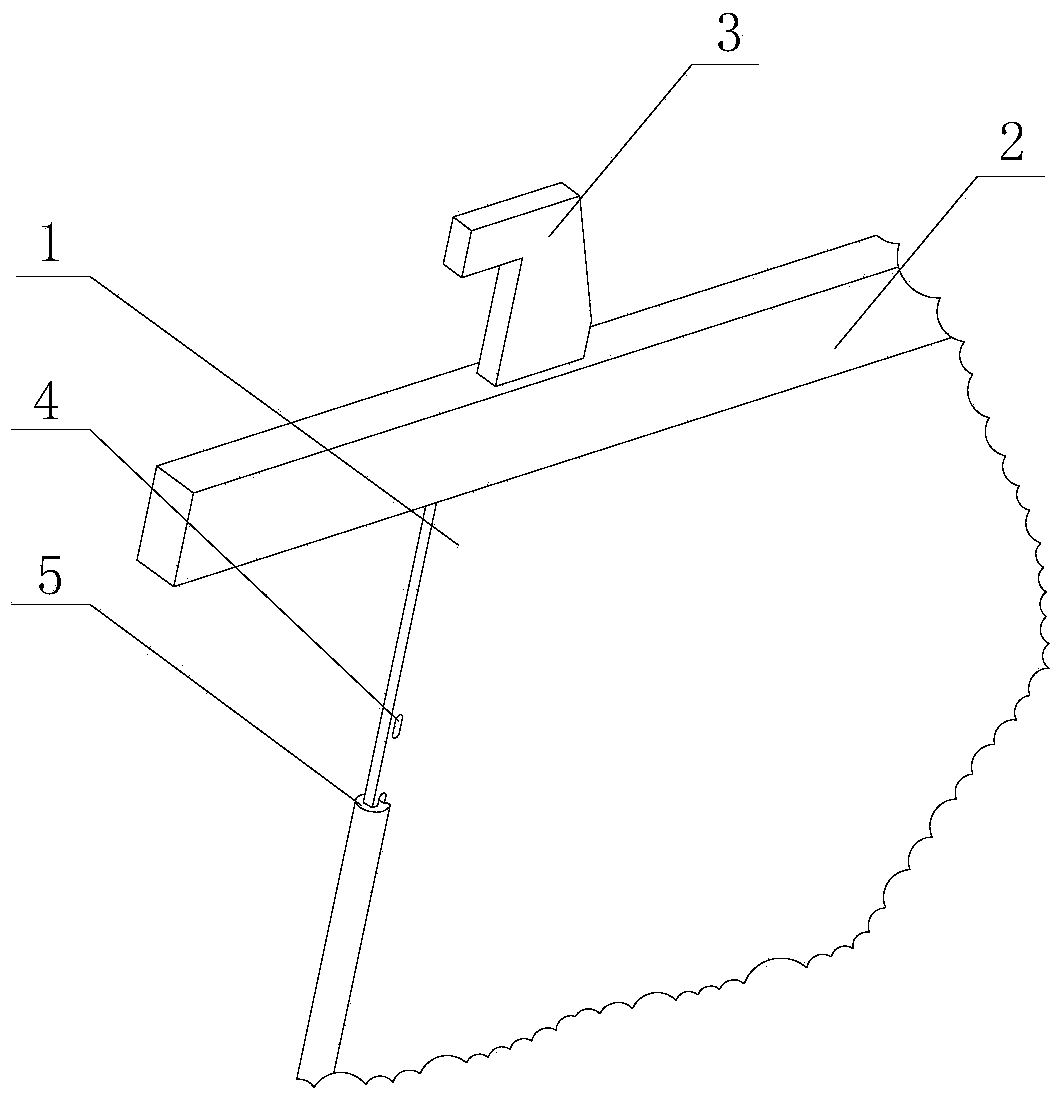

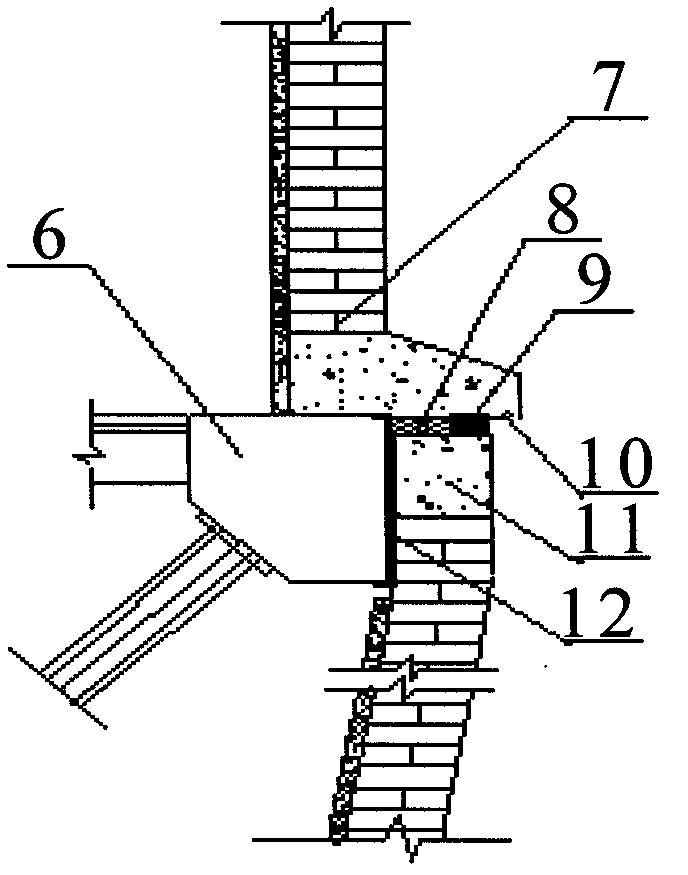

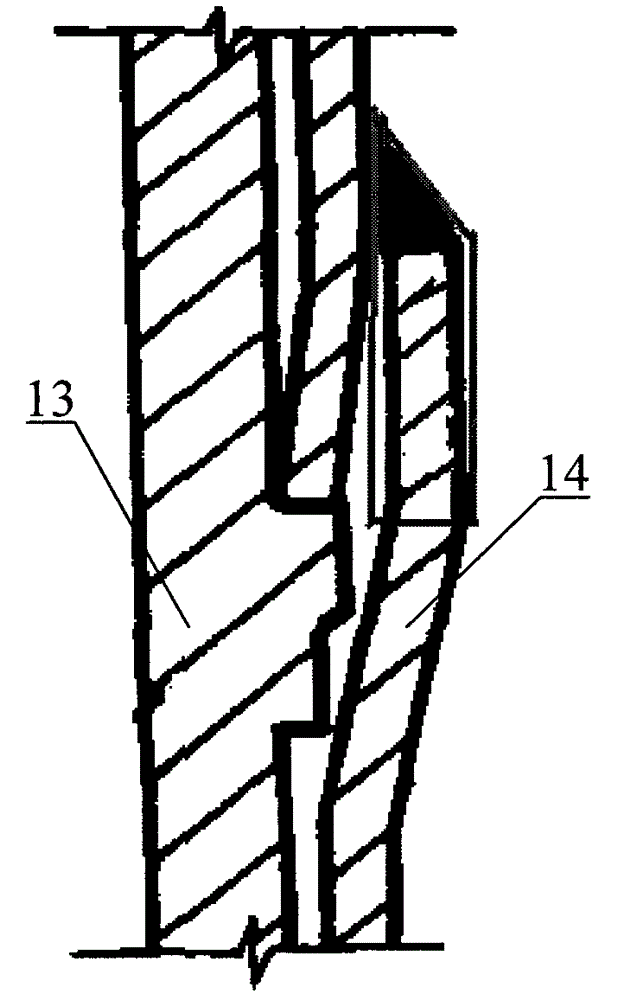

Drill-buried type prefabricated pipe pile for electric transmission line

InactiveCN110241813AReduce earthwork volumeLess foundation excavationBulkheads/pilesAcoustic transmission lineTransmission line

The invention relates to a drill-buried type prefabricated pipe pile for an electric transmission line. The drill-buried type prefabricated pipe pile comprises an internal flow-guiding component, a flow-guiding steel pipe, a prefabricated miniature pipe pile, a grouting head, a grouting head top plate, a grouting hole, a grouting steel pipe, a grouting head bottom plate, reinforcing ribs, an open hole, a top plate, a pore, bolt holes, an external positioning nesting component, four fork feet, angle steel and mortar, the internal flow-guiding component and the external positioning nesting component are connected through the grouted mortar, the internal flow-guiding component comprises the flow-guiding steel pipe, the prefabricated miniature pipe pile and the grouting head, the reinforcing ribs are welded into the grouting steel pipe, the open hole is formed in the grouting steel pipe, the top plate is welded to the top of the flow-guiding steel pipe and provided with the pore, the bolt holes are formed in the four corners of the top plate, and the four fork feet are welded to the outer wall of the external positioning nesting component through the angle steel at equal distances. The drill-buried type prefabricated pipe pile has the advantages of small environmental influence, high construction efficiency, reliable quality and low cost, and is suitable for being used and promoted.

Owner:STATE GRID CORP OF CHINA +1

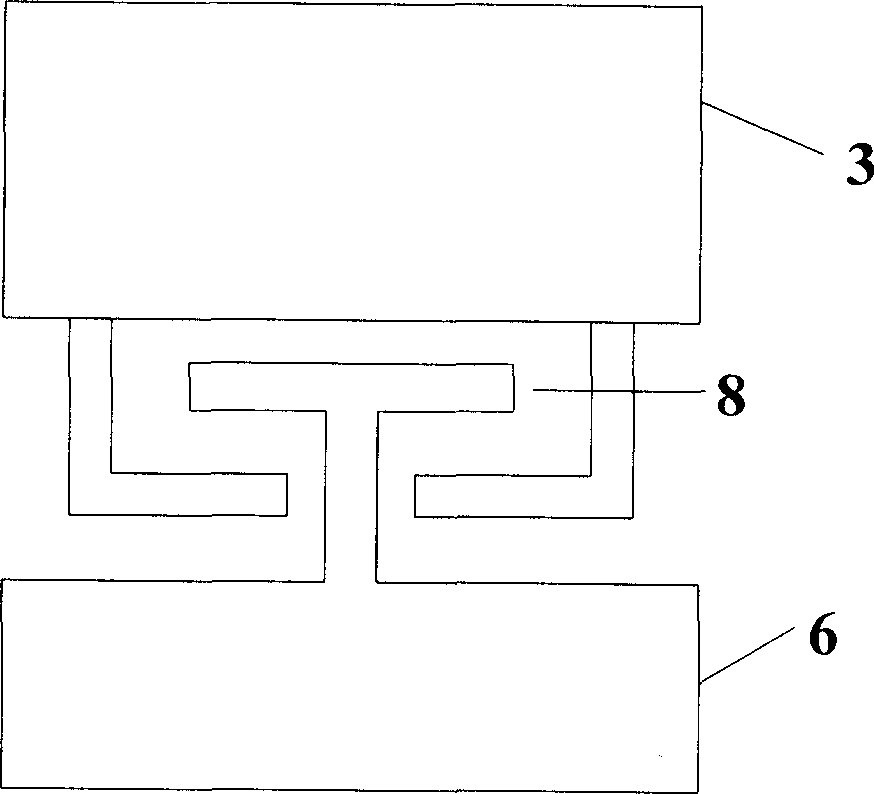

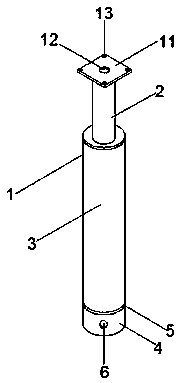

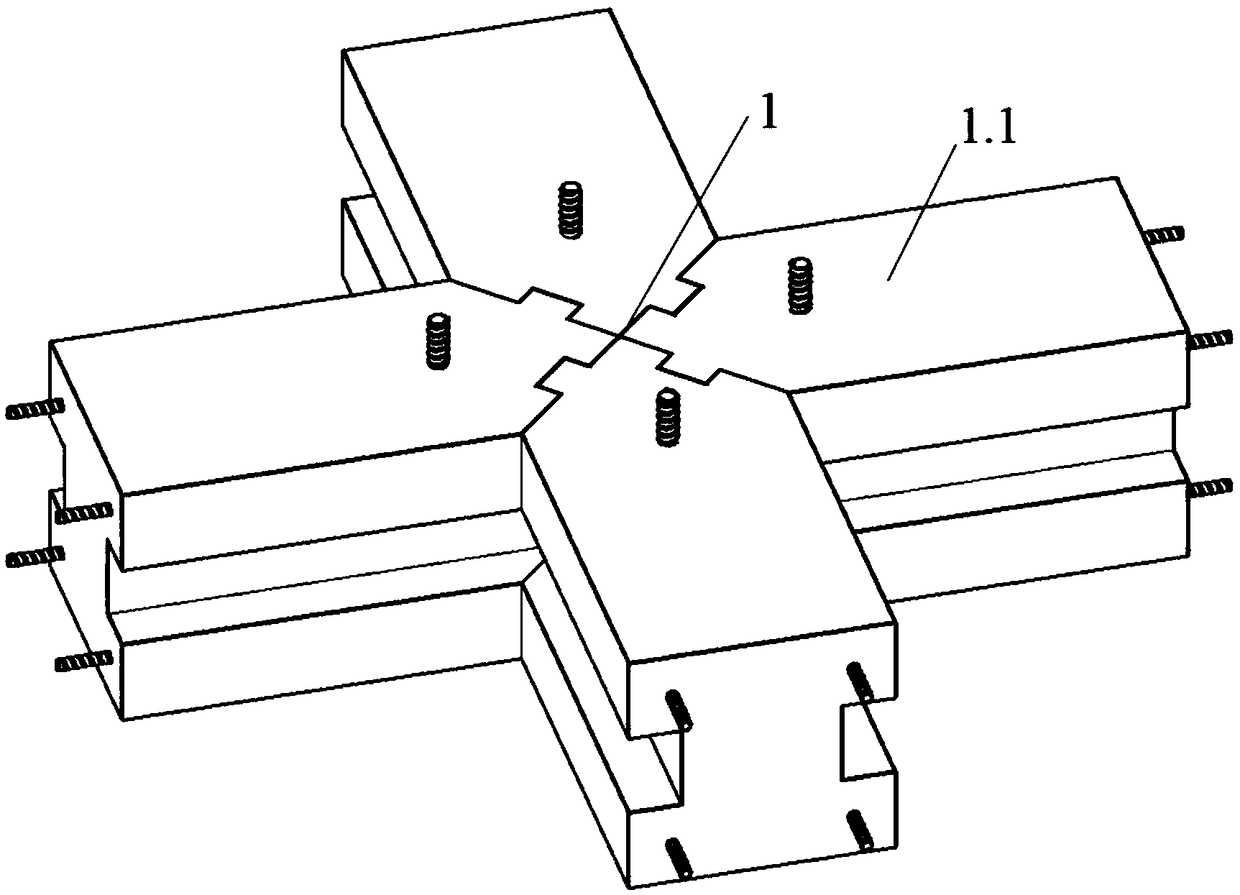

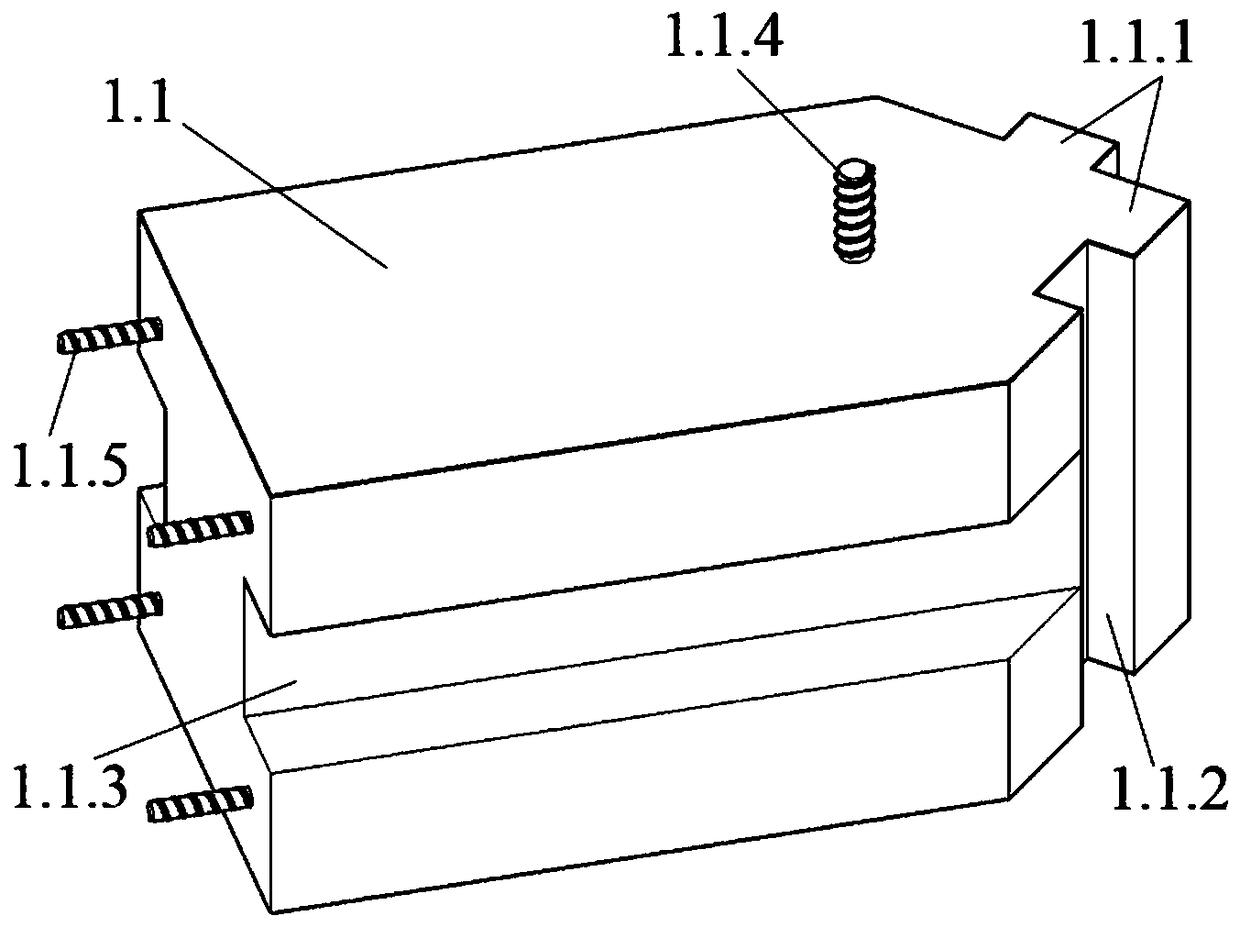

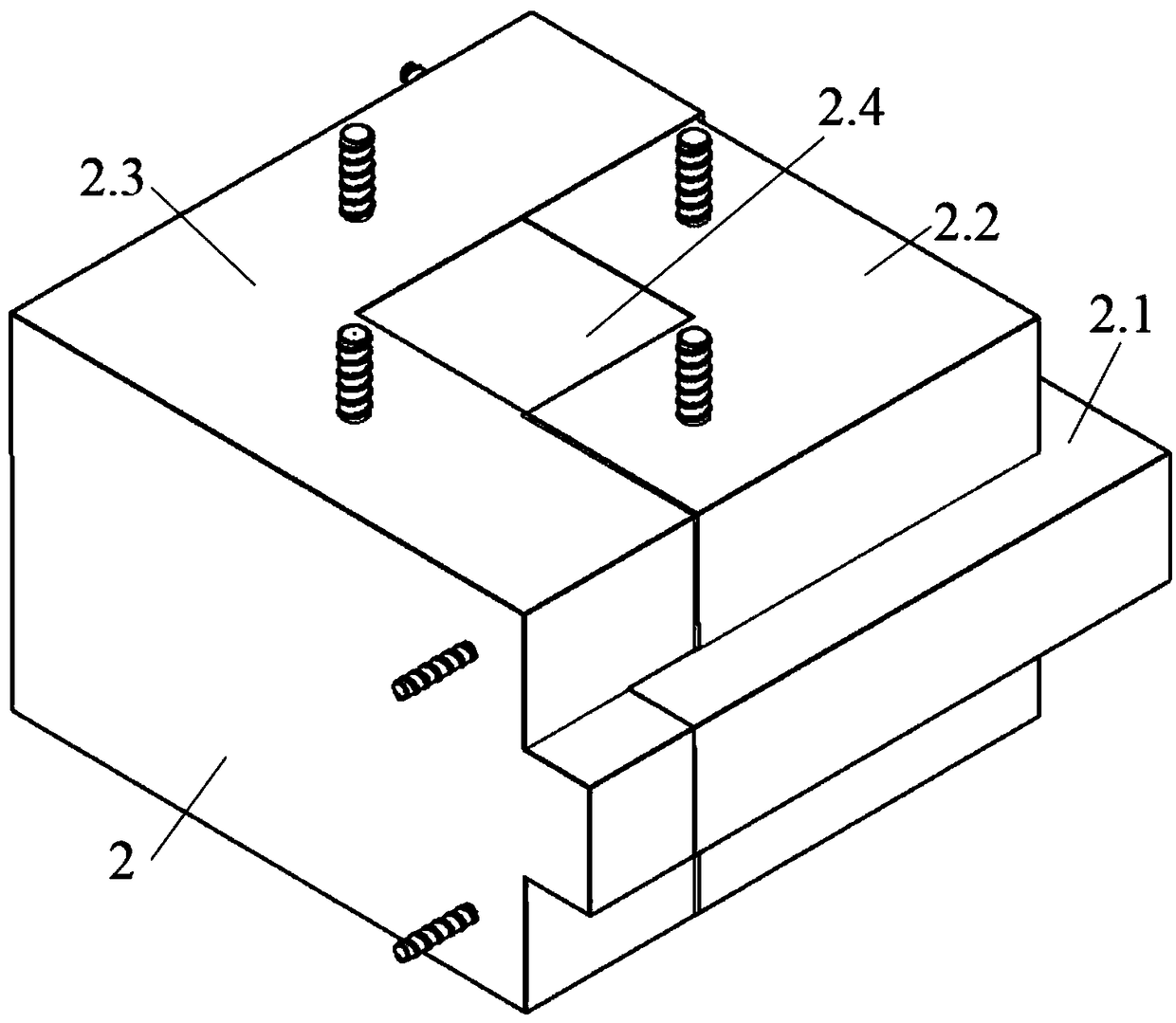

Assembly type power transmission line anchor rod static pressure miniature pile foundation and construction method thereof

ActiveCN108643219ASmall amount of workNo vibrationFoundation engineeringMaterial resourcesEngineering

The invention relates to an assembly type power transmission line anchor rod static pressure miniature pile foundation. The foundation comprises a first connecting main body and second connecting mainbodies, wherein the first connecting main body and the second connecting main bodies form a square bearing table, the first connecting main body is in a cross shape, and is formed by splicing the same four parts in a mutual embedding mode, the number of the second connecting main bodies is four, the four second connecting main bodies are distributed in a crossed grid of the first connecting mainbody and are spliced with the first connecting main body in a mutual embedding mode, each second connecting main body is in a concentric square shape and is formed by splicing two parts in a mutual embedding mode, and the two sides of each splicing joint between the side wall of the first connecting main body and the side wall of the corresponding second connecting main body are connected and fixed through a connecting steel plate, a pre-buried screw rod and a nut. All components of the assembly type power transmission line anchor rod static pressure miniature pile foundation with the design are prefabricated in factories and assembled on site, the construction is simple, convenient and fast, the influence on the environment is small, manpower and material resources are saved, and full-mechanical construction of the power transmission line foundation is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Preparation method for integrated thermal insulating outer wall of precast outer wall panel facing thermal insulation

InactiveCN107060248AImprove insulation qualityReduce pollutionCovering/liningsCeramic shaping apparatusThermal insulationWetting transition

A method for preparing a prefabricated exterior wall panel with decorative surface and thermal insulation integrally formed thermal insulation exterior wall, comprising the following steps: ① taking the exterior wall panel and the exterior wall veneer panel for use; ② spraying on the exterior surface of the exterior wall panel and the interior surface of the exterior wall veneer panel Polyurethane infiltrates the transition layer; ③ Paste 4 thickness control panels on the inner surface of the exterior wall veneer; ④ Arrange multiple exterior wall veneer panels on the exterior wall panel; ⑤ Use T-shaped rubber strips to fill the gaps between the exterior wall veneer panels ; ⑥ Stick the large formwork on the outer surface of the exterior wall veneer; ⑦ Use well-shaped steel beams to fasten the outside of the large formwork; ⑧ Pouring polyurethane liquid into the cavity between the exterior wall panel and the exterior wall veneer; ⑨ Polyurethane hair After the foam is cured, the formwork, leak-proof frame, T-shaped rubber strips and well-shaped steel beams are removed, and the prefabricated exterior wall panels are formed after caulking to form an integrated thermal insulation exterior wall. It is completely produced in the factory to reduce on-site pollution, ensure the quality of the project, and greatly reduce the cost of the project.

Owner:周珊

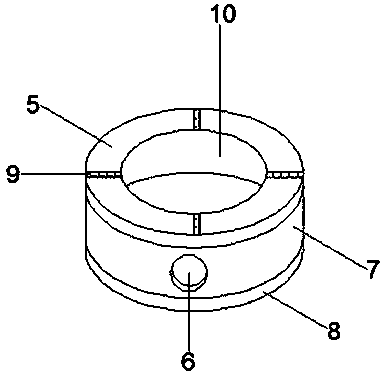

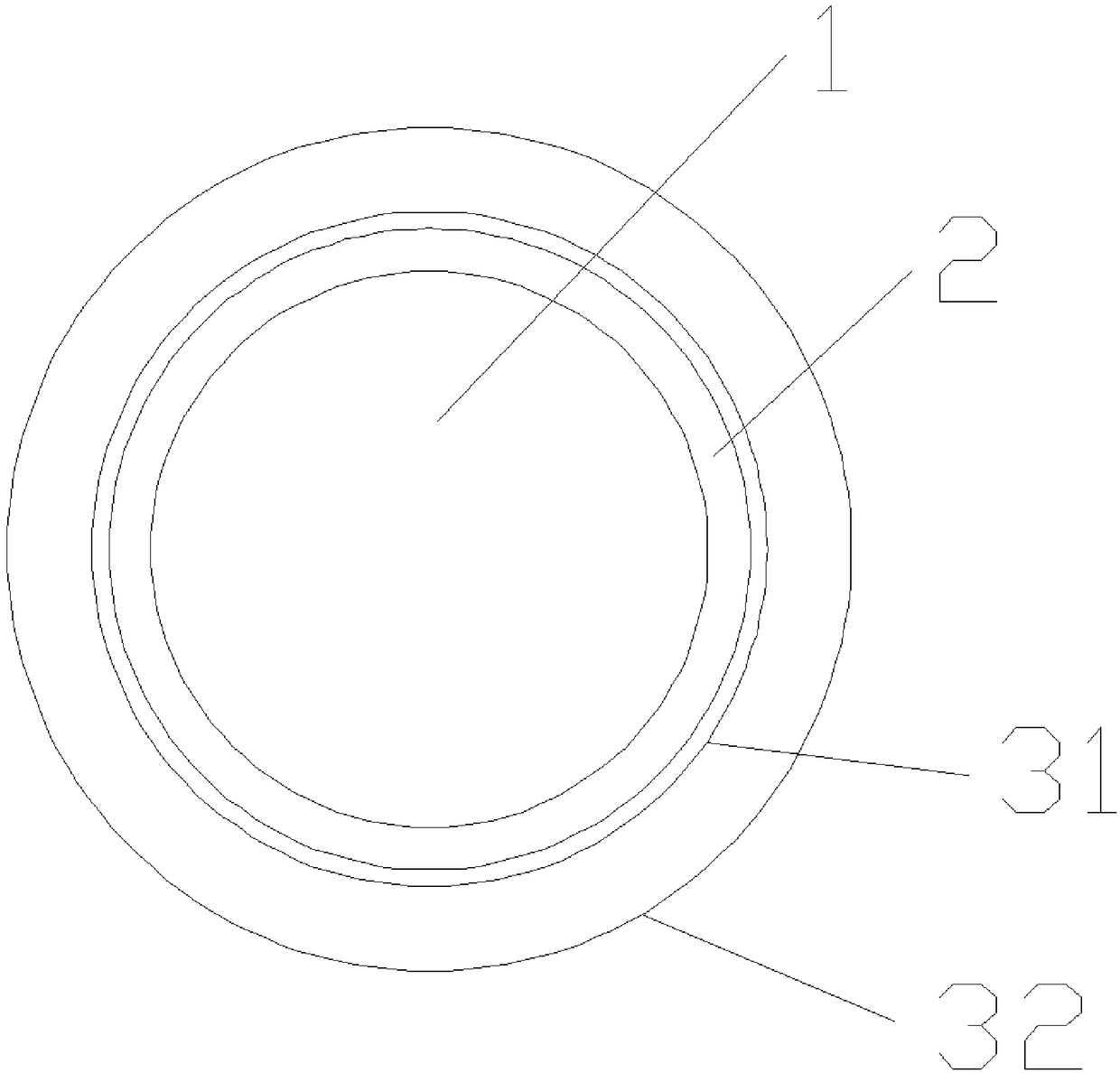

Clearance control method for adhesion of tube target

InactiveCN108546921AControl clearanceClearance is validVacuum evaporation coatingSputtering coatingTitaniumEngineering

The invention discloses a clearance control method for adhesion of a tube target. The method comprises a back tube and a tube target material; the back tube is prepared from titanium or stainless steel; the tube target material is prepared from metal or ceramic; the outer side of the tube target material is provided with a regulating ring; the tube target material and the back tube are coated withthe regulating ring; the regulating ring comprises an inner ring body, an outer ring body and sealing flanges, wherein the sealing flanges are arranged at the two end faces; the sealing flange at oneend is provided with a regulating component which is used for regulating the same-diameter distance from the inner ring body to the outer ring body; the inner side surface of the inner ring body adheres to the tube target material; and in a using process, the regulating component is used for regulating the inner ring body to adhere to the tube target material, is locked and is then heated. The method disclosed by the invention is used for effectively controlling a clearance between the back tube and the tube target material.

Owner:苏州精美科光电材料有限公司

Antique imitation treatment method of date wood

InactiveCN104942929ASimple way to do old workReduce intensityWood treatment detailsPretreatment apparatusSodium bicarbonateAqueous solution

The invention relates to an antique imitation treatment method of date wood. The antique imitation treatment method comprises the following steps: (1) peeling fresh date wood, washing mucus away from the surface, then coating the surface of the date wood with sodium bicarbonate, and then carrying out air drying for 10-15 days; (2) washing impurities away from the surface of the date wood, soaking in a treatment liquid at 35 DEG C for 12 hours, flushing clean with clear water, and then keeping the temperature at 58 DEG C under the relative humidity of 42% for 6 hours; and (3) soaking the date wood (treated in step (2)) in a urea aqueous solution with the gravity concentration of 2.5% at 22-30 DEG C for 30 hours, fishing out, cleaning with clear water, keeping the temperature at 46 DEG C under the relative humidity of 32% for 3 hours, and then keeping the temperature at 38 DEG C under the relative humidity of 20% for 10 hours. The treatment method is even and good in effect.

Owner:FUNAN XINGGUANG ARTS & CRAFTS CO LTD

Cutting adhesive tape for processing semiconductor materials, and preparation method thereof

ActiveCN110205043AGood initial adhesionPromote sheddingFilm/foil adhesivesPolyureas/polyurethane adhesivesSemiconductor materialsMicrosphere

The present invention relates to the field of adhesive tapes, and concretely relates to a cutting adhesive tape for processing semiconductor materials, and a preparation method thereof. The adhesive tape for processing semiconductor materials comprises a substrate layer and an adhesive layer, and raw materials for preparing the adhesive layer comprise 80-100 parts of an olefinic acid substance, 0.1-10 parts of a crosslinking agent, 0.05-0.1 part of an initiator, 30-50 parts of polyisocyanate, 80-120 parts of a solvent and 5-15 parts of expanded microspheres.

Owner:广东硕成科技股份有限公司

Negative plate with insulating sealed edge

The invention discloses a negative plate with an insulating sealed edge, which comprises a negative plate body and a conductive beam, wherein the conductive beam is connected with one end of the negative plate body; a hanger is arranged on the conductive beam; the negative plate further comprises an insulating sealed edge band; the insulating sealed edge band is integrally cast with one side edge of the negative plate body. According to the invention, an insulating material is directly formed and tightly bonded to the edge of the negative plate via plastifying, extruding and cooling through an injection molding machine, so as to become the insulating sealed edge band of the negative plate, so that mechanical striking installation is not needed, the mounting procedure is eliminated, and the mounting cost is reduced; the insulating material is tightly bonded with the negative plate without a gap, so that an acid liquor can not enter the edge of the negative plate to prevent the acid liquor from corroding the negative plate; the negative plate with the insulating sealed edge is acid-resisting, corrosion-resisting, simple in structure and excellent in sealing effect.

Owner:周才益

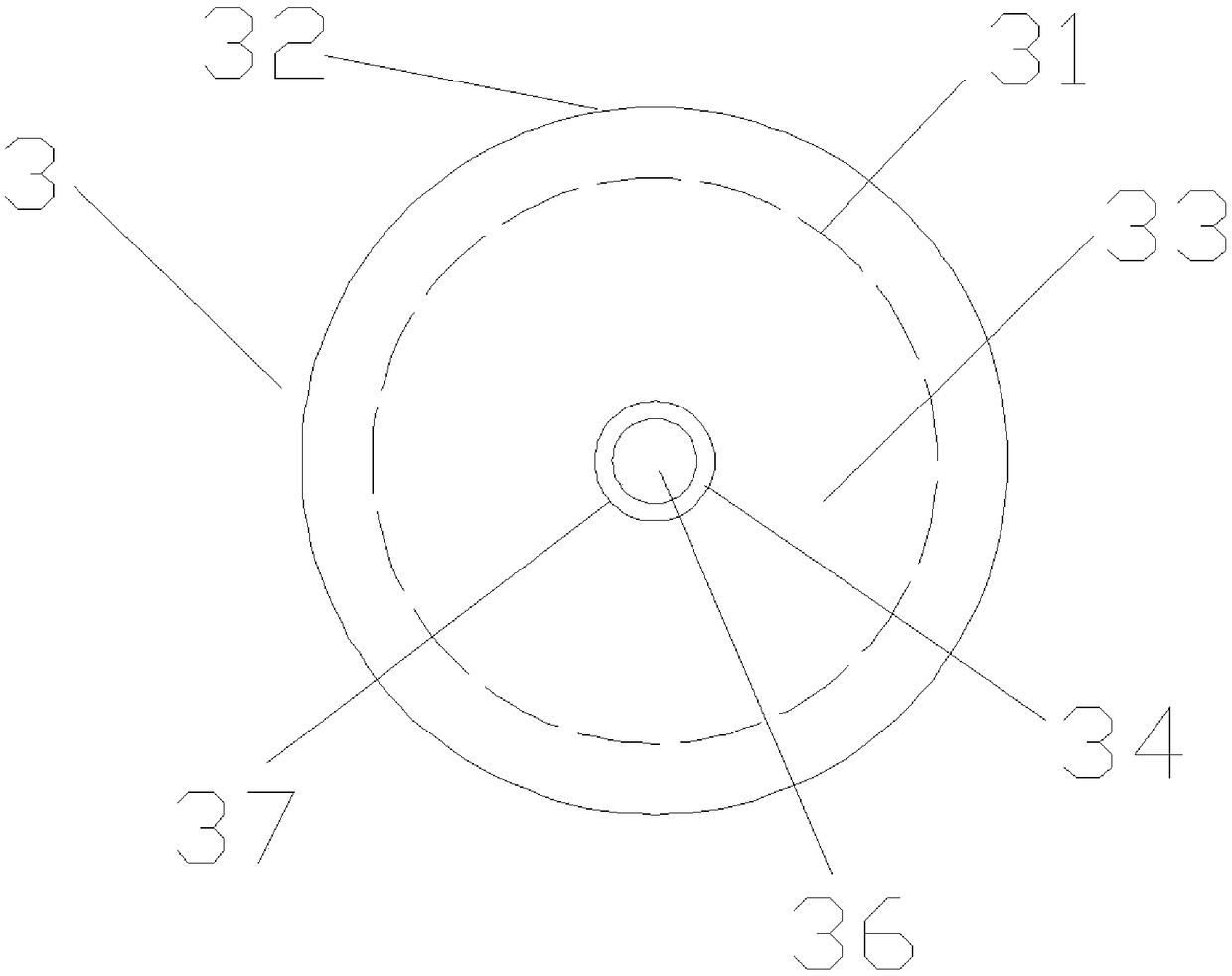

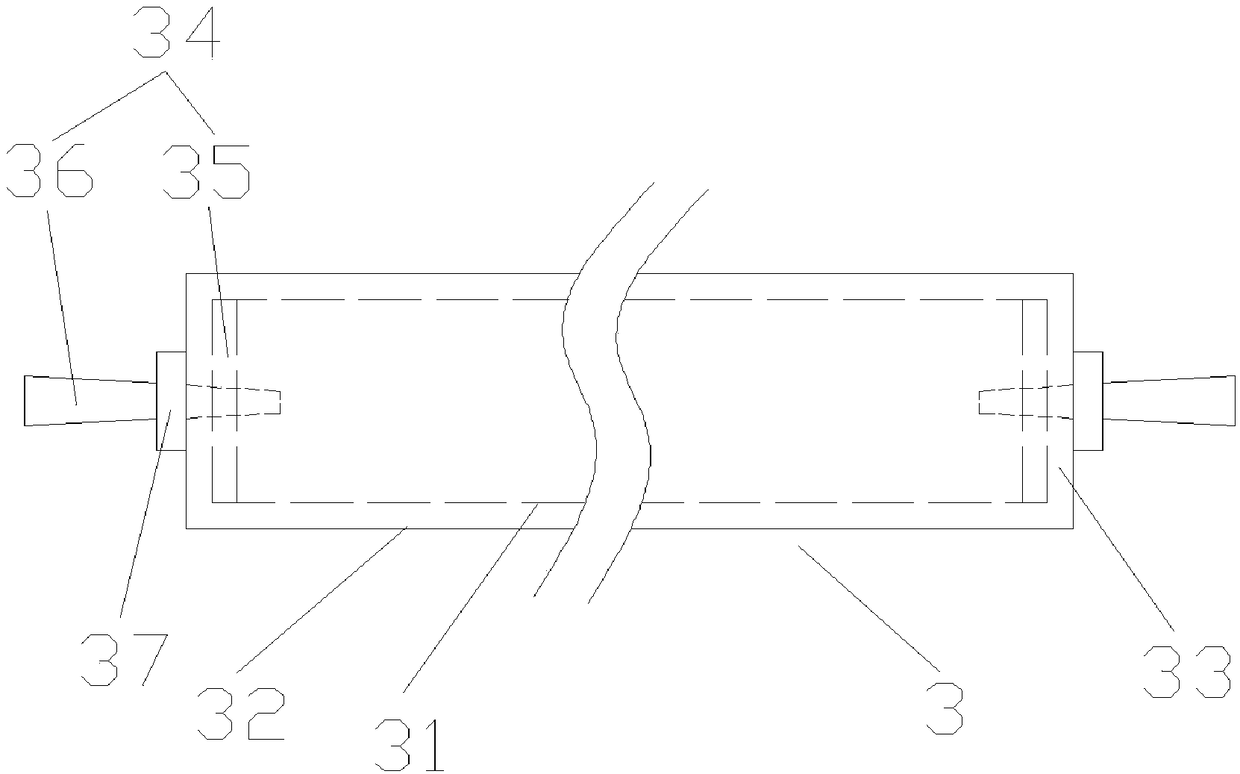

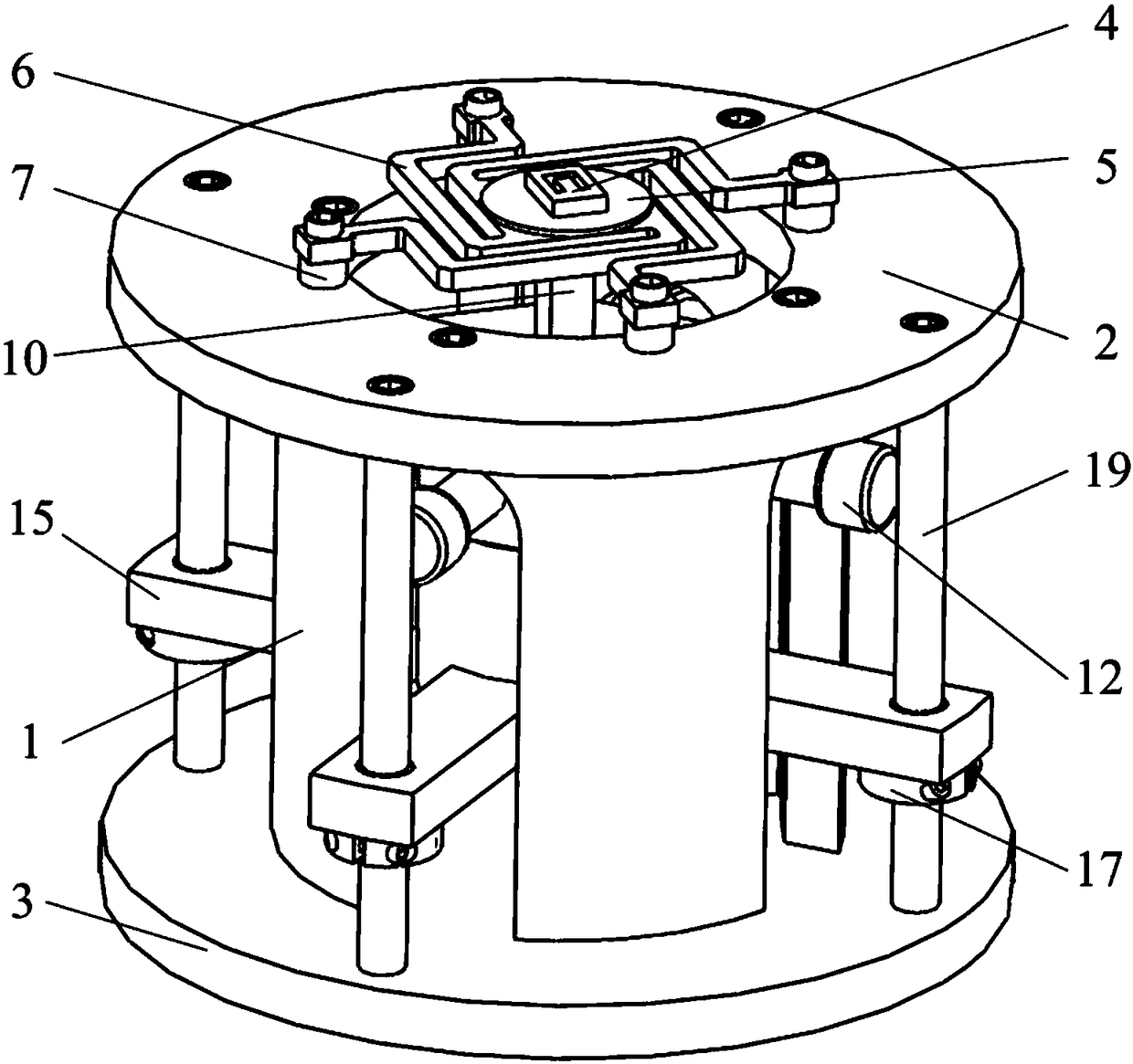

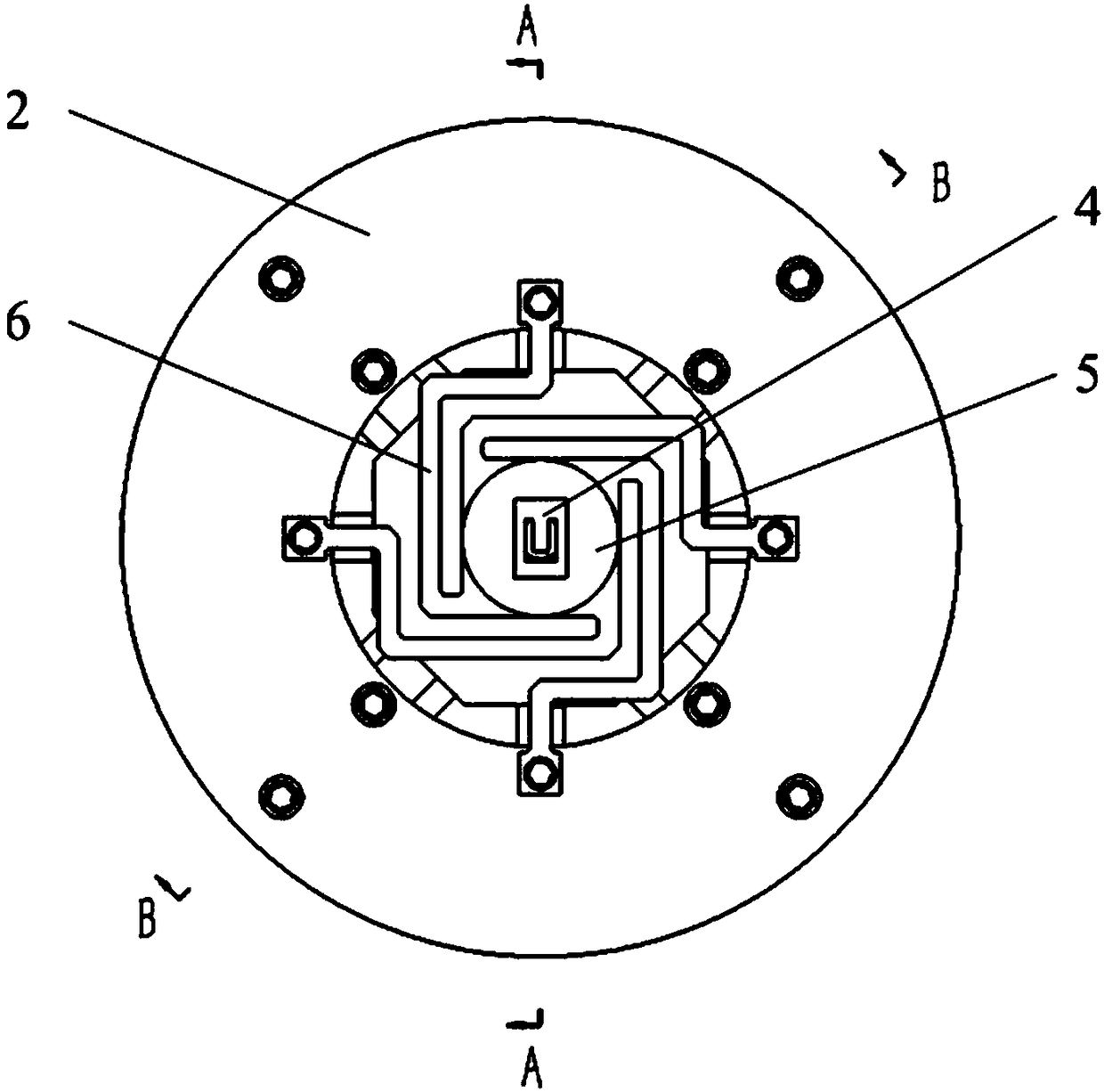

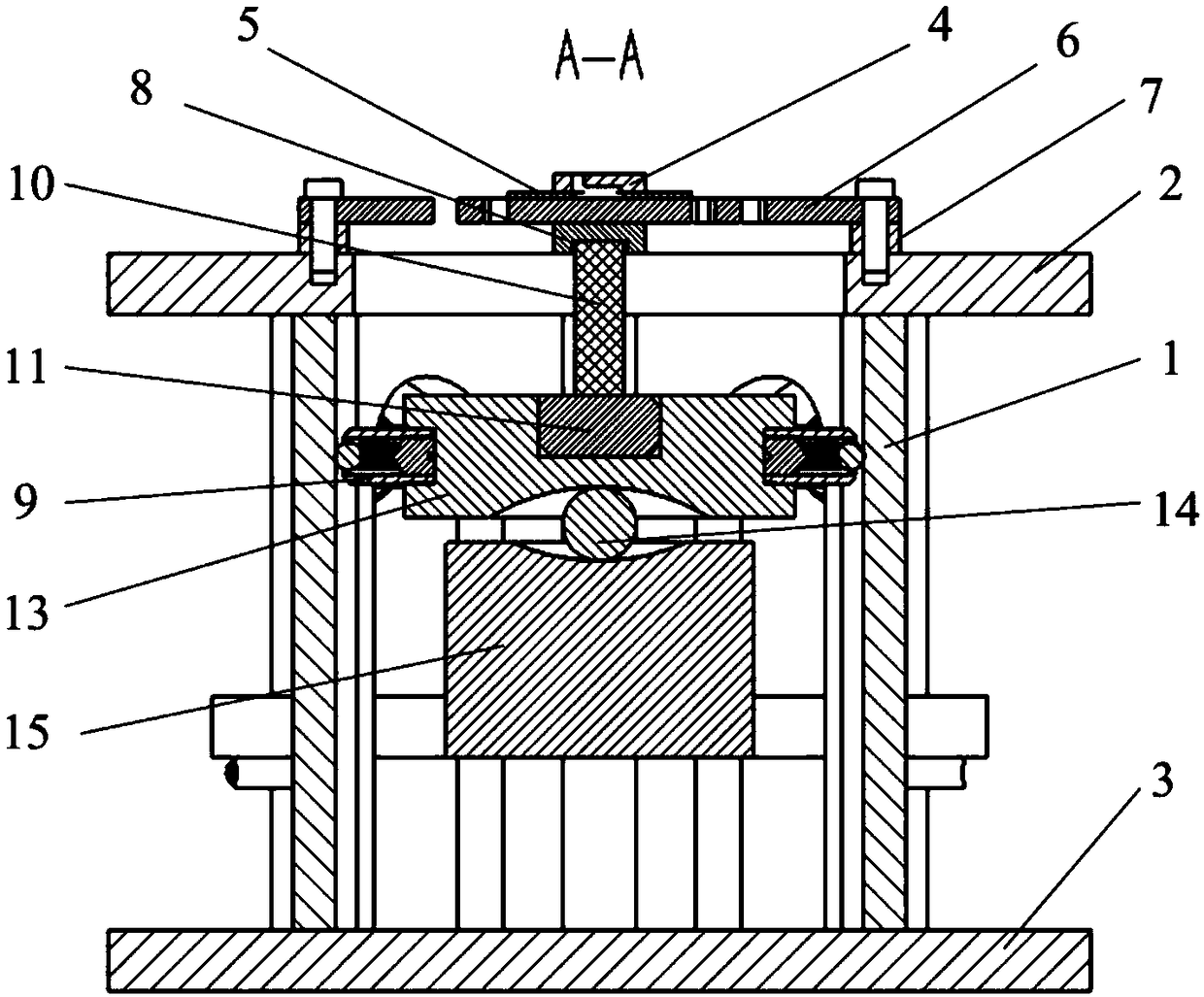

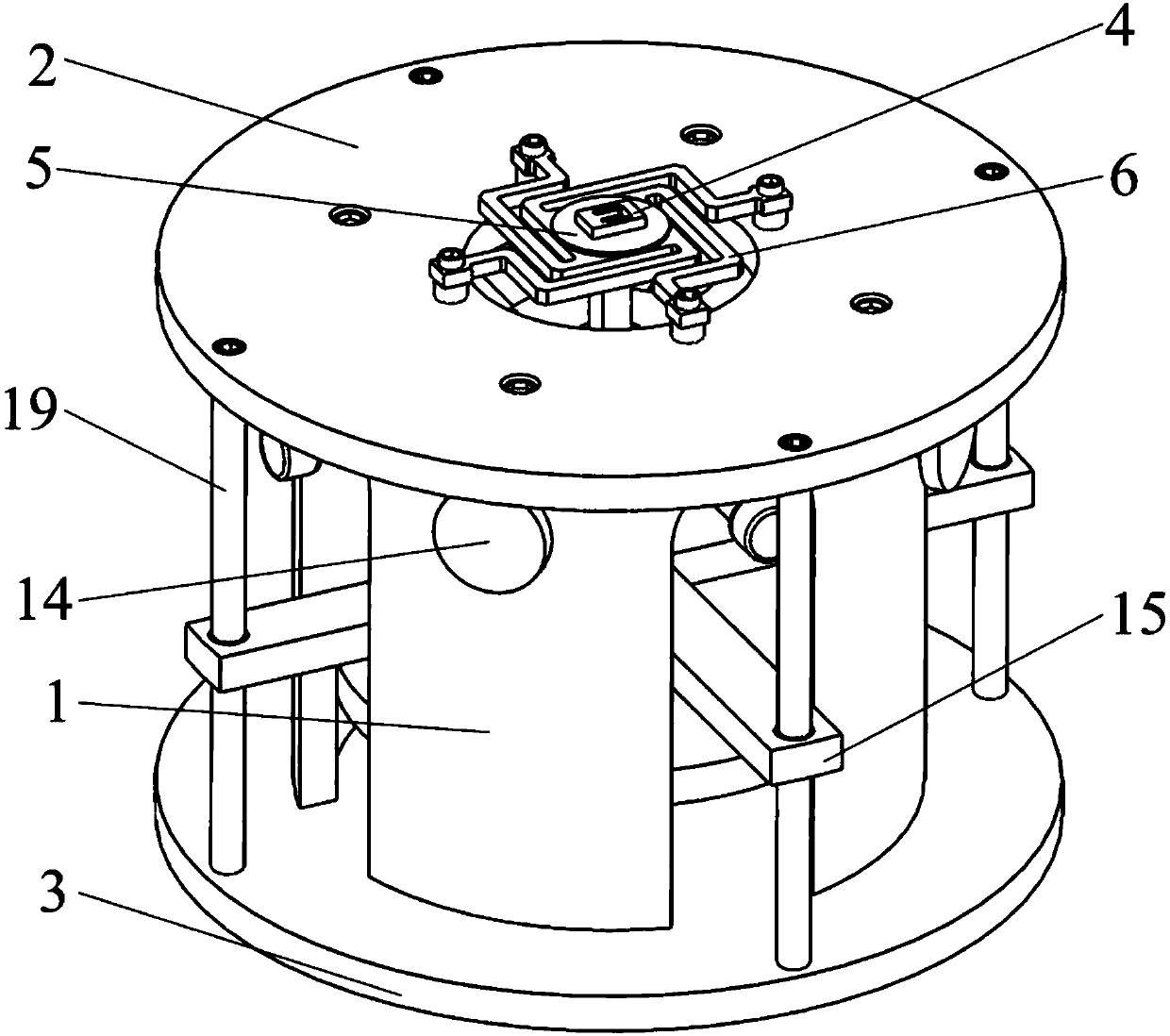

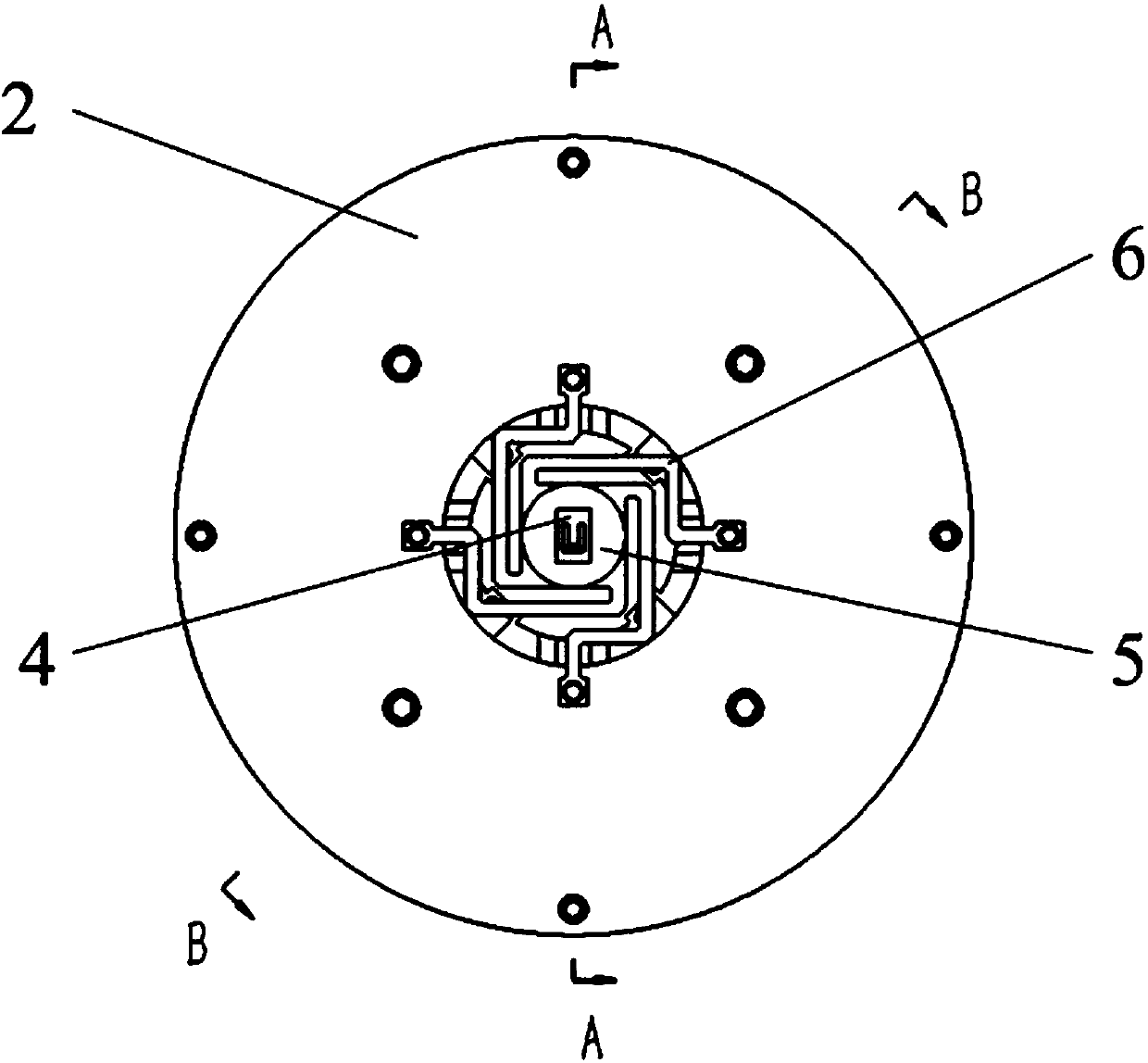

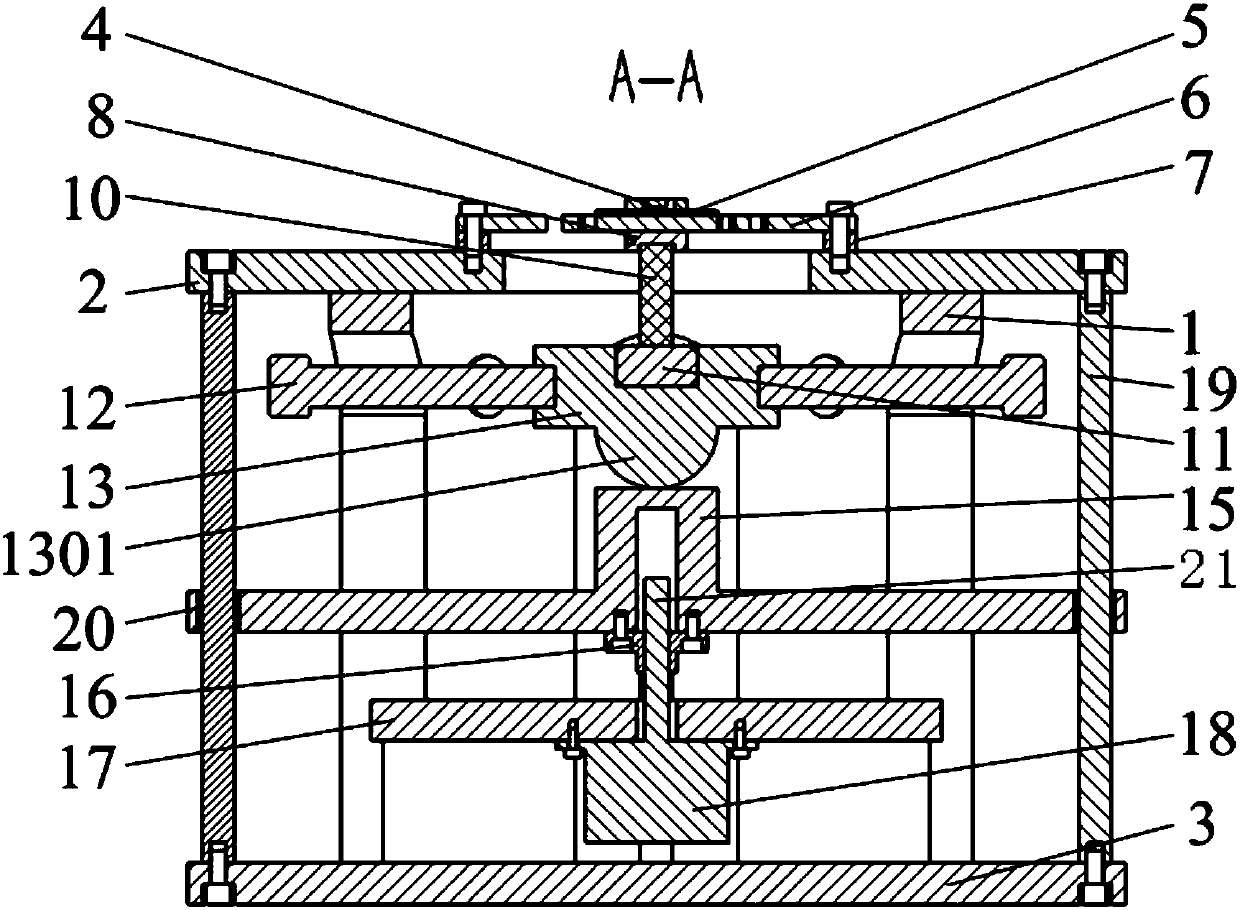

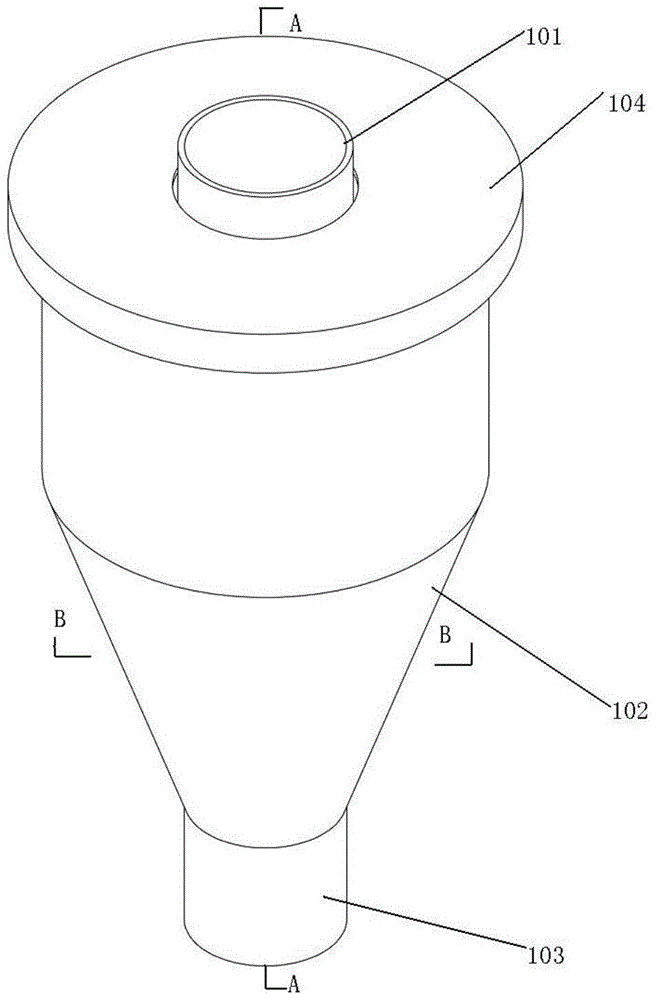

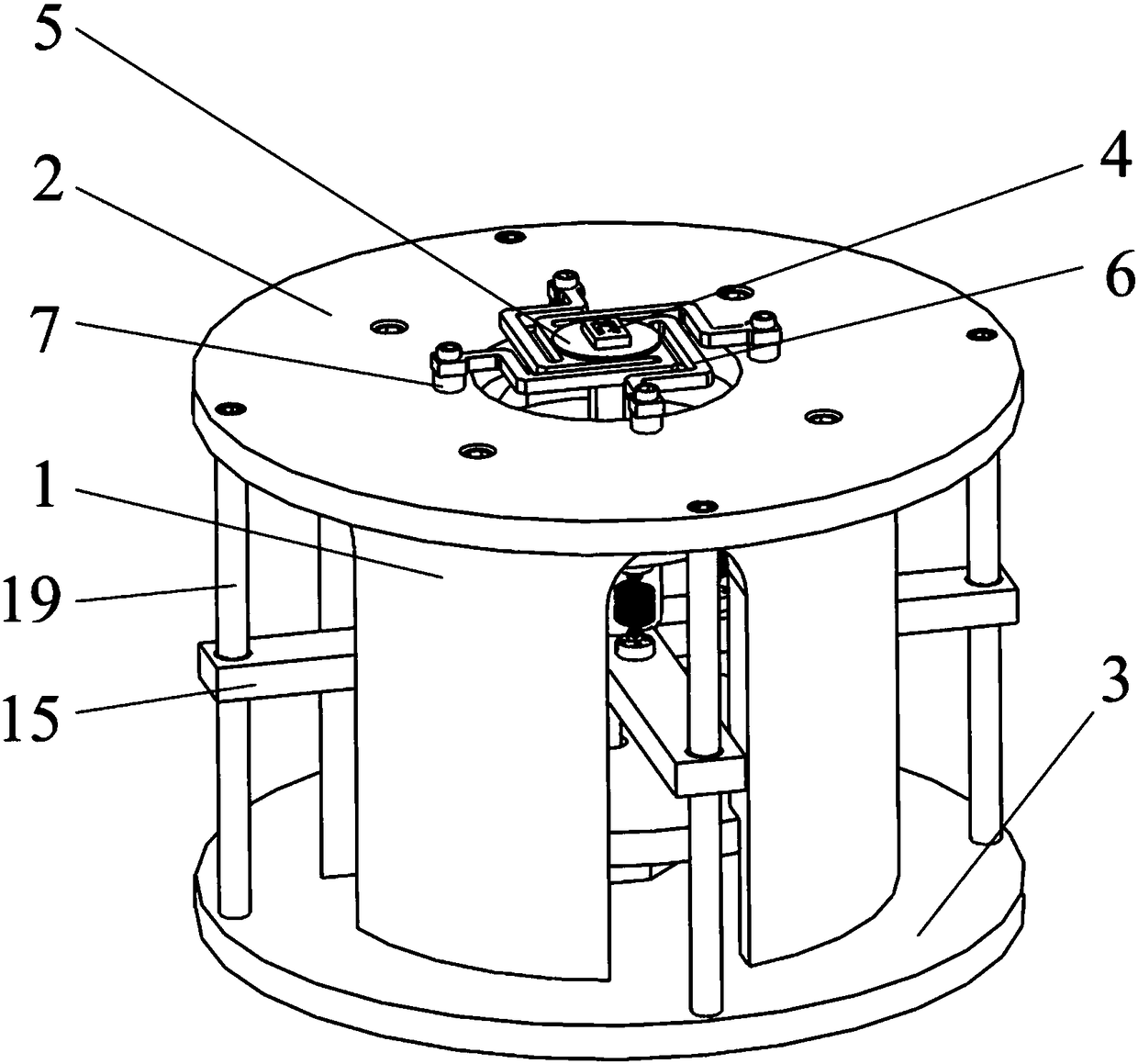

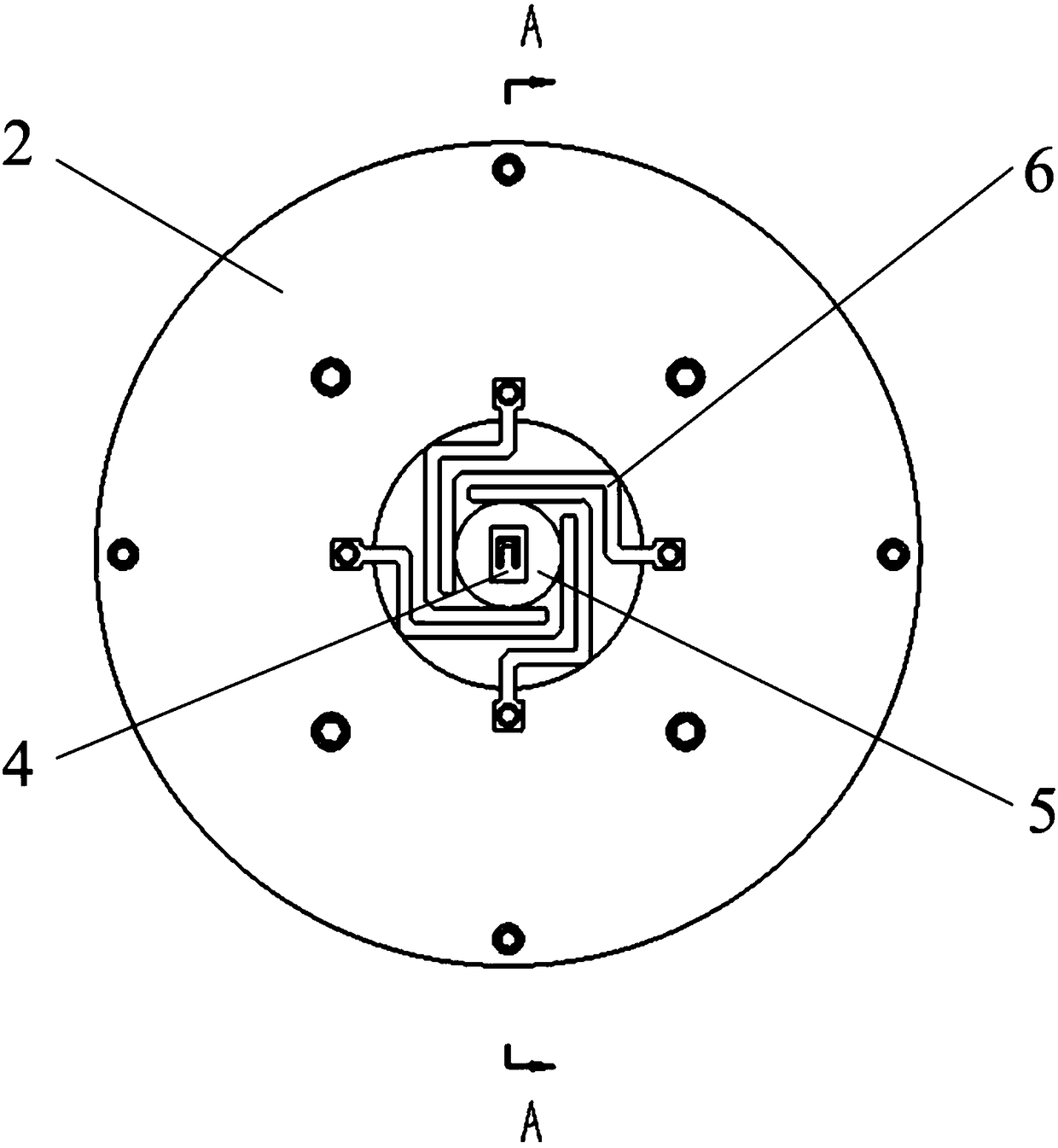

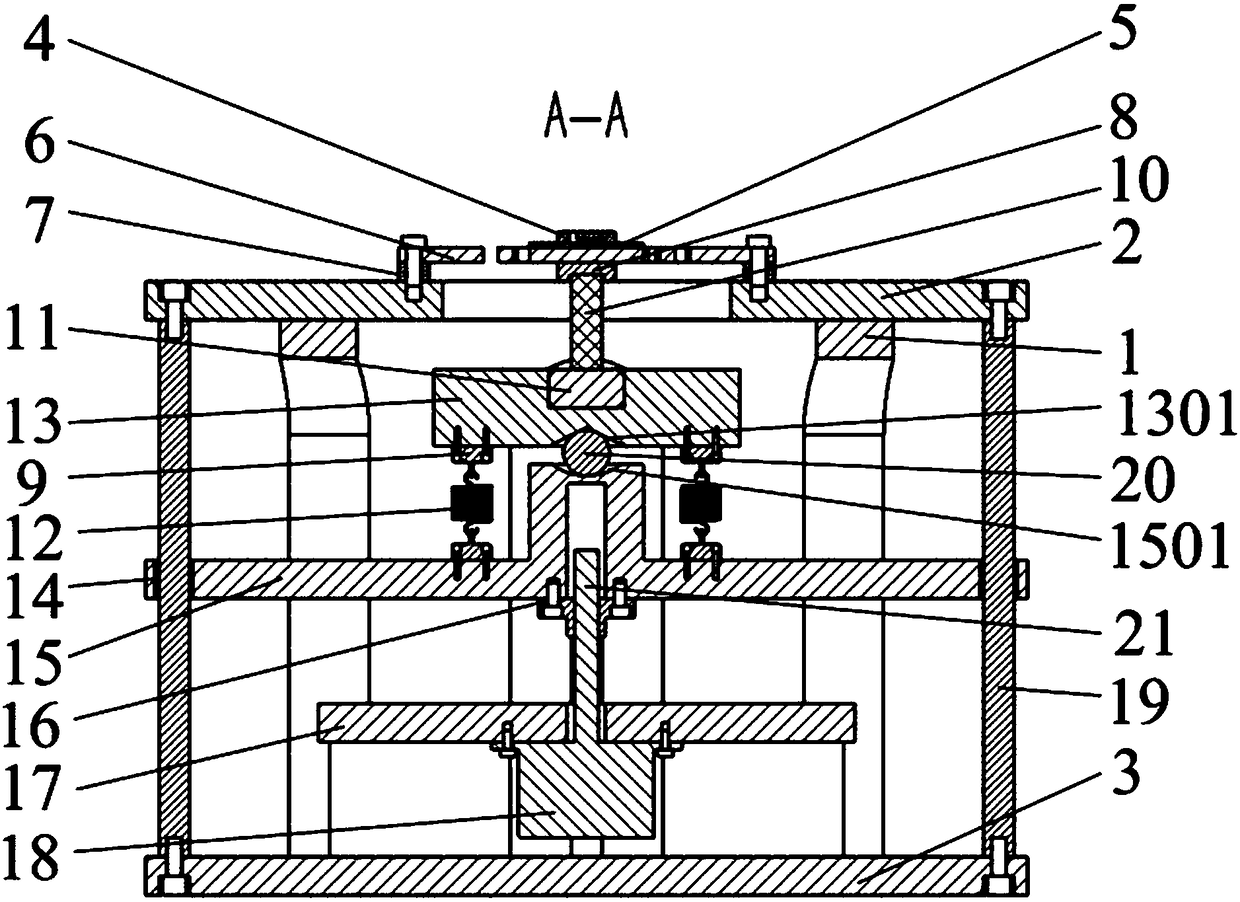

Four-axis type piezoelectric ceramic excitation device for testing dynamic characteristics of MEMS microstructure

The invention discloses a four-axis piezoelectric ceramic excitation device for testing the dynamic characteristics of an MEMS microstructure. The device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, a steel ball, an elastic supporting part and an MEMS microstructure. An annular top plate is arranged at the upper end of the sleeve. The microstructure is arranged on the annular top plate through the elastic supporting piece. Guide shafts are uniformly distributed between the annular top plate and the bottom plate. The lower connecting block is provided with guide supporting arms. The guide supporting arms penetrate through the wall of the sleeve to be sleeved on the guide shafts. Locking devices are arranged on the guide supporting arms respectively. Spherical grooves are formed in the upper connecting block and the lower connecting block respectively. The piezoelectric ceramic is clamped between thepressure sensor and the elastic supporting part. The outer edge of the upper connecting block is jacked into the inner wall of the sleeve through a ball head plunger. According to the device, pre-tightening forces of different sizes can be applied to the piezoelectric ceramic, and the obtained measurement values of pre-tightening forces are more accurate. As a result, the adjustment process for compensating the parallelism error between two working surfaces of the piezoelectric ceramic becomes more smooth and smoother. As a result, dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

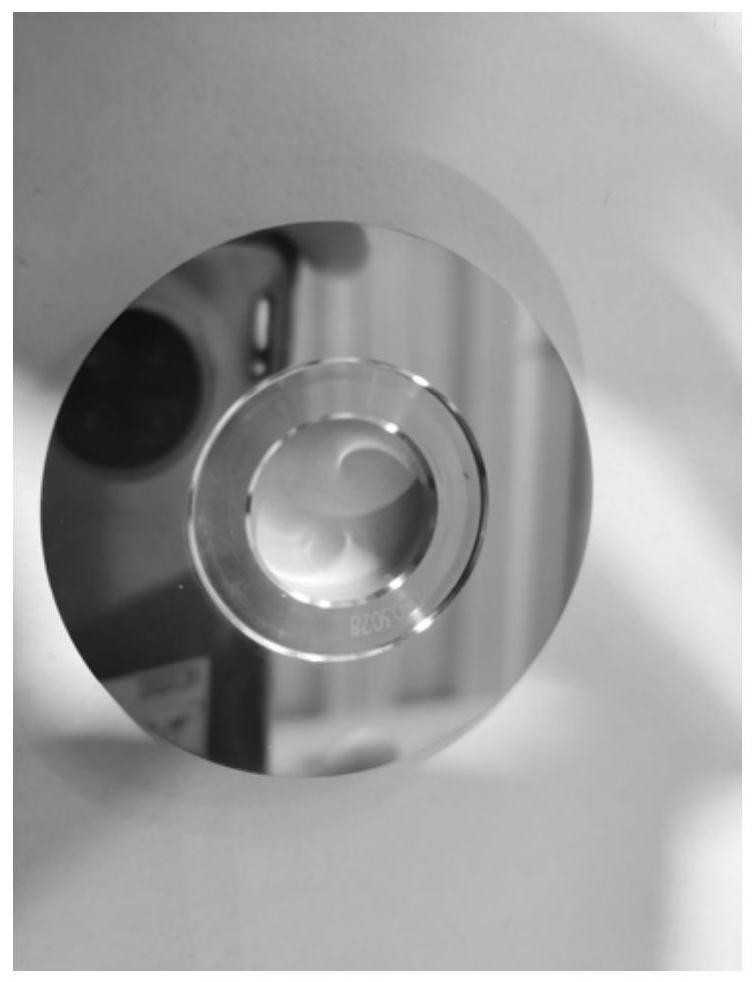

Hub type dicing blade, preparation method thereof and application of hub type dicing blade in gallium arsenide material processing

ActiveCN112746304AImprove rigidityImproving the performance of processing gallium arsenideElectrolytic coatingsFine working devicesChemical treatmentGallium arsenate

The invention discloses a hub type dicing blade, a preparation method thereof and application of the hub type dicing blade in gallium arsenide material processing. An aluminum alloy matrix is subjected to chemical treatment after being ground, and then is put into diamond electroplating liquid for electroplating, and an electroplated blade is obtained; the electroplated blade is subjected to outer circle finishing and lathe machining, then chemical exposure is carried out, then polishing is carried out, and the hub type dicing blade is obtained; and the diamond electroplating liquid is composed of diamond, nickel sulphamate, cobalt sulphamate, nickel sulfate, boric acid and water. The invention discloses the novel dicing blade which is ultrathin, the thickness of the dicing blade is 10-15 microns, and the dispersity of grinding materials is good; and when gallium arsenide materials are processed, a notch is narrow, no crack exists, and the cutting film entering rate is low.

Owner:赛尔科技(如东)有限公司

Inverse piezoelectric effect-based MEMS microstructure four-shaft type off-chip vibration excitation device

InactiveCN108020392ASmooth adjustment processReduce shear forceShock testingMicrostructureEngineering

An inverse piezoelectric effect-based MEMS microstructure four-shaft type off-chip vibration excitation device disclosed by the present invention comprises a sleeve, the stacked piezoelectric ceramics, a pressure sensor, the upper and lower connecting blocks and an MEMS microstructure, and is characterized in that a supporting plate and an electric lead screw transmission mechanism connected withthe lower connecting block are arranged in the sleeve, the lower end of the upper connecting block is equipped with a hemispherical round head and presses on the lower connecting block, and the piezoelectric ceramics are clamped between the pressure sensor and an elastic supporting member; the ball head plungers are uniformly distributed on the circumference between the upper connecting block andthe sleeve, the steel balls at the inner ends of the ball head plungers push into a chute at the outer edge of the upper connecting block, and the guiding shafts penetrating the lower connecting blockare uniformly distributed in the sleeve. The device can apply different pre-tightening forces on the stacked piezoelectric ceramics flexibly, so that the pre-tightening force measurement values are more accurate, an adjustment process for compensating a parallelism error of the two working surfaces of the stacked piezoelectric ceramics becomes more smooth, the shear forces between the stacked piezoelectric ceramics are reduced, and the dynamitic characteristic parameters of the MEMS microstructure are convenient to test.

Owner:BOHAI UNIV

Protecting method of electrode guide rod for insulating corrosion of electrolyte atmosphere

The invention discloses a protecting method of an electrode guide rod for insulating corrosion of an electrolyte atmosphere, and relates to a protecting method of an electrolyte guide rod of a noble electrode aluminum electrolysis cell. The protecting method is characterized in that a seal filling material is made by using aluminum oxide powder, quartz powder, sodium carbonate powder, electrolyte powder and glass powder as raw materials, wraps around the electrode guide rod, and forms a protecting layer which is of a thick melted glass body and is used for sealing a gap and insulating the electrolyte atmosphere and absorbing a swelling stress when normal electrolysis runs. By adopting the protecting method, the electrode guide rod is protected, so that the corrosion of the electrolyte atmosphere can be effectively insulated.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

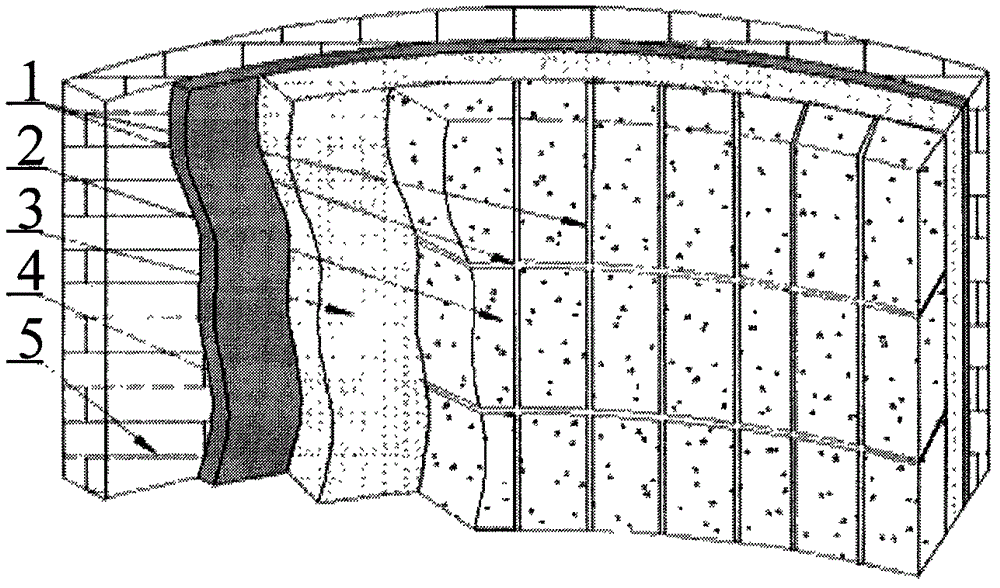

expansion sealer

ActiveCN103994428BNo crackingWill not cause crackingFluidized bed combustionApparatus for fluidised bed combustionEngineeringMechanical engineering

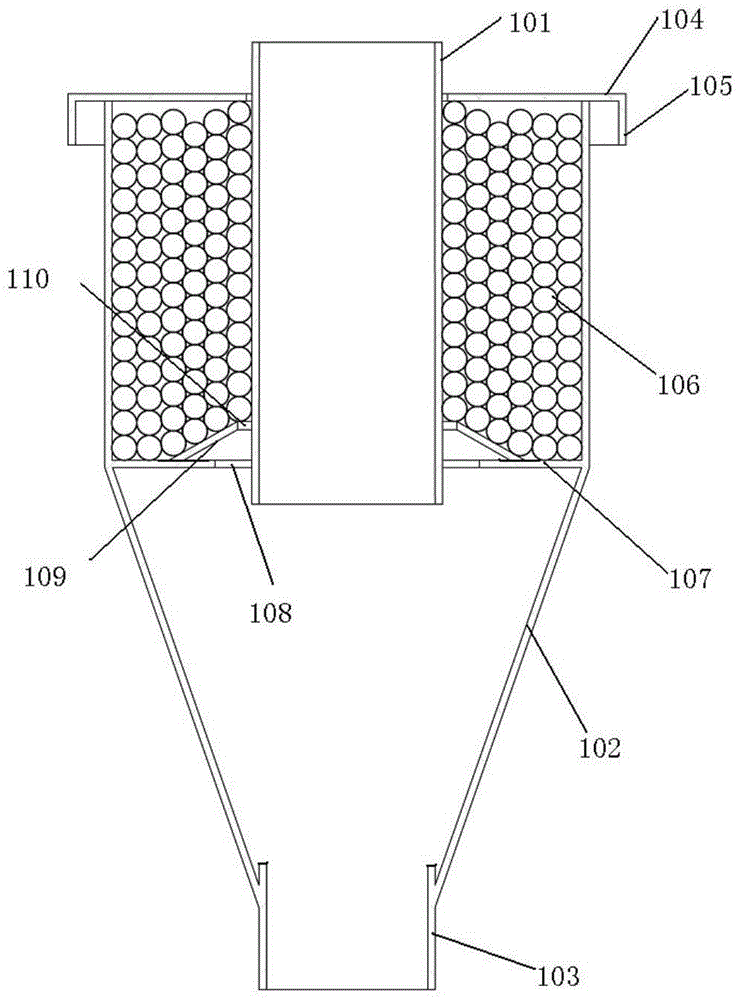

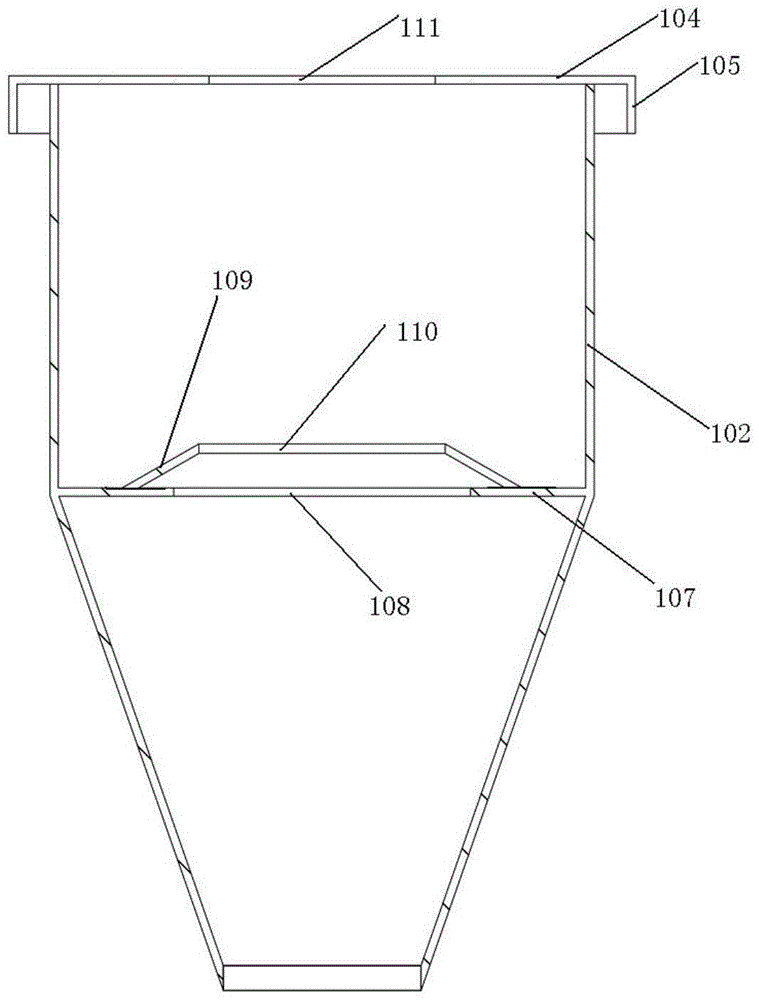

The invention relates to the field of boiler equipment, and in particular relates to an expansion sealer. The expansion sealer is characterized in that a shell is a hollow cavity with openings at two ends; a fixed sealing disk is arranged in the hollow cavity; a moving sealing disk is arranged on the fixed sealing disk; one end of an upper residue discharging pipe sequentially penetrates through the opening in one end of the shell, the moving sealing disk and the fixed sealing disk and is arranged in the shell; gaps are respectively formed between the fixed sealing disk and the upper residue discharging pipe and between the moving sealing disk and the upper residue discharging pipe; a plurality of sealing bodies are arranged in an accommodating space encircled by the shell, the fixed sealing disk, the moving sealing disk and the upper residue discharging pipe and are used for filling the gaps. The expansion sealer provided by the invention has the advantages that the upper residue discharging pipe can move along different directions in a discharging process of high-temperature ash residues, and the gaps can be filled with the sealing bodies at any time, so that a joint of the residue discharging pipe and a hearth cannot be cracked, the ash residues cannot be leaked, and the phenomena of environment pollution, unplanned boiler shutdown and economic loss are avoided.

Owner:DATANG WUAN POWER GENERATION

Four-axis excitation device for performing out-of-chip excitation on MEMS microstructure

InactiveCN108168814AReduce shear forceRegulation stabilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectricitySteel ball

The invention discloses a four-axis excitation device capable of dynamically driving an MEMS microstructure. The excitation device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, a steel ball, an elastic supporting part and the MEMS microstructure; an annular top plate is arranged at the upper end of the sleeve, the microstructure is arranged on the annular top plate through the elastic supporting part; guide shafts are uniformly distributed between the top plate and the bottom plate, the lower connecting block is uniformly provided with guide support arms which penetrate through the sleeve wall and sleeve the guide shafts; the upper connecting block and the lower connecting block are respectively providedwith a conical groove and a spherical groove which are matched with each other, tension springs are uniformly distributed between the upper connecting block and the lower connecting block to make thesteel ball be clamped between the conical groove and the spherical groove; and the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting part. According to the device, pre-tightening force of different sizes can be applied to the piezoelectric ceramics, meanwhile, the obtained pre-tightening force measurement value is more accurate, so that the adjustment processof the parallelism error of the two working surfaces of the compensation piezoelectric ceramic can be smoother, and dynamic characteristic parameters can be tested conveniently.

Owner:BOHAI UNIV

Anti-corrosion chimney and anti-corrosion method for chimney

The invention discloses an anti-corrosion chimney lining structure and a chimney anti-corrosion method. The innermost layer of the chimney has a glass fiber reinforced plastic lining structure, and the structure forms an independent smoke exhaust function. The part outside the lining is only load-bearing structure. After adopting the fiberglass lining structure, the load-bearing structural layer of the chimney is completely isolated from the wet flue gas (acid liquid), the chimney will not be corroded, and it is convenient for construction and reduces the construction period.

Owner:张蕊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com