Hub type dicing blade, preparation method thereof and application of hub type dicing blade in gallium arsenide material processing

A gallium arsenide, wheel hub technology, applied in the field of processing tools, can solve the problems of slow growth of single crystals, weak mechanical strength of materials, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

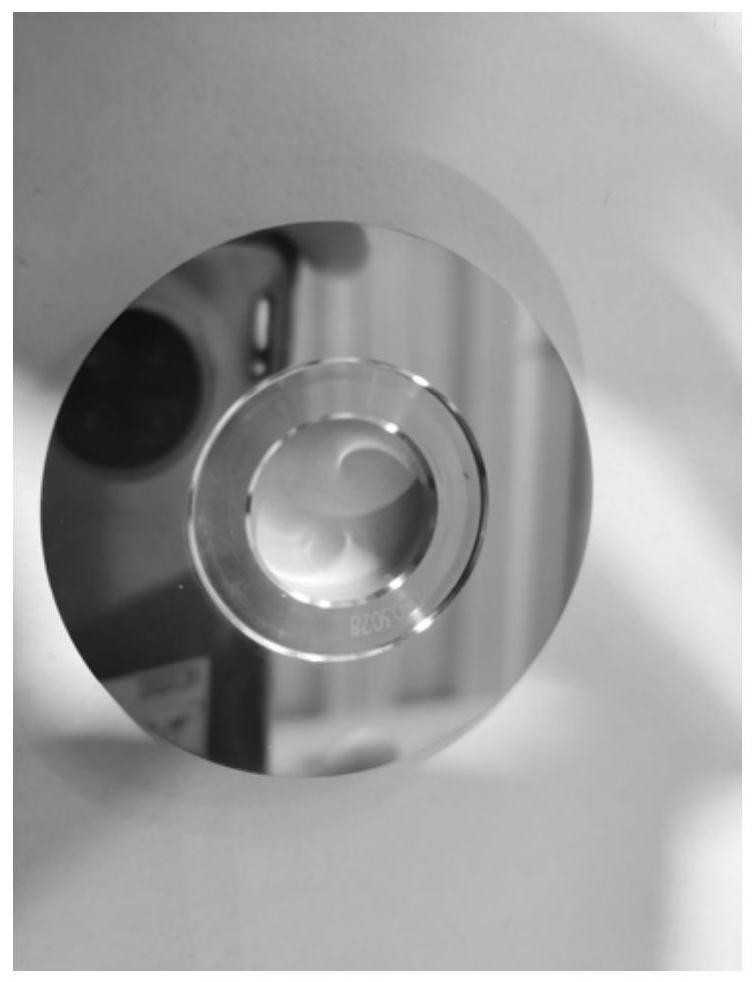

[0032] Put the commercially available aluminum alloy substrate in the grinding jig, and perform grinding with stainless steel grinding disc and damping polishing cloth in sequence on the existing grinding machine. ) water dispersion, the concentration is 200g / L, the grinding time is 10min; the pressure of the damping polishing cloth (HSL / Hua Shili) is 10kg when grinding, and the grinding fluid is aluminum alloy polishing fluid (polishing fluid manufacturer: Haide Precision Aluminum Alloy Polishing Fluid, Diluted with water at a mass ratio of 1:2), drip 15ml of grinding liquid on the damping polishing cloth every minute, the grinding time is 15min, and finally wash with water and dry; get the ground aluminum alloy substrate, see the attached picture for the physical picture figure 1 , the diameter of the inner hole is 19.0542~19.055mm, that is, the roundness of the inner hole is 0.8 μm, and the roundness of the inner hole of the prepared hub-type dicing knife is less than 1 μm. ...

Embodiment

[0082] In Example 1, no shedding, snake cutting and knife breaking occurred; in Comparative Example 1, snake cutting occurred after 100 meters and the knife broke after cutting 300 meters; in Comparative Example 2, the knife broke after cutting 560 meters; in Comparative Example 3, the cutting was good in the early stage, 665 meters Edge chipping occurred, and cracking occurred at 730 meters; the blade of comparative example 4 was not broken, but the gallium arsenide wafer was obviously cracked; the blade of comparative example 5 was not broken, and there was no snake cutting, but at 835 meters, the gallium arsenide material collapsed; comparative example The six blades were not broken, and there was no snake cutting, but at 818 meters, the gallium arsenide material collapsed.

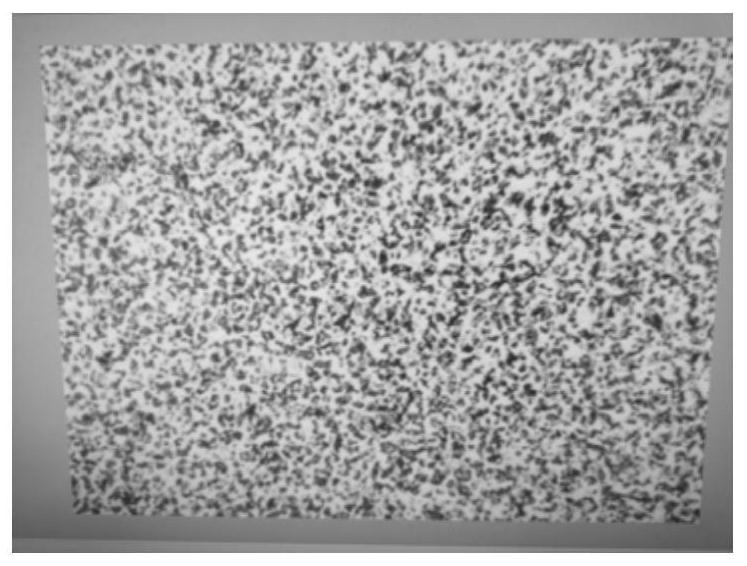

[0083] The hub-type scribing knife of the present invention (Example 1) has good processing performance, and the GaAs material after processing has no cracking, see the attached Figure 5 ; The gallium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com