Vacuum light-condensing through high-temperature heat collecting pipe

A heat collecting tube and high temperature technology, which is applied in the field of vacuum concentrating direct high temperature heat collecting tubes, can solve the problems of difficult processing, complicated processing methods, breakage, etc., and achieves simple and easy system design, ensures vacuum heat insulation effect, and improves light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

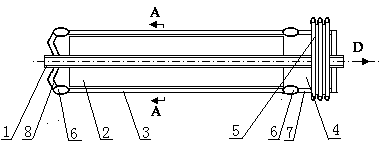

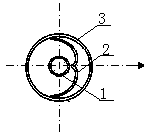

[0016] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Depend on figure 1 and figure 2 It can be seen that the present invention includes an outer tube 3, an inner tube and a light-concentrating reflector 2, the outer tube 3 is a glass tube, the inner tube coaxially arranged is a heat-absorbing heat-conducting tube 1, and one end of the outer tube 3 is provided with an axially deformable metal end cap 8, and the other end is provided with a valve-capable metal tube 7 head, the metal end cap 8 and the valve-capable metal tube 7 are sealed with the end of the outer tube 3 to form a vacuum sealed cavity 4, suction Both ends of the heat pipe 1 protrude from the vacuum sealed cavity 4; The metal end cap 8 and the valveable metal tube 7 in the head 5 are solidified with the end of the outer tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com