Patents

Literature

87results about How to "Improve insulation quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

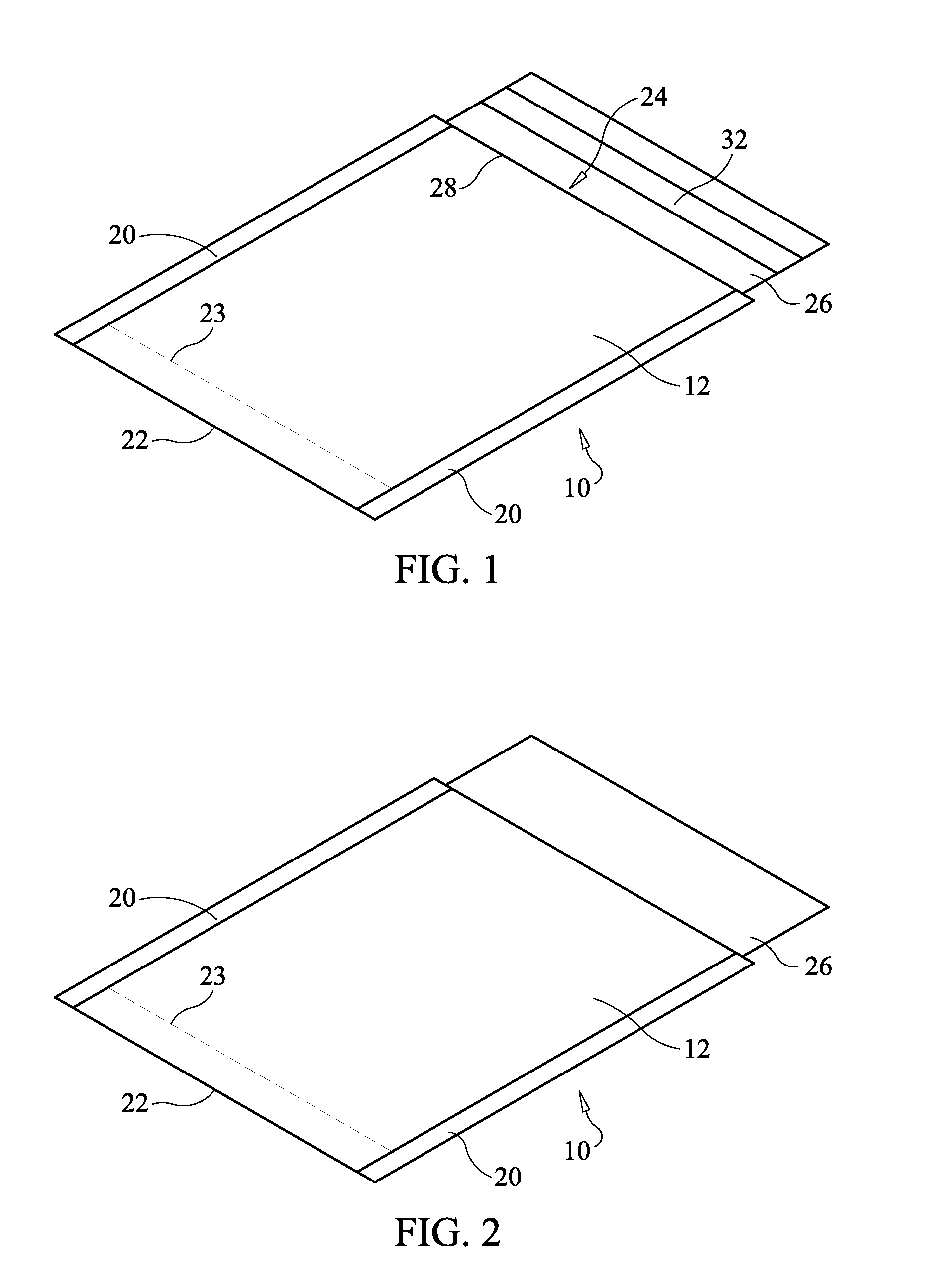

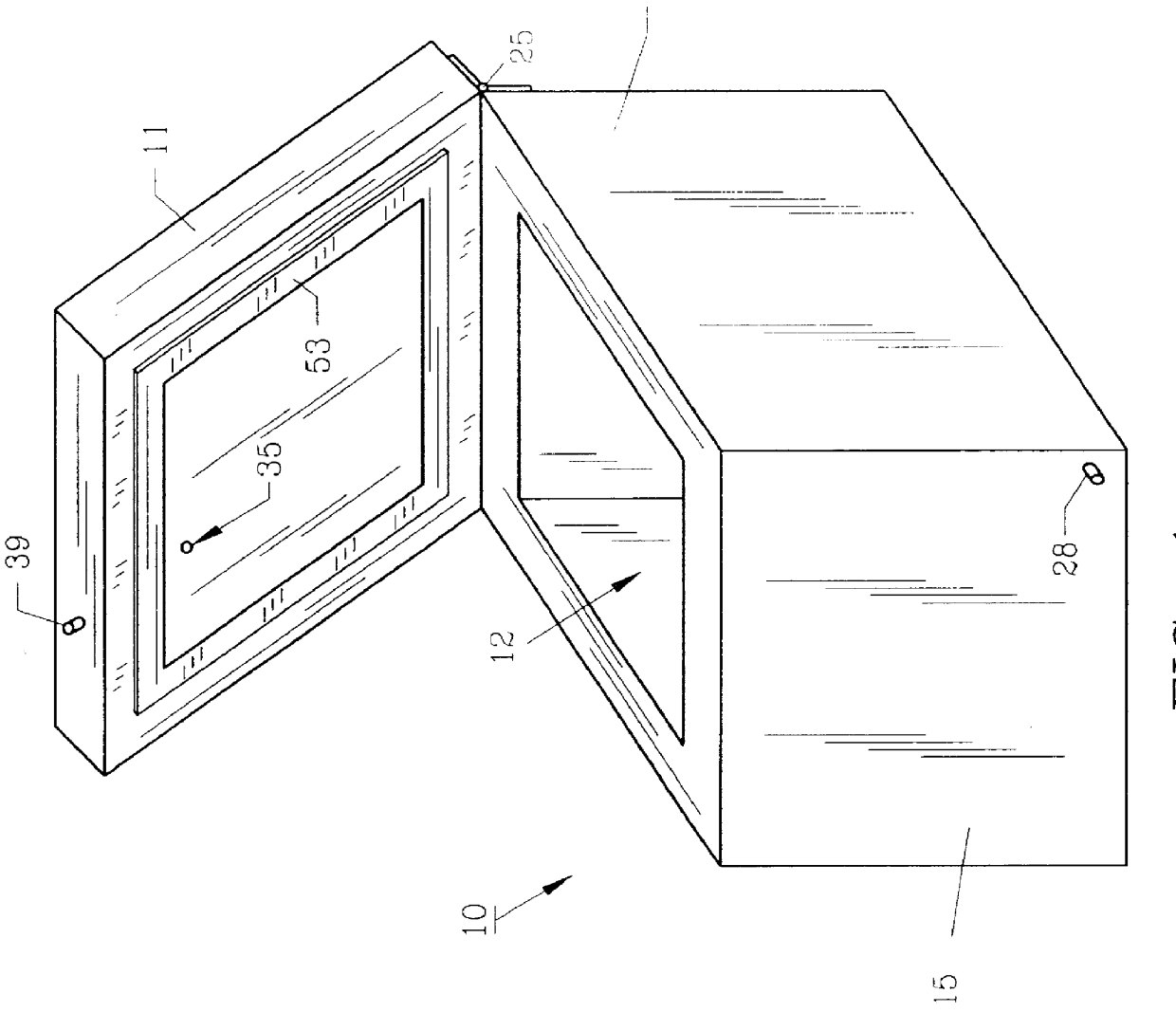

"green" temperature-controlled mailer

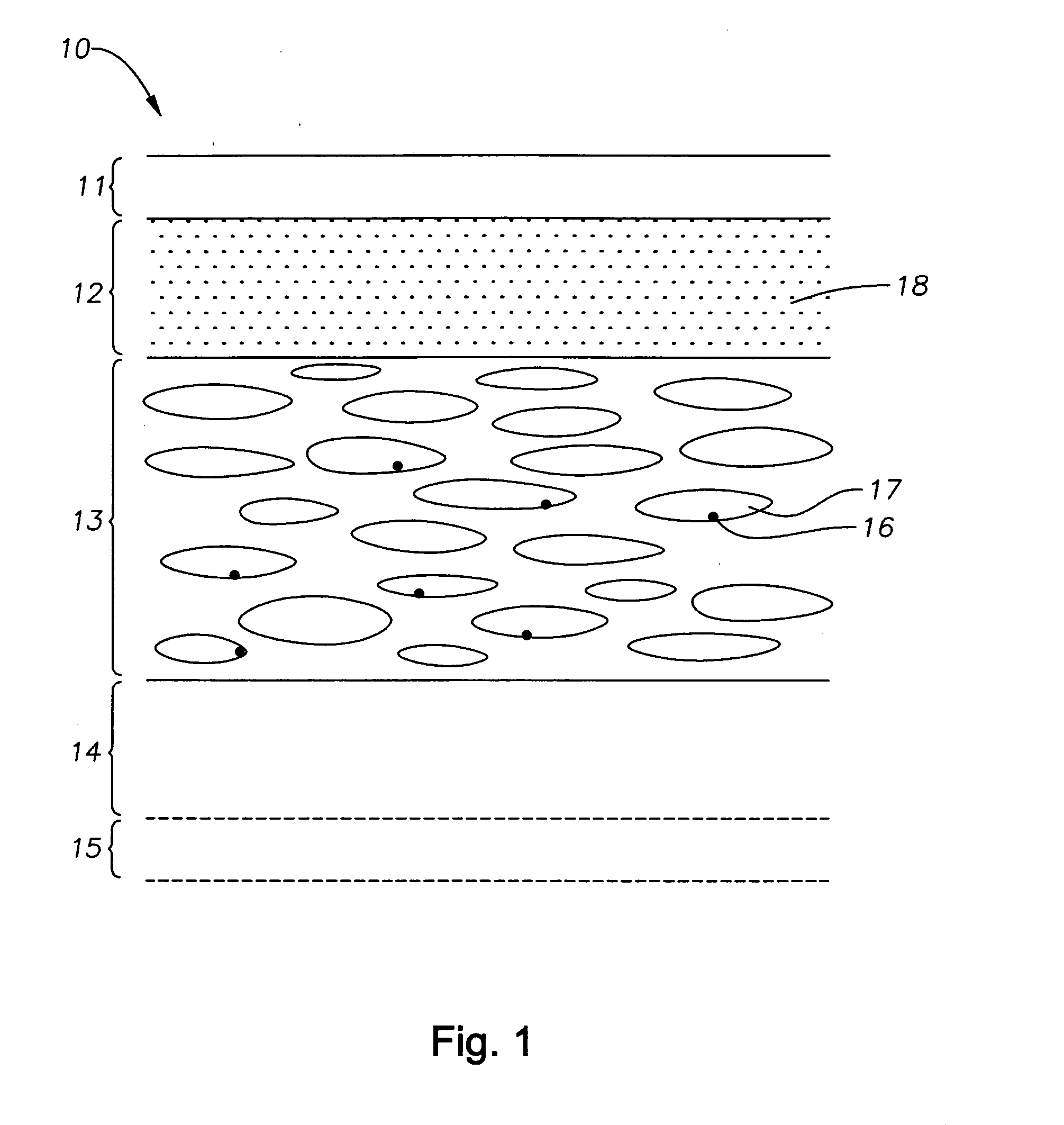

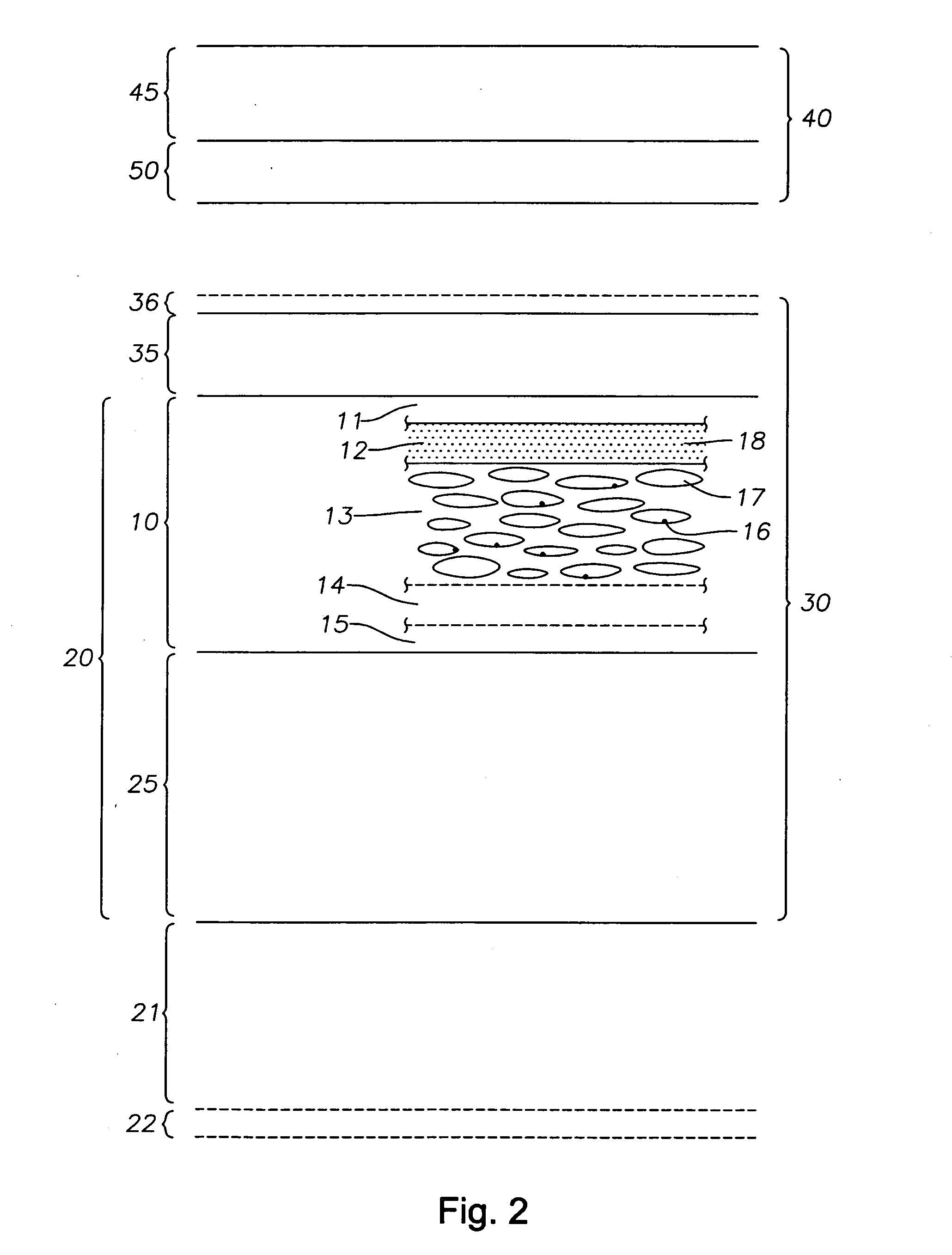

ActiveUS20110114513A1Cost efficiencyImprove insulation qualityWrappersDomestic cooling apparatusThin membraneEngineering

A mailer has an outer, longitudinally extending, biodegradable film with lateral edges folded on itself to form a pocket having an opening and sealable by a flap. An assembly is composed of an inner, longitudinally extending, biodegradable film having lateral edges and a longitudinal extending pad composed of textile cuttings and microbial and superabsorbent powders. The inner film extends longitudinally around the pad and is attached to the pad. The assembly is positioned in the pocket with the inner film being sealed to the outer film adjacent the opening to the pocket trapping the pad between the outer and inner films. Sealing tape is mounted on the inner film adjacent to the pocket to seal the pocket closed. The lateral edges of both the outer and inner films, which extend laterally beyond the pad, are heat sealed together. A container has an outer box an inner insulative layer. The insulative layer is made from flocked textiles and is mixable with absorbatives and antimicrobials.

Owner:MILLER DRAYTON GRANVILLE

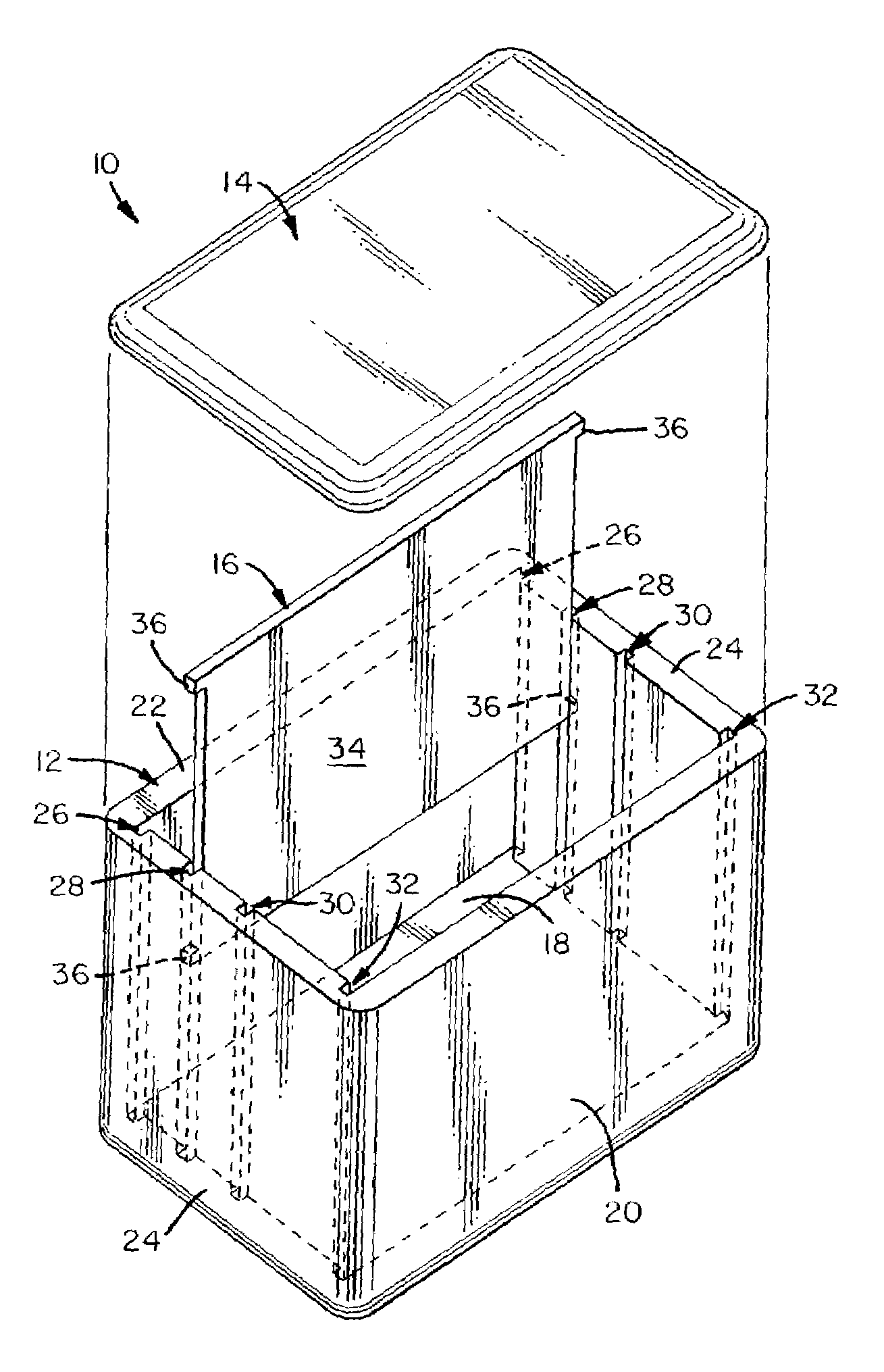

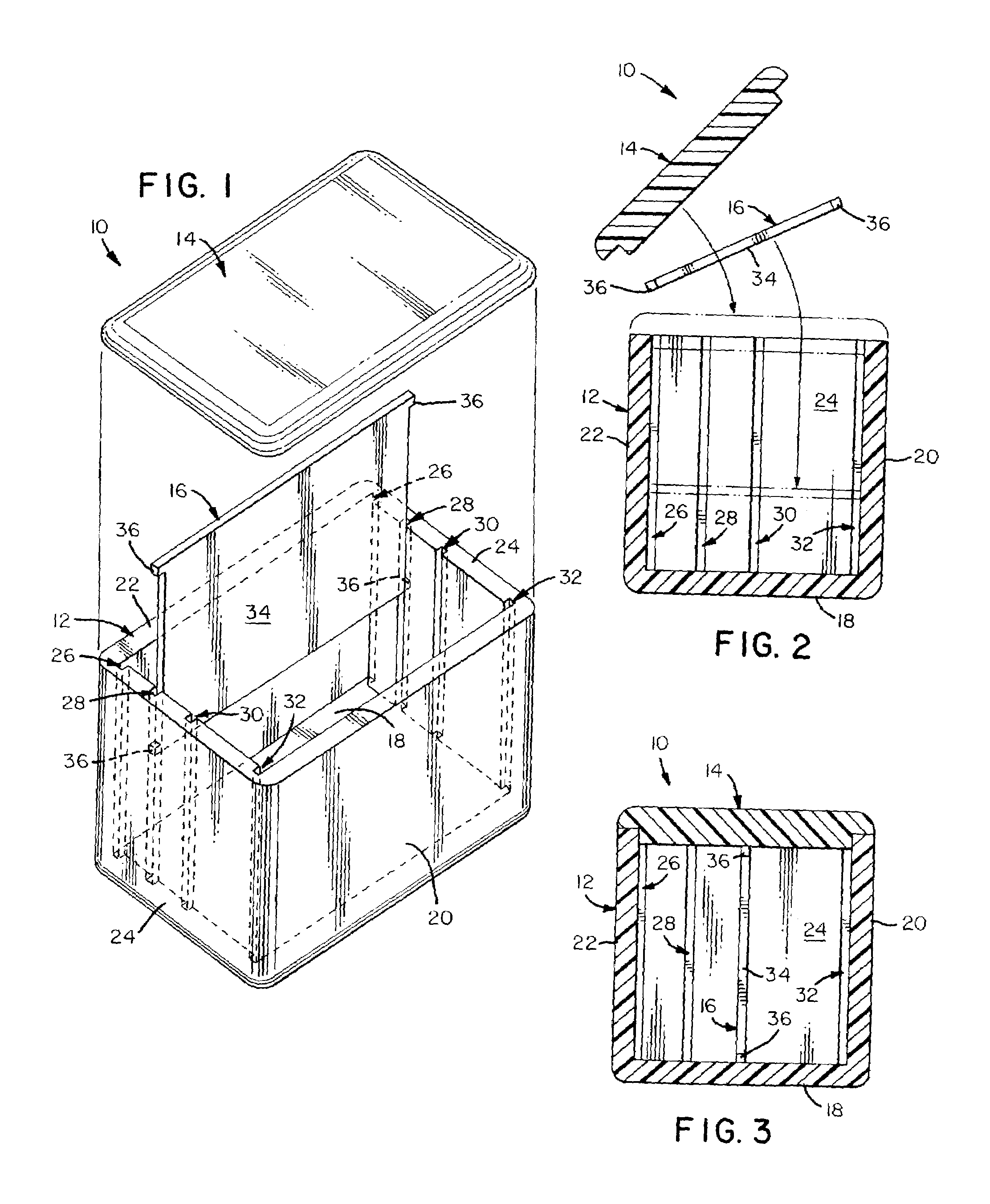

Partitioned ice chest

InactiveUS6966450B2Improve insulation qualityReduce storage capacityDomestic cooling apparatusLighting and heating apparatusMechanical engineeringEngineering

Owner:ASKEW STACY W

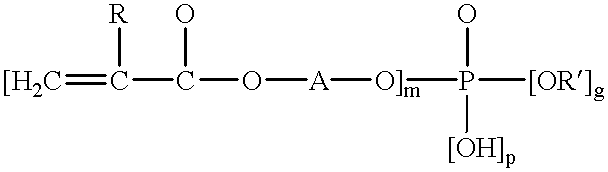

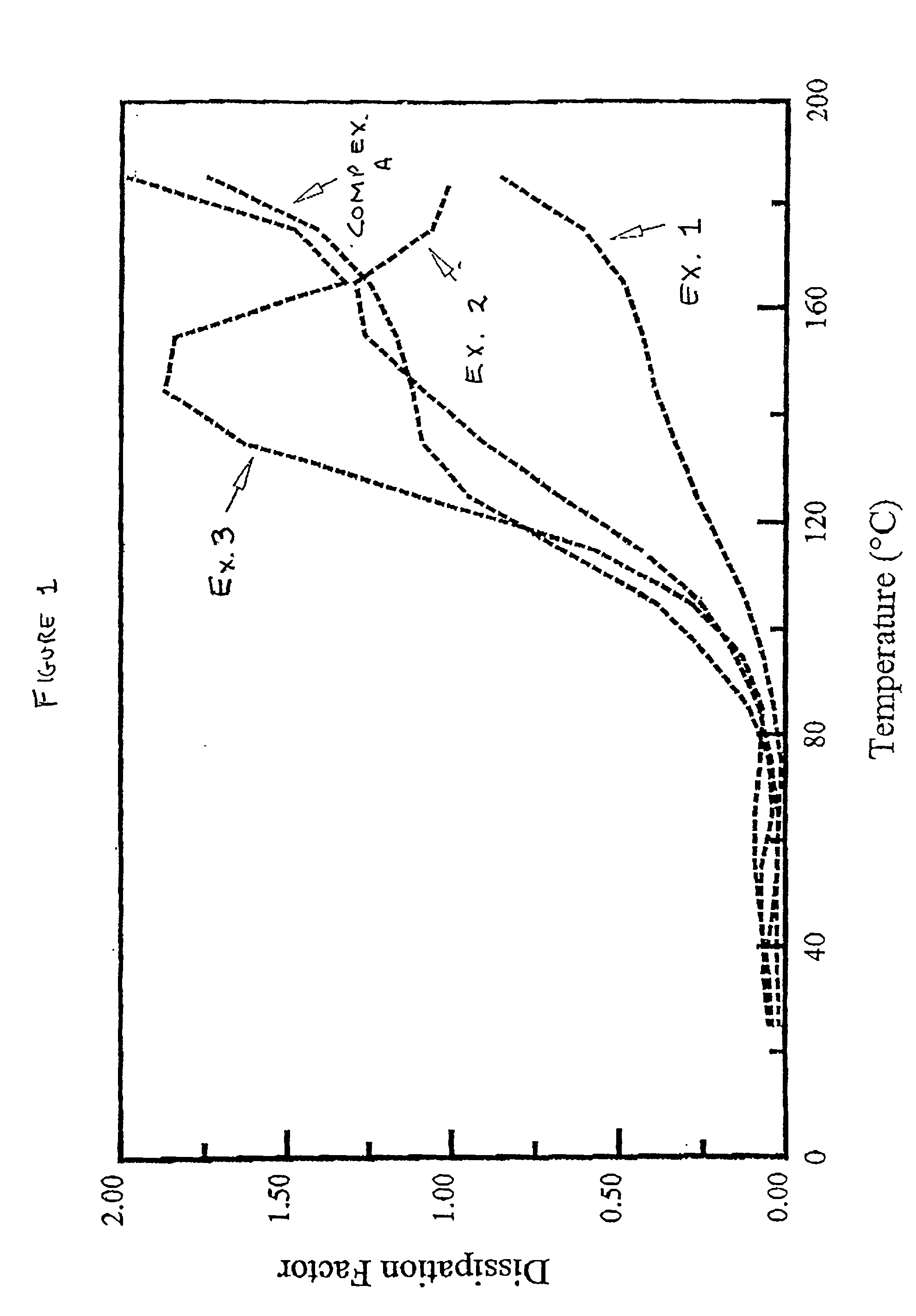

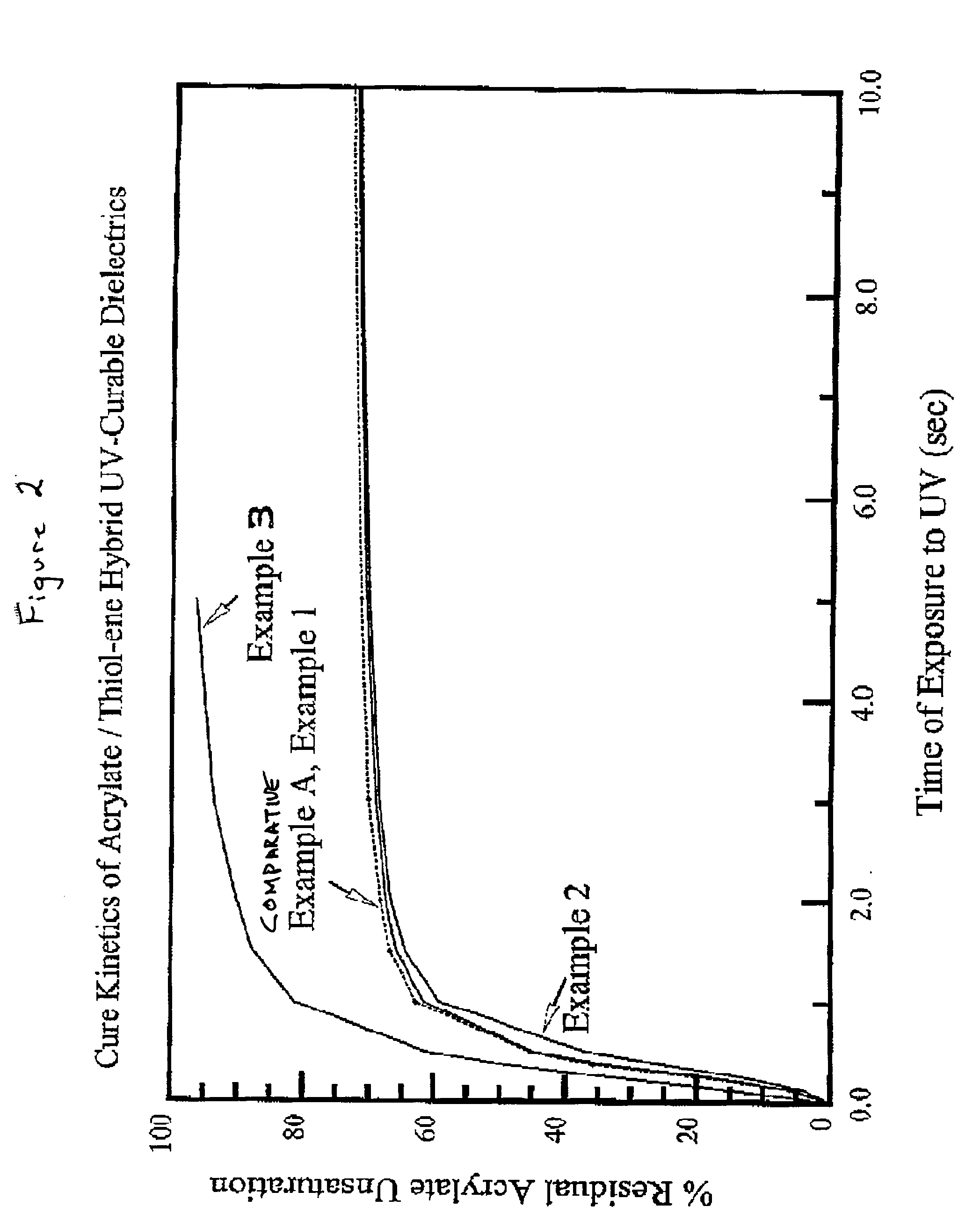

Dielectric, radiation-curable coating compositions

InactiveUS20020004537A1Improve curing speedFacilitates co-polymerizationGroup 4/14 element organic compoundsPlastic/resin/waxes insulatorsDielectric loss factorElectrical conductor

Owner:DSM IP ASSETS BV

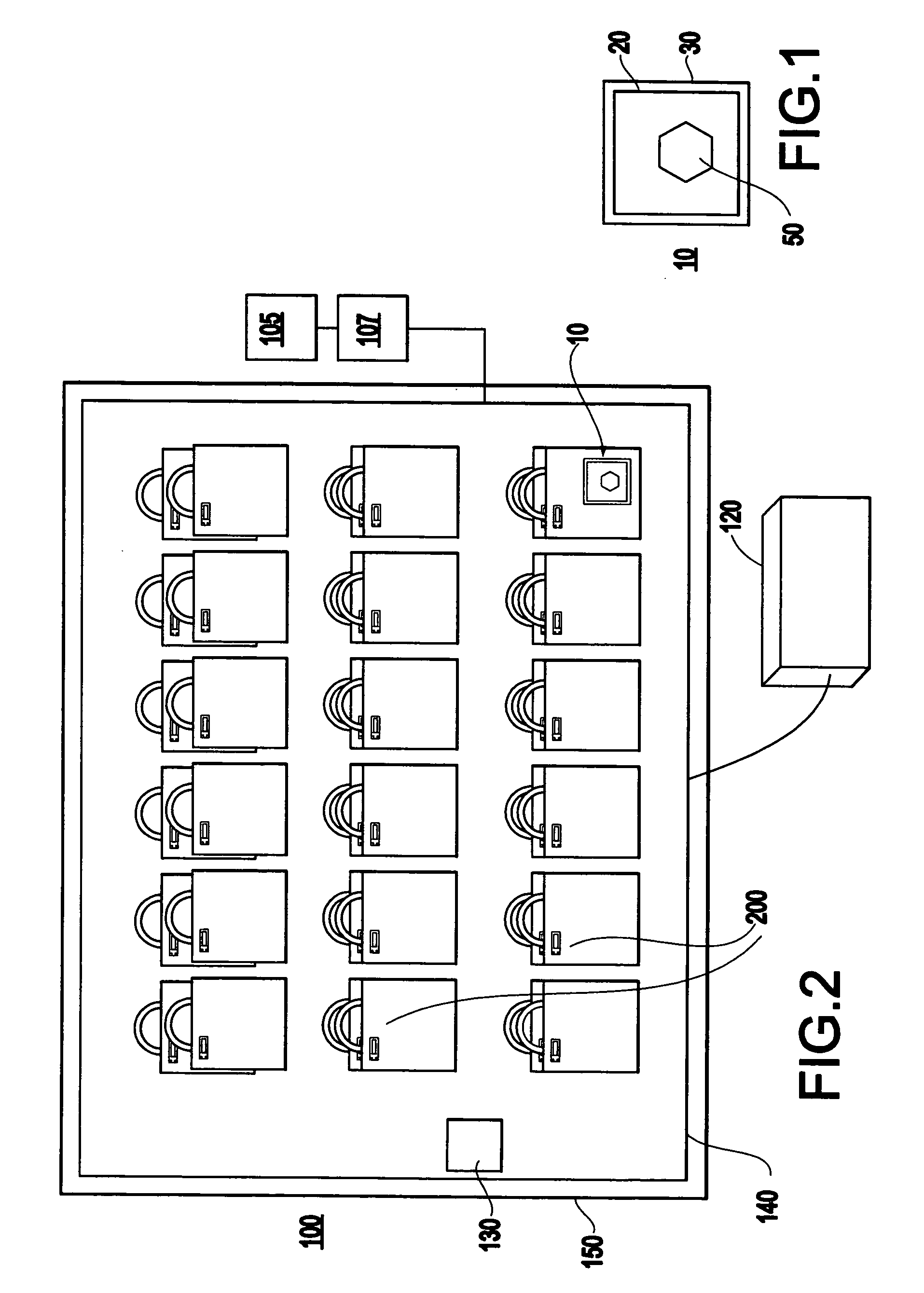

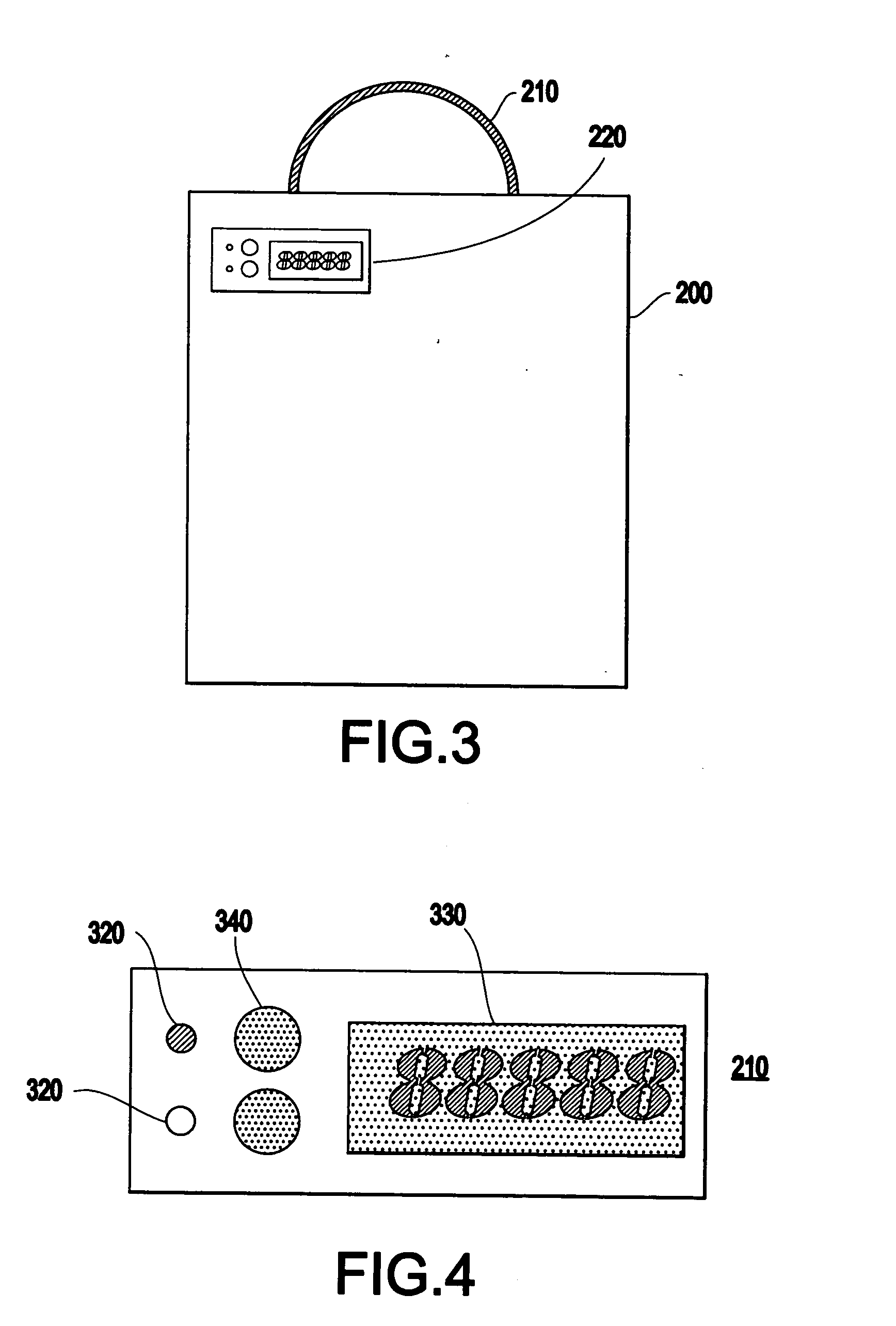

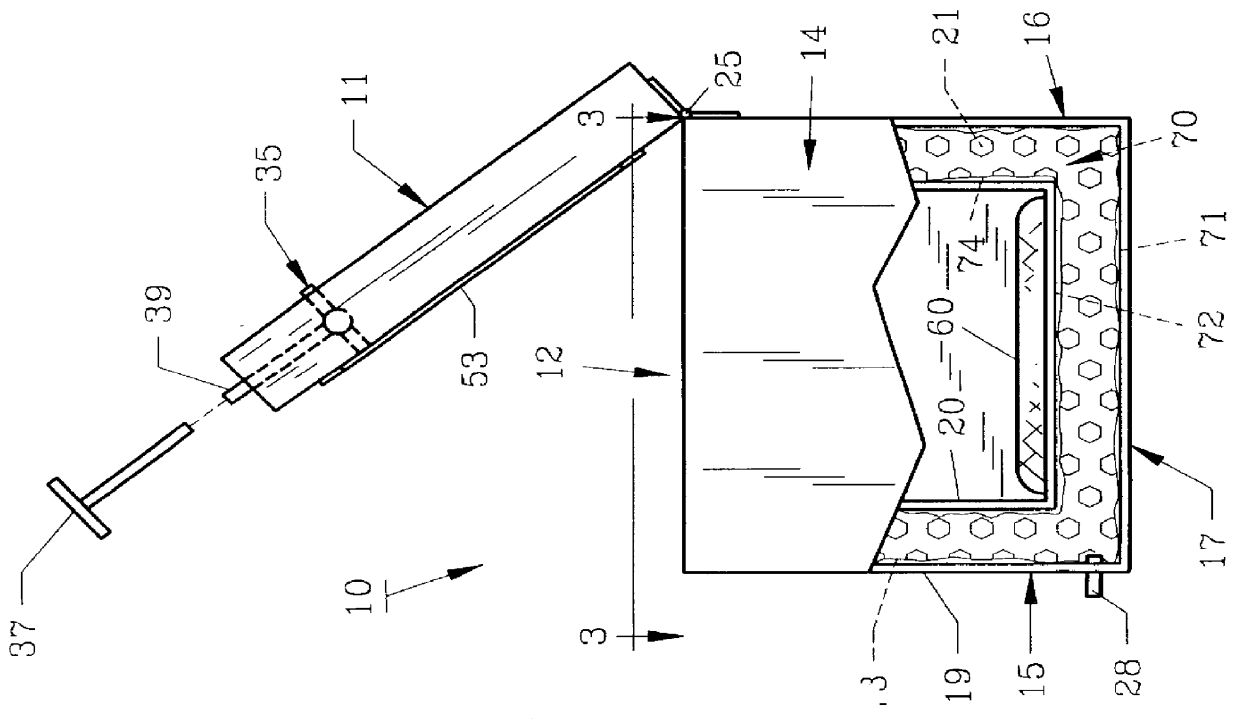

System and method for packaging and delivering a temperature-sensitive item

InactiveUS20050029149A1Low costEliminate needContainer decorationsLevel indicationsTransceiverBiomedical engineering

A system and method for packaging and delivering a temperature-sensitive item includes an insulated package having a substantially rigid container for containing the item, and a vacuum-sealed outer shell surrounding said container, and an insulated drop box having a first transceiver, for storing the insulated package.

Owner:VISIBLE ASSET INC

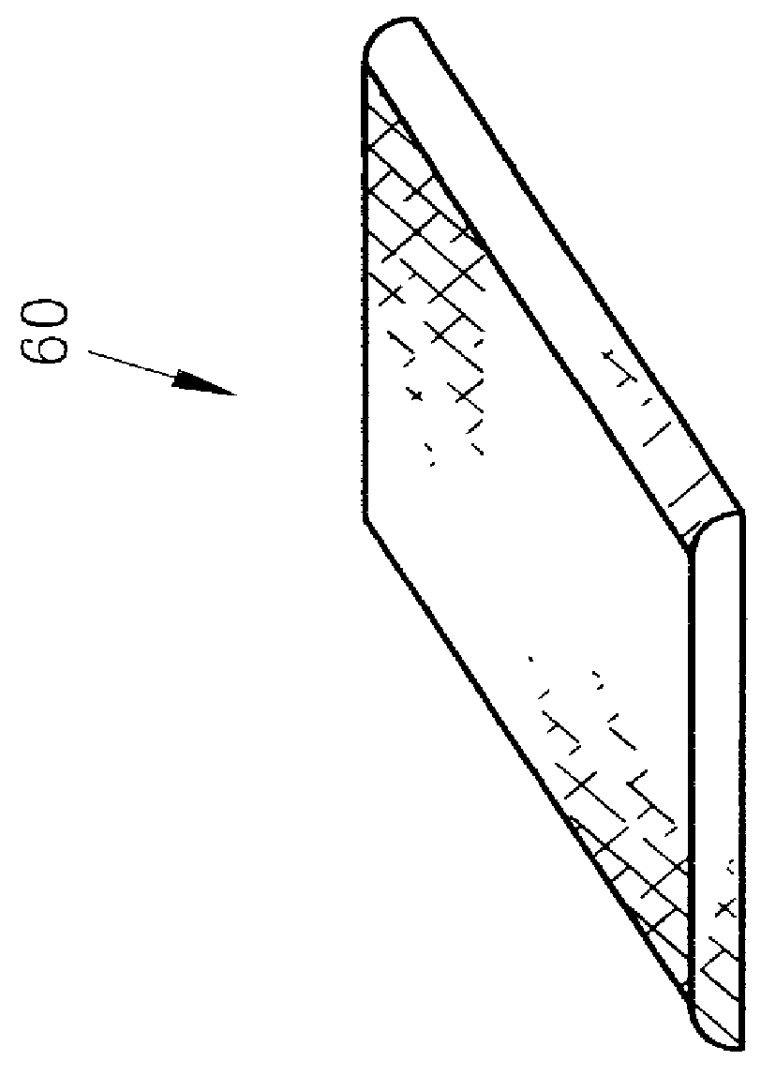

Insulated chest and method

InactiveUS6062040AImprove insulation qualityImprove cooling effectLighting and heating apparatusPackaging under vacuum/special atmosphereEngineeringTemperature control

Owner:PHASE CHANGE ENERGY SOLUTIONS INC

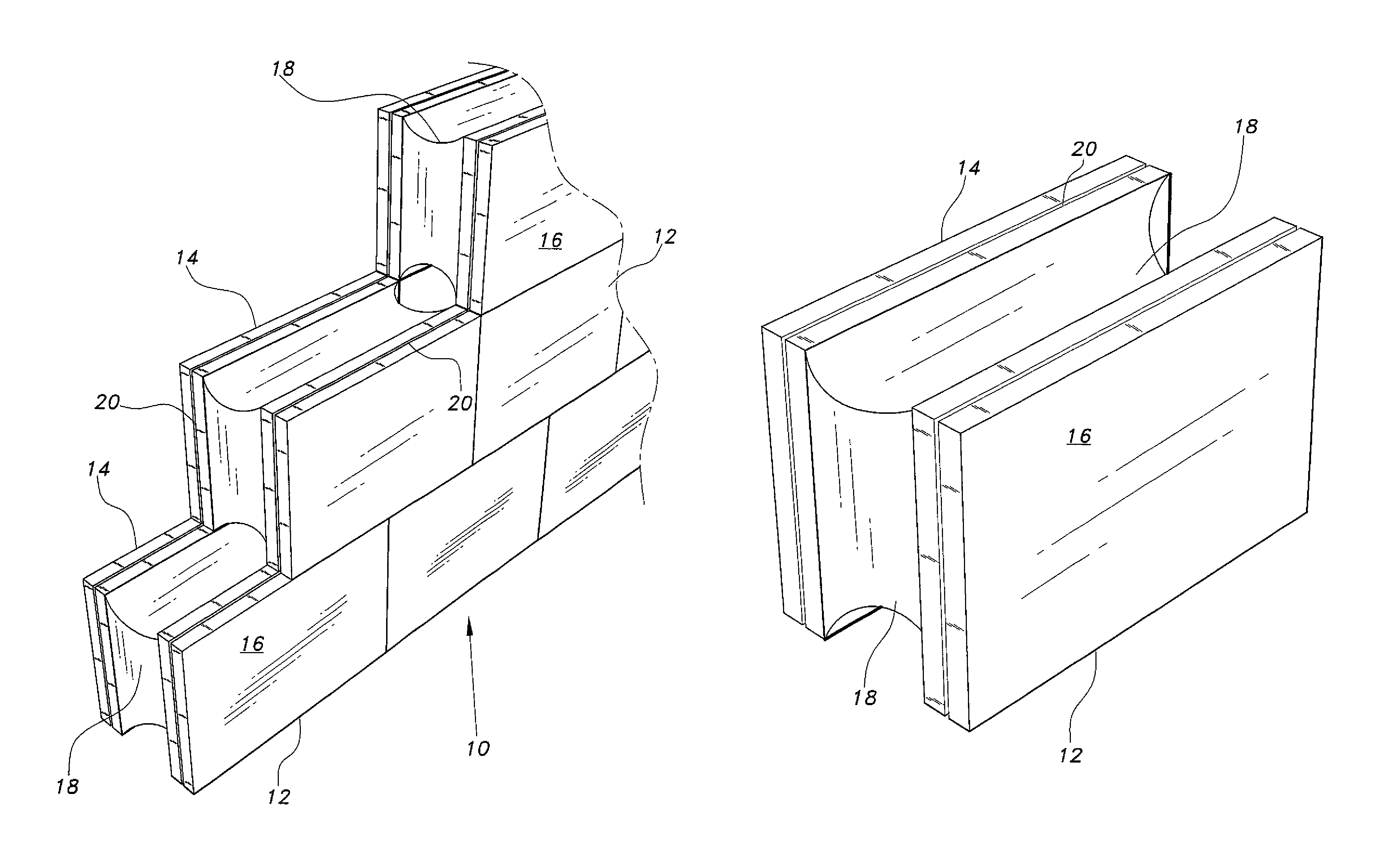

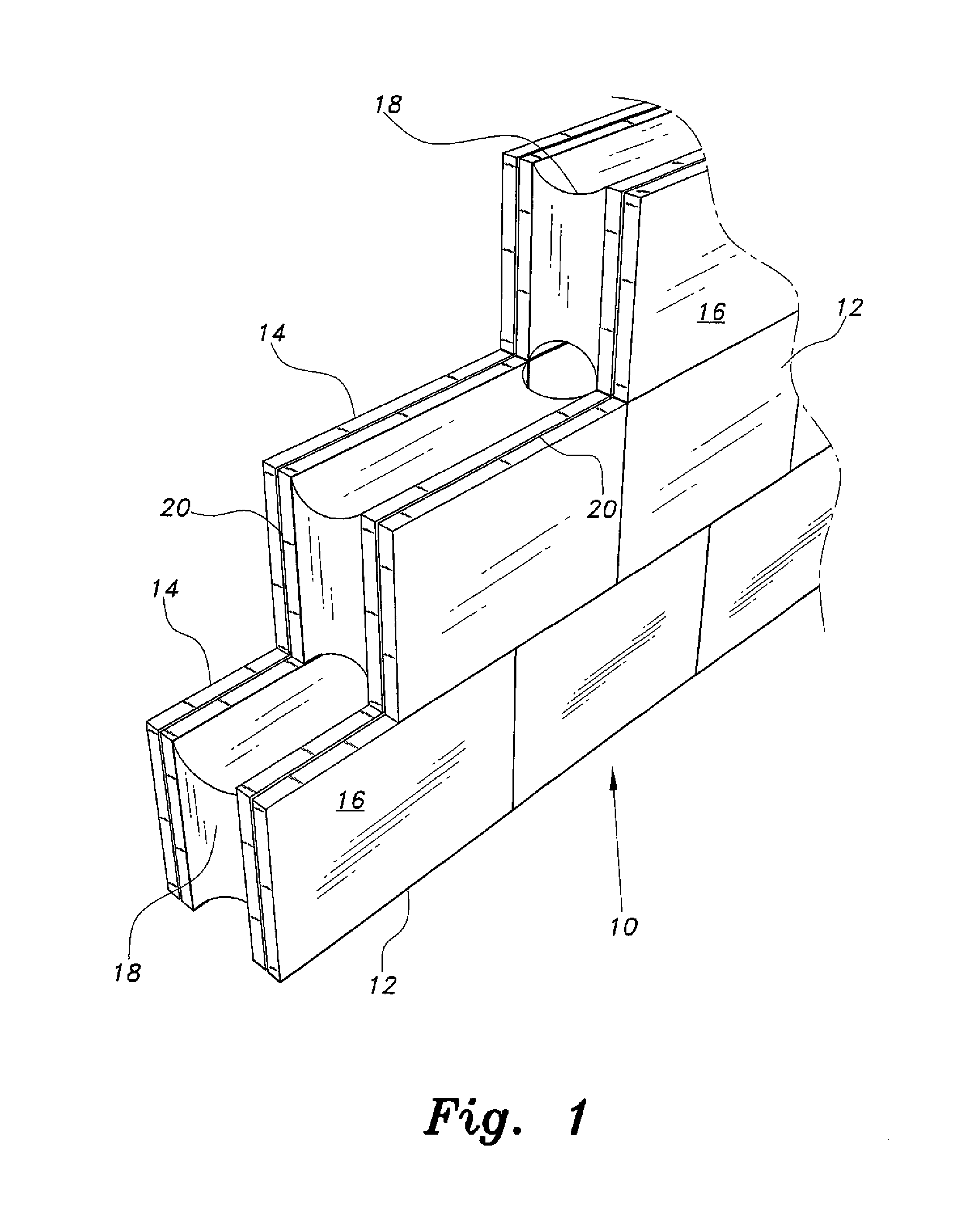

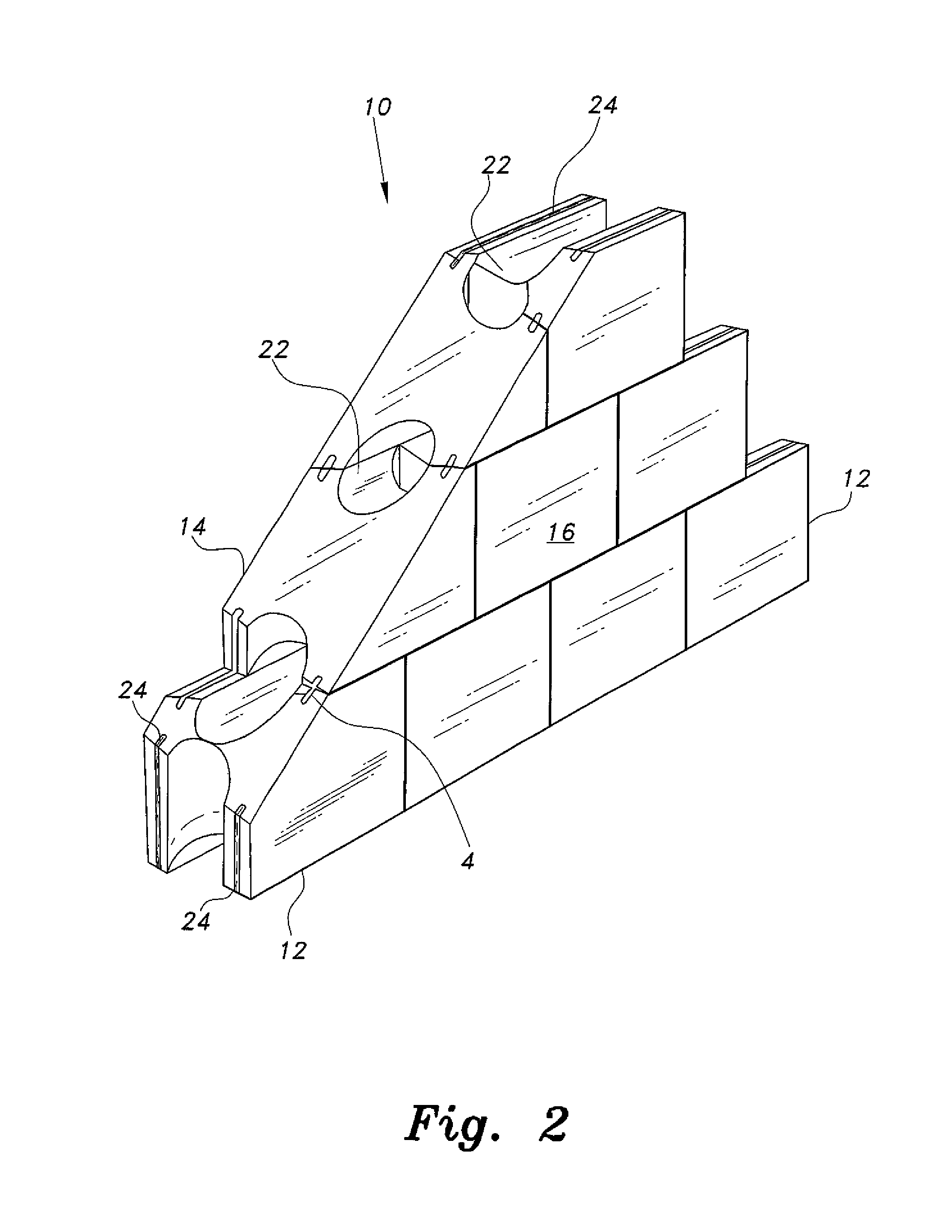

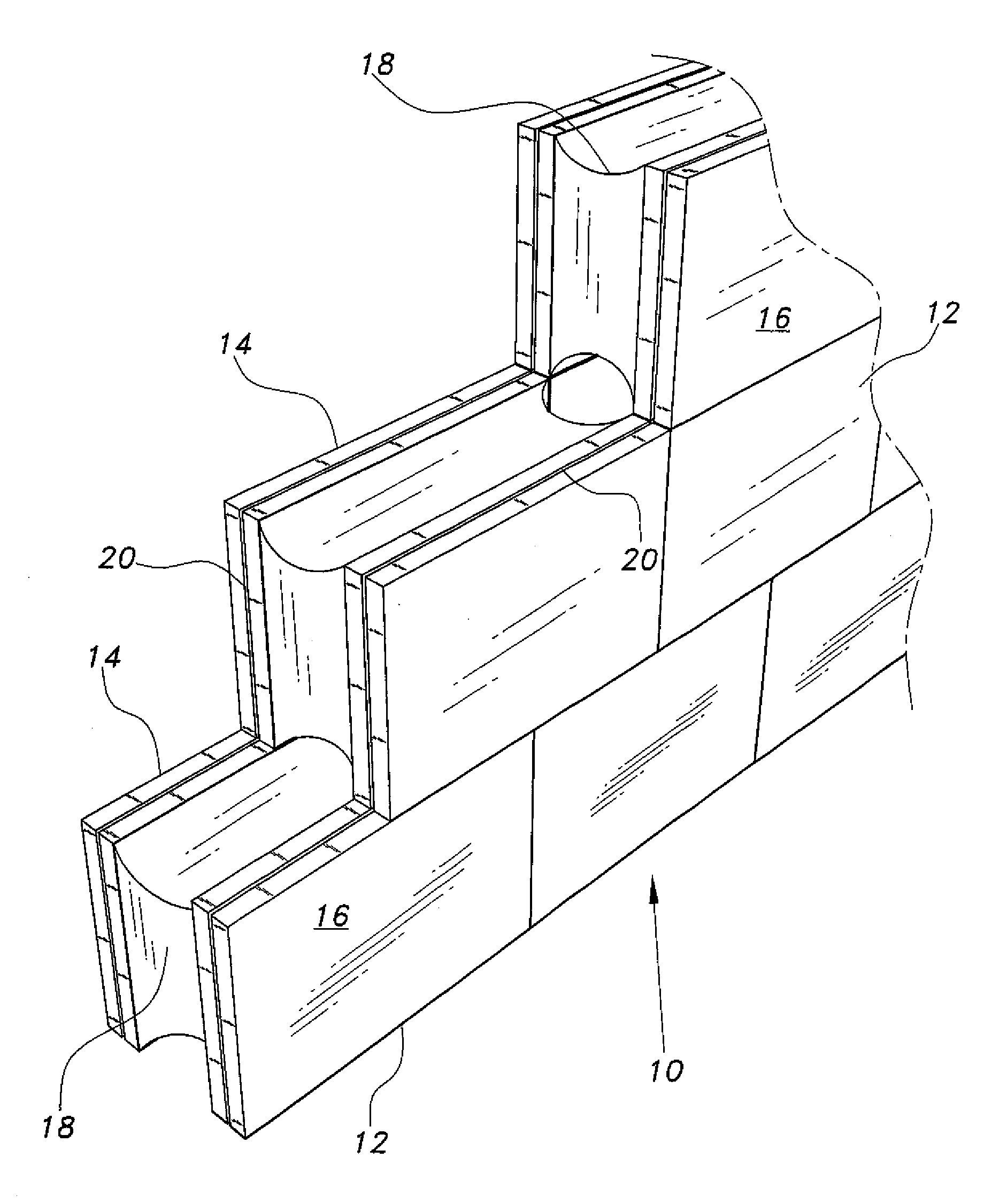

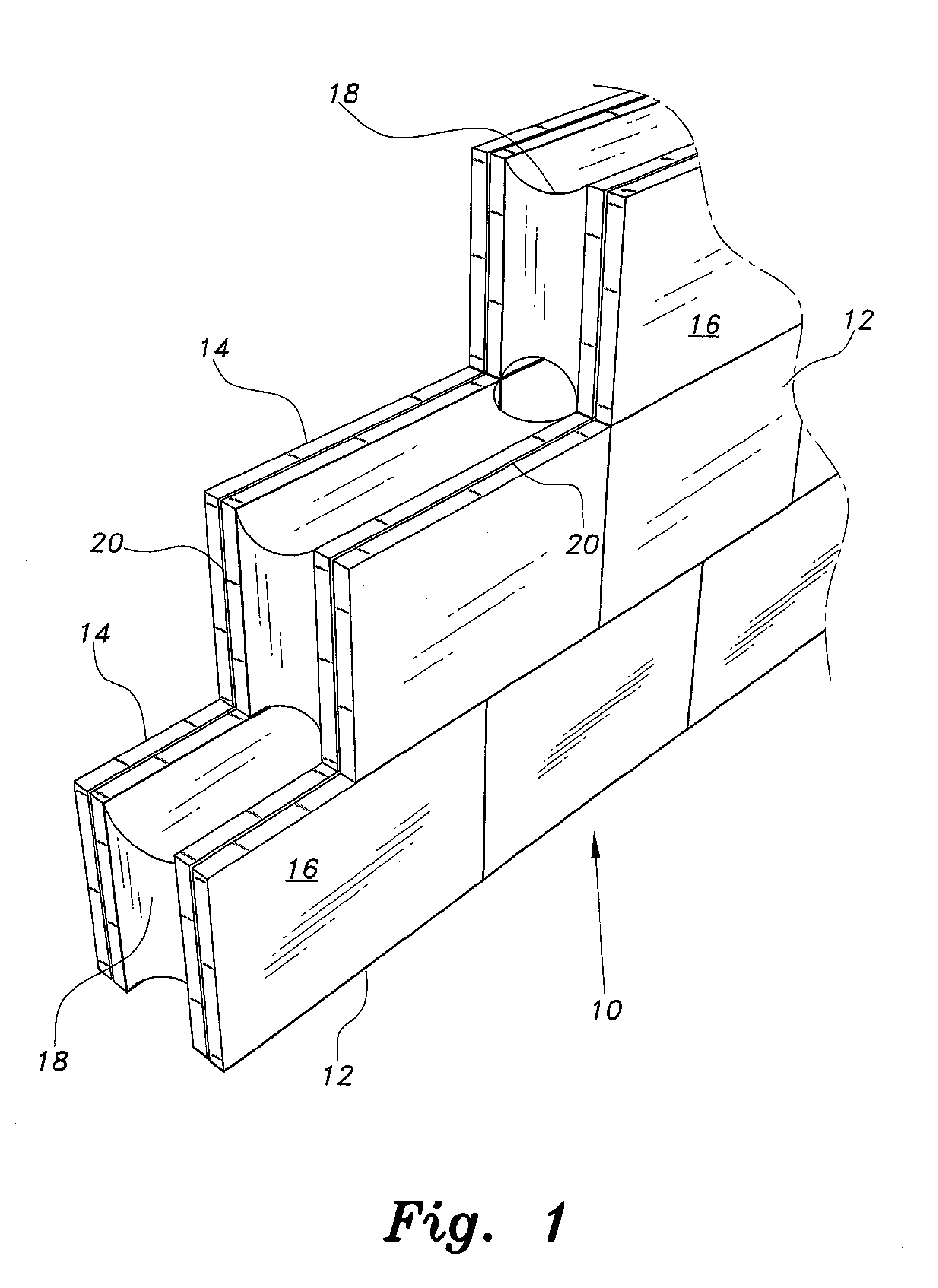

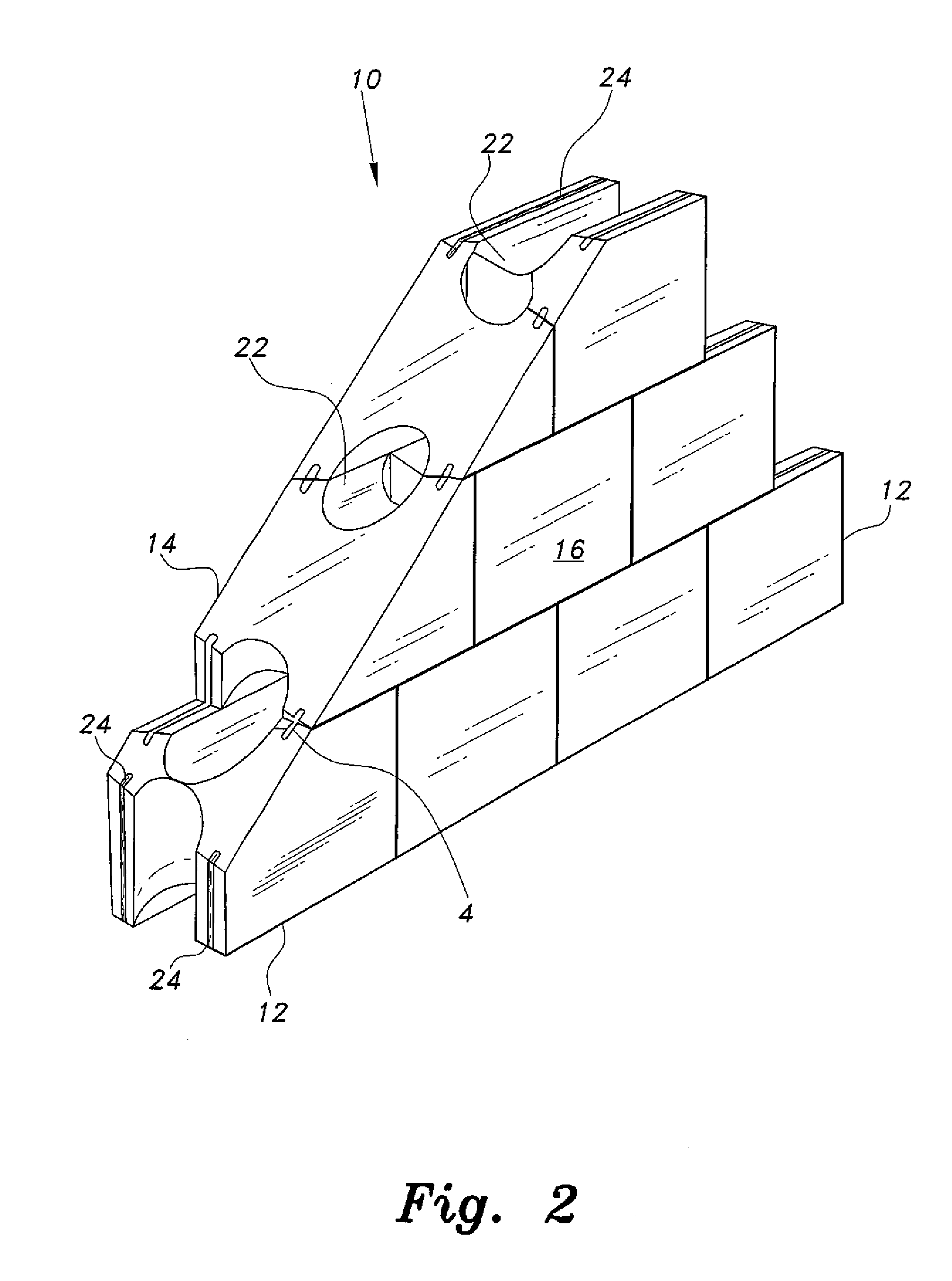

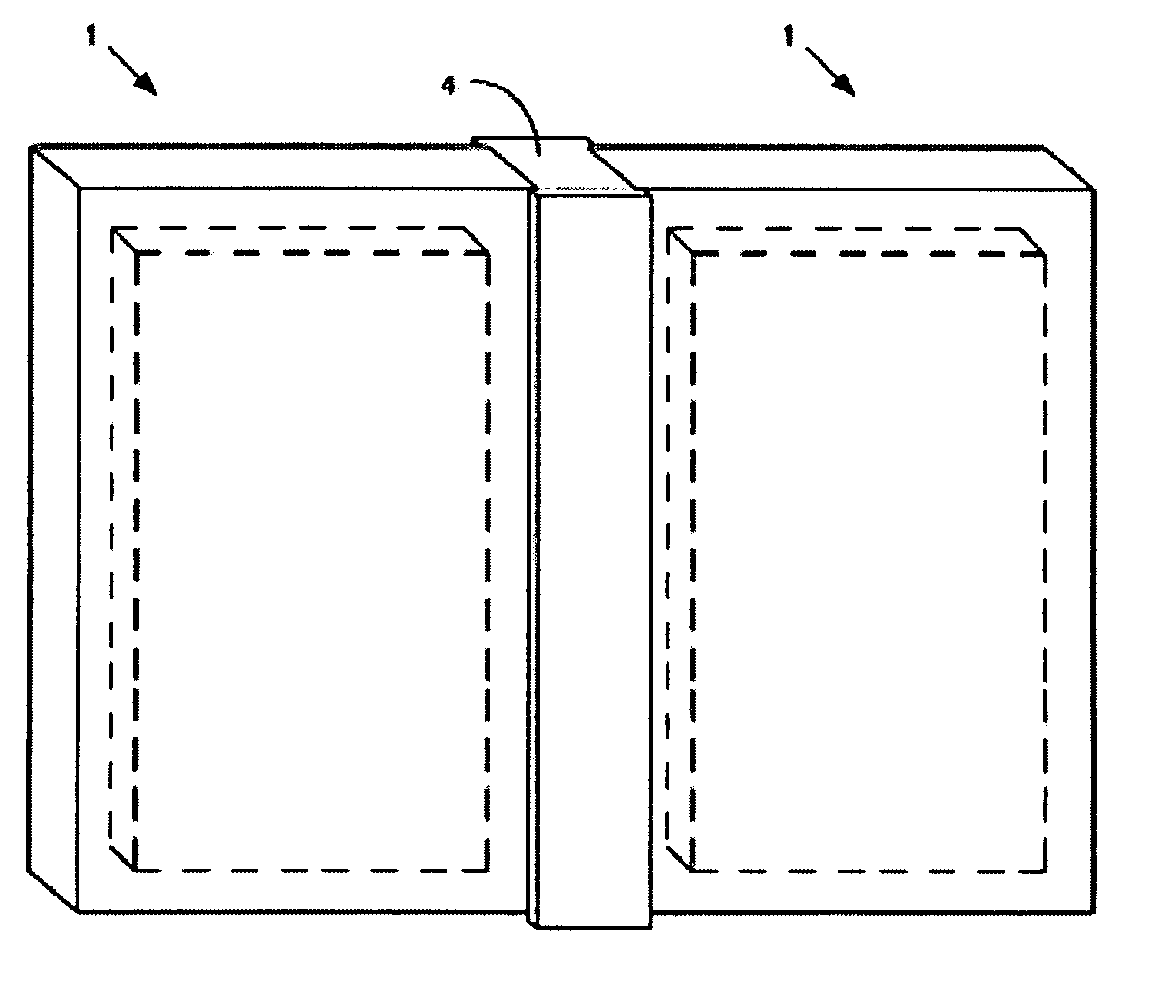

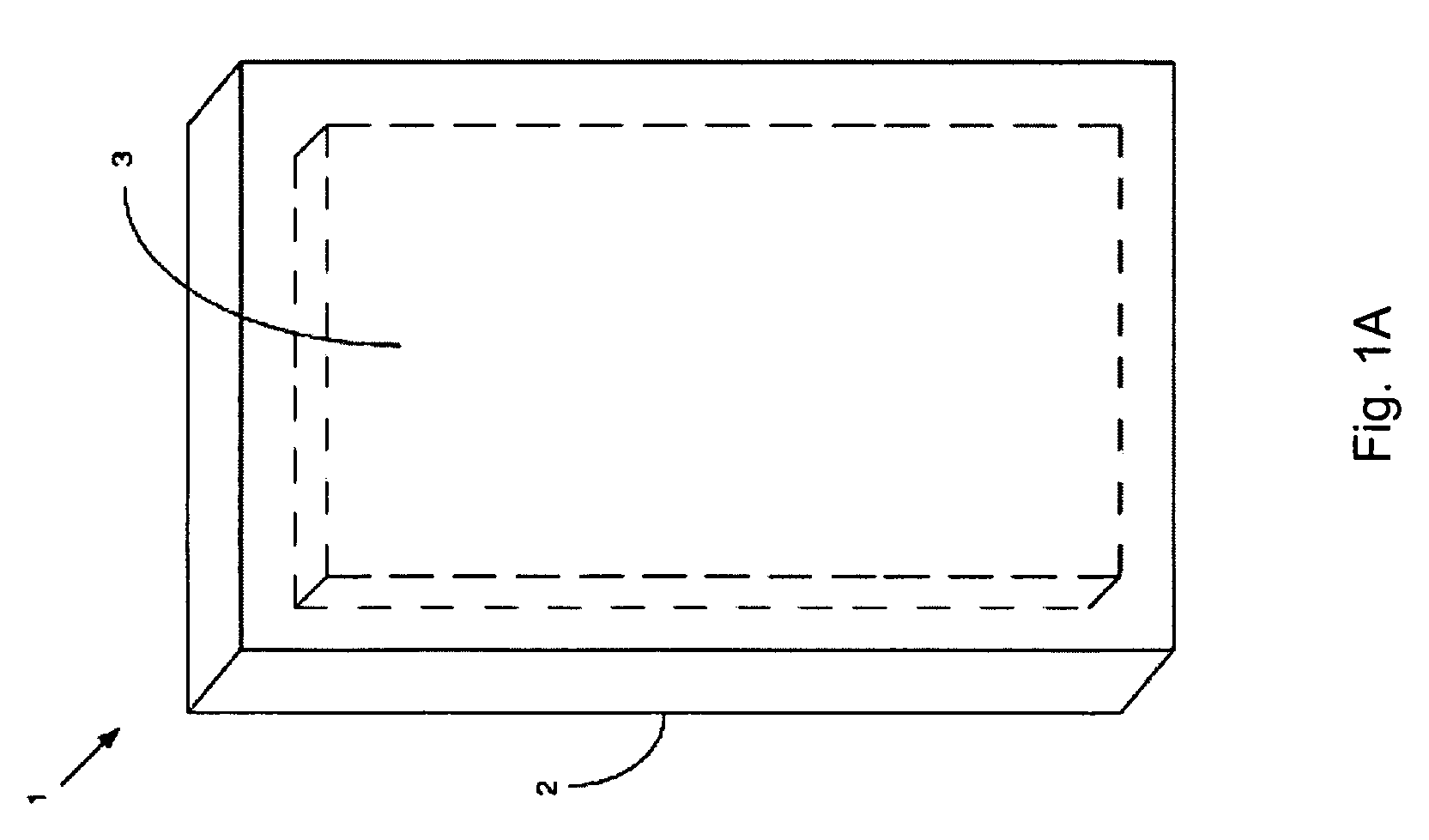

Wall building system and method

InactiveUS8820024B1Efficiently employedImprove stabilityConstruction materialStrutsStructural engineeringUltimate tensile strength

The wall building system and method uses a block for building walls and other structures. The block is formed with an external face member and an internal face member connected by an inner core, which has an outer surface formed with a concave profile. The block is fabricated in one piece to enhance strength and stability. Each face is provided with a continuous groove therearound. The continuous grooves are adapted to receive locking elements therein to interlock the blocks. Utilizing a locking element eliminates the need for binding compounds, such as mortar, thereby greatly reducing labor and material costs.

Owner:ABDULLAH MOHAMMAD A H S H +1

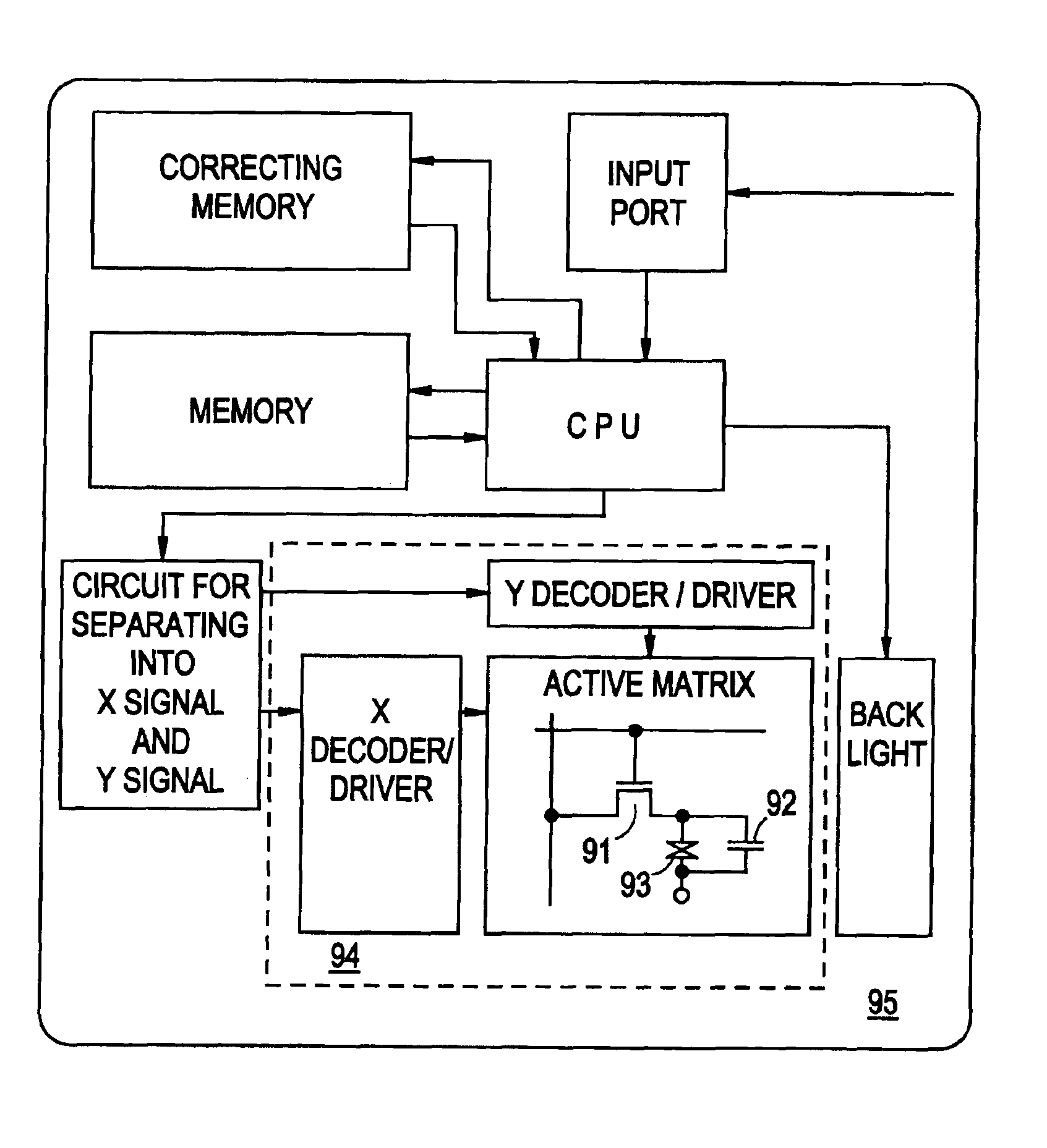

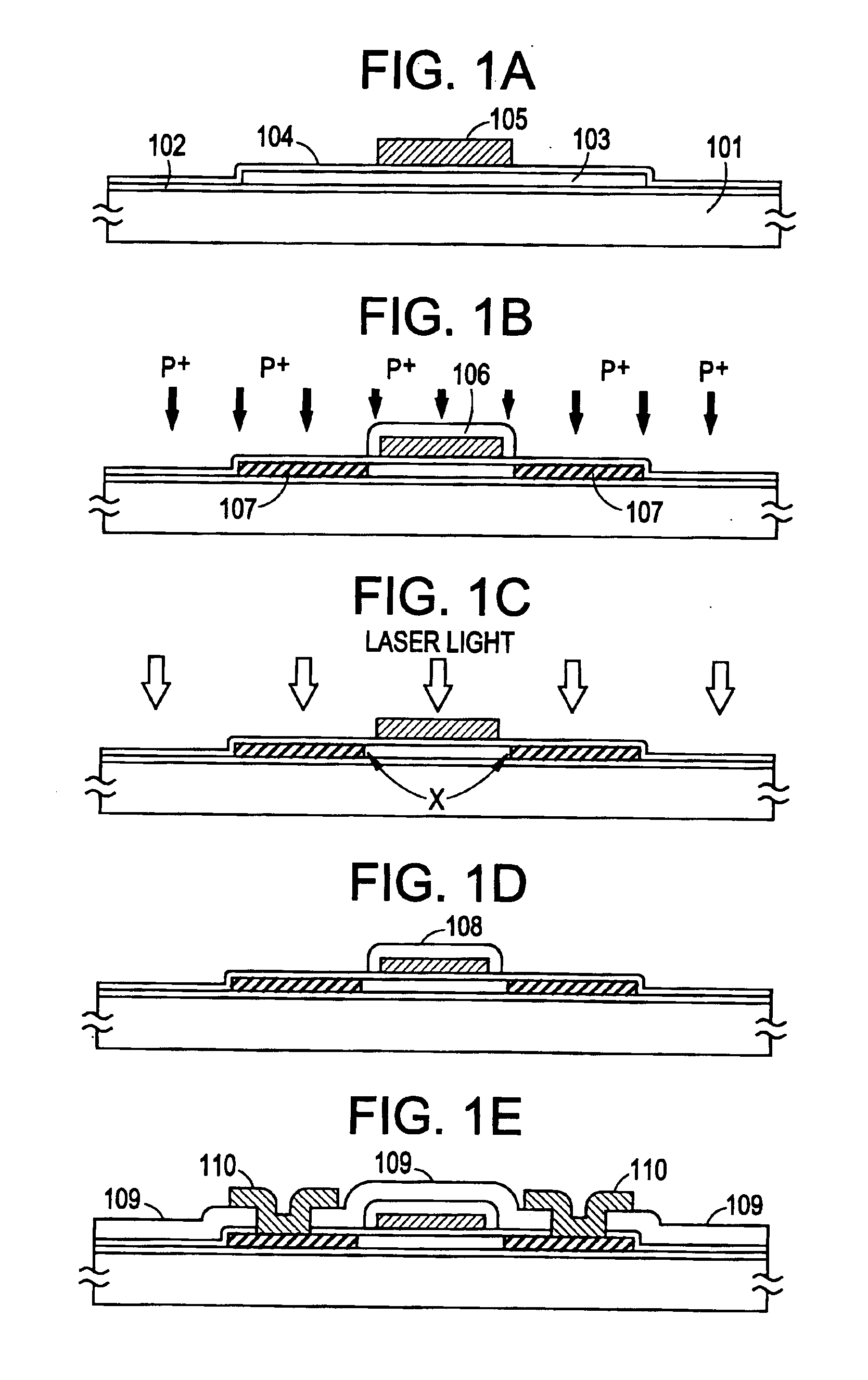

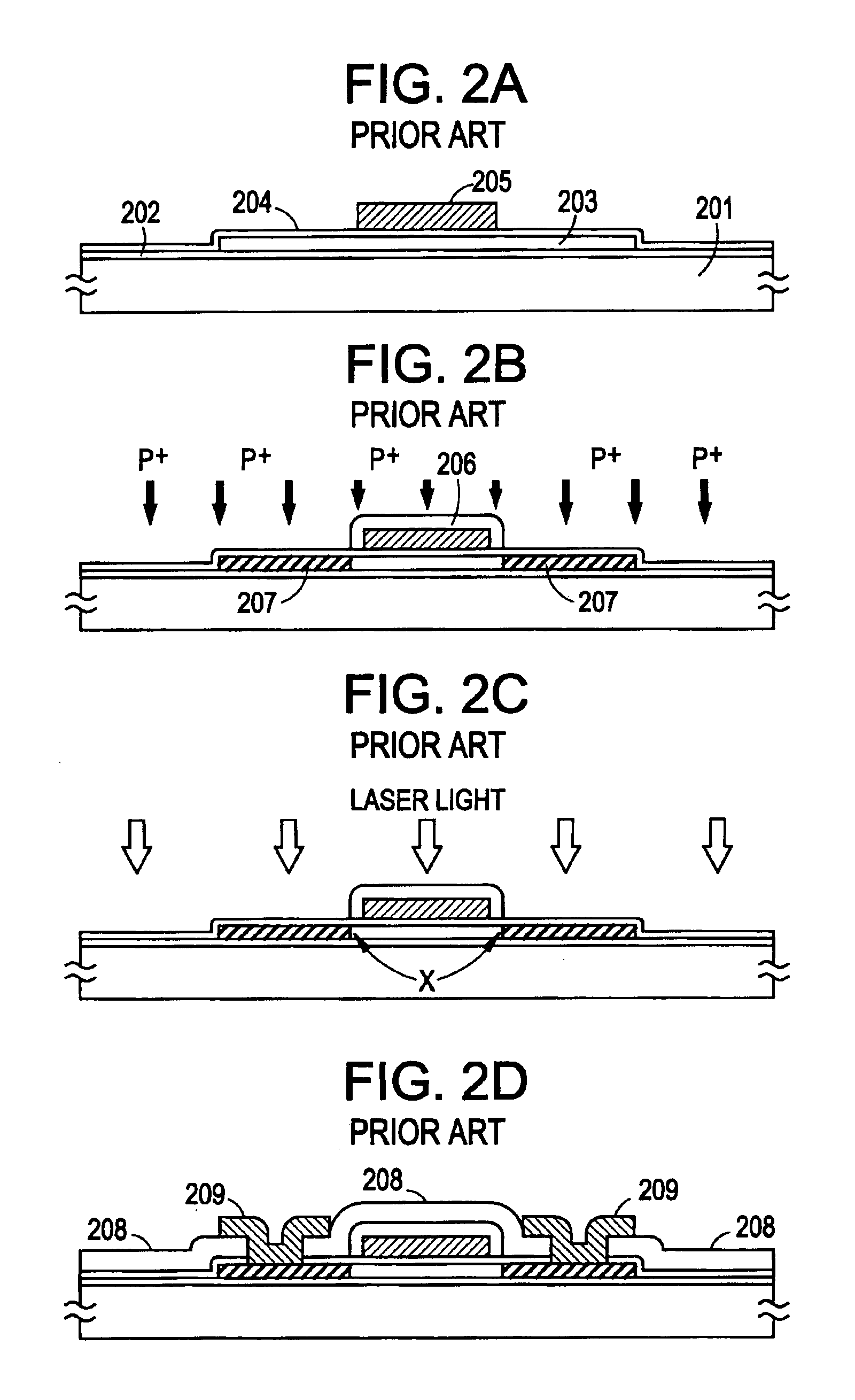

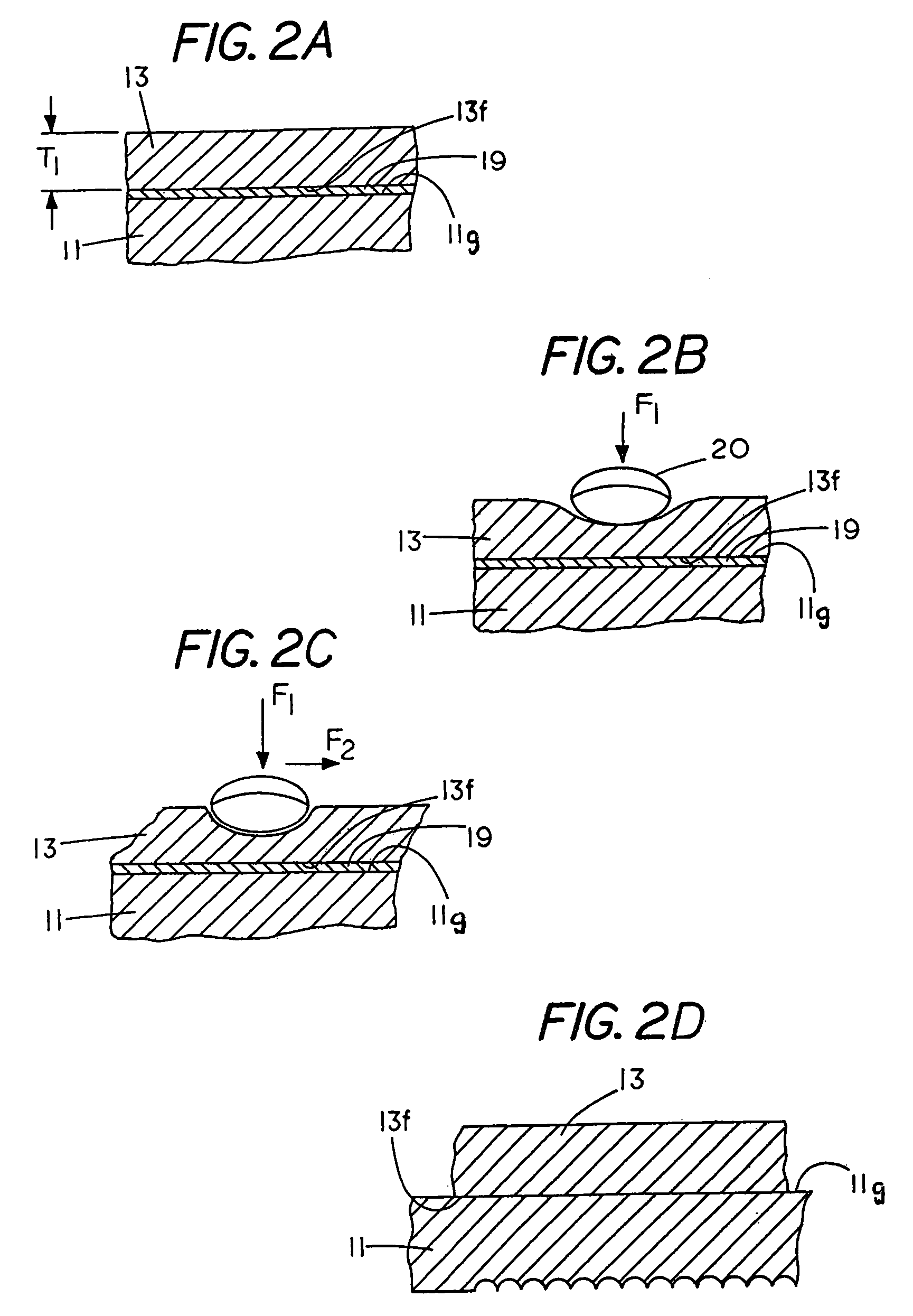

Semiconductor device having a gate oxide film with some NTFTS with LDD regions and no PTFTS with LDD regions

InactiveUS6995432B2Improve insulation qualityReduce couplingTransistorSemiconductor/solid-state device detailsLight beamOptoelectronics

A MIS type semiconductor device and a method for fabricating the same characterized in that impurity regions are selectively formed on a semiconductor substrate or semiconductor thin film and are activated by radiating laser beams or a strong light equivalent thereto from above so that the laser beams or the equivalent strong light are radiated onto the impurity regions and on an boundary between the impurity region and an active region adjoining the impurity region.

Owner:SEMICON ENERGY LAB CO LTD

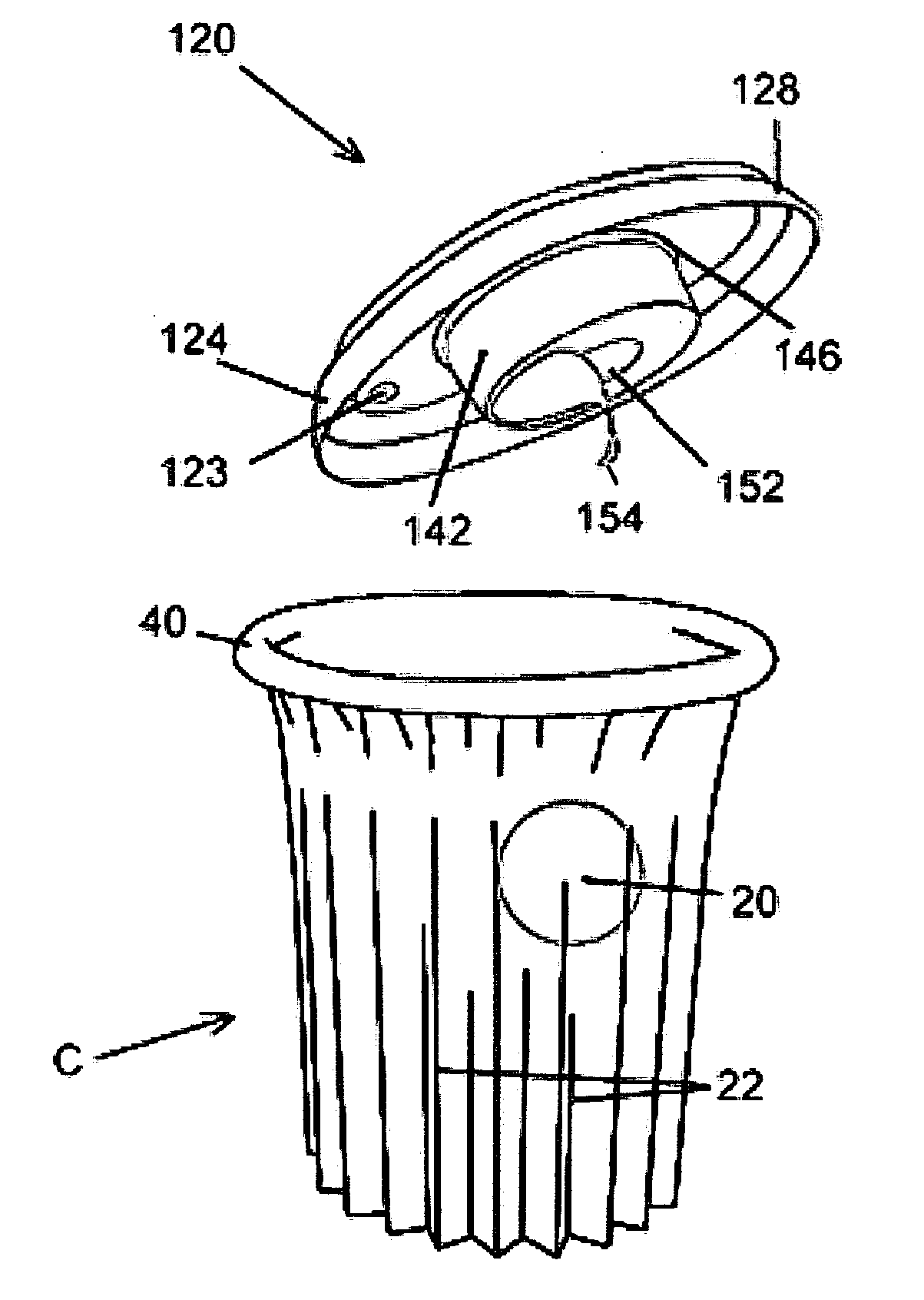

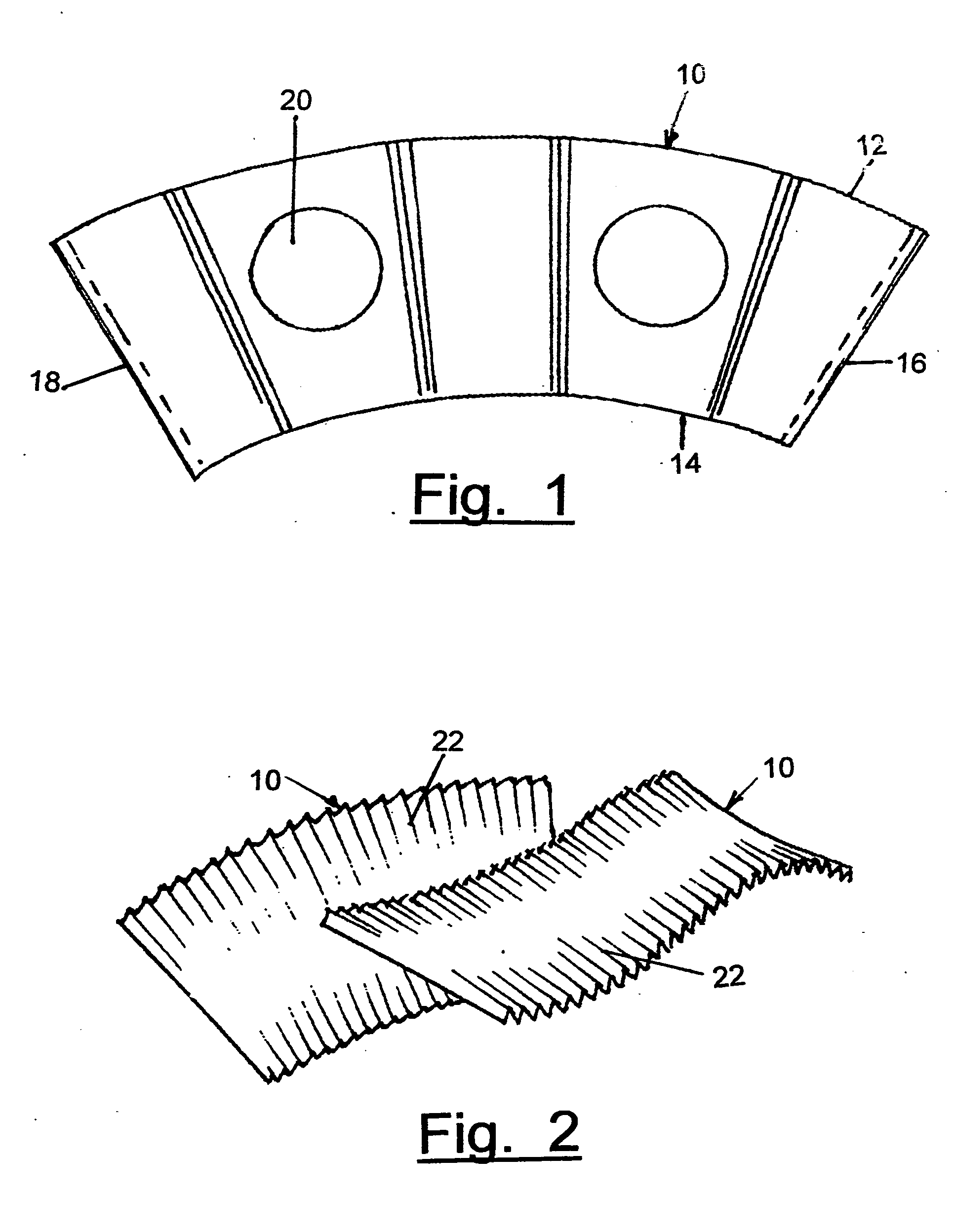

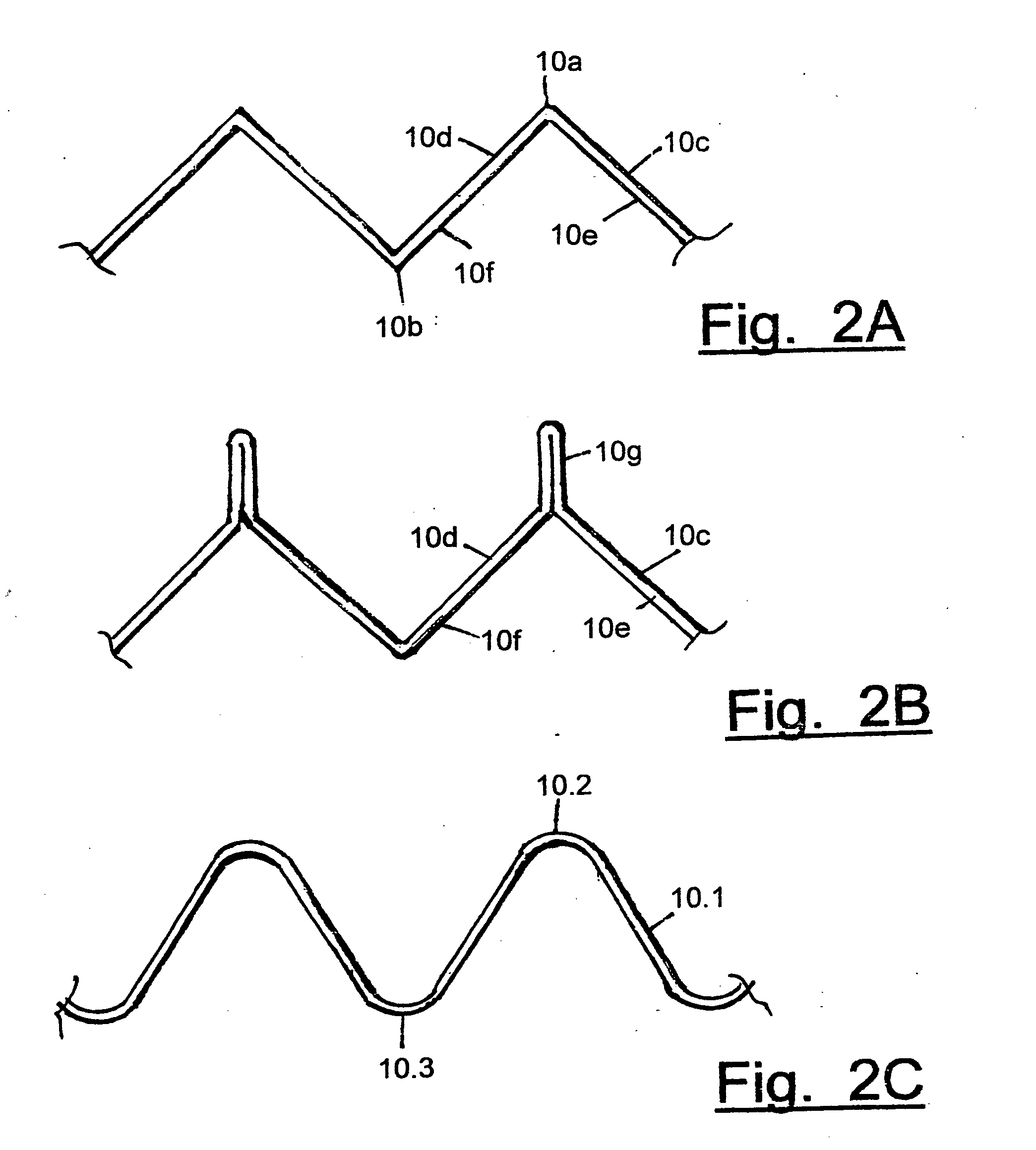

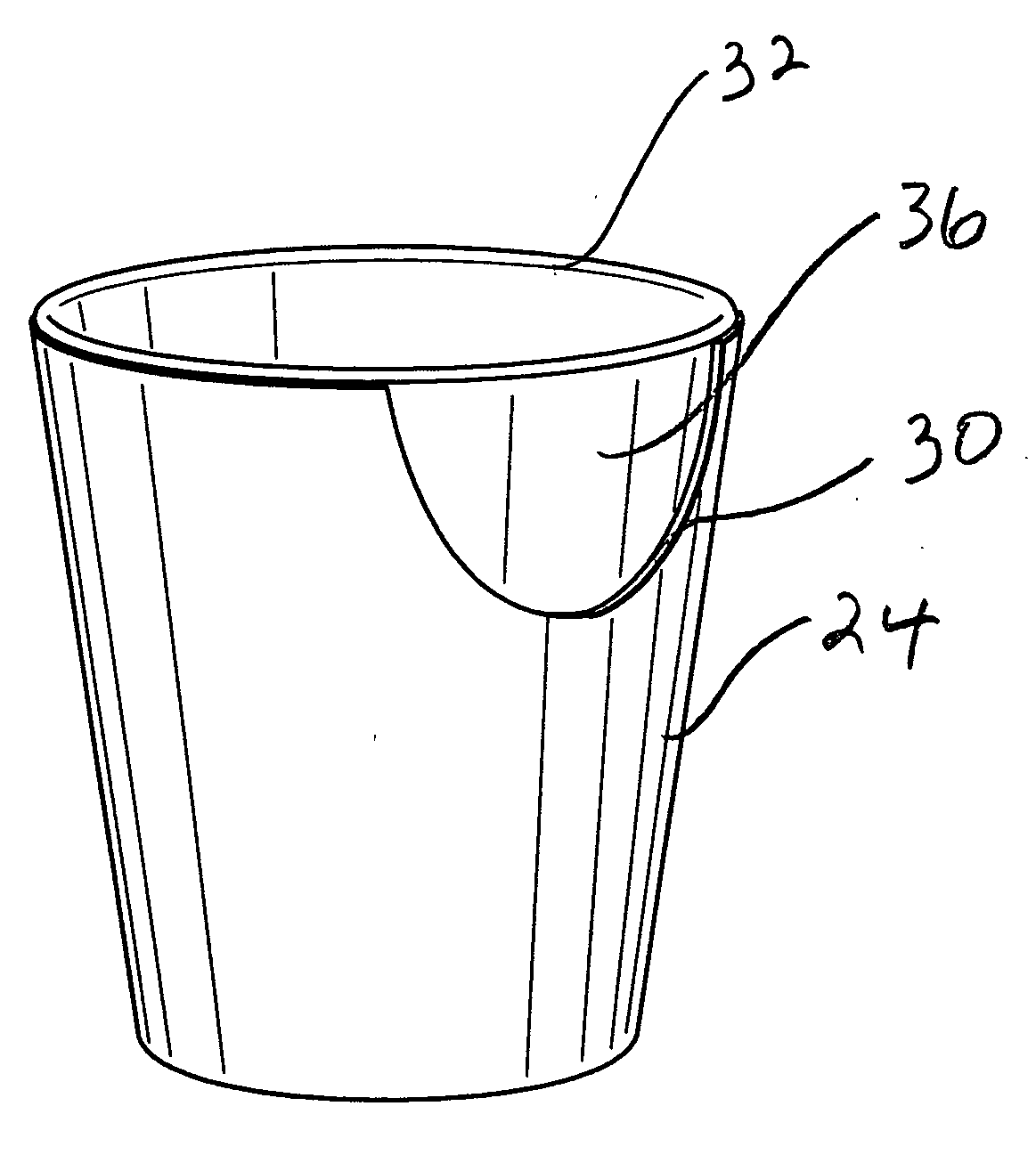

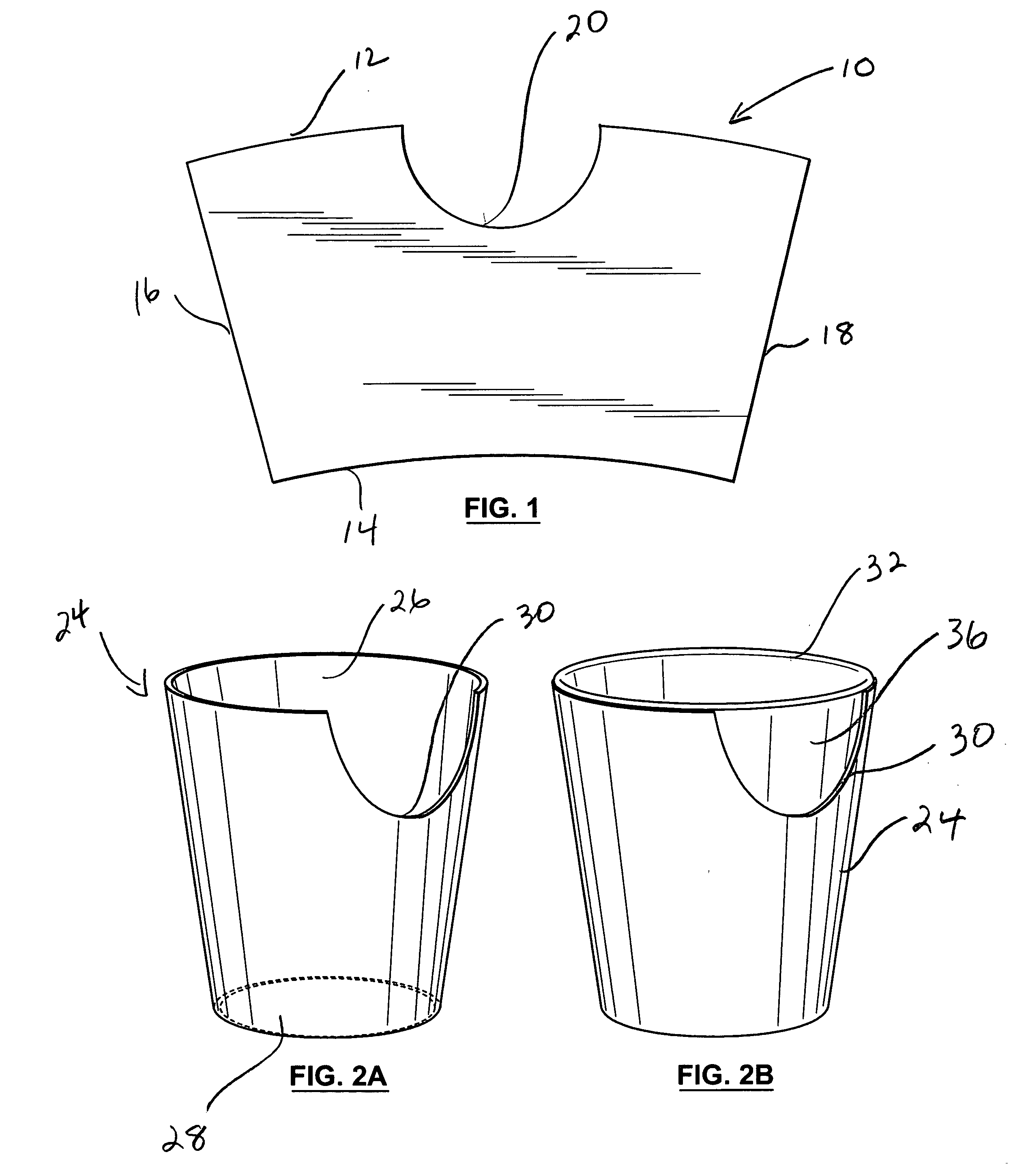

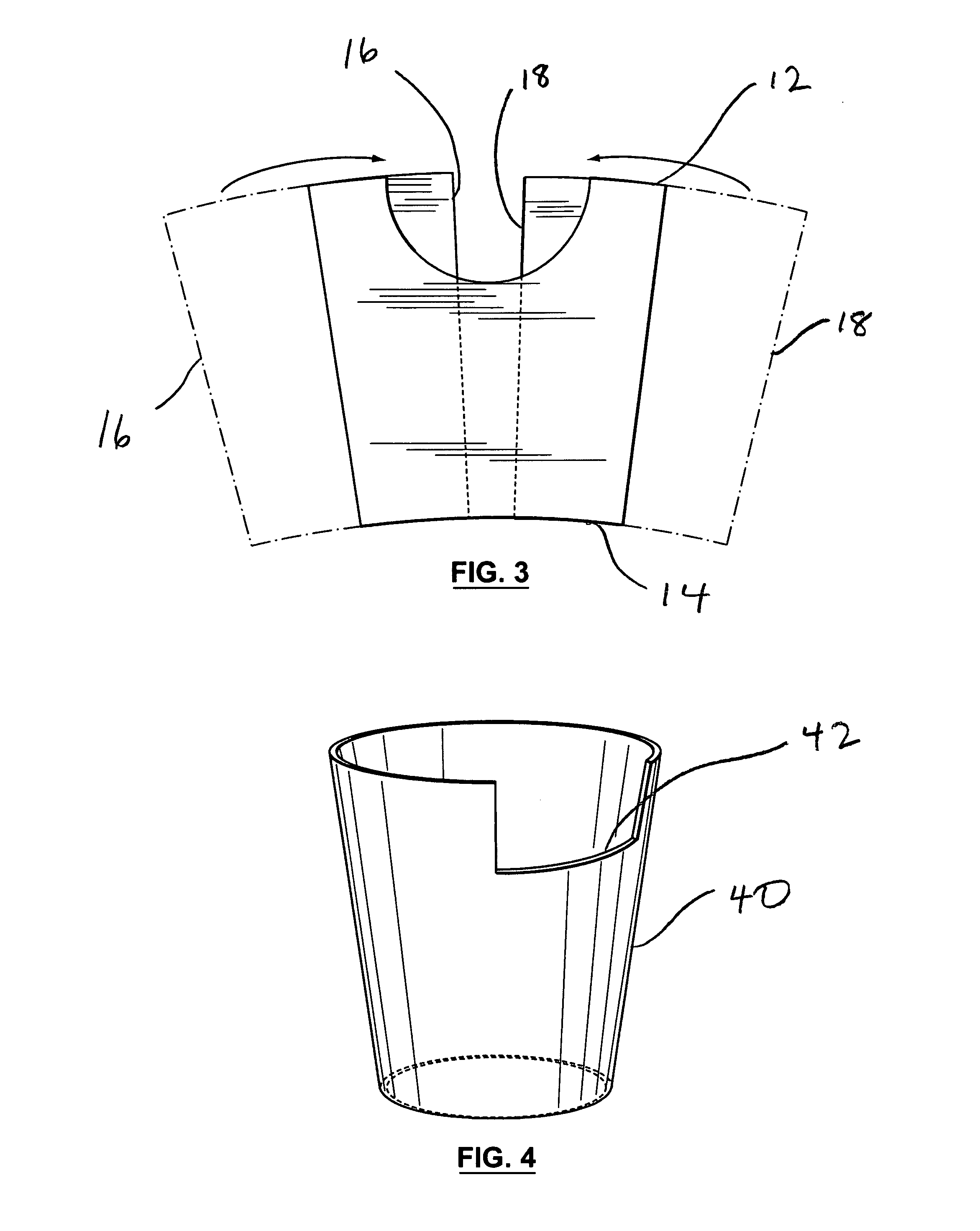

Disposable paper cups, method of making, and handling of such cups

InactiveUS20050269390A1Improve insulation qualitySmall surface areaDomestic cooling apparatusLighting and heating apparatusCard stockTrademark

There are now provided disposable paper cups, method of making, and handling of such cups. The cup may comprise a pleated disposable paper cup with a zigzag shaped, pleated cylindrical body, an open top and closed bottom. The cup may be constructed of a paper card stock evenly folded to create parallel pleats that serve to decrease the energy transfer between hot or cold beverages contained in the cup and a user's hand, enabling the user to hold onto the container for an extended period of time without pain or discomfort. The application further relates to an arrangement configured to prepare a personalized brew of coffee or the like, with a lid that can be punctured to flow hot liquid over a material configured to make a drink and into a disposable cup. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, the abstract is not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:MARTIN CONRAD D

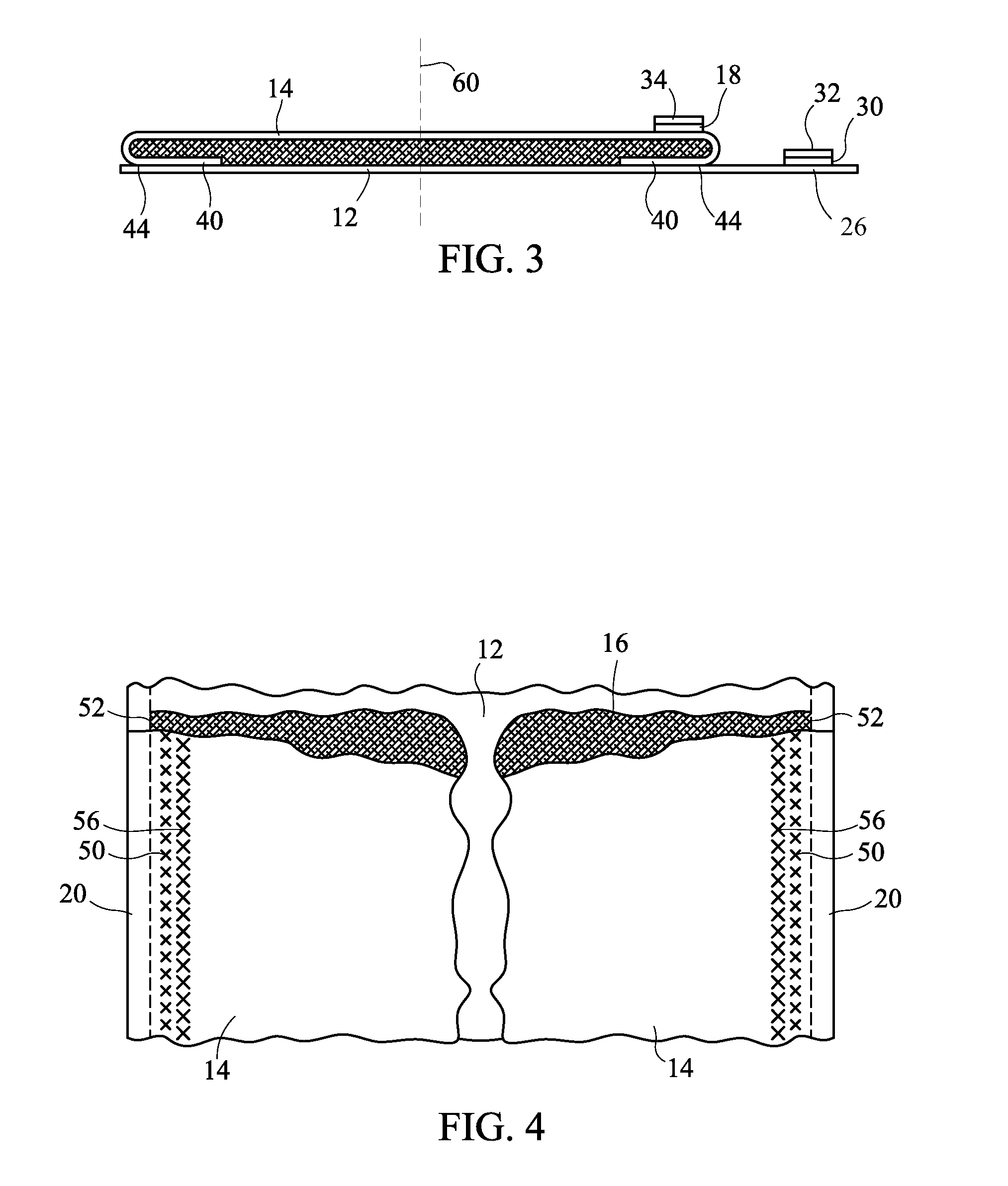

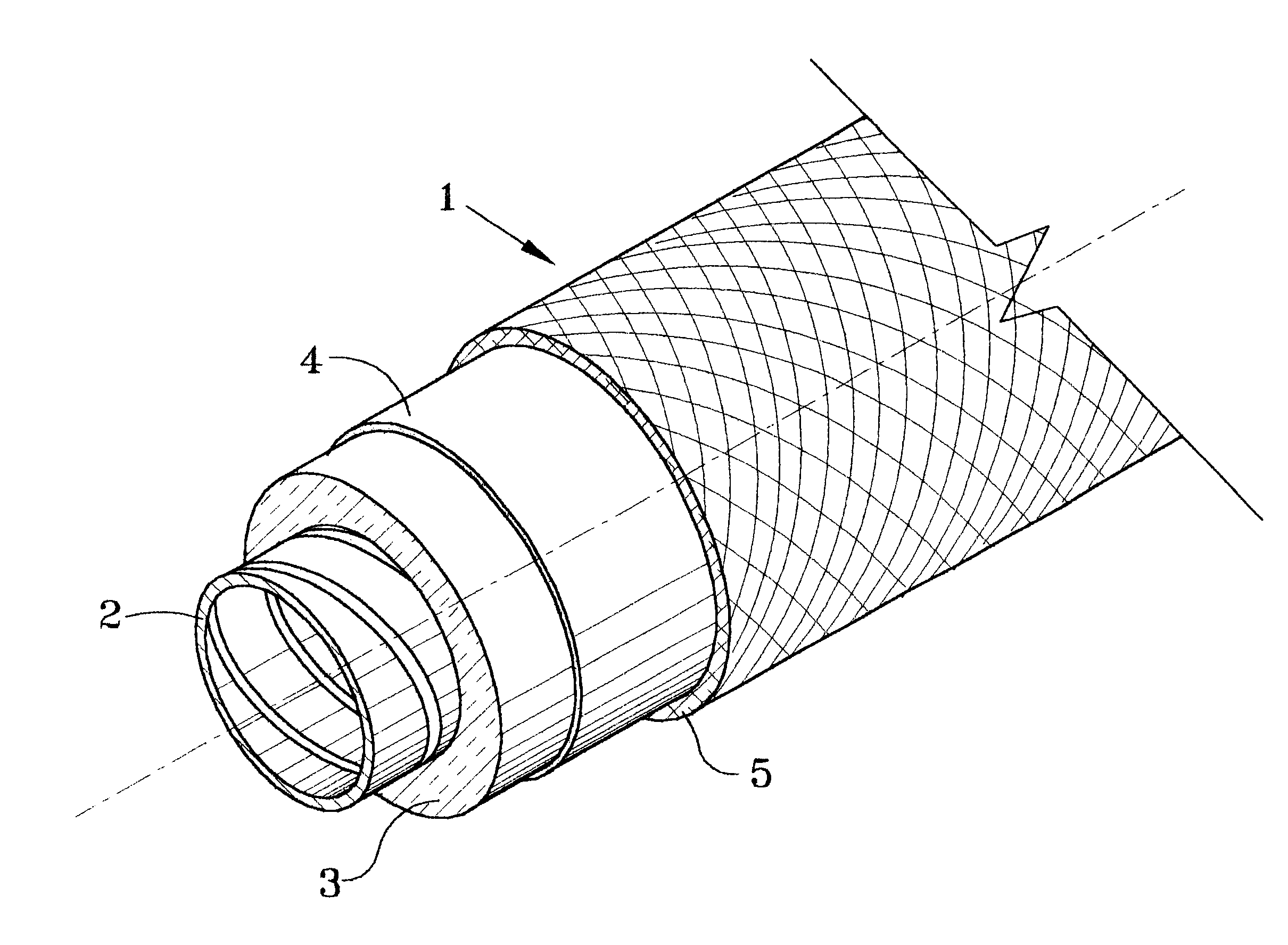

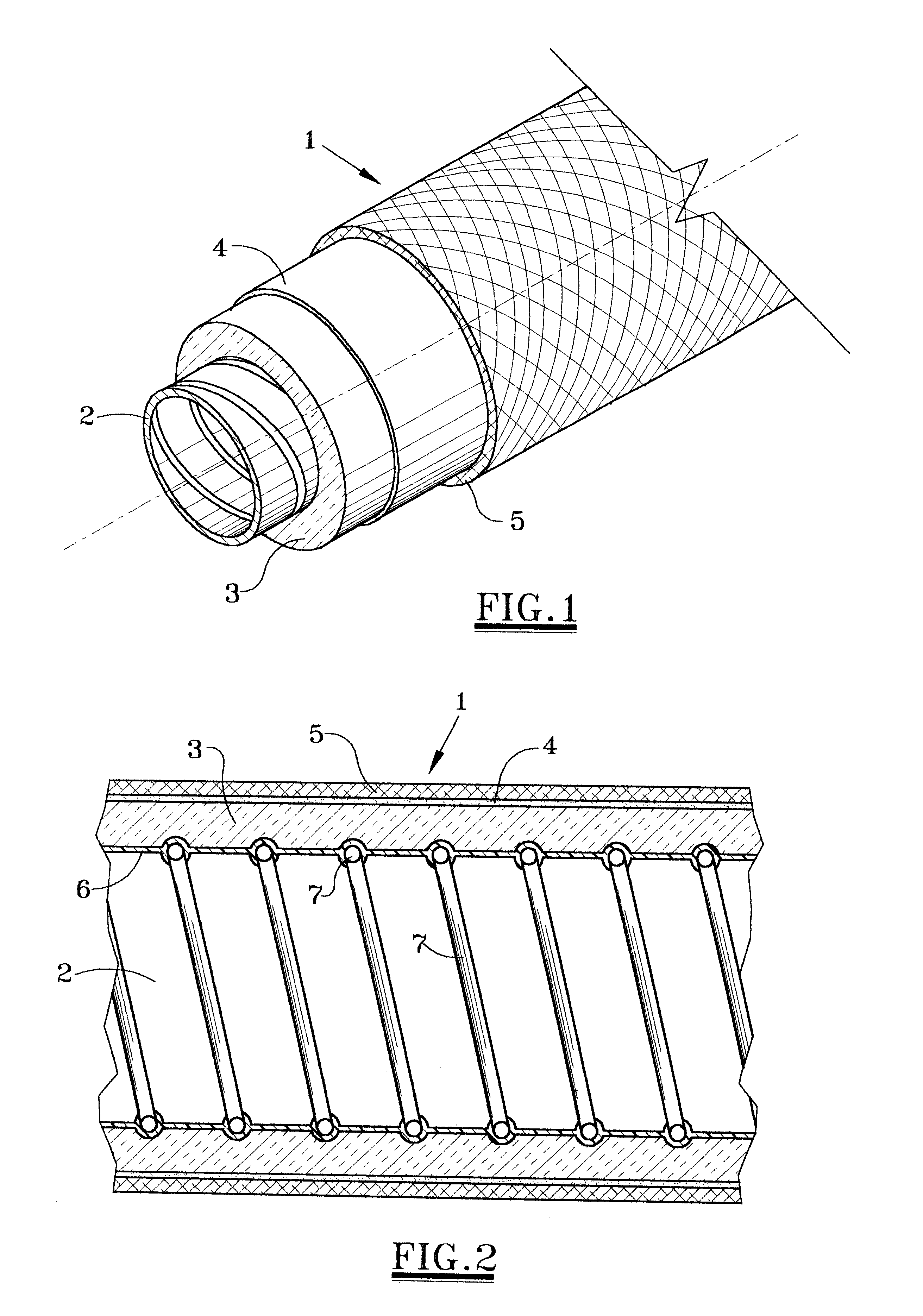

Flexible air ducting

InactiveUS6425419B1Improve insulation performanceEliminate riskLighting and heating apparatusFlexible pipesAdhesiveEngineering

Composite flexible air ducting comprising an elongated inner lining of plastic reinforced by a spirally wound coil member providing an elongated continuous air passage; a layer of natural fiber insulation surrounding the inner lining and an outer sheath surrounding the layer of natural fiber insulation. The outer sheath and the layer of fiber insulation are bonded to each other by a layer of adhesive having substantial thermal insulating properties.

Owner:ATTRA SHARON L

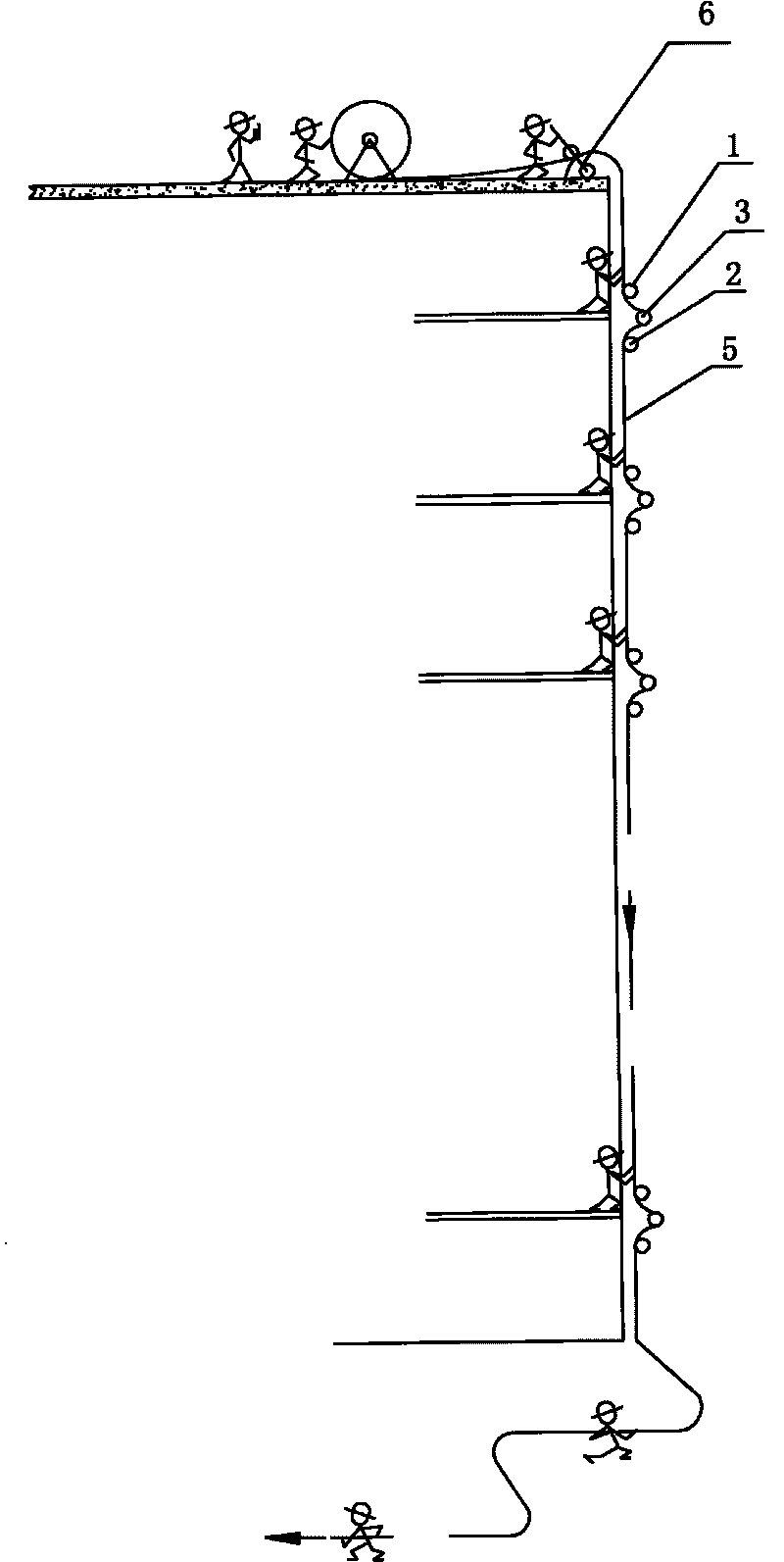

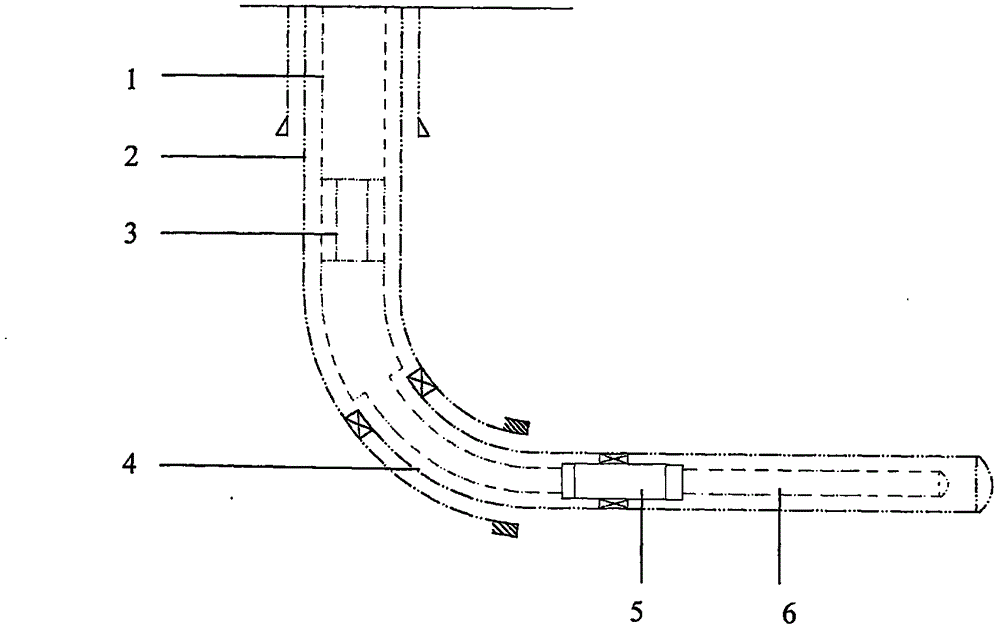

Method for laying vertical cables for extra-high building

InactiveCN101728790AImprove insulation qualityEasy to controlApparatus for laying cablesHigh riseGravitation

The invention discloses a method for laying vertical cables for extra-high buildings. A whole roll of cables is lifted to a high-rise floor, the cables are laid from top to bottom by using high-level potential, and the gravity acceleration caused by a put-down process is overcome by using damp retarders which are arranged in sections so that the effect is safe and rapid, and the insulation quality of the cables is sound. The time spent for putting each cable from the highest point to an underground is 7-8 minutes according to comprehensive calculation, and the put-down speed of the cable is stable with desired control, and only 20 operation staffs are needed to lay the vertical cables in more than 60 layers of vertical cable wells so as to save the labor forces. The invention solves the technical problem of laying the vertical cables of the extra-high buildings, thereby having the advantages of safety, rapidness, labor-saving, material-saving, obvious economic effect and wide promotion use value on the laying of the vertical cables of high buildings and extra-high buildings, and simultaneously ensuring the sound insulation quality of the cables.

Owner:GUANGDONG IND EQUIP INSTALLATION

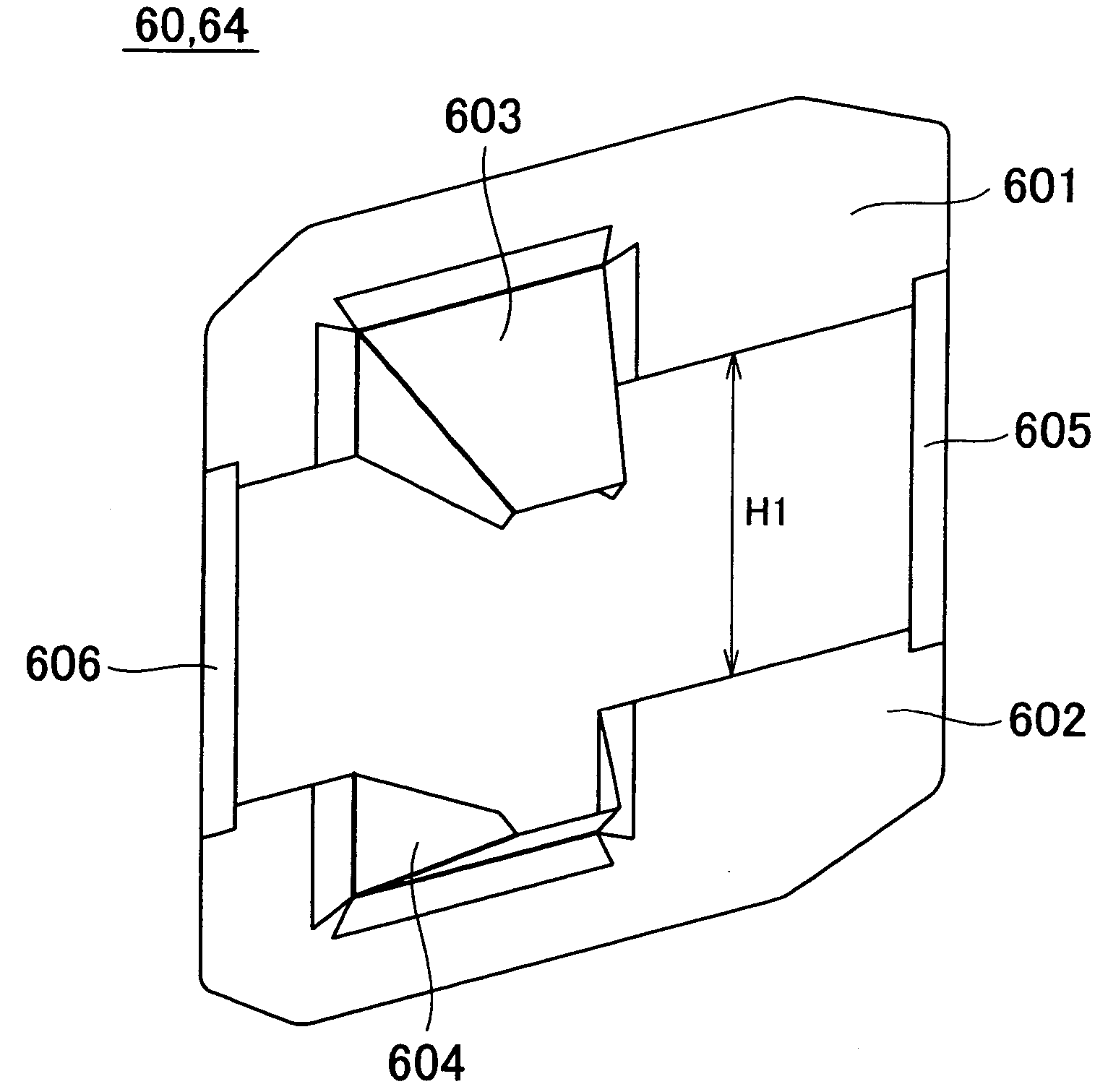

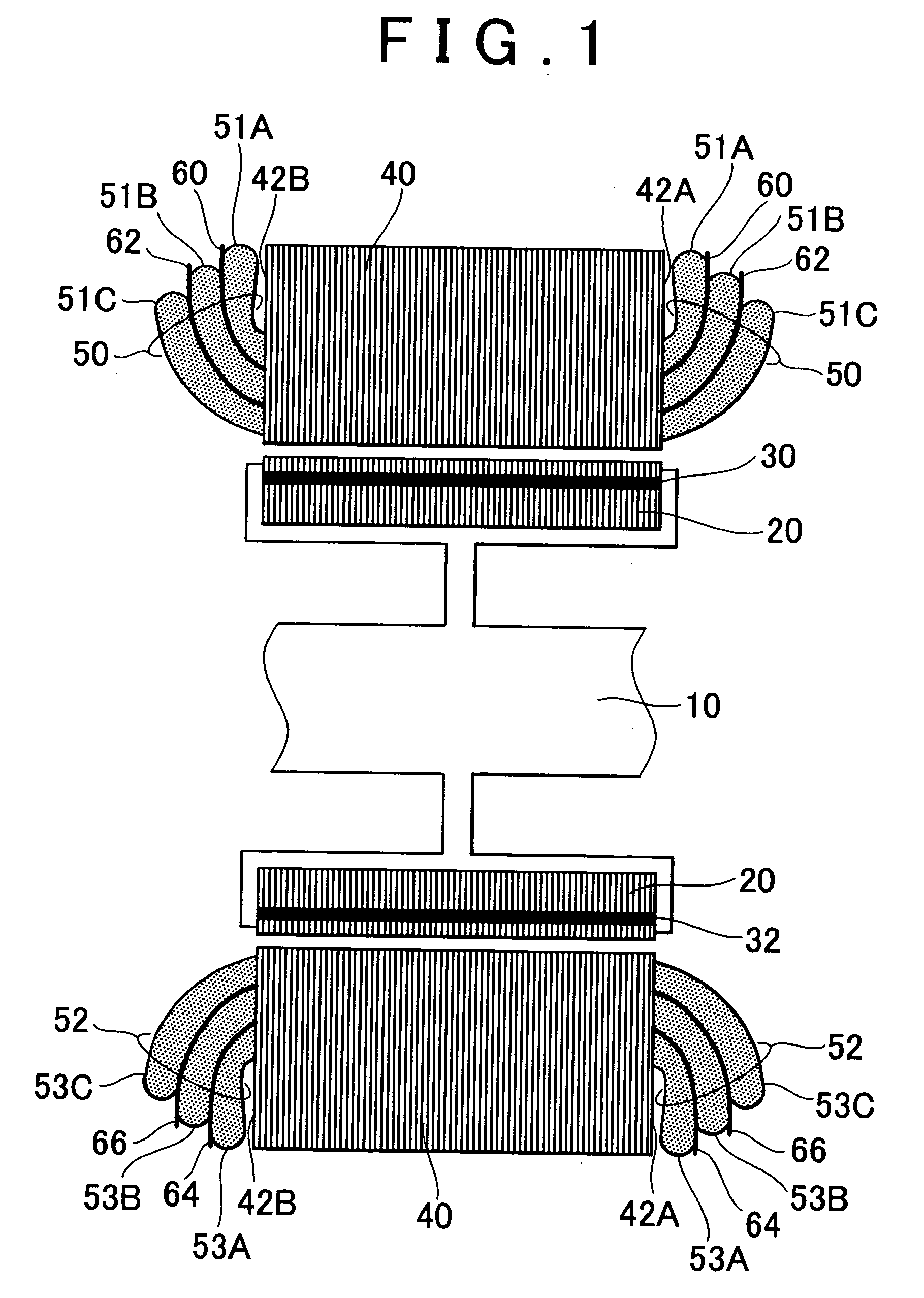

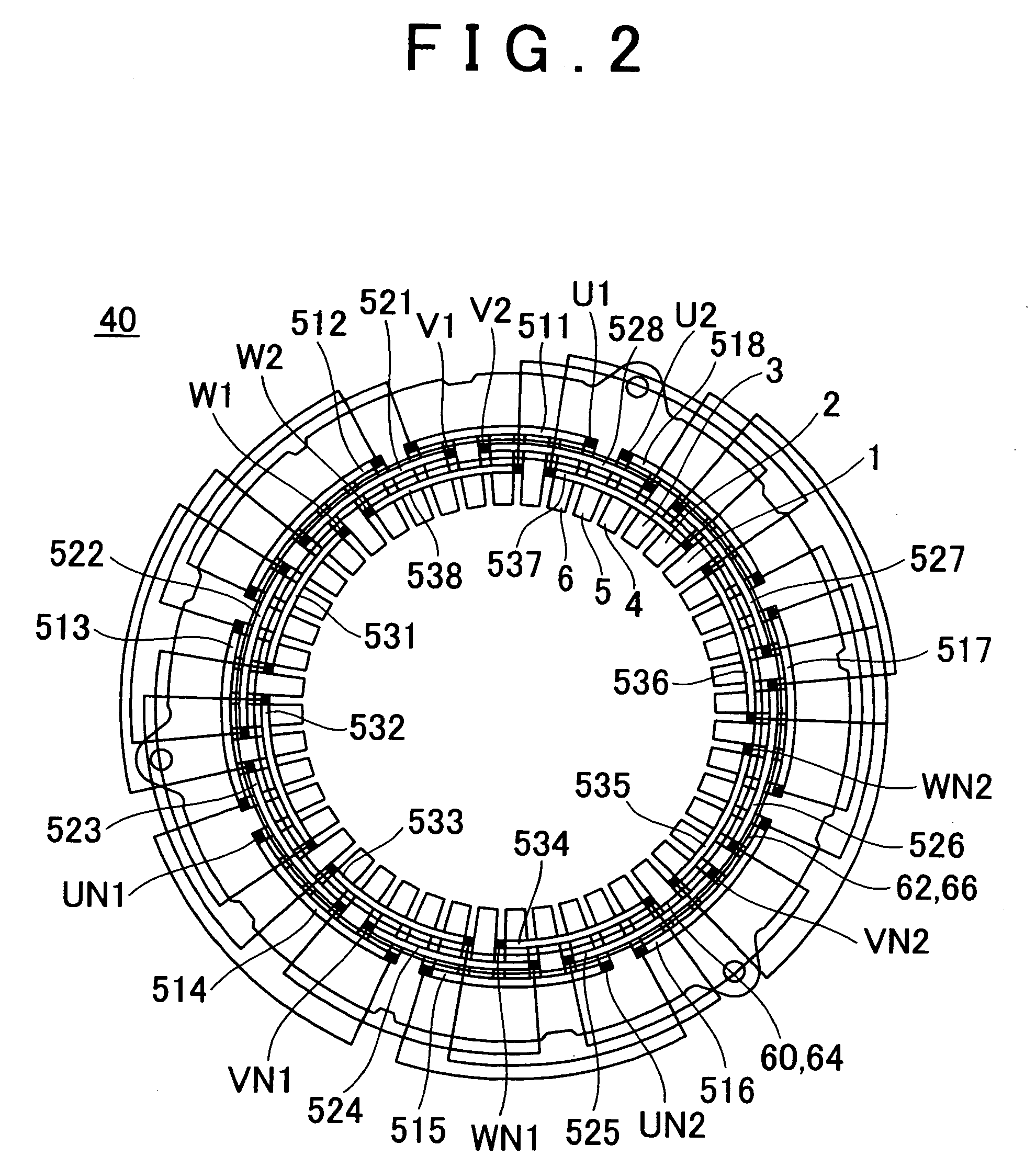

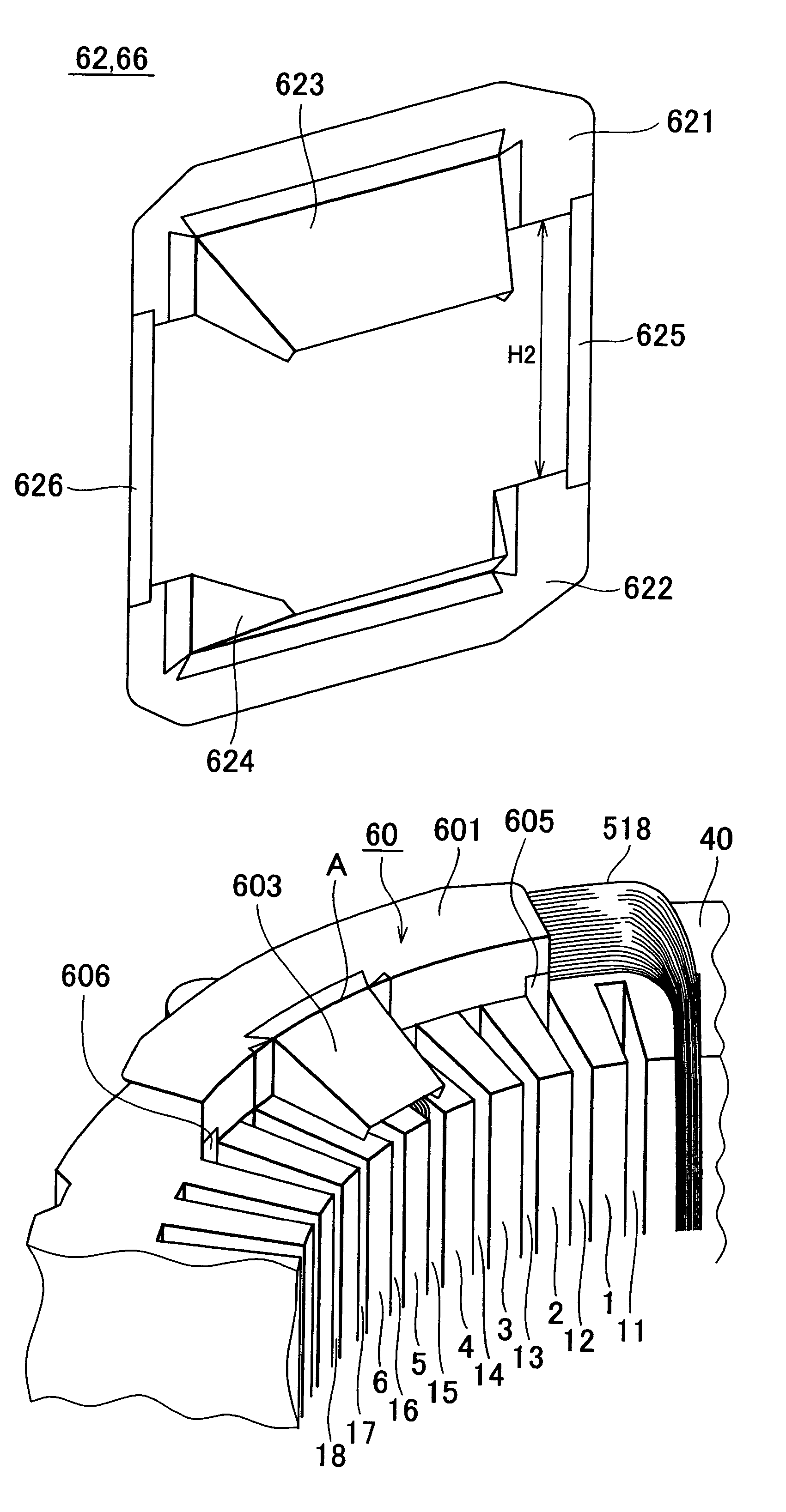

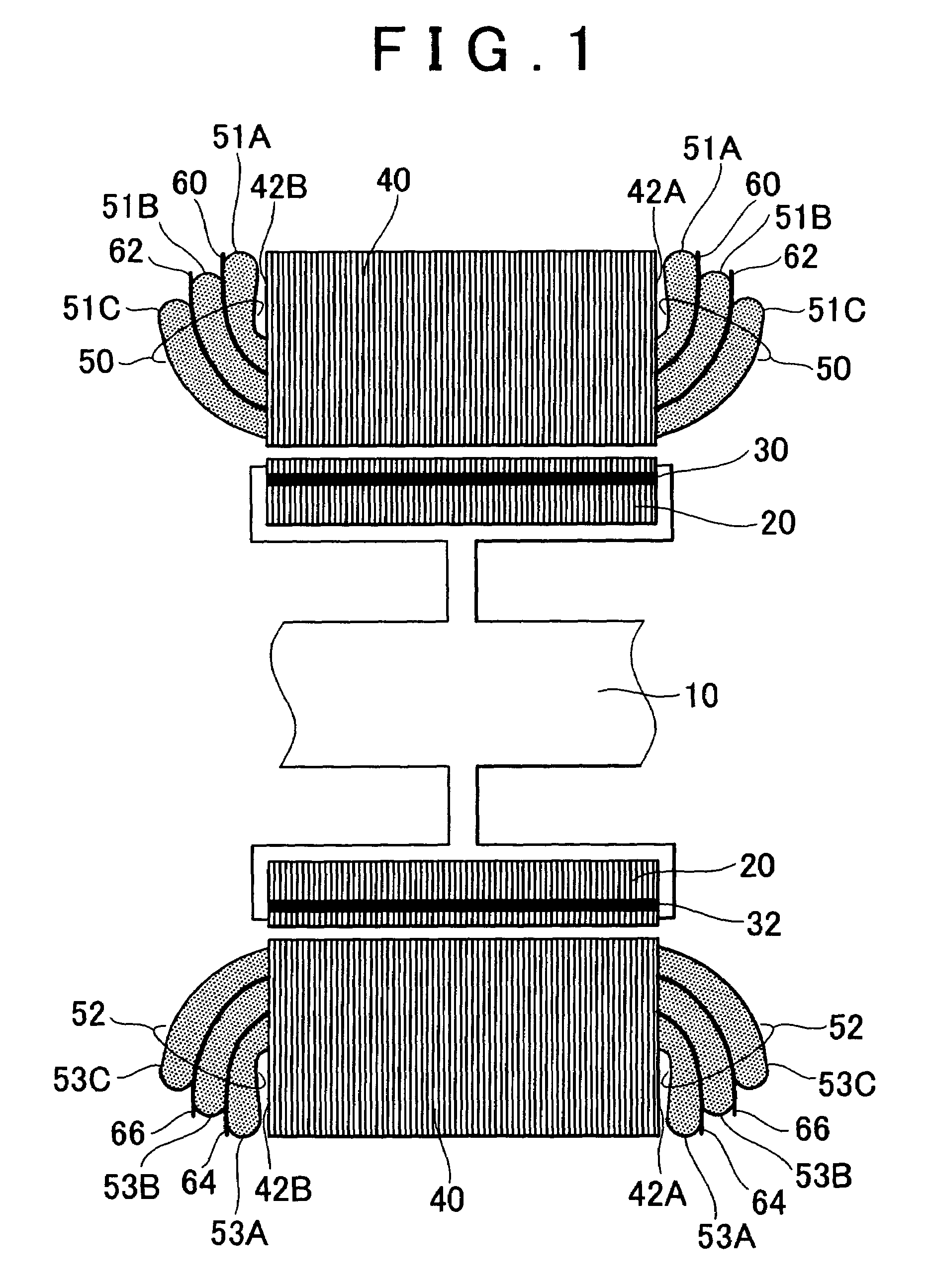

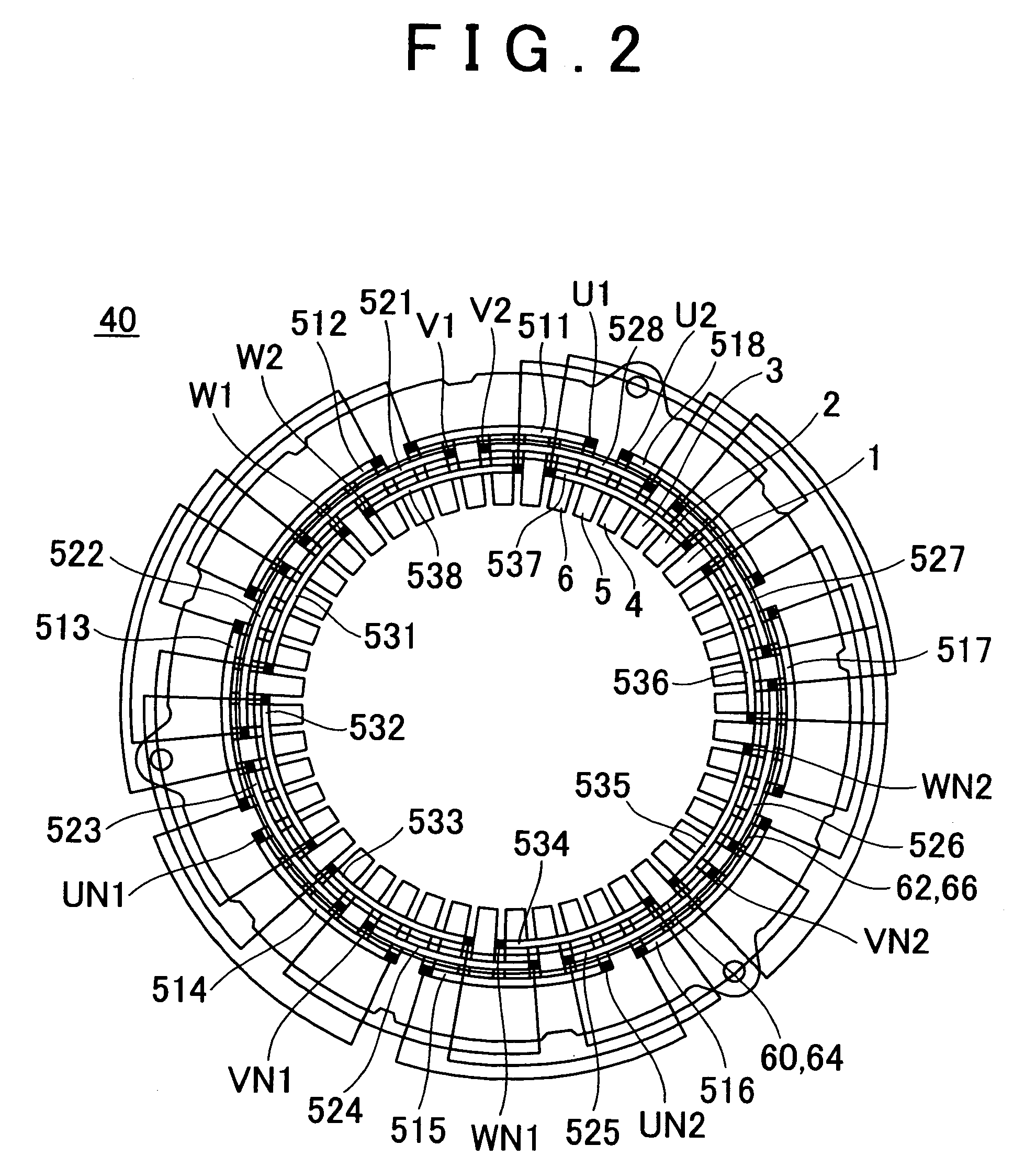

Phase insulation paper and electric motor provided with phase insulation paper

ActiveUS20050168097A1High strengthImprove insulation qualityWindings insulation materialWindings insulation shape/form/constructionStator coilElectric motor

Three-dimensional portions are made of the same PET resin as are flat portions, only thicker. That is, the three-dimensional portions are more rigid than the flat portions. The three-dimensional portions are bonded to the flat portions at cutout portions thereof by a thermo-compression sheet or adhesive tape or the like. Connecting portions are made of PET resin that is thinner than the PET resin of which the flat portions are made. A phase insulation paper is provided in which the connecting portions are bonded at both ends to the flat portions, and an electric motor is provided in which the phase insulation paper is inserted between stator coils.

Owner:TOYOTA JIDOSHA KK

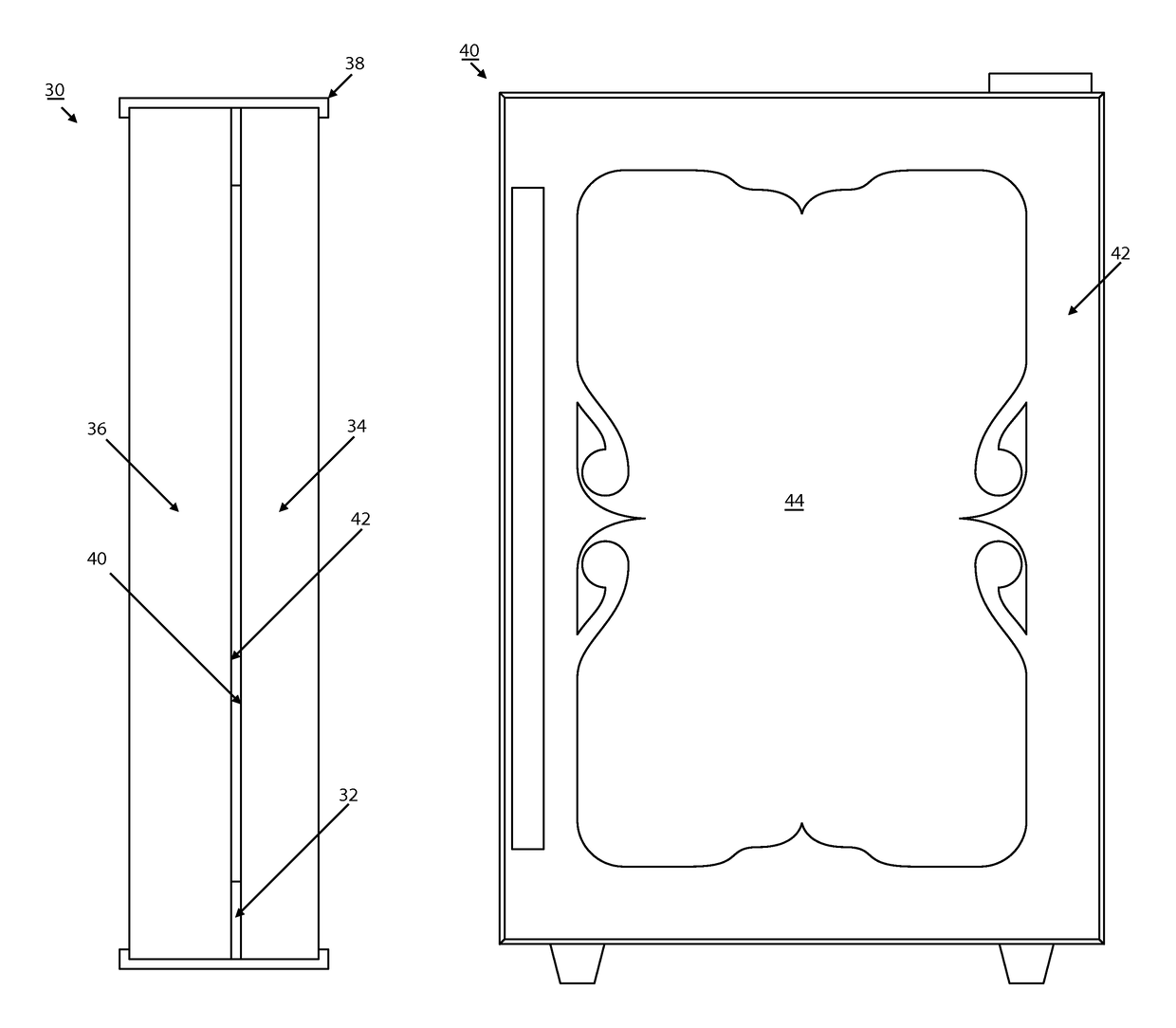

Beverage container holder

A holder for a coated paper cup is provided. The holder is made from a stretch material that has good insulating properties, such as neoprene. The holder has an open top end and an open bottom end and is tapered to fit a cup.

Owner:DEXEL DAN +2

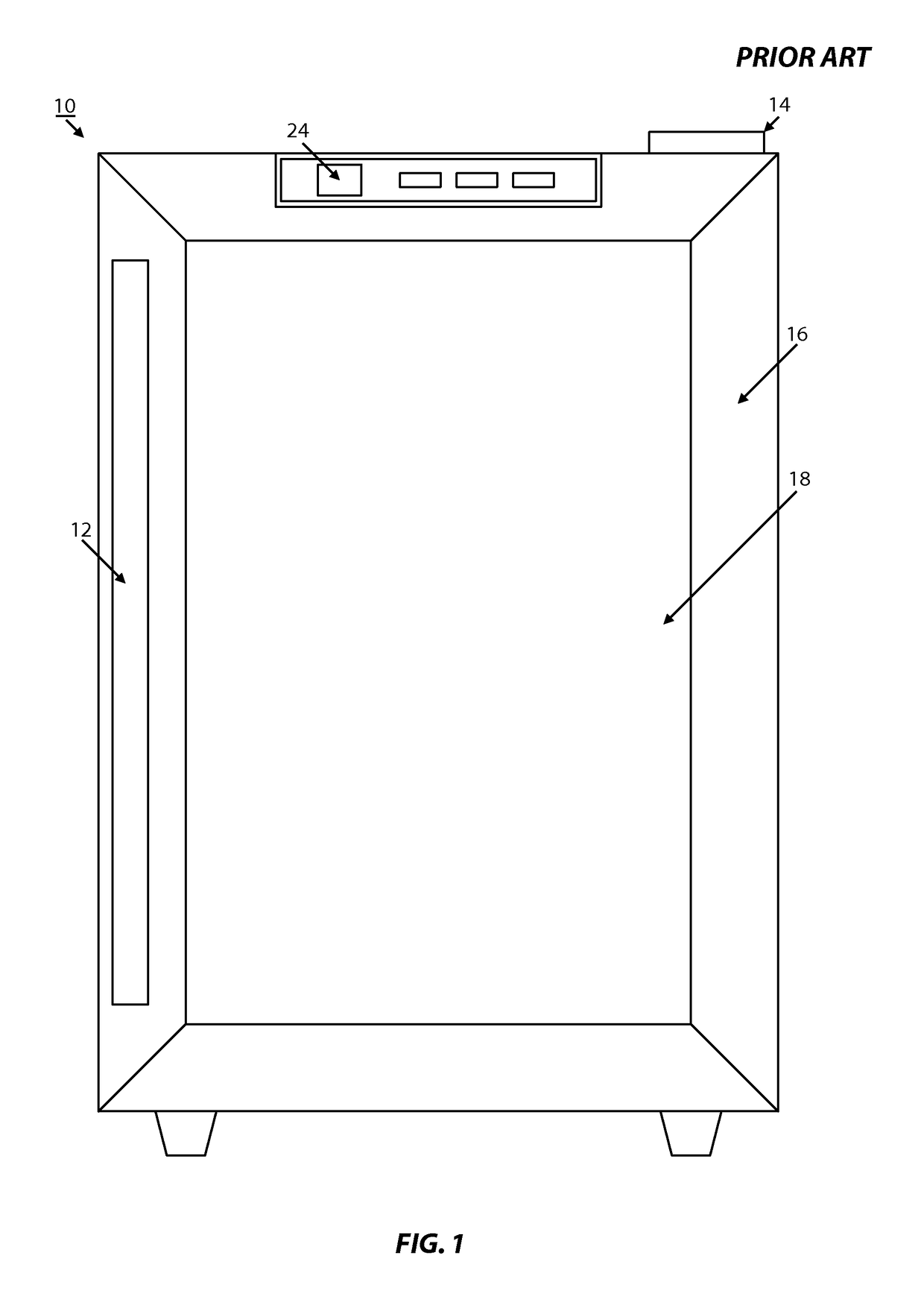

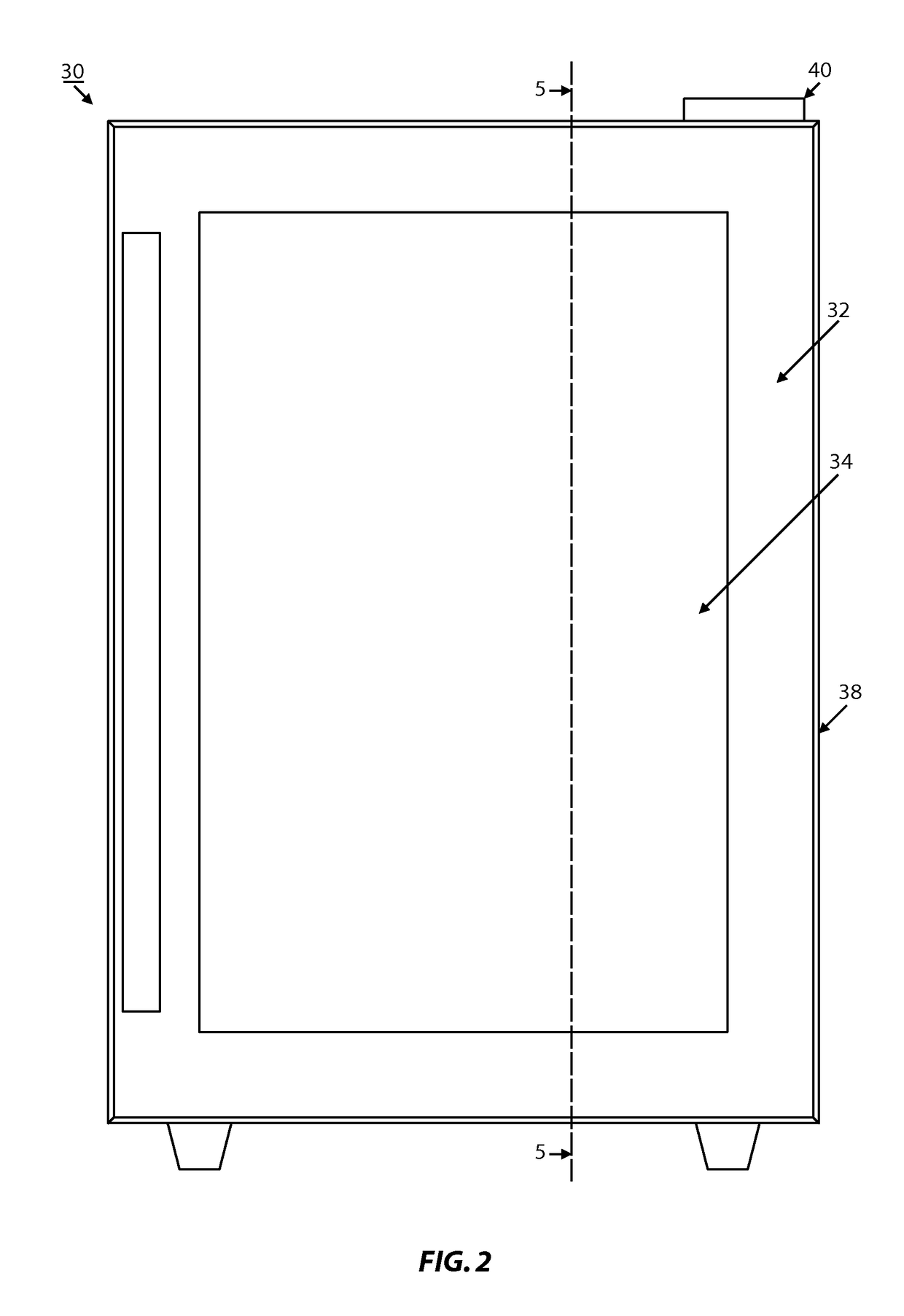

Decorative appliance door

ActiveUS9976753B2Improve insulation qualityShow cabinetsDoors for stoves/rangesEngineeringReflective layer

Owner:GREENFIELD WORLD TRADE

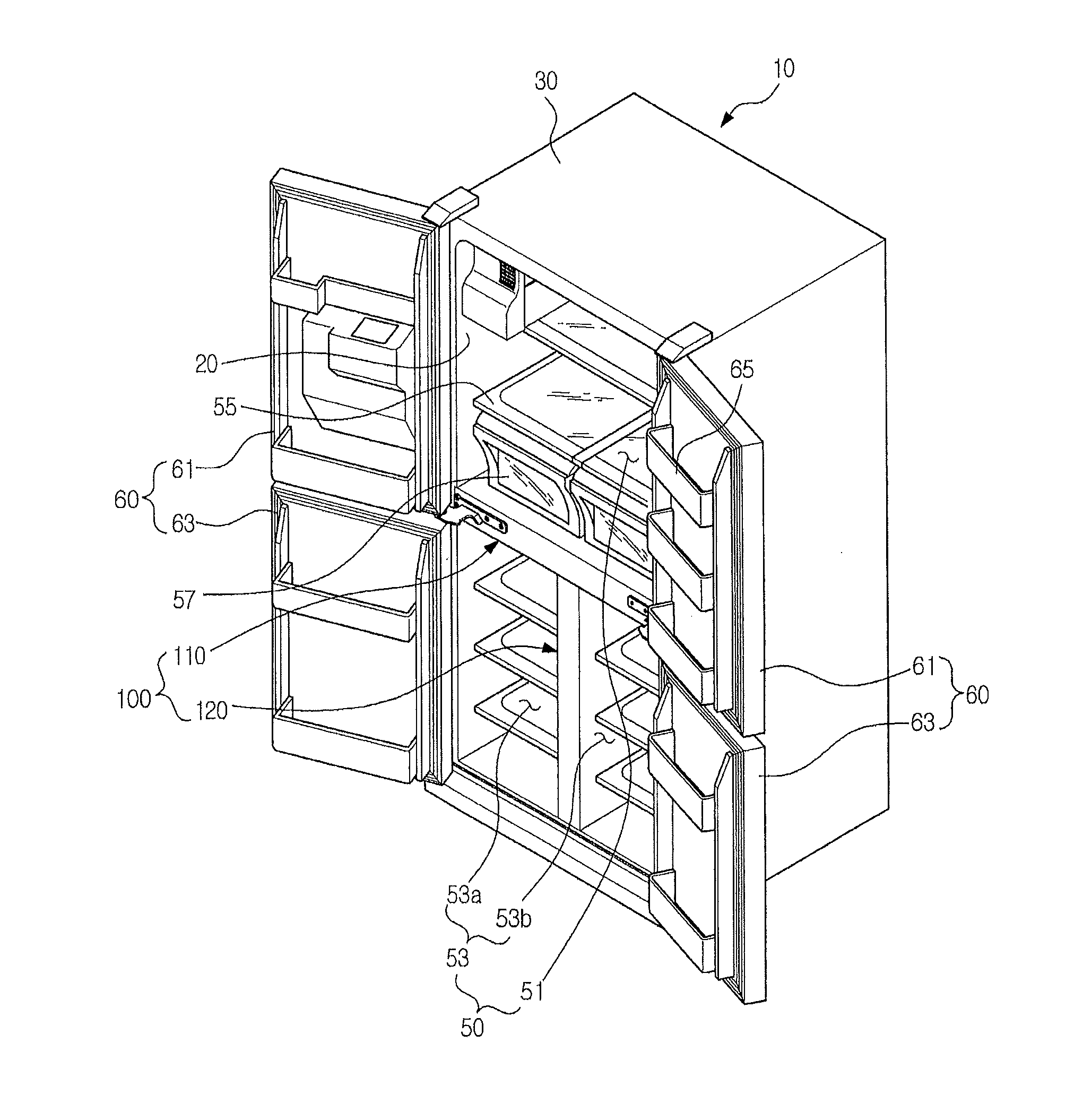

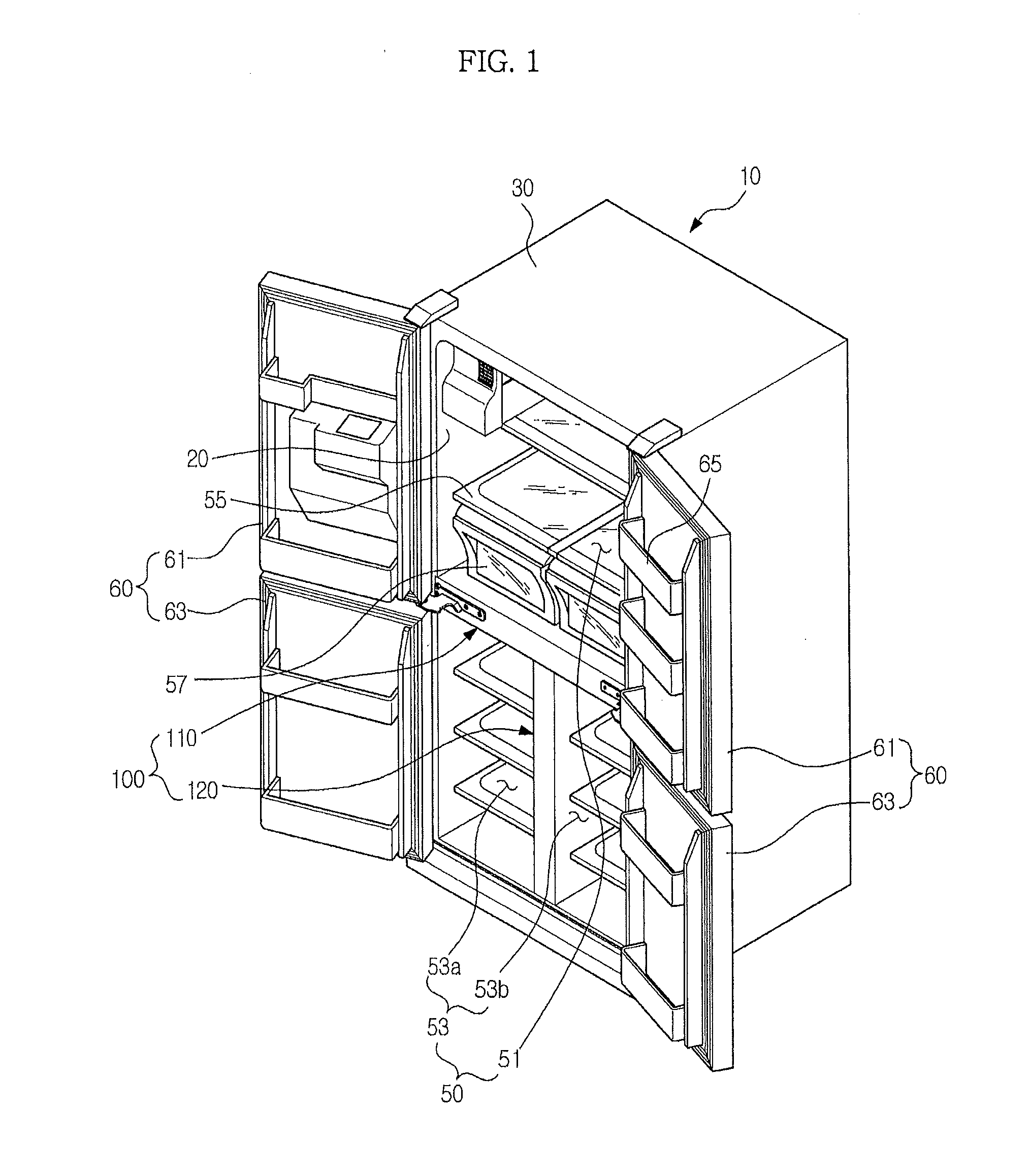

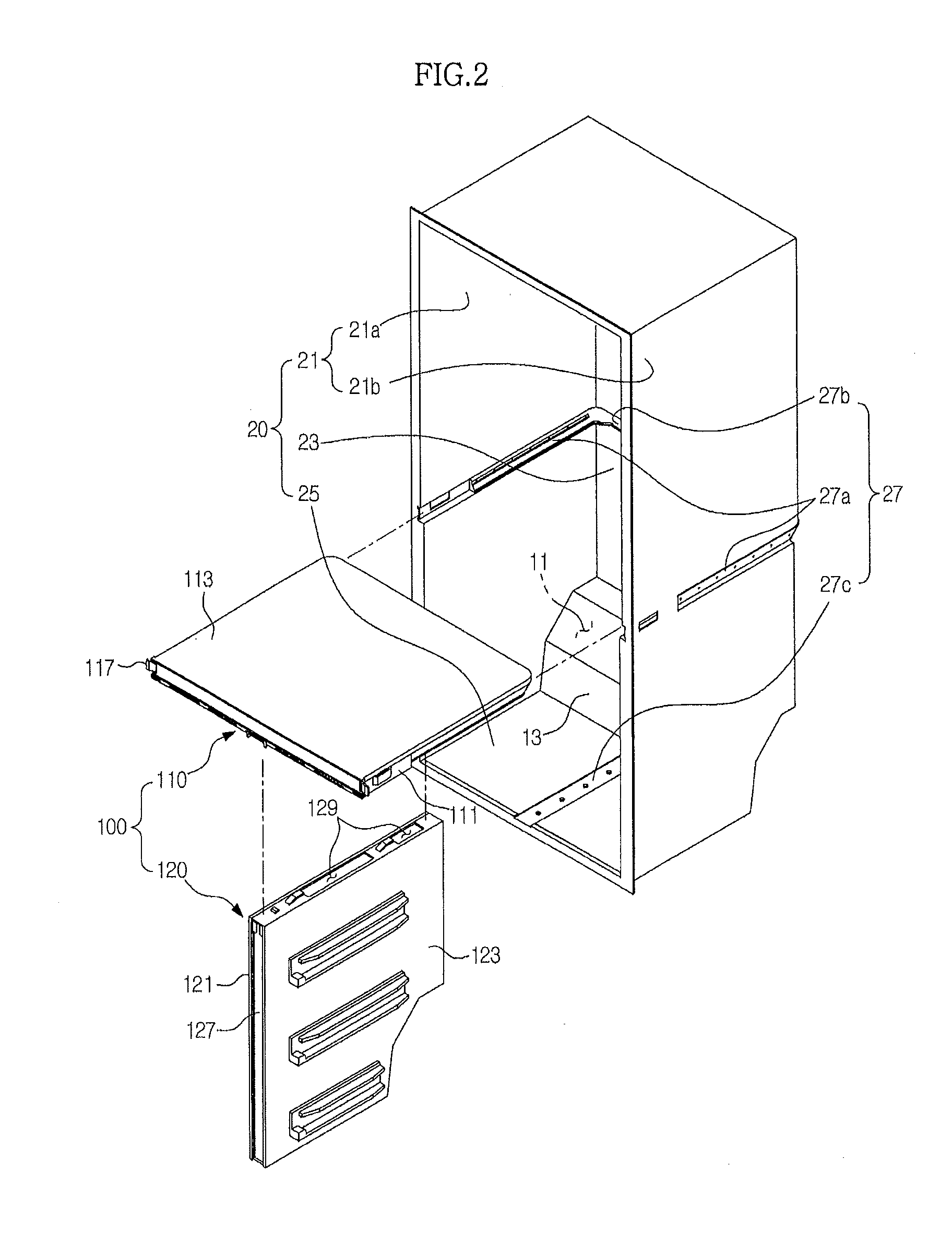

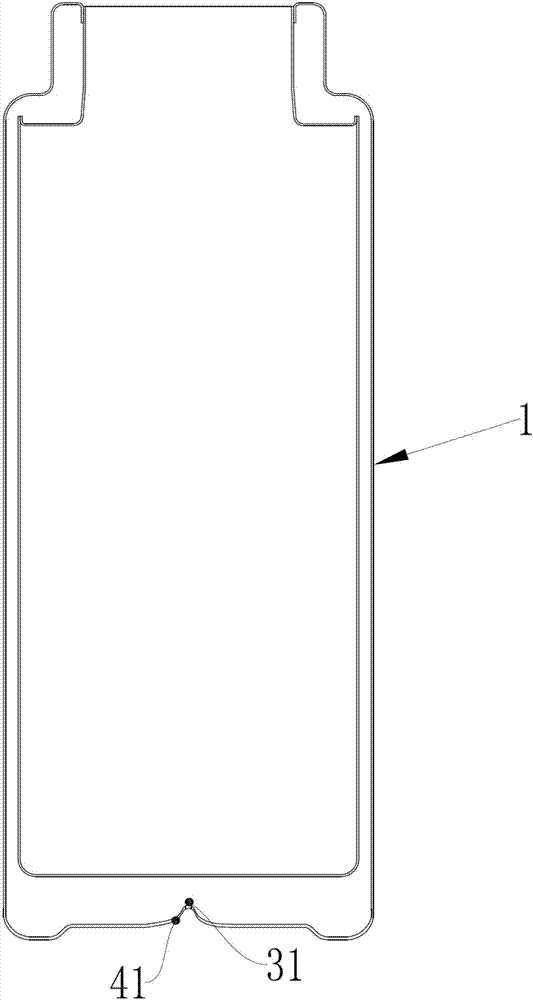

Refrigerator and manufacturing method thereof

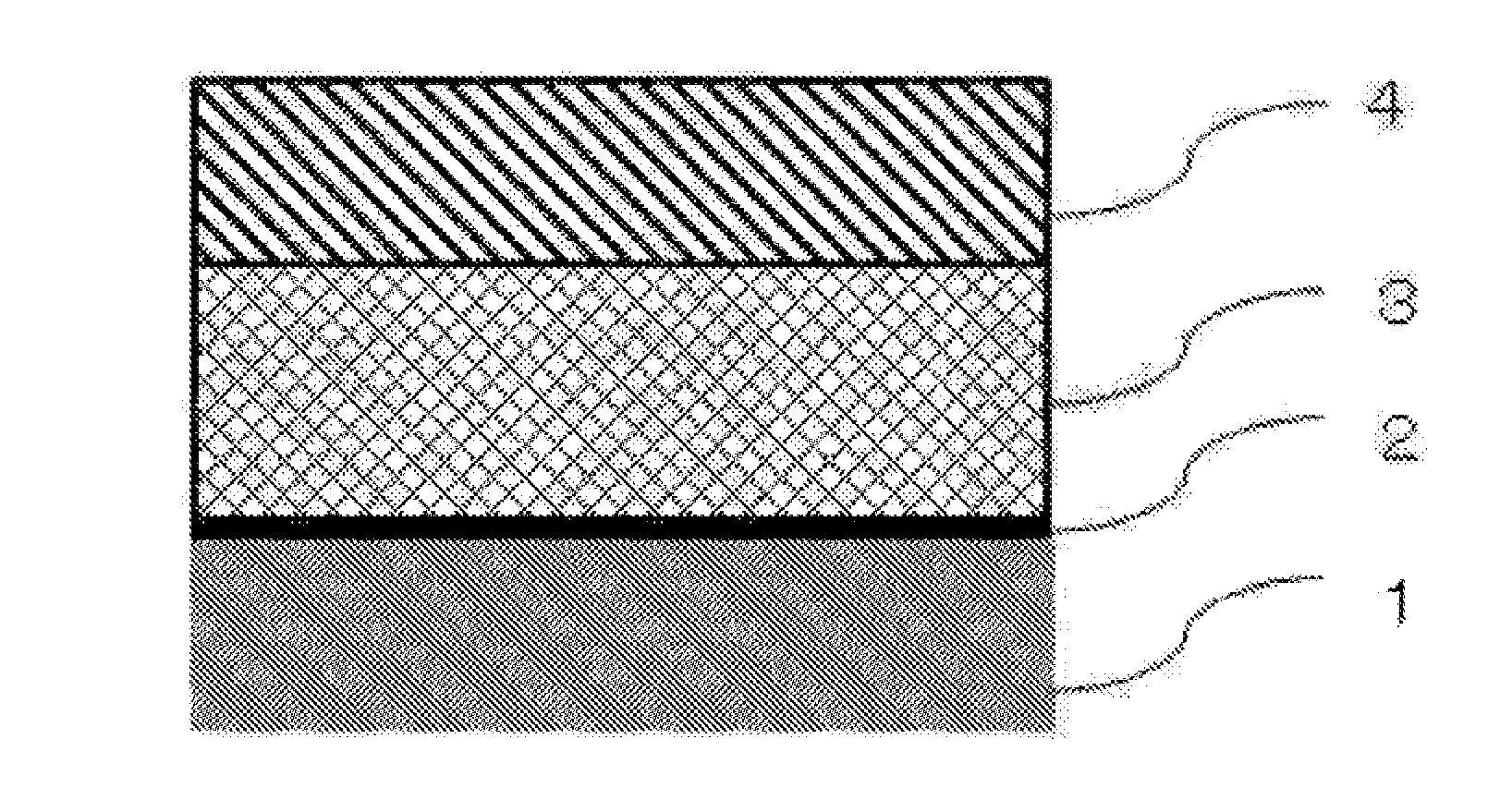

InactiveUS20160102905A1Improve insulation qualityLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

A refrigerator and a manufacturing method thereof including processes of separately manufacturing partitions dividing a storage space into a plurality of storage chambers from a main body including an inner casing and an outer casing, coupling the partitions to an inner surface of the inner casing, filling a space between the inner casing and the partitions with an insulator, and filling the partitions with the insulator by filling a space between the inner casing and the outer casing with the insulator. Since the insulator uniformly fills the partitions dividing the storage space into the plurality of storage chambers, the partitions may possess improved insulating qualities.

Owner:SAMSUNG ELECTRONICS CO LTD

Resin composition for sealant layer of battery packaging material

ActiveUS20160197318A1Suppress generationImprove seal strengthOther chemical processesJackets/cases materialsElastomerPolymer science

A resin composition can impart high insulating properties, sealing properties, and moldability to a battery packaging material. A resin composition minimizes cracks when used in the sealant layer of a battery packaging material and a heat seal section of the material is bent, and can impart high insulating properties. A resin composition for use in the sealant layer of a battery packaging material contains: at least one of a propylene-ethylene random copolymer having a melting point of 156° C. or more and an ethylene content of 5 mass % or less and a propylene-ethylene block copolymer having a melting point of 158° C. or more and an ethylene content of 7 mass % or less; and a polyolefin elastomer having a melting point of 135° C. or more. A resin composition for the sealing layer of a battery packaging material contains a polyolefin resin having an isotactic fraction of 99% or less.

Owner:DAI NIPPON PRINTING CO LTD

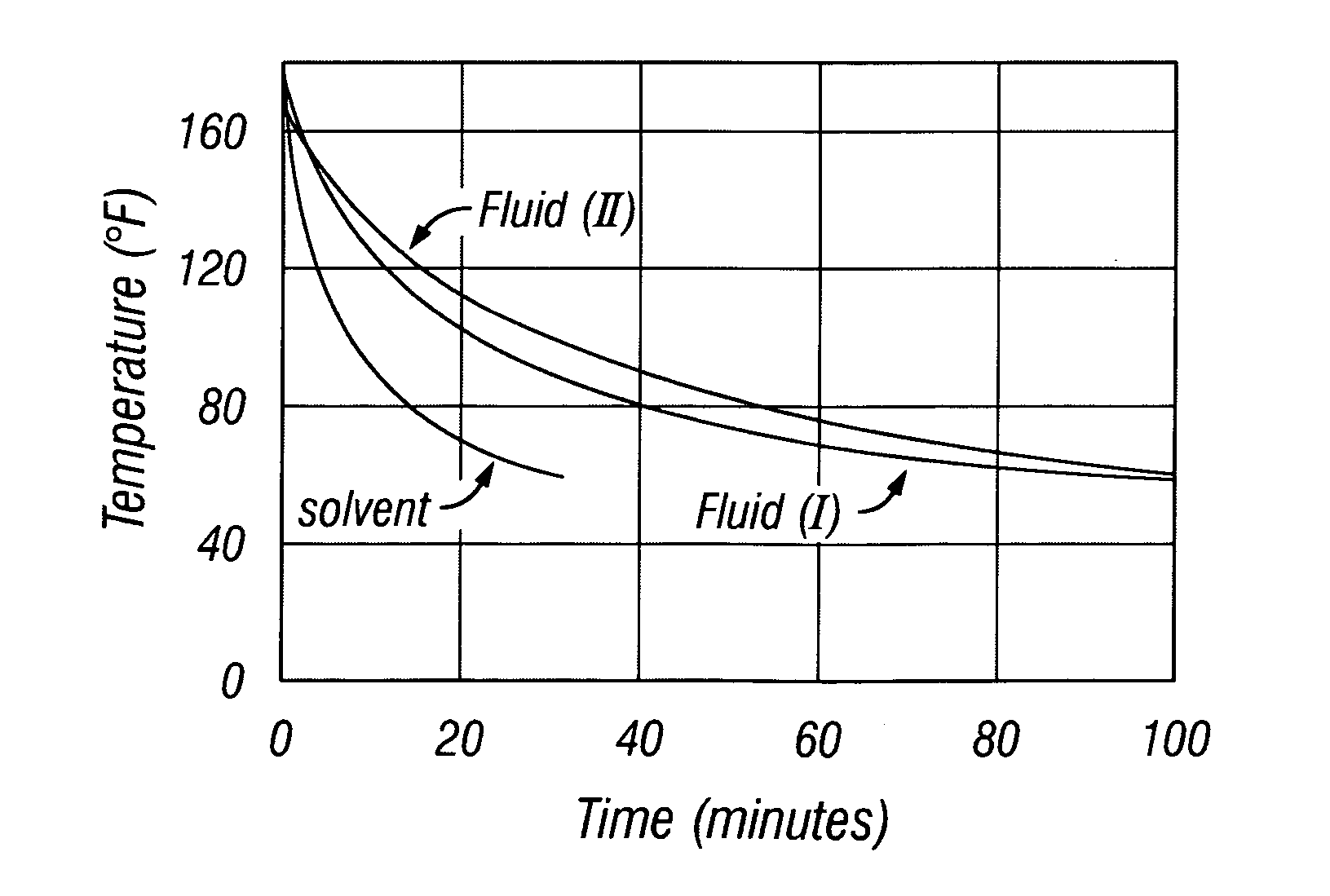

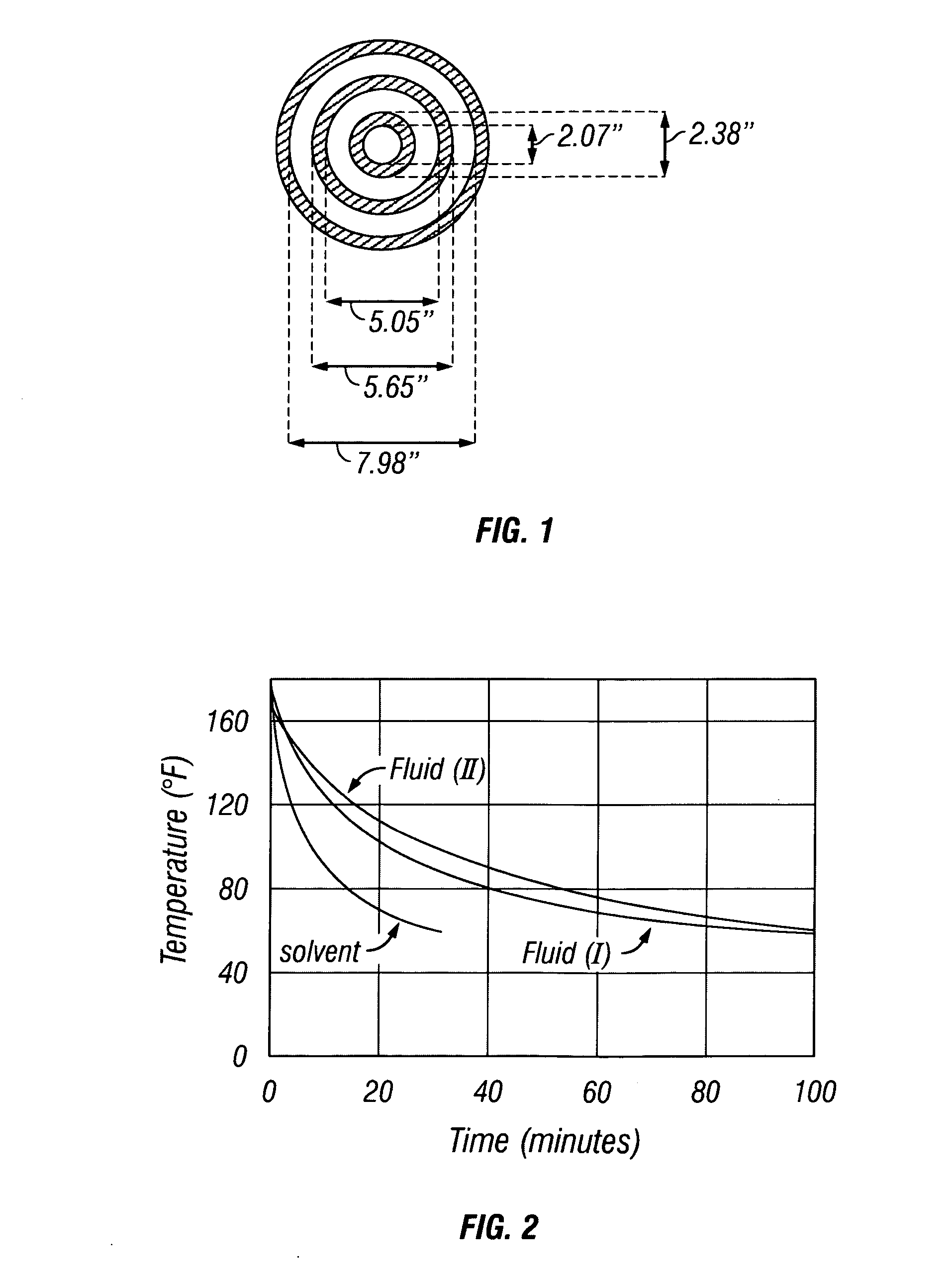

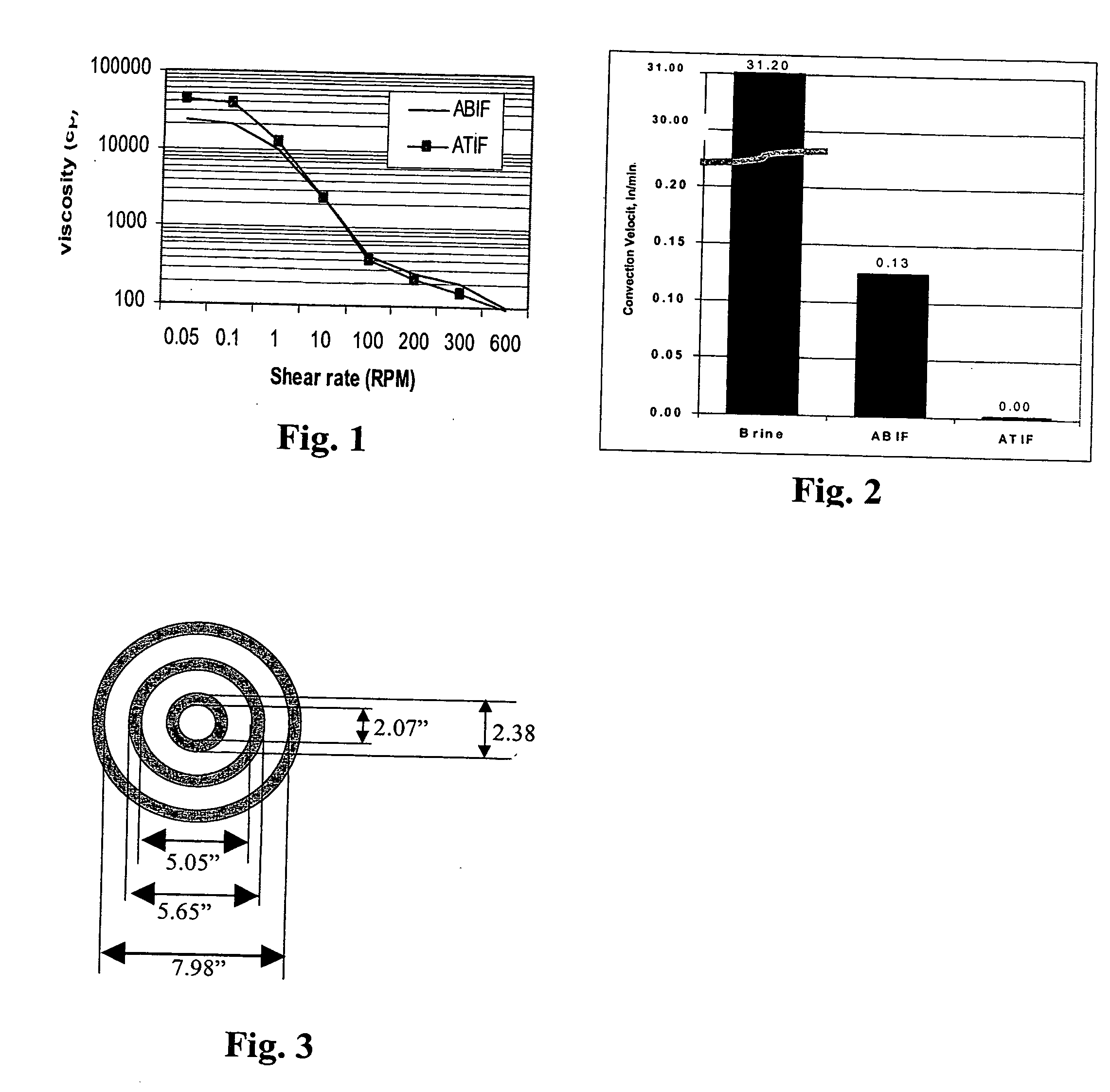

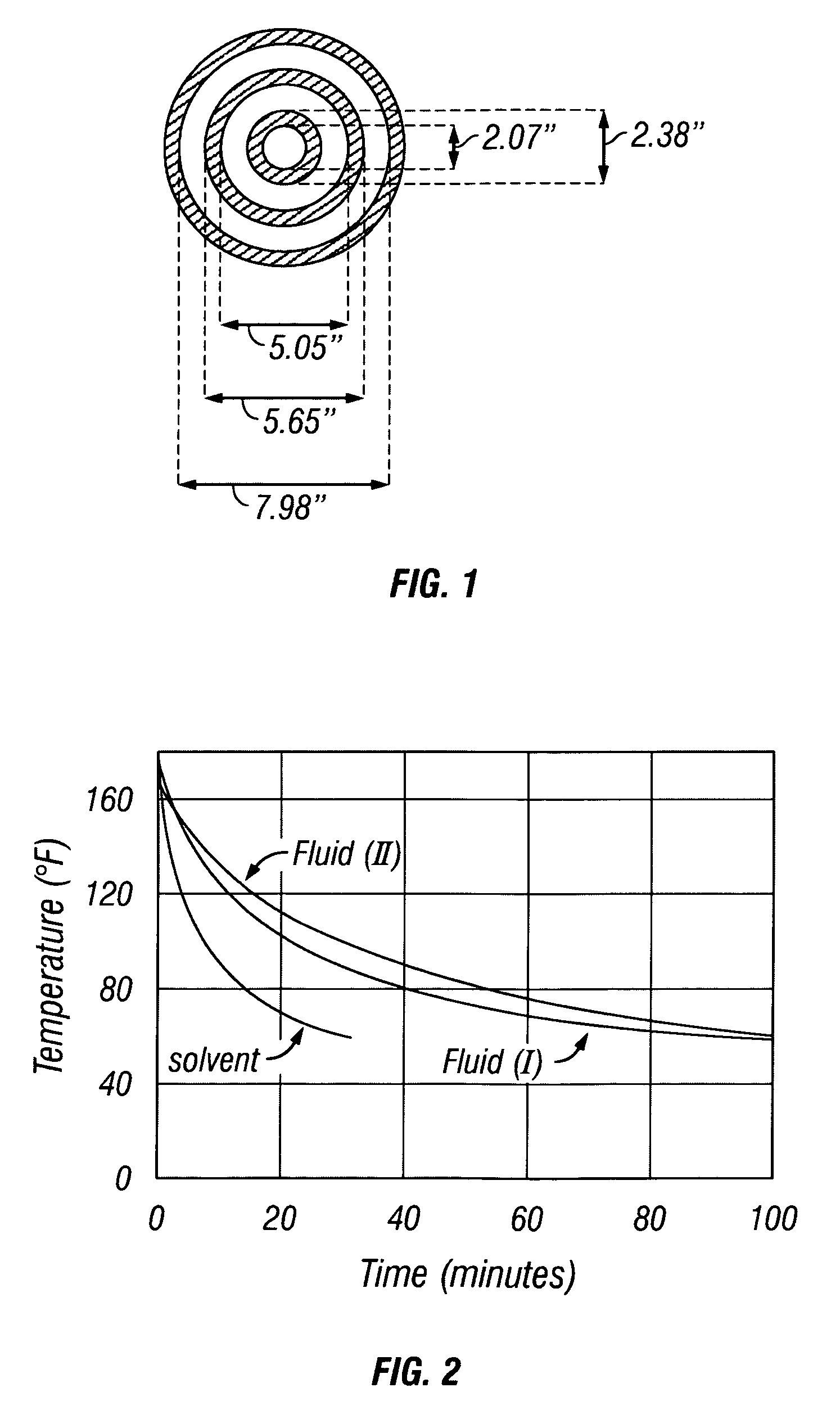

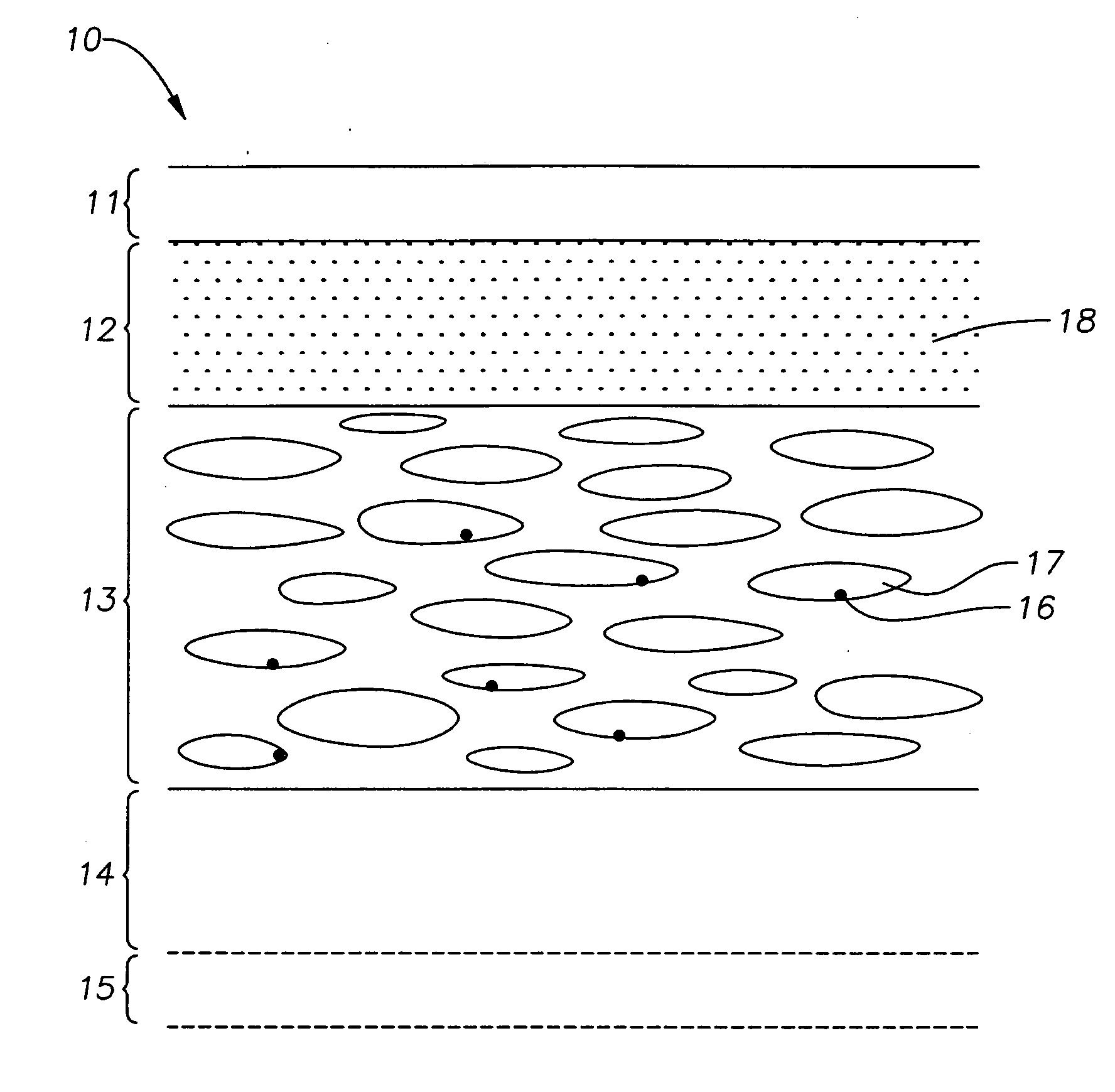

Method of using thermal insulation fluid containing hollow microspheres

InactiveUS20080113883A1Reduce convection flow velocityImprove insulation qualityOther chemical processesInsulationParticulatesMicrosphere

A thermal insulating fluid contains microspheres of hollow spherical particulates. The presence of the hollow spherical particles improves the thermal insulating properties of the fluid by imparting to the thermal insulating fluid a low heat transfer coefficient. The hollow particulates may be inorganic or organic in nature and include hollow spheres of glass, ceramics and plastics. The thermal insulating fluid is capable of controlling the heat transfer from a production tubing or transfer pipe to one or more surrounding annuli and the environment. In addition to reducing heat transfer in the producing well, heat transfer in the fluid produced from the well is also minimized.

Owner:BAKER HUGHES INC

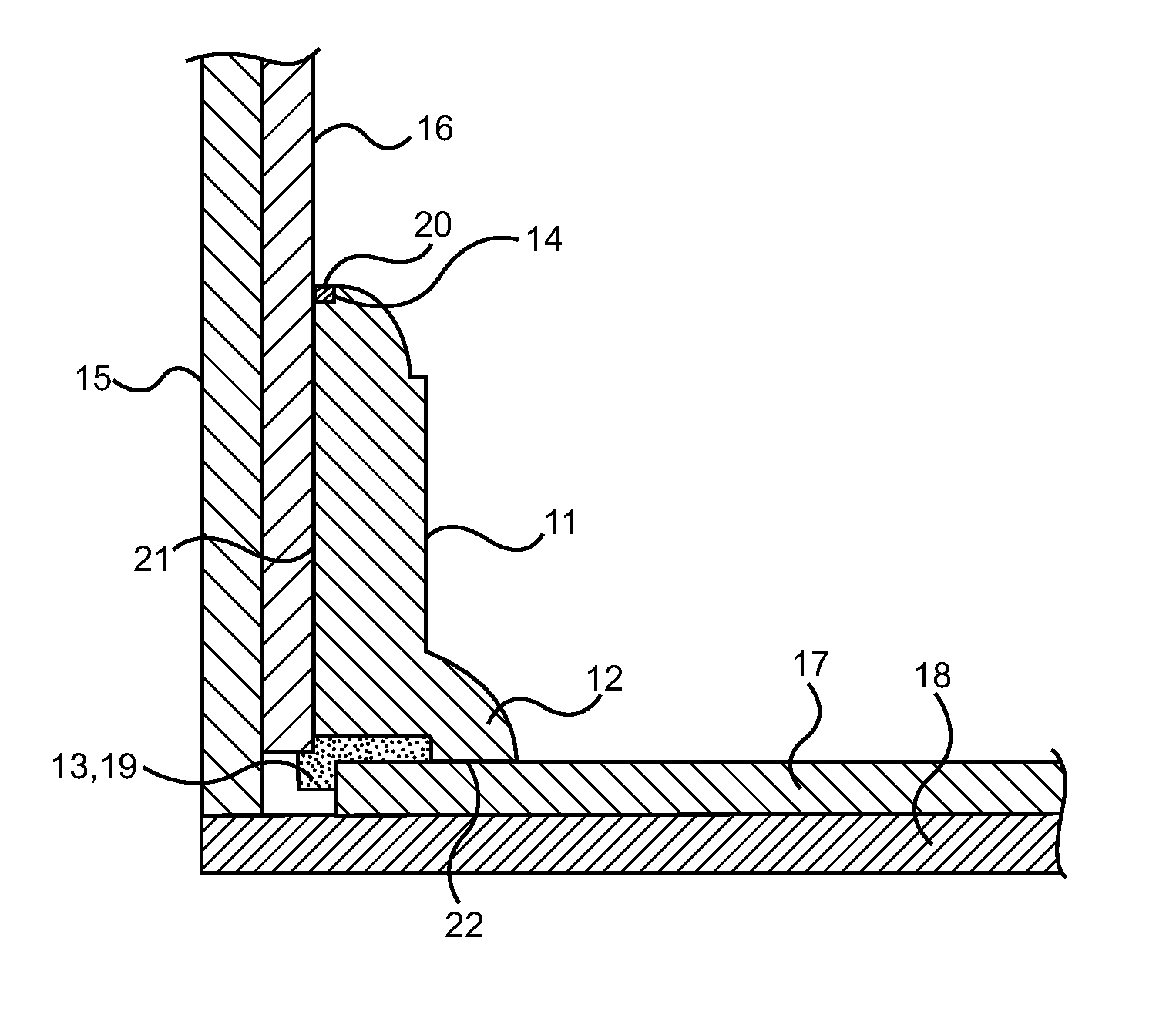

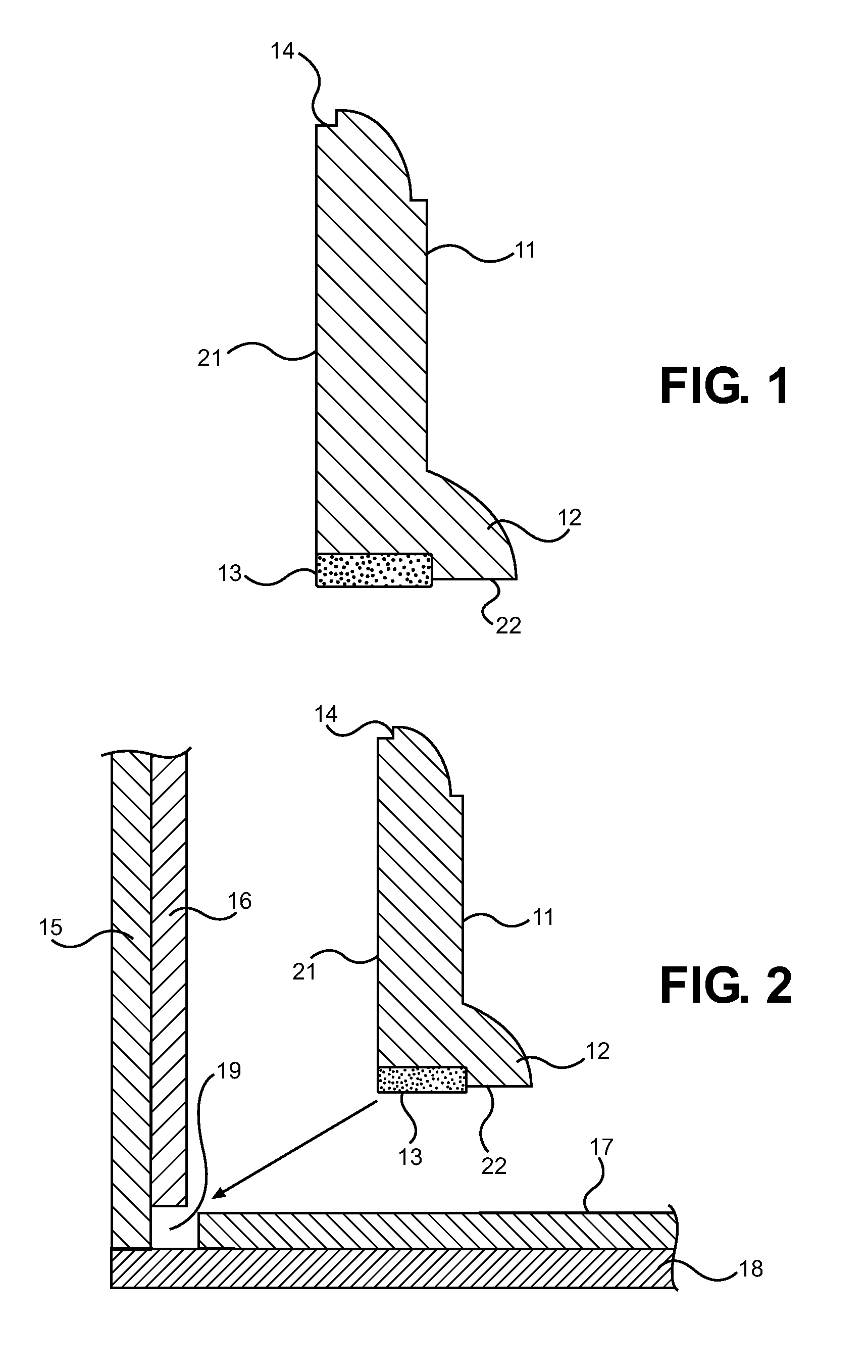

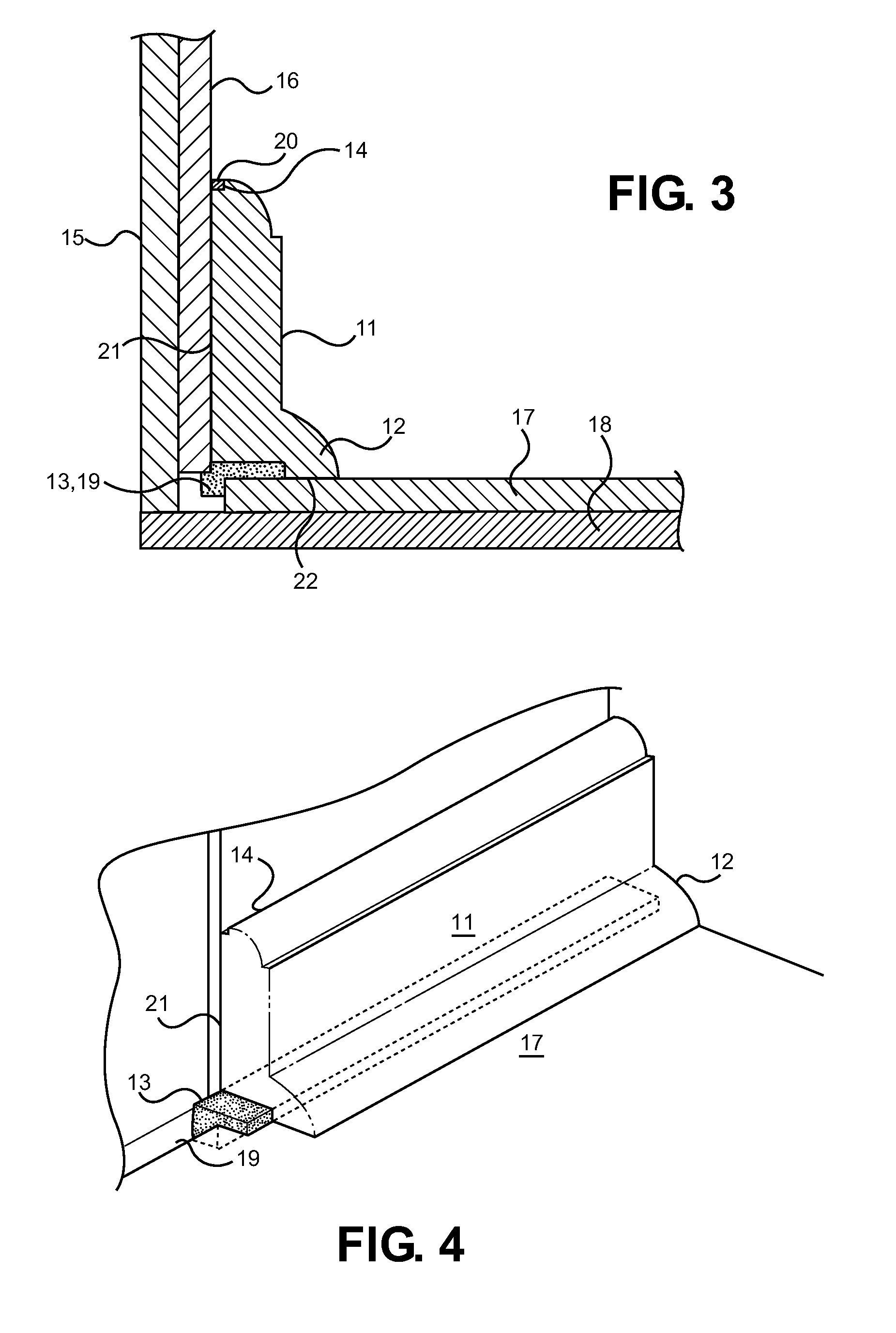

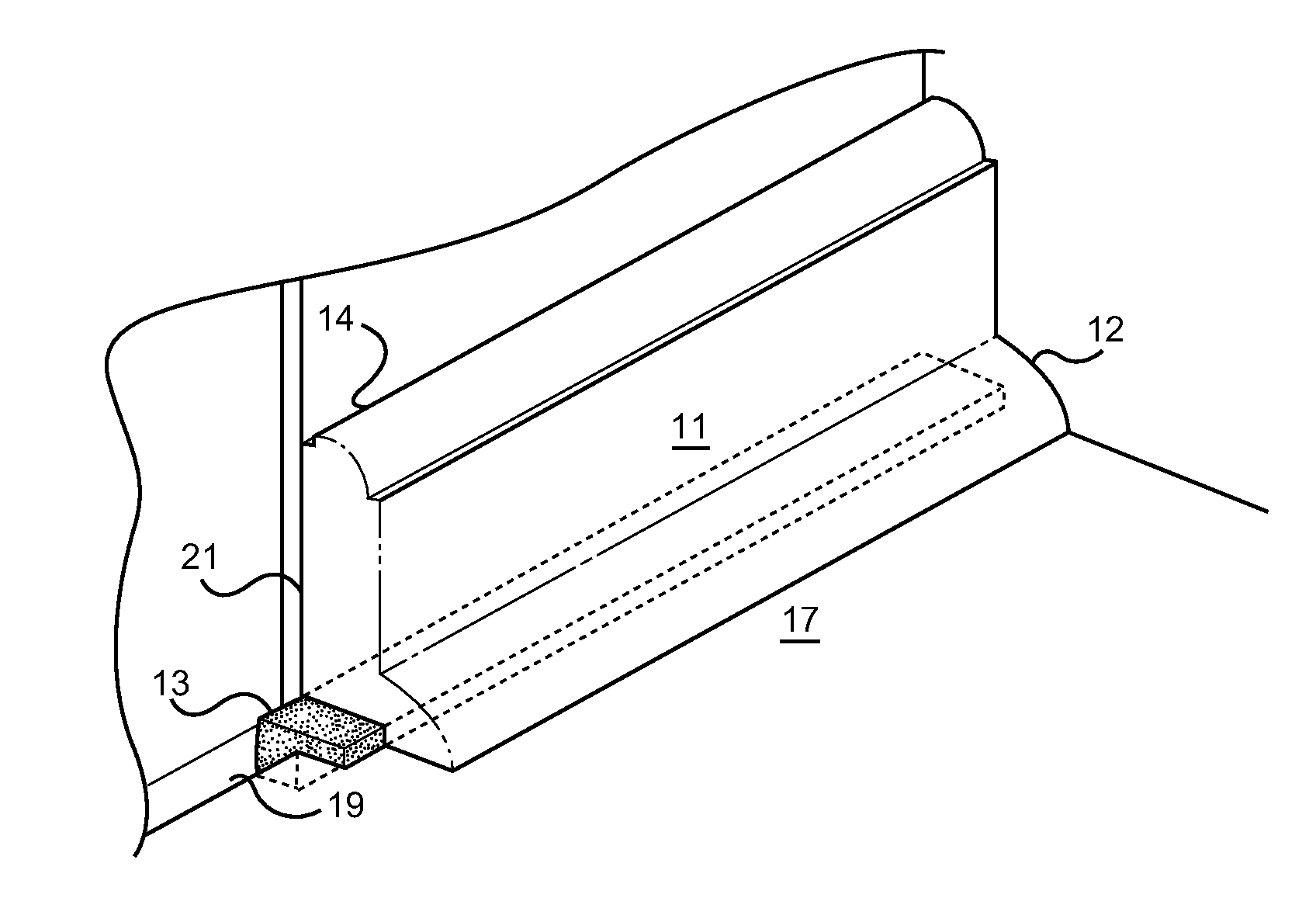

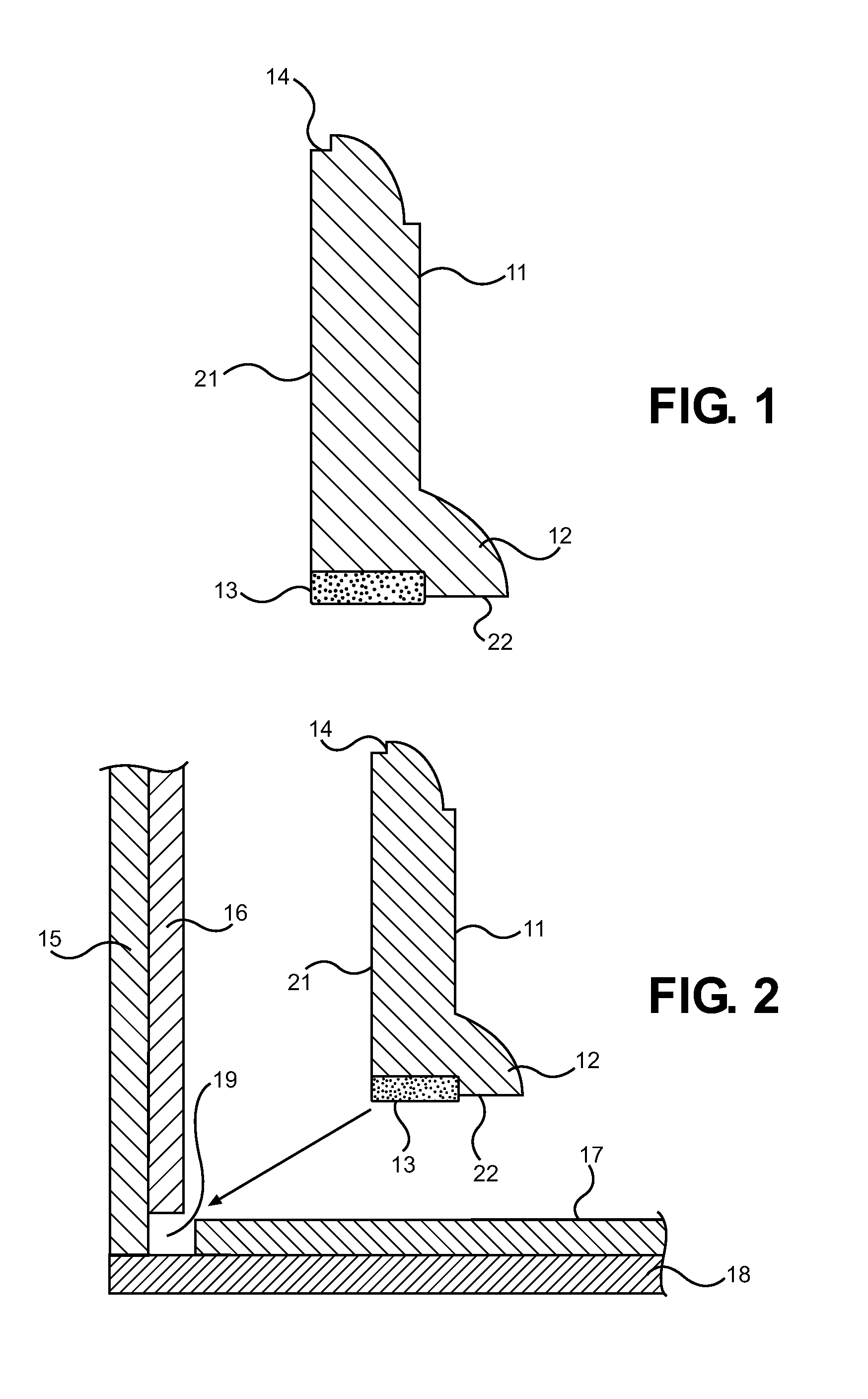

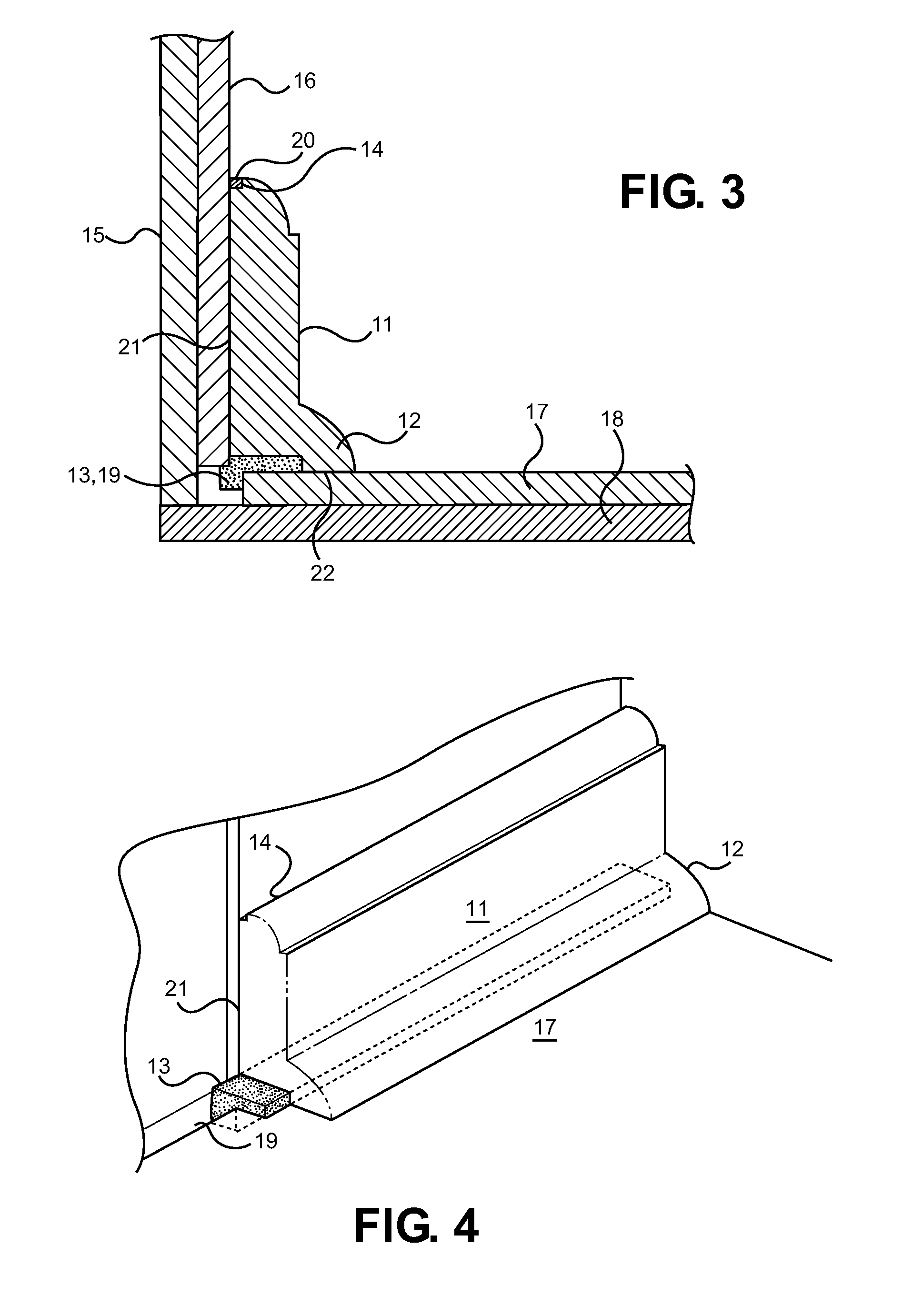

Insulated and efficient baseboard construction

InactiveUS8733042B2Ease and convenienceImprove insulation performanceBuilding roofsWallsBaseboardBuilding construction

A baseboard structure having air gap insulation, an integrated quarter-round molding segment, and an upper caulk channel for providing a unitary baseboard element for rapid and improved installation. The baseboard comprises an outer, decorative surface having an integrated quarter round element, a lower surface adapted to lie flush on a floor surface, a backside surface and an upper caulk channel. A section of compressible insulation material is located at the junction of the backside and lower surfaces, and is adapted to be pressed into any gaps between the flooring and the wall to seal any air gaps or gaps in thermal resistance. The device incorporates a caulking channel at the junction of the backside and outer surfaces such that the installer may create a seamless transition between the top of the baseboard and the wall with a quantity of caulk while the baseboard lower surface lies flush with floor.

Owner:DANIOCEK JEFFREY +1

Method of using water-superabsorbent polymer in production tubing and pipes

InactiveUS20070167542A1Low viscosityEasy to pumpCosmetic preparationsDrilling rodsSuperabsorbent polymerHeat losses

A thermal insulating packer fluid contains at least one water superabsorbent polymer and optionally water and / or brine, and a viscosifying polymer. The composition is capable of inhibiting unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli. The viscosity of the composition is sufficient to reduce the convection flow velocity within the annulus.

Owner:BAKER HUGHES INC

Wall building system and method

InactiveUS20140250819A1Efficiently employedImprove stabilityConstruction materialWallsArchitectural engineeringStructural engineering

Owner:ABDULLAH MOHAMMAD A H S H +1

Phase insulation paper and electric motor provided with phase insulation paper

ActiveUS7122936B2High strengthImprove insulation qualityWindings insulation materialWindings insulation shape/form/constructionStator coilEngineering

Three-dimensional portions are made of the same PET resin as are flat portions, only thicker. That is, the three-dimensional portions are more rigid than the flat portions. The three-dimensional portions are bonded to the flat portions at cutout portions thereof by a thermo-compression sheet or adhesive tape or the like. Connecting portions are made of PET resin that is thinner than the PET resin of which the flat portions are made. A phase insulation paper is provided in which the connecting portions are bonded at both ends to the flat portions, and an electric motor is provided in which the phase insulation paper is inserted between stator coils.

Owner:TOYOTA JIDOSHA KK

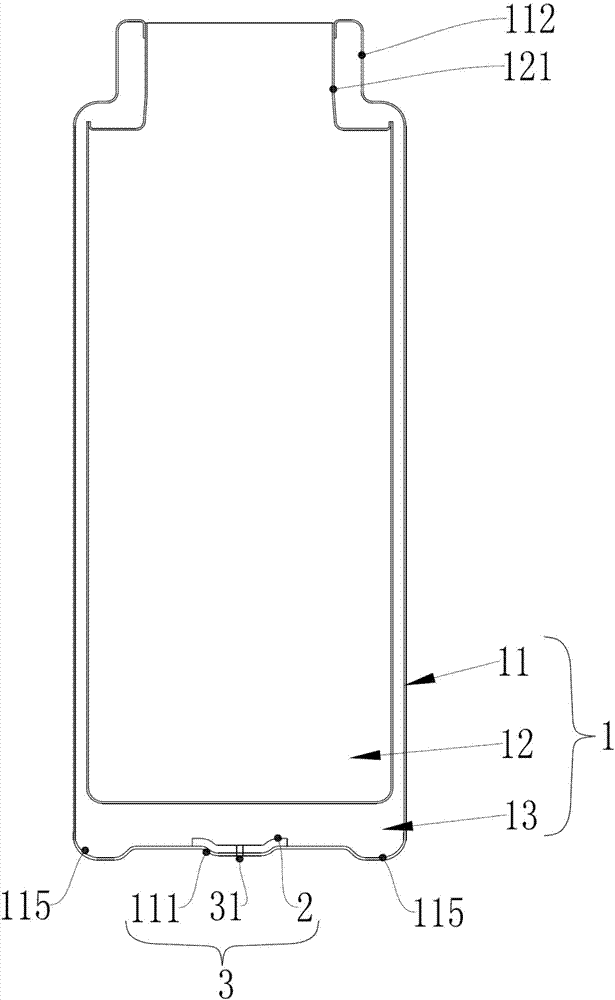

Manufacturing method of novel vacuum heat preservation container and manufactured vacuum heat preservation container thereof

InactiveCN107296522ANot easy to dropAvoid enteringDomestic cooling apparatusLighting and heating apparatusEngineering

Owner:FOSHAN KEITH TITANIUM TECH CO LTD

Method of using thermal insulation fluid containing hollow microspheres

InactiveUS7625845B2Improve insulation qualityReduction factorInsulationFluid removalParticulatesMicrosphere

A thermal insulating fluid contains microspheres of hollow spherical particulates. The presence of the hollow spherical particles improves the thermal insulating properties of the fluid by imparting to the thermal insulating fluid a low heat transfer coefficient. The hollow particulates may be inorganic or organic in nature and include hollow spheres of glass, ceramics and plastics. The thermal insulating fluid is capable of controlling the heat transfer from a production tubing or transfer pipe to one or more surrounding annuli and the environment. In addition to reducing heat transfer in the producing well, heat transfer in the fluid produced from the well is also minimized.

Owner:BAKER HUGHES HLDG LLC

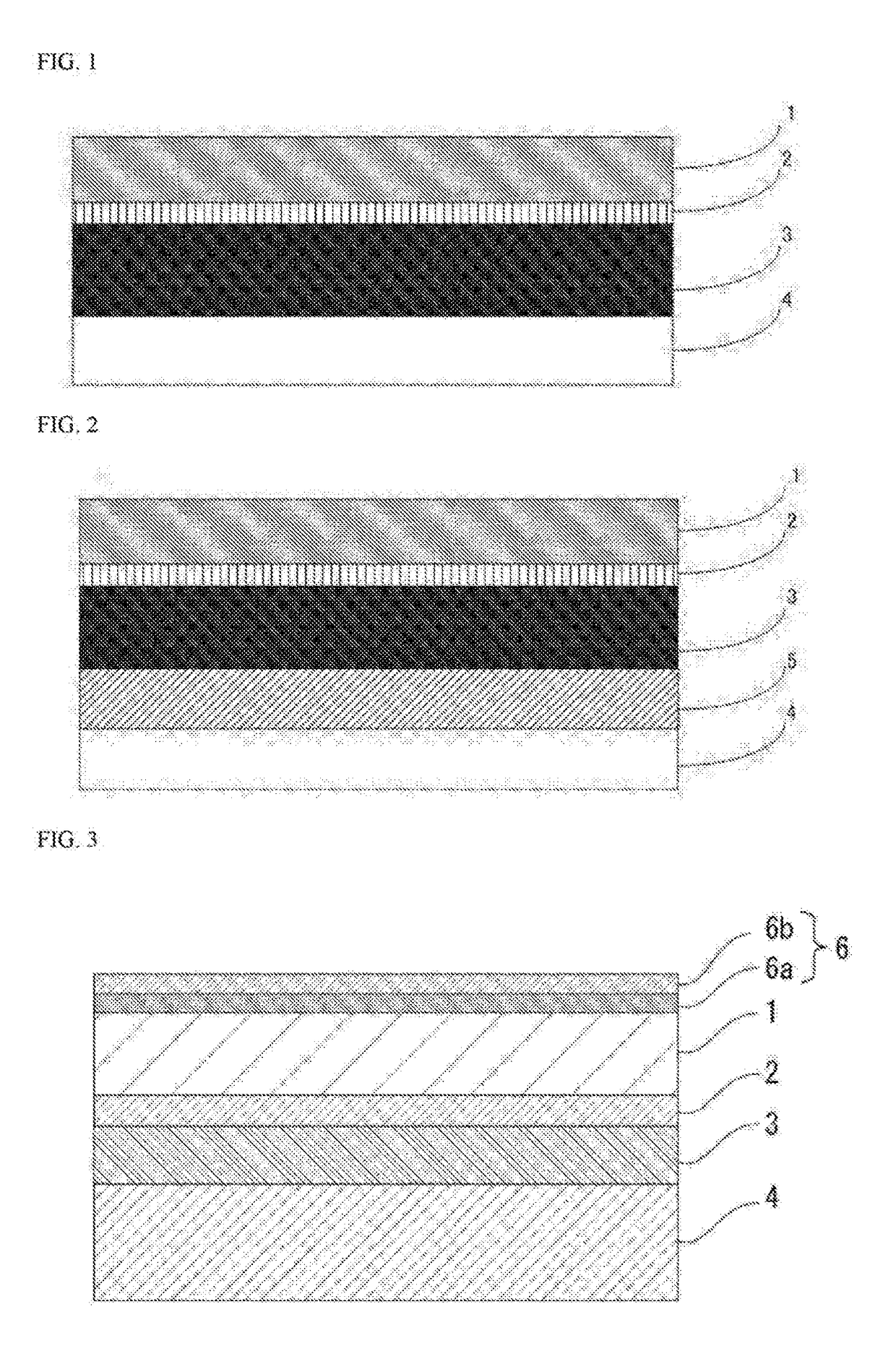

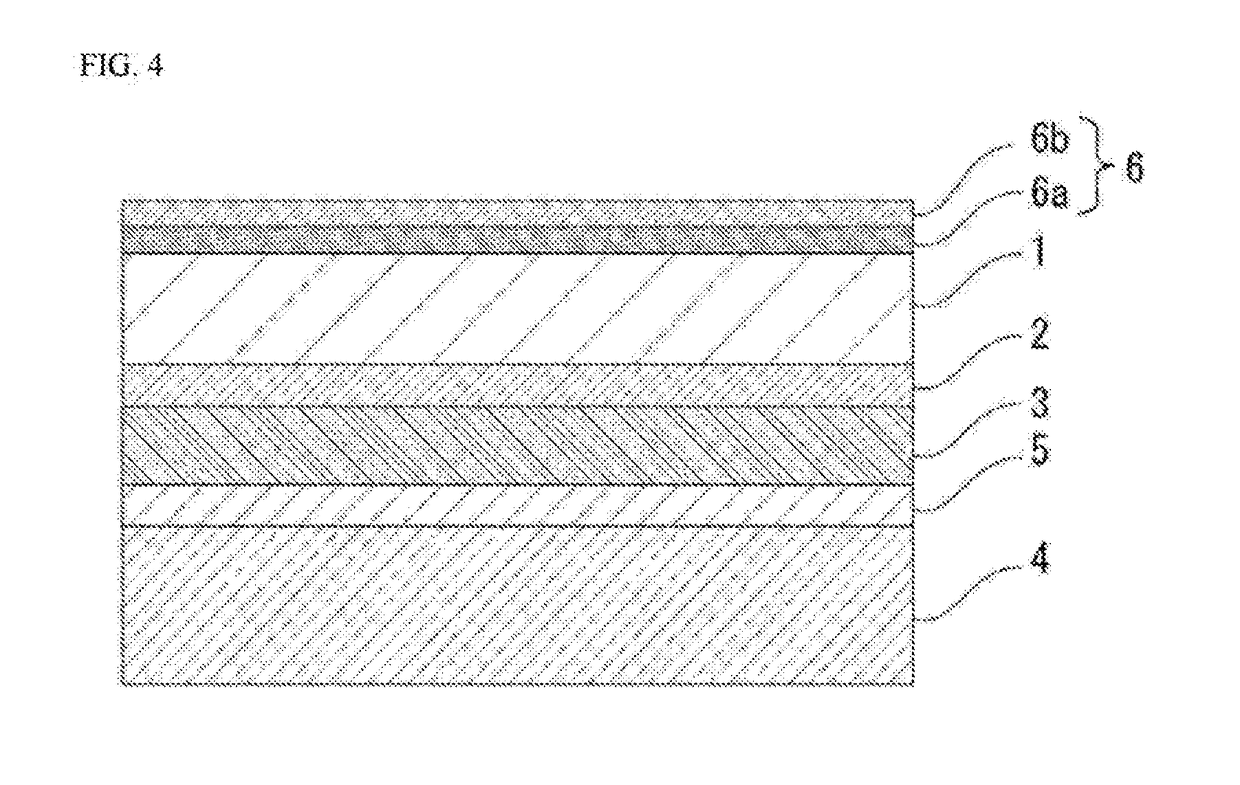

Composite film

InactiveUS20080009413A1Improve aesthetic appearanceImprove functionalitySynthetic resin layered productsAblative recordingThermal insulationWhitening Agents

A composite film useful for image supporting media, including: a first layer containing a thermoplastic polymer and optionally containing a whitening agent; a second layer containing a thermoplastic polymer and a whitening agent; a third layer containing a thermoplastic polymer and a cavitating agent, wherein the third layer is a cavitated layer; optionally a fourth layer containing a thermoplastic polymer and optionally a whitening agent; and optionally a fifth layer containing a thermoplastic polymer and optionally a whitening agent; wherein the second layer is between the first layer and the third layer, the third layer is between the second layer and the optional fourth layer, and the optional fourth layer is between the third layer and the optional fifth layer. Embodiments may have the advantage(s) of improved outer surface characteristics, compressibility, thermal insulation, whiteness, and / or stiffness.

Owner:JINDAL FILMS AMERICAS LLC

Structural elements and method for fabricating structural elements

InactiveUS20070051060A1High insulation qualityGood structural strengthBuilding roofsRoof coveringStructural elementEngineering

A composite panel structure includes a flange beam assembly including: a web assembly; and a first flange assembly attached in an essentially perpendicular fashion to the web assembly. The composite panel structure further includes at least two panel assemblies. Each panel assembly includes: a foam layer; a first high-density material layer secured to the foam layer; and at least one recess configured to receive at least a portion of the first flange assembly.

Owner:IGREEN CONSTR

Insulated and Efficient Baseboard Construction

InactiveUS20120210667A1Ease and convenienceImprove insulation performanceCovering/liningsBuilding componentsBaseboardEngineering

A baseboard structure having air gap insulation, an integrated quarter-round molding segment, and an upper caulk channel for providing a unitary baseboard element for rapid and improved installation. The baseboard comprises an outer, decorative surface having an integrated quarter round element, a lower surface adapted to lie flush on a floor surface, a backside surface and an upper caulk channel. A section of compressible insulation material is located at the junction of the backside and lower surfaces, and is adapted to be pressed into any gaps between the flooring and the wall to seal any air gaps or gaps in thermal resistance. The device incorporates a caulking channel at the junction of the backside and outer surfaces such that the installer may create a seamless transition between the top of the baseboard and the wall with a quantity of caulk while the baseboard lower surface lies flush with floor.

Owner:DANIOCEK JEFFREY +1

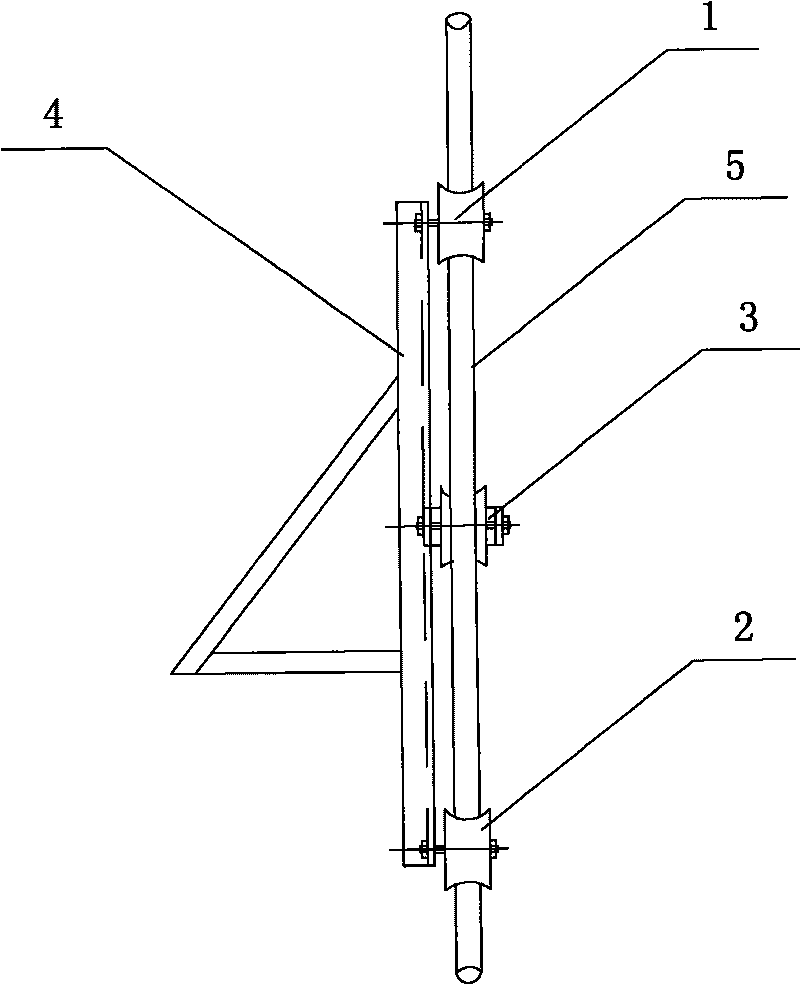

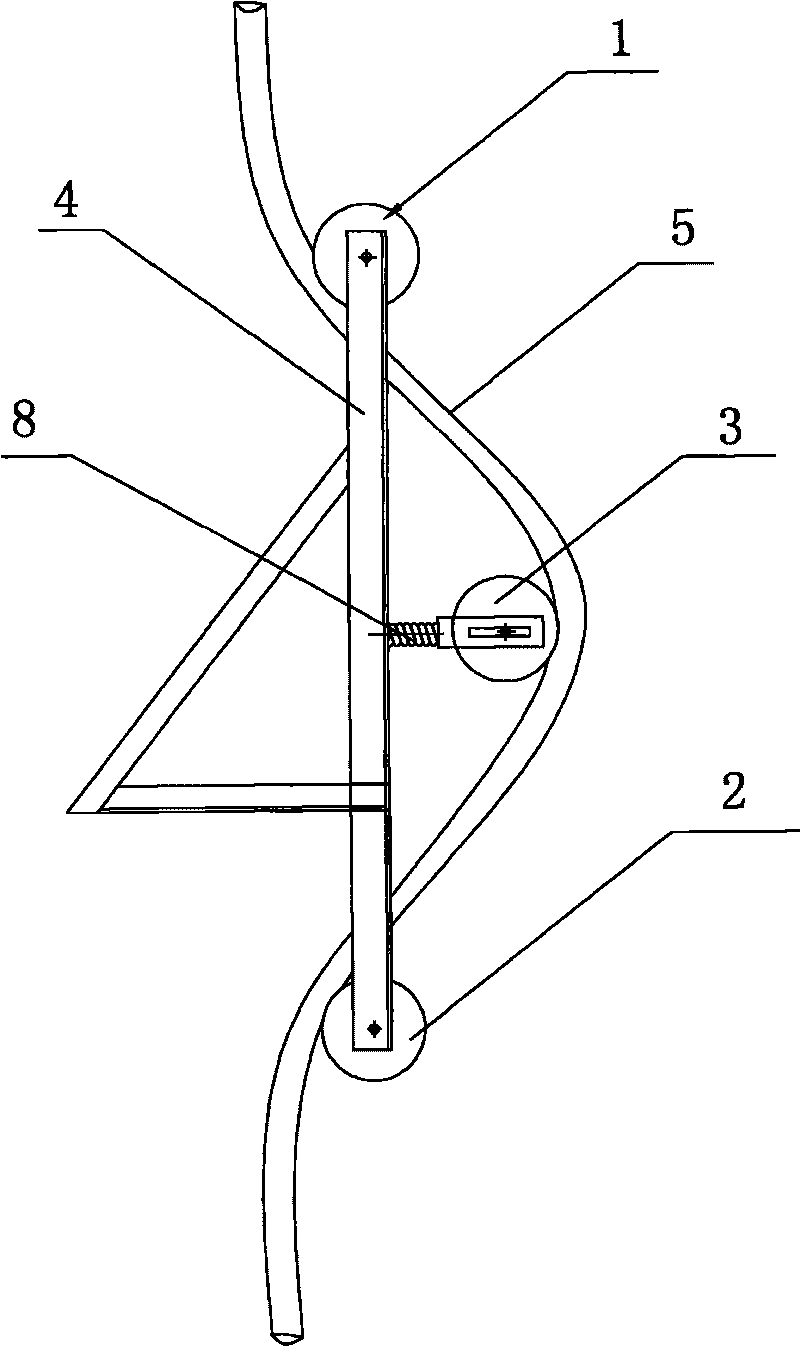

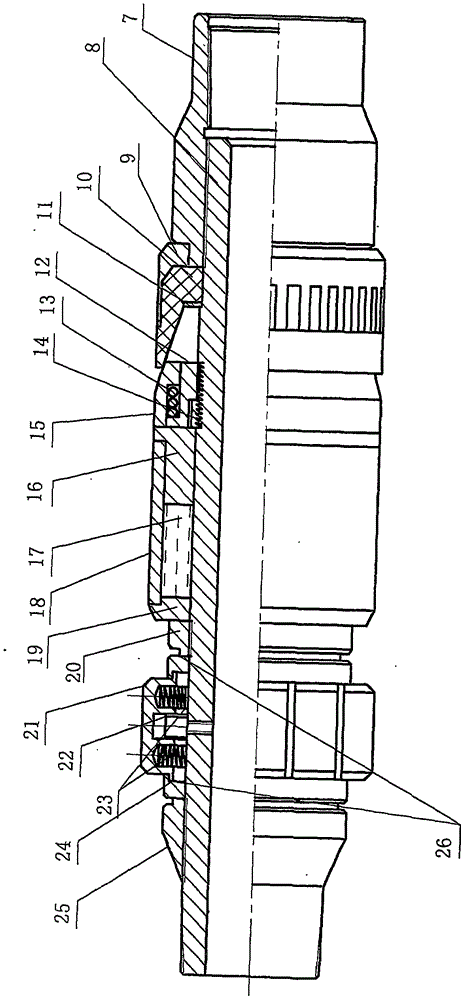

Mechanical thermal insulation type horizontal well steam injection string

ActiveCN106194138AReduce insulation costsImprove insulation qualityInsulationFluid removalThermal insulationEngineering

The invention discloses a mechanical thermal insulation type horizontal well steam injection string. The mechanical thermal insulation type horizontal well steam injection string comprises a steam injection string body and is characterized in that the steam injection string body is connected with a thermal insulation steam injection device in series, and the thermal insulation steam injection device is composed of a thermal packer and a radial positioning mechanism arranged on a blocking ball barrier on a central pipe of the thermal packer. After the mechanical thermal insulation type horizontal well steam injection string is realized, as the thermal insulation steam injection device is arranged, the mechanical thermal insulation type horizontal well steam injection string can carry out mechanical thermal insulation treatment on each sleeve pipe of a horizontal well according to use needs. Therefore, compared with the prior art, the thermal insulation cost of sleeve pipes of the horizontal well can be effectively lowered, the thermal insulation quality is improved, and thermal insulation operation is simplified.

Owner:郭欣竹

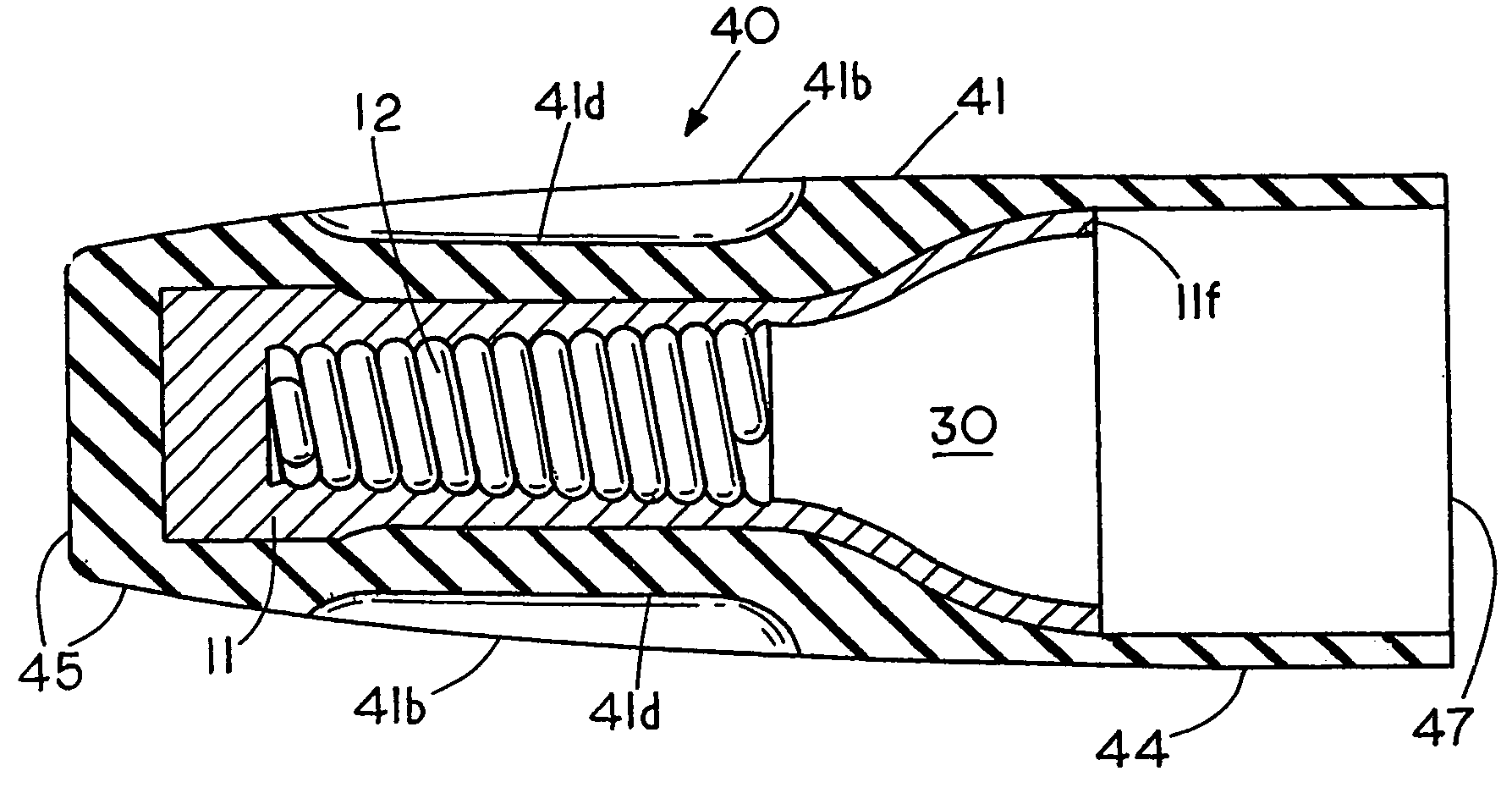

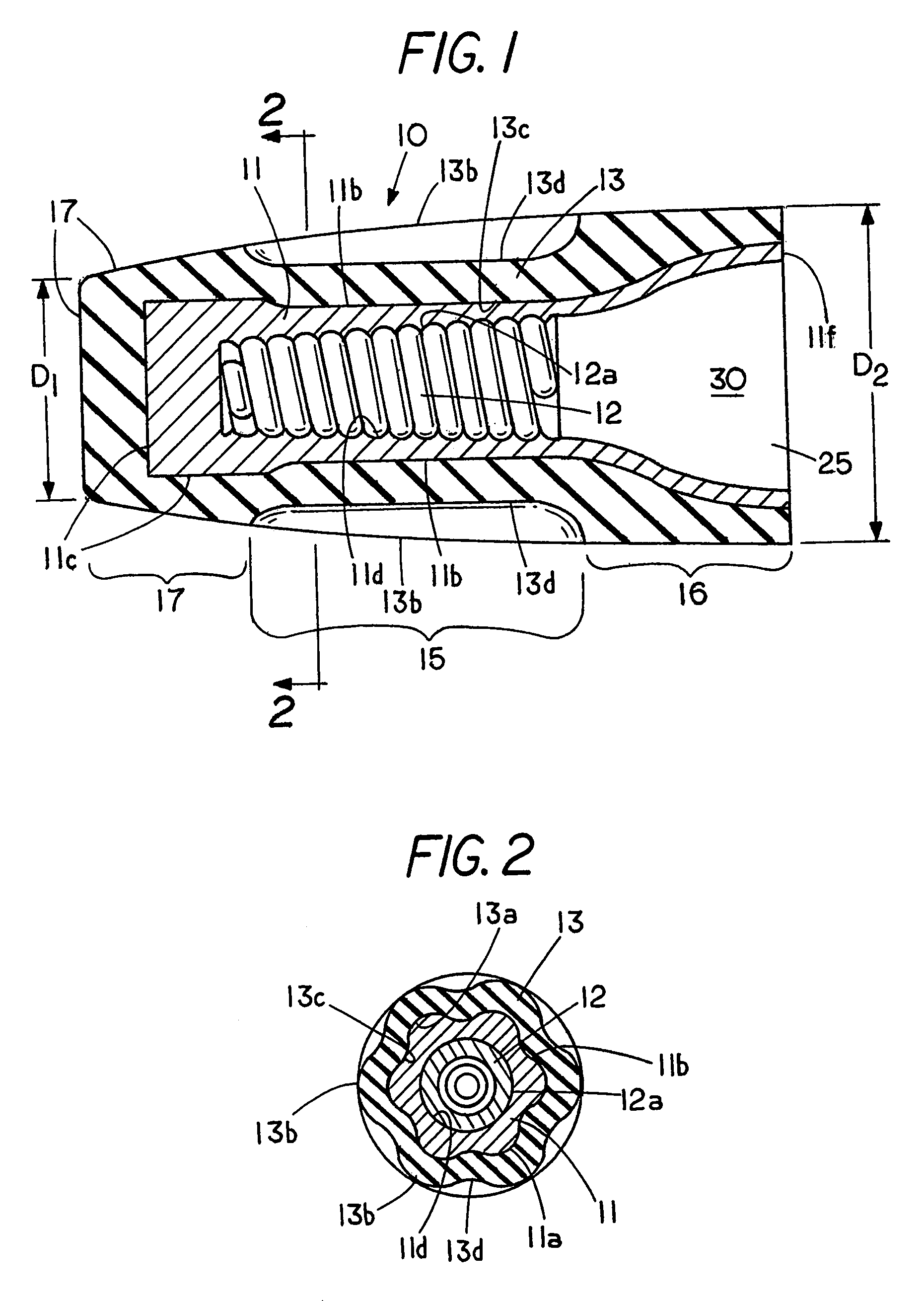

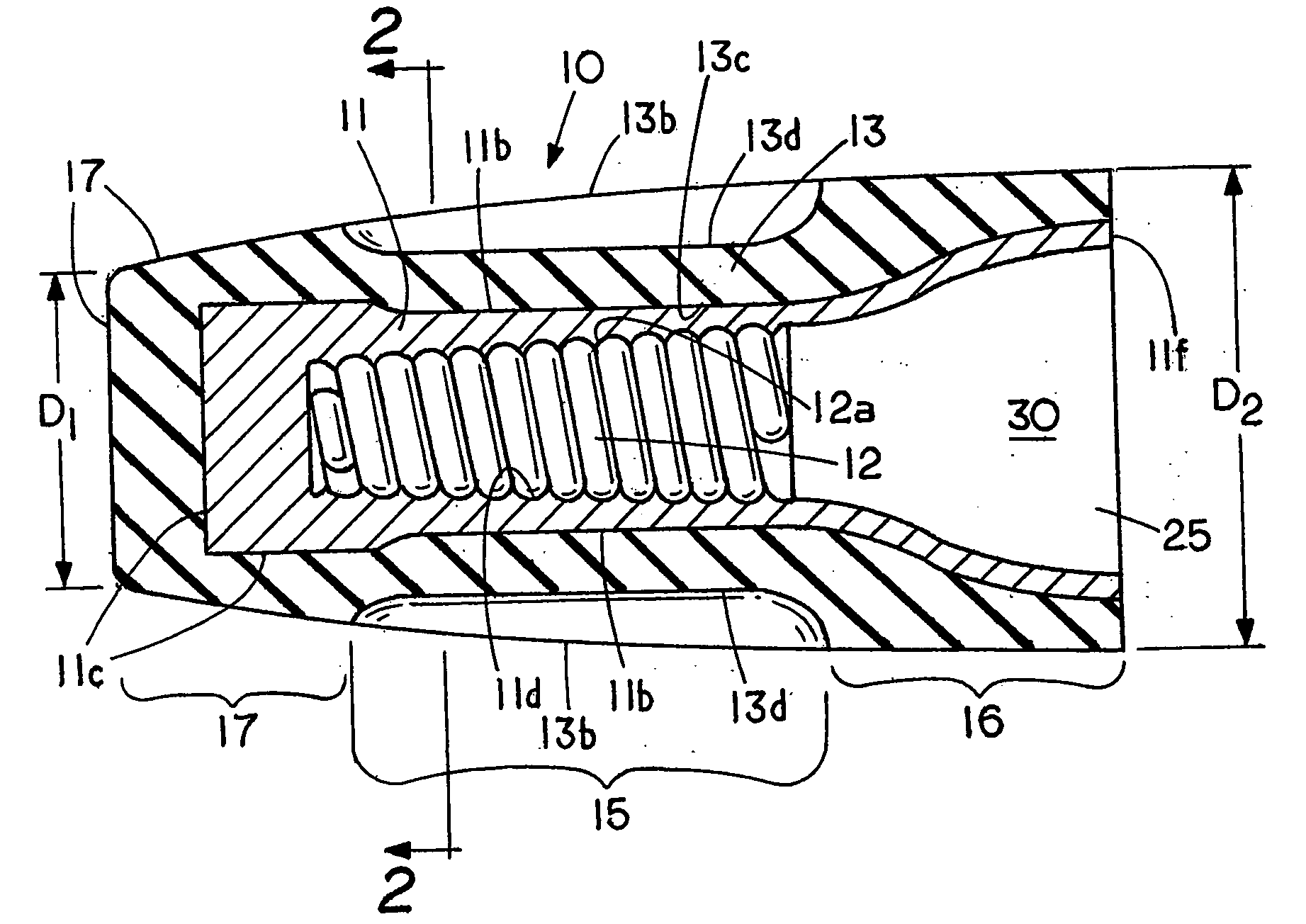

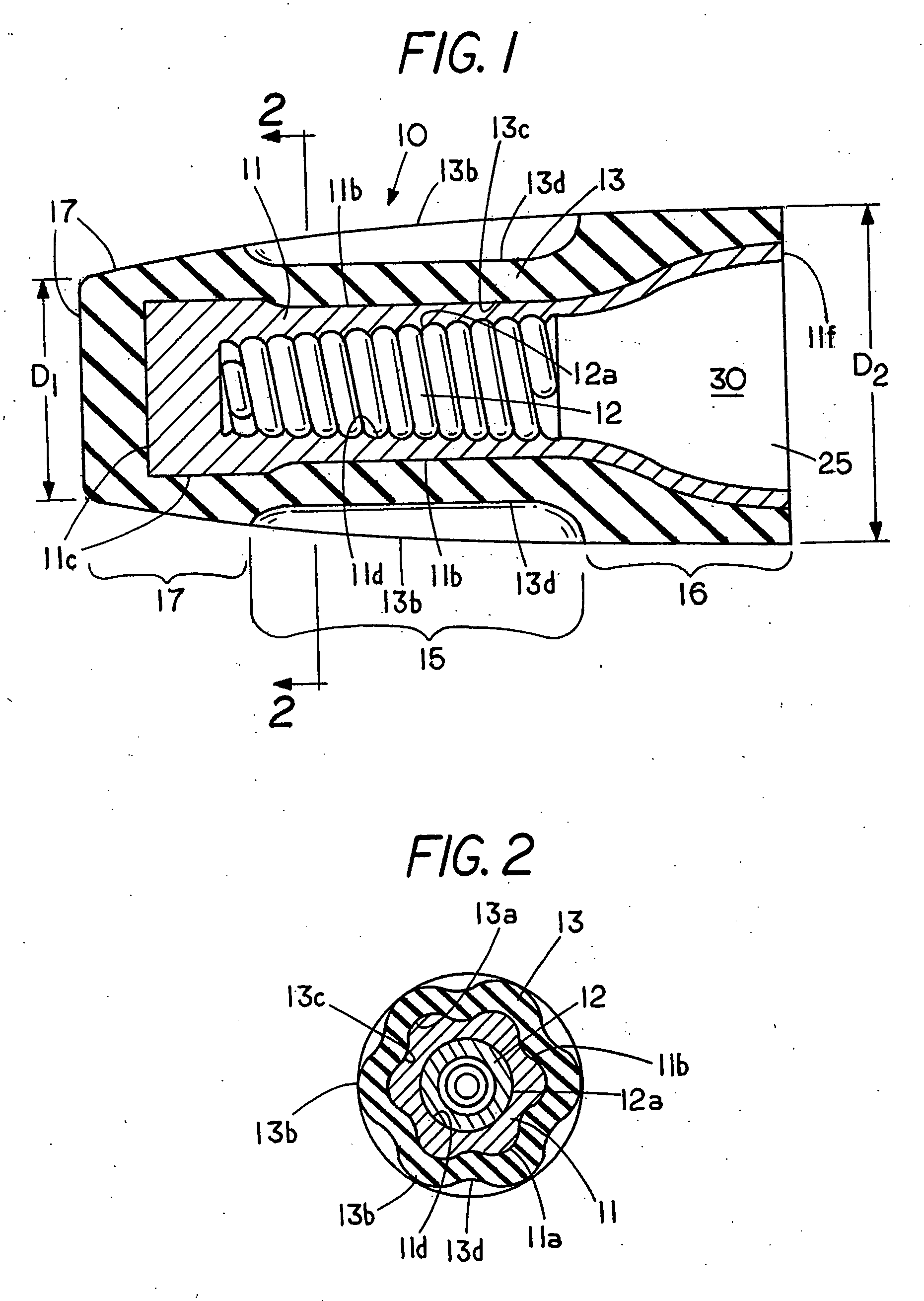

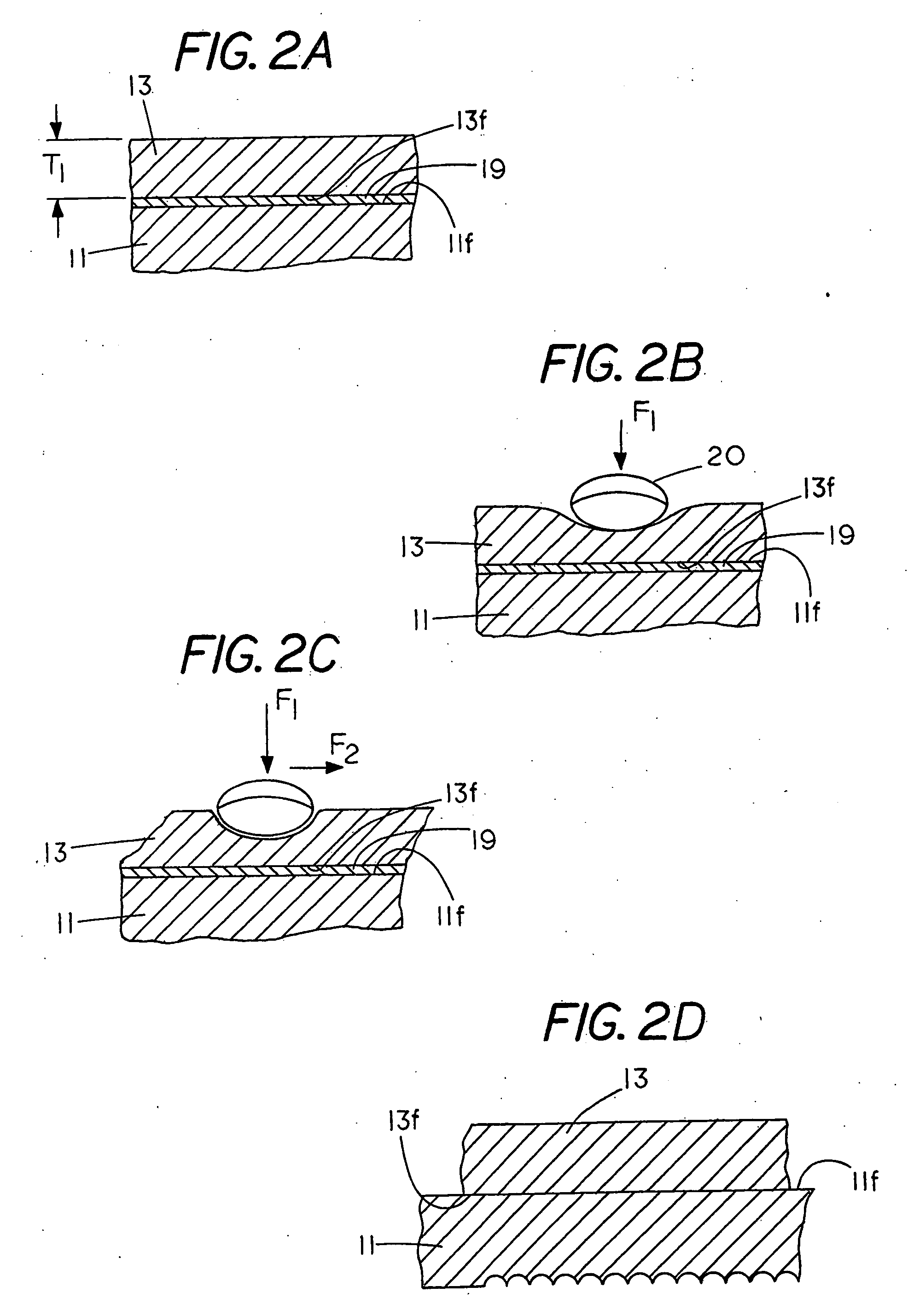

Twist-on wire connector

ActiveUS7560645B2Multiple degrees of responsiveness to finger pressureImprove insulation qualityCoupling device engaging/disengagingCoupling device detailsEngineeringMechanical engineering

Owner:THE PATENT STORE

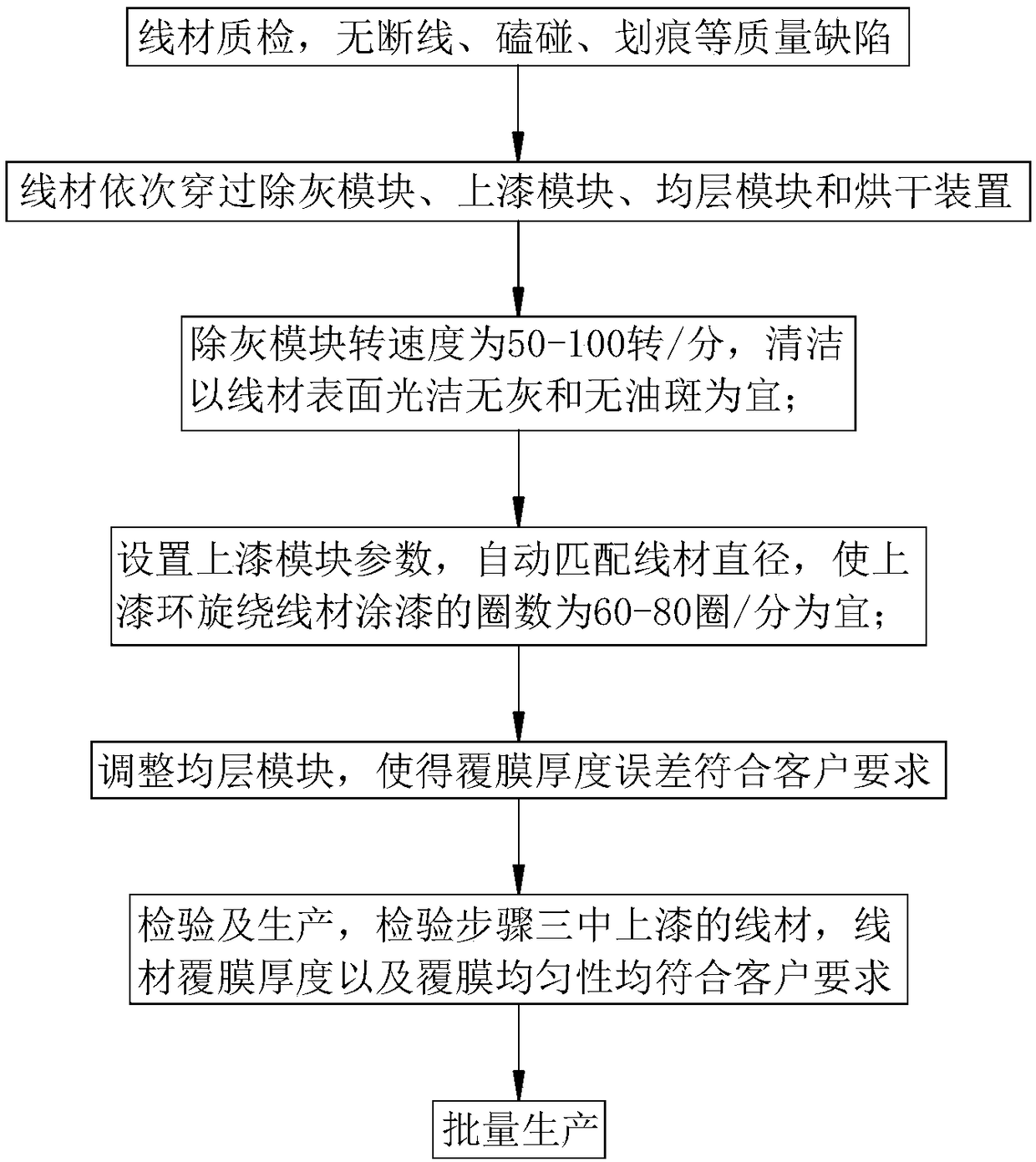

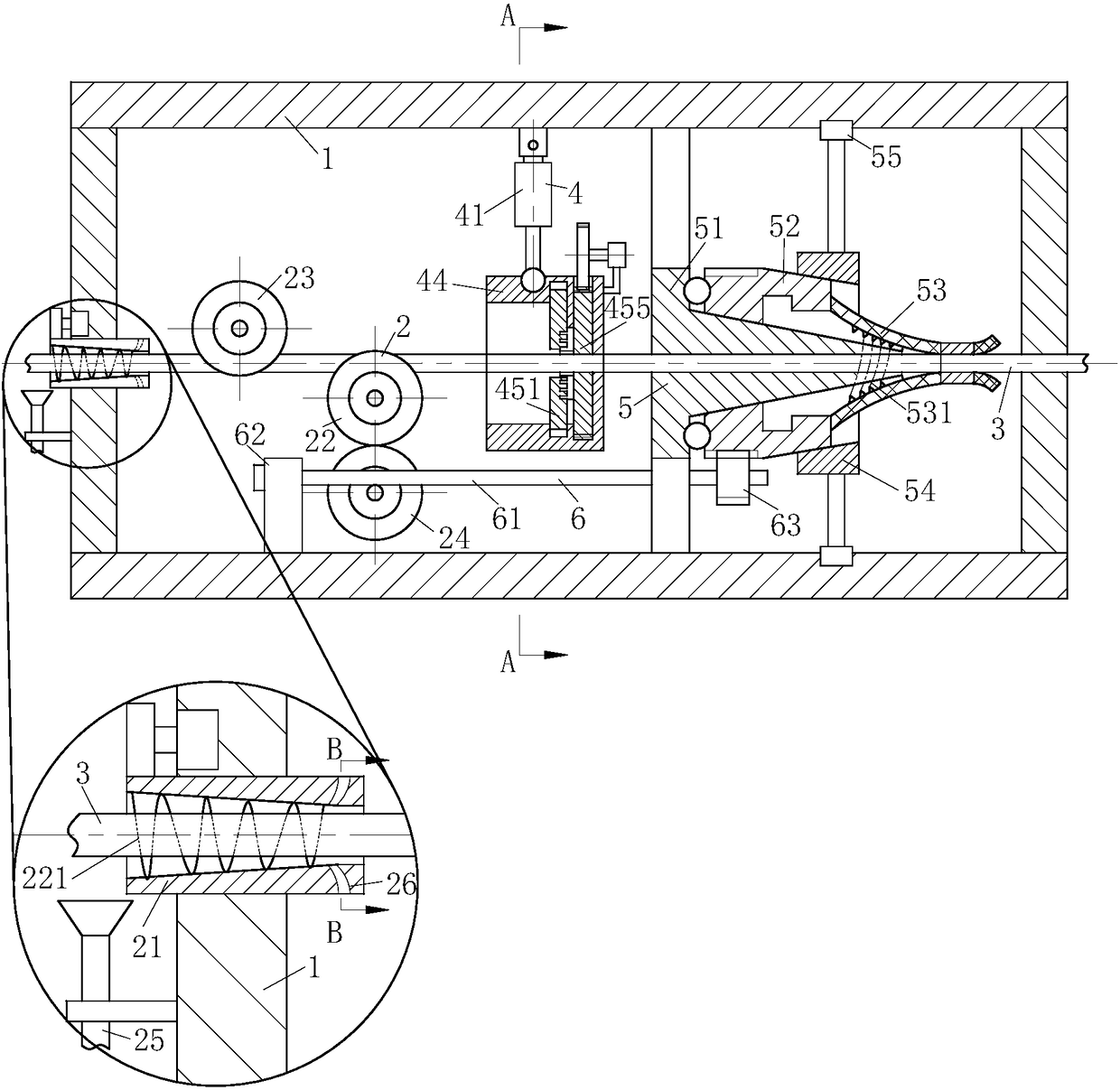

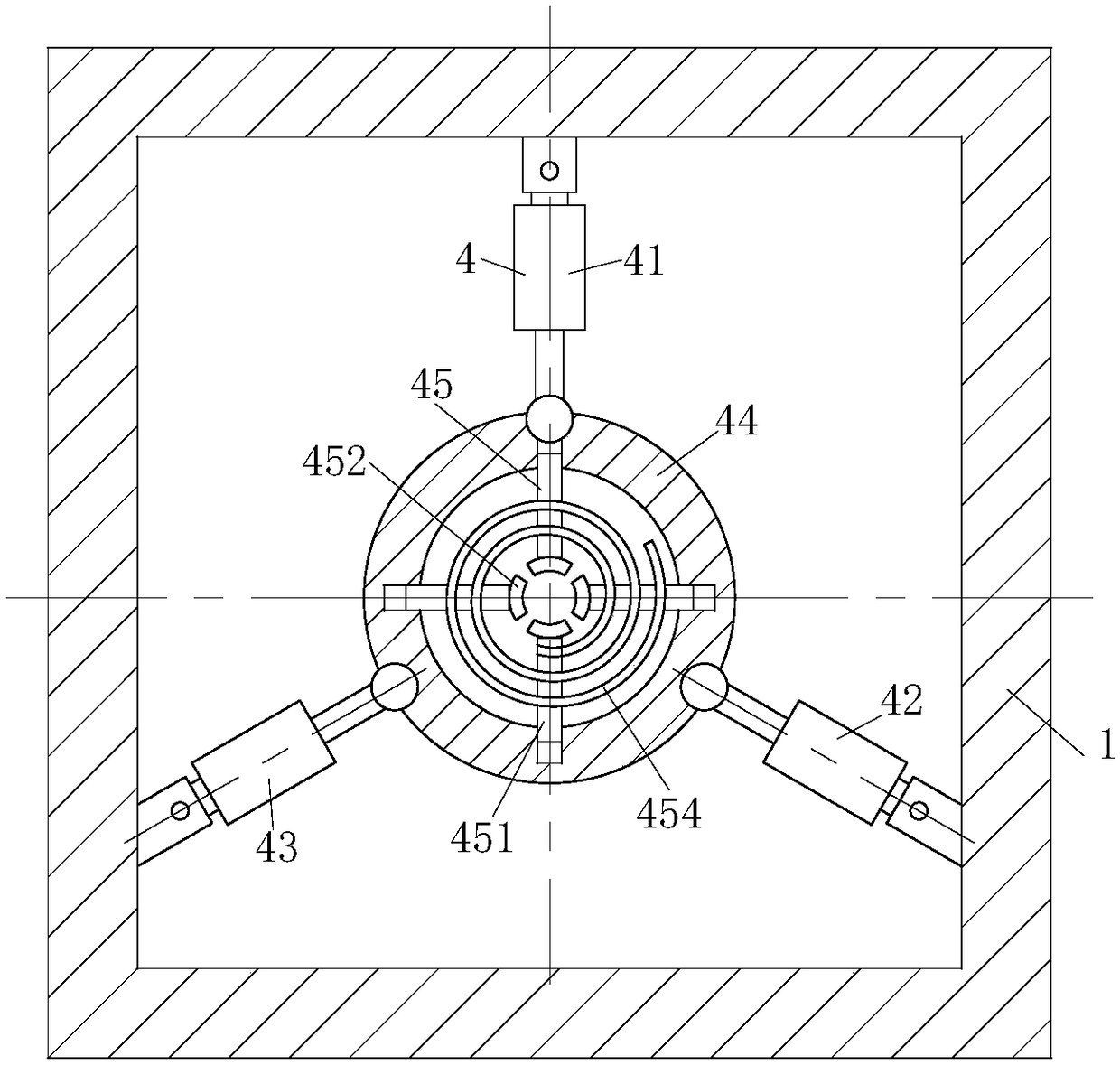

Automatic varnishing method for wire rods of enameled wires

ActiveCN108538514AImprove film qualityImprove coating uniformityInsulating conductors/cablesWire rodEngineering

The invention belongs to the enameled wire processing technical field and relates to an automatic varnishing method for the wire rods of enameled wires. According to the step 1 of the method of the invention, a wire rod is inspected, so it can be ensured that the wire rod is free of quality defects such as wire fracture, bump-cased damage and scratches; and strengthening quality management is enhanced to reduce the influence of other factors on varnishing quality. According to the step 2 of the method, the wire rod passes through an ash removal module, a varnishing module, a layer-uniformizingmodule and a drying device sequentially. According to the step 3, the rotation speed of the ash removal module ranges from 50 to 100 rpm, and it is advisable that the surface of the wire rod should be cleaned until the surface of the wire rod is smooth and is free of dust and oil spots; the parameters of the varnishing module are set so as to automatically match the diameter of the wire rod, andit is advisable that the number of turns of the rotation of a varnishing ring around the wire rod to varnish the wire rod should be 60 to 80 turns per minute; and the layer-uniformizing module is adjusted, so that coating thickness error can meet the requirements of customers. According to the step 4, after the wire rod is inspected as a qualified product, batch production is carried out. According to the automatic varnishing method for the wire rods of the enameled wires of the invention, the above varnishing devices are adopted, the surface coating of the wire rod is uniformized, and therefore, the uniformity of the coating can be improved, and the insulation quality of the wire rod can be improved.

Owner:红旗集团江西铜业有限公司

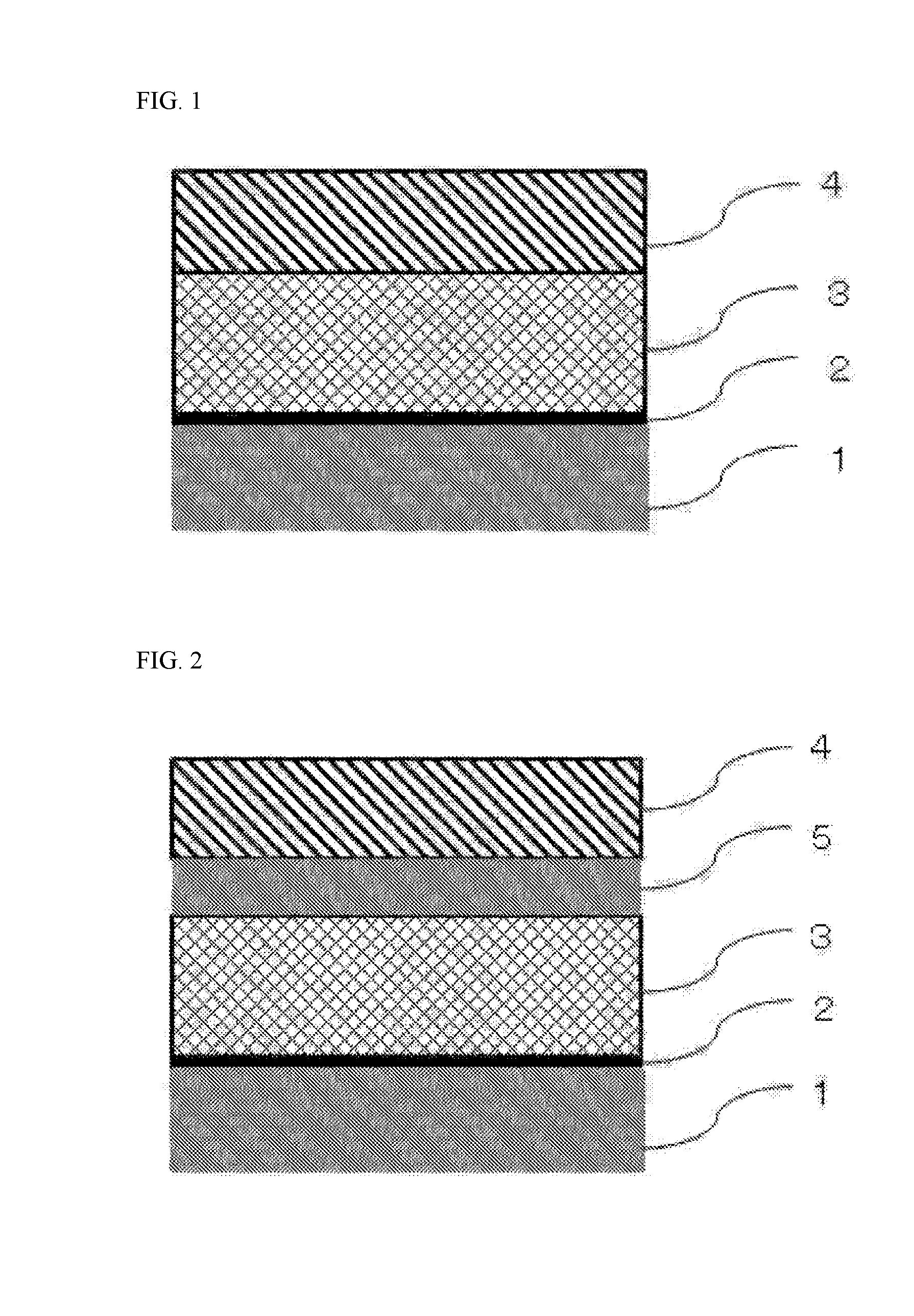

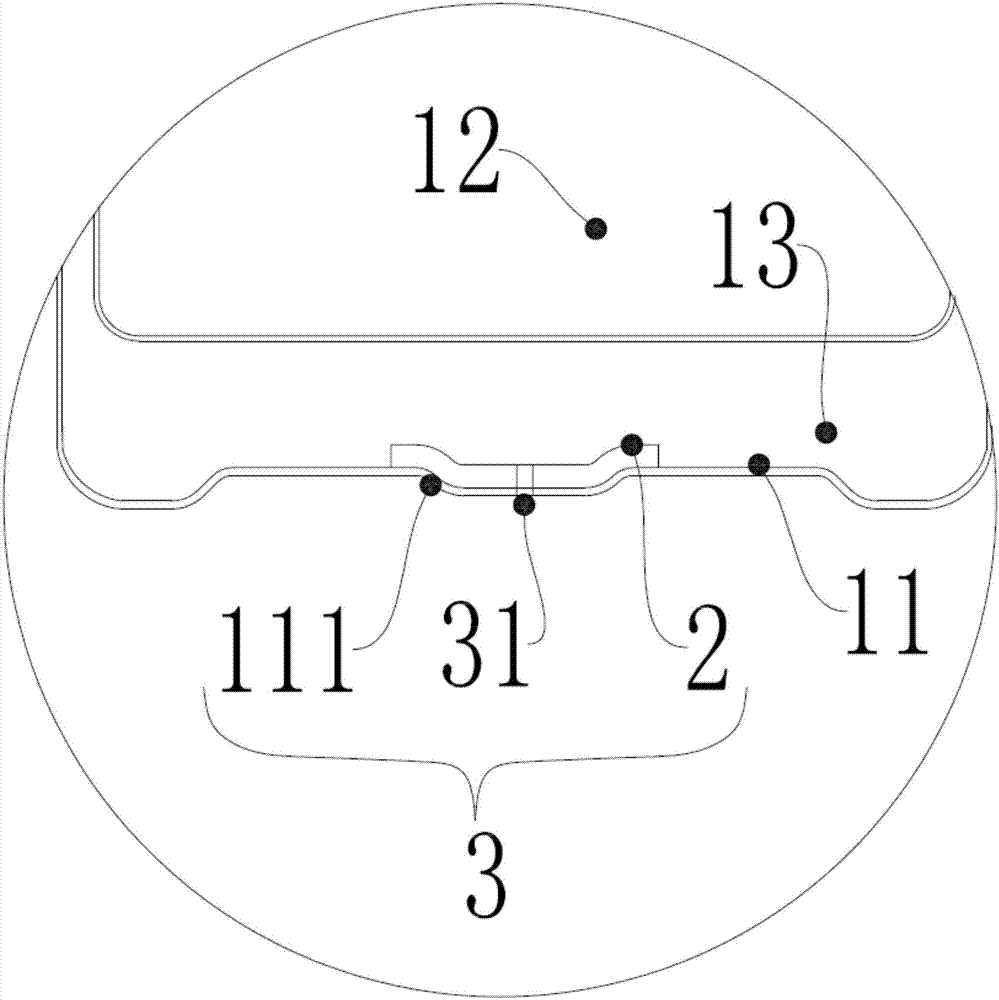

Battery packaging material

ActiveUS20170092902A1Improve insulation qualityGood moldabilityFlexible coversWrappersAdhesiveEngineering

A battery packaging material of a first aspect identifiable from the outside has exceptional moldability, insulating properties, and reduced external appearance defects and seal defects. A battery packaging material of the second aspect identifiable has post-molding concealment and adhesion properties, exceptional electrolyte resistance and surface insulating properties. The battery packaging material of the first aspect includes a laminate of at least a base material, adhesive, metal and sealant layers sequentially laminated, at least one of the base material and adhesive layers includes a dye. The battery packaging material of the second aspect includes a laminate of at least a decorative, base material, metal and sealant layers sequentially laminated; the decorative layer has at least a first and second decorative layers from the base material layer side. The decorative layer includes coloring and matting agents. The resin ratio is at least 60% by mass for the first and second decorative layers.

Owner:DAI NIPPON PRINTING CO LTD

Twist-on wire connector

ActiveUS20070084620A1Avoid fingersAvoid hand injuriesCoupling device engaging/disengagingCoupling device detailsEngineeringMechanical engineering

A twist-on wire connector having a finger friendly unbiased cushioned cover that covers not only the normal hand gripping region but at least part or all of the normal non-hand gripping region of the twist-on wire connector so that regardless of the way the twist-on wire connector is grasped the user fingers engage the cushioned cover to inhibit finger and hand injury and fatigue from repeated securement of twist-on wire connectors to electrical leads and a method of making a twist-on wire connector with a cushioned cover by placing a soft to the touch material on the exterior surface of the twist-on wire connector.

Owner:THE PATENT STORE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com