Structural elements and method for fabricating structural elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

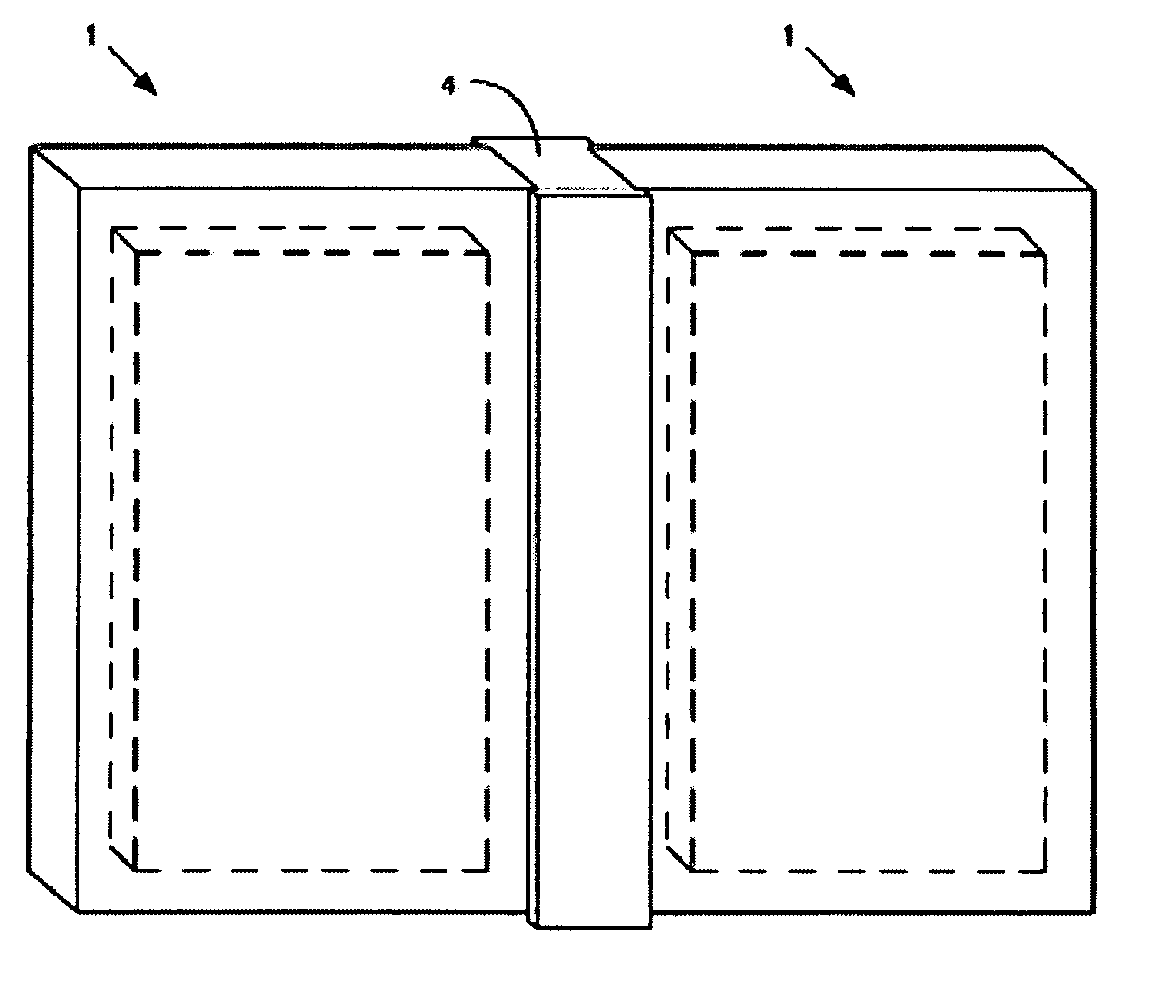

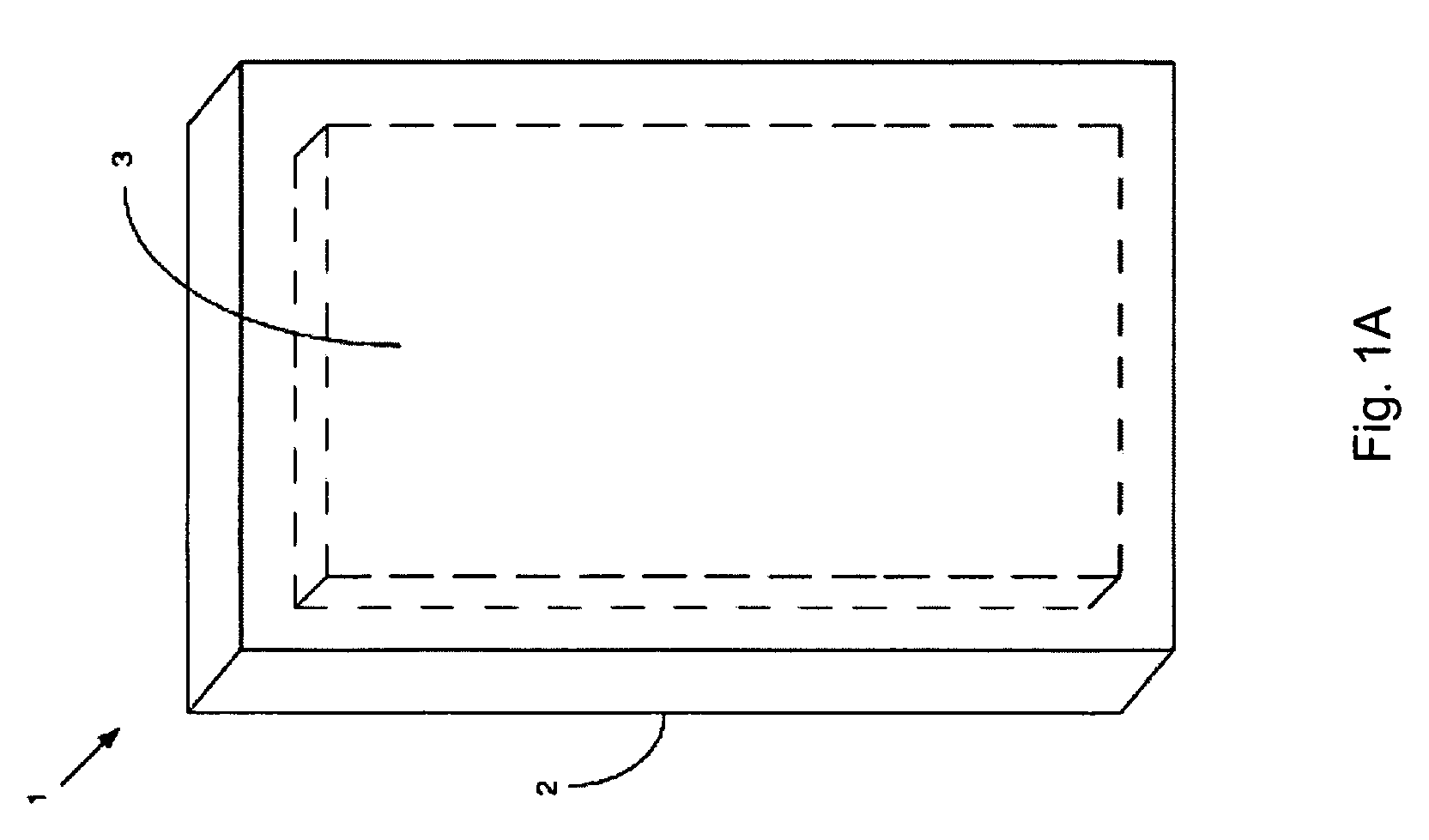

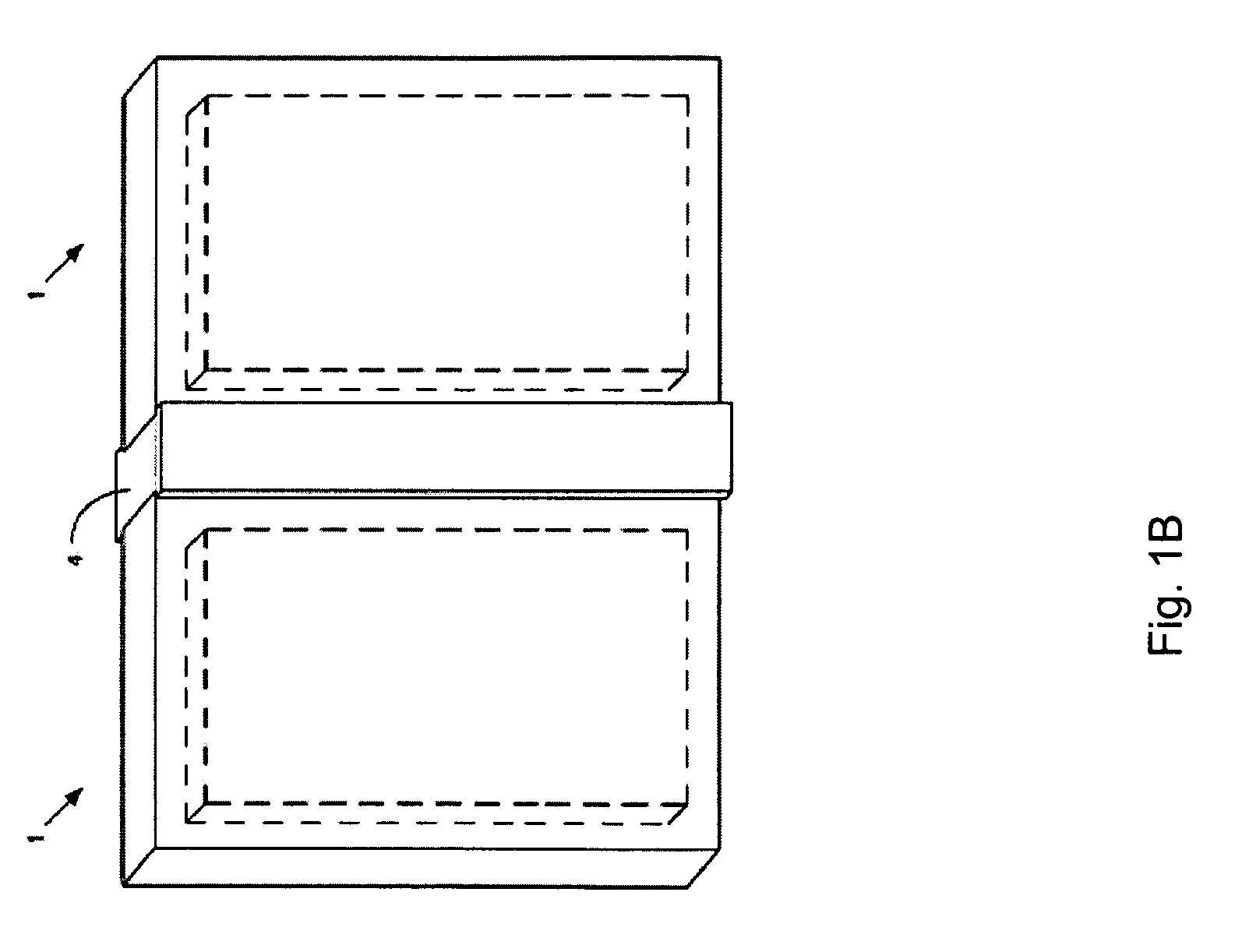

[0028] Referring to FIG. 1A, a segment 1 of a privacy (or barrier) wall includes an outer concrete shell 2 that surrounds an inner foam core 3. When used as part of a privacy wall, segment 1 provides a durable outer shell 2 that is fabricated from concrete and allows a structure to last a long period of time. The foam core 3 is protected by the outer concrete shell 2. The foam core 3 provides several advantages over solid concrete wall segments that are typical of the prior art. One advantage provided by segment 1 is that due to the lighter weight created by the foam core 3, it is less expensive to transport prefabricated segments 1 from a factory to the job site. In addition, it is also easier to put the segments 1 into position due to their lighter weight. Another important advantage provided by the invention is that the foam core 3 provides better sound insulation than the outer concrete shell 2. Since privacy walls are usually constructed to protect residential neighborhoods fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com