Wall building system and method

a building system and wall technology, applied in the field of building construction, can solve the problems of large planning, high labor intensity, and relatively high cost of architectural techniques used in this form of construction, and achieve the effects of reducing labor and material costs, improving strength and stability, and good insulating qualities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

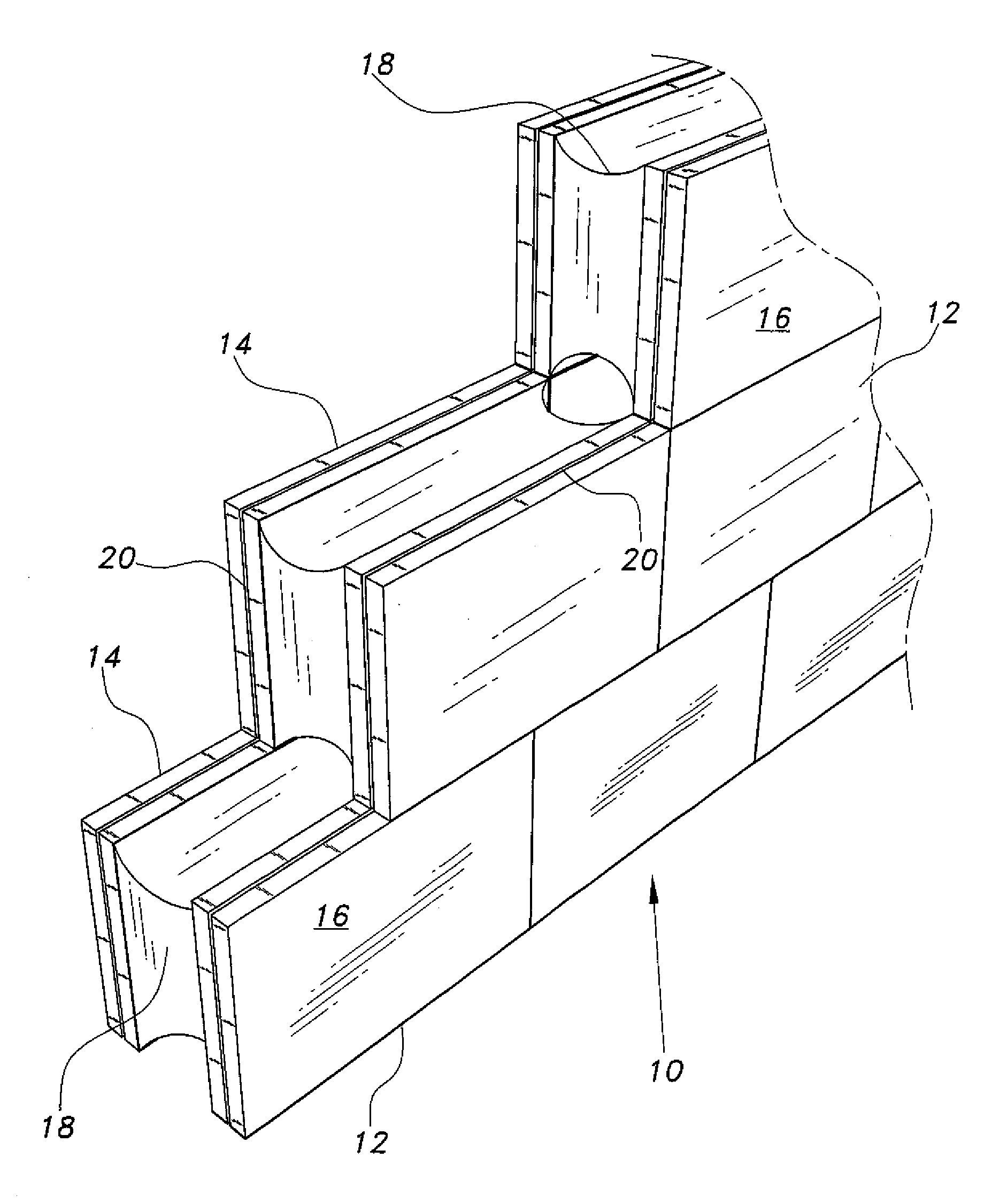

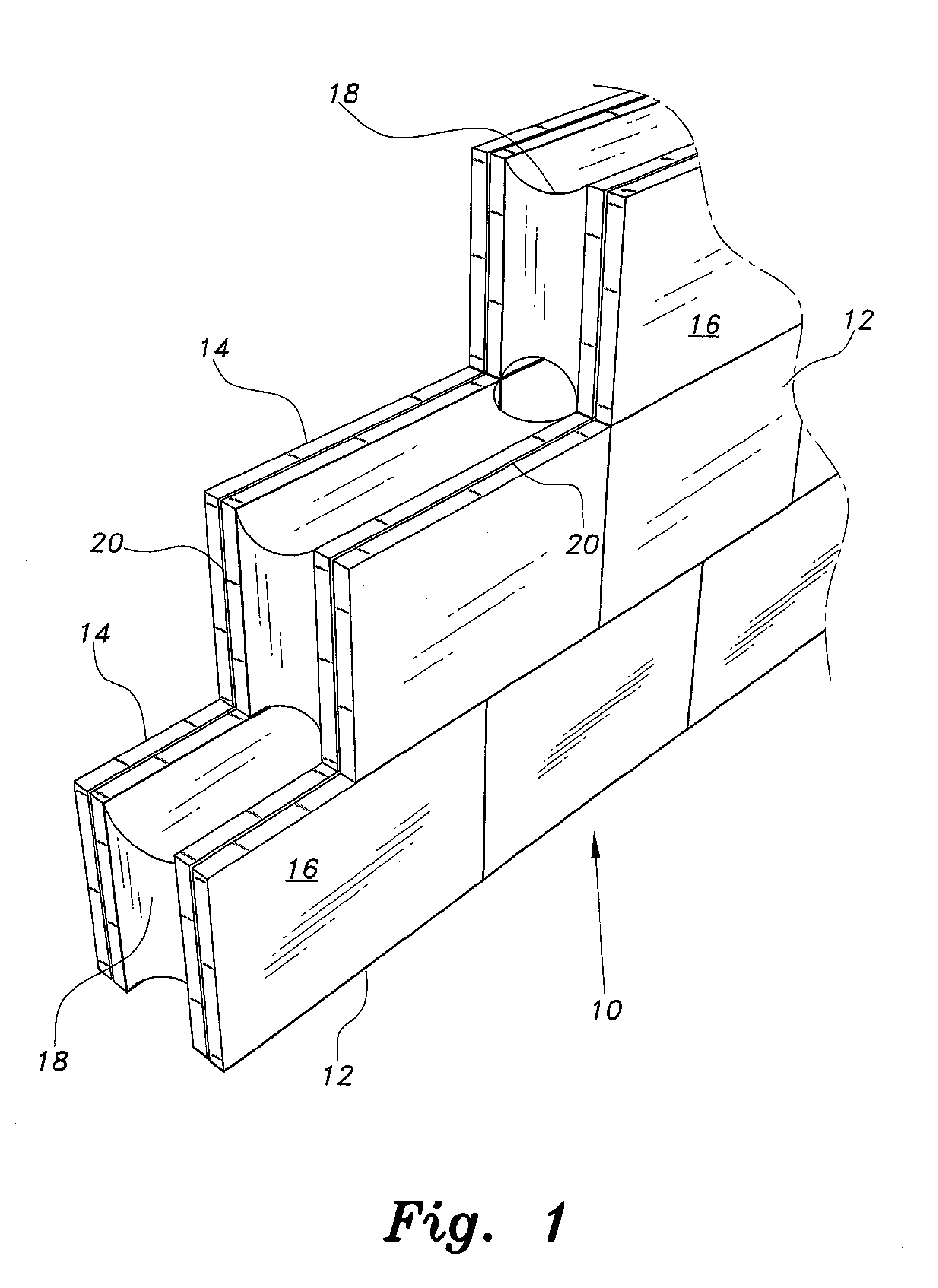

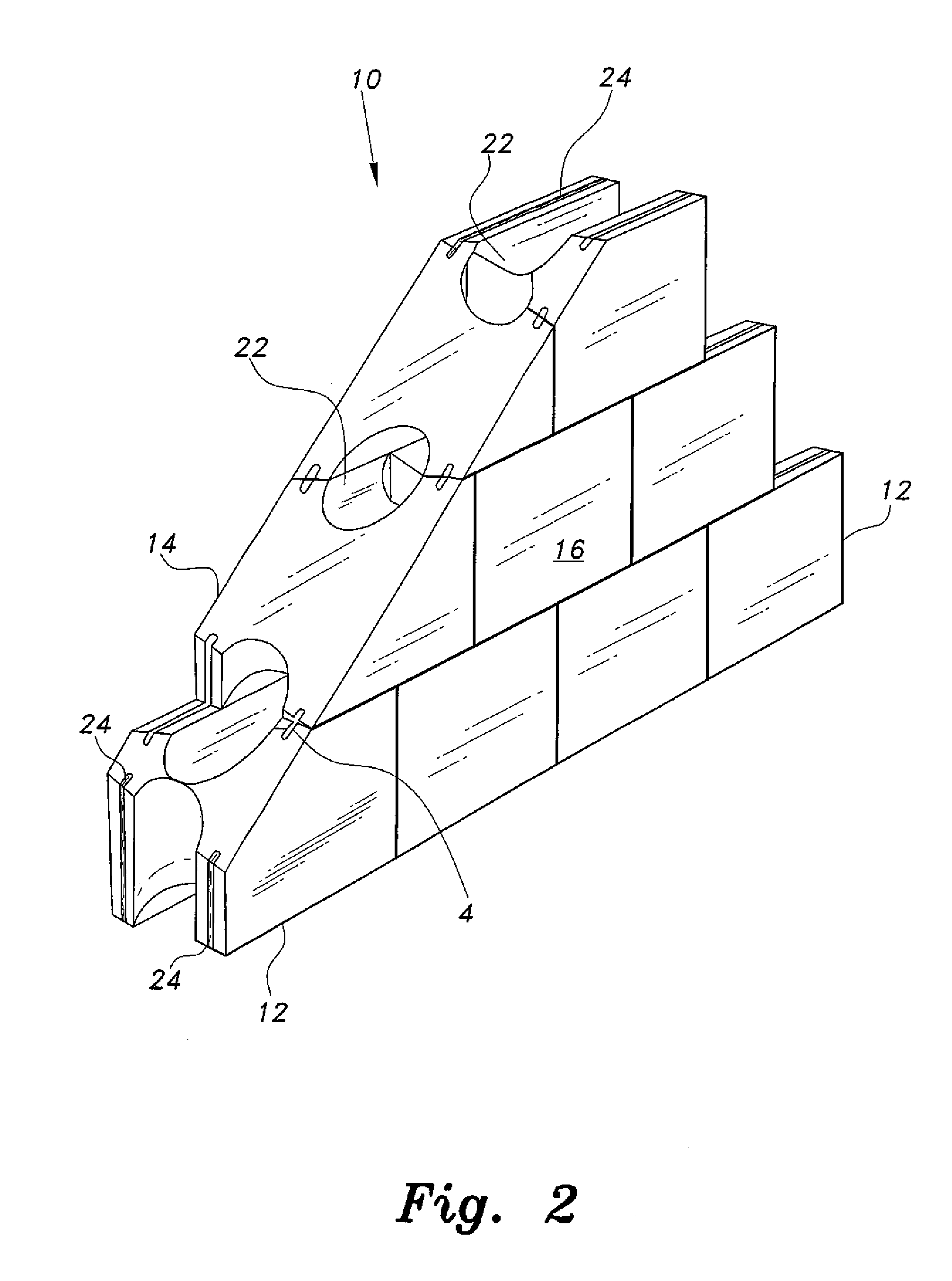

[0016]Referring to FIGS. 1-3, the wall building system is generally indicated at 10. Walls in the system 10 comprise a series of prefabricated block elements 12 that are assembled layer by layer to form the wall. Each block element 12 comprises an inner face member 14 and an outer face member 16 that are connected via a profiled core member 18. Each face member 14, 16 is provided with a continuous groove 20 around the face. The core member 18 is designed in a concave profile so that channels or passages 22 are formed in the wall when the blocks 12 are assembled. The core 18 is fabricated from materials having good insulation qualities. As indicated above, the passages 22 permit the insertion of electrical wiring, plumbing conduits and the like during the assembly process. The exposed surfaces of each face member 14, 16 can be plastered and painted before assembly. Connecting elements 24, preferably fabricated from steel, are inserted in the grooves 20 and interwoven between respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com