Disposable paper cups, method of making, and handling of such cups

a technology of paper cups and disposable cups, applied in the field of disposable cups, can solve problems such as some stale conditions, and achieve the effects of improving insulation quality, reducing surface area, and improving safety and ease of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

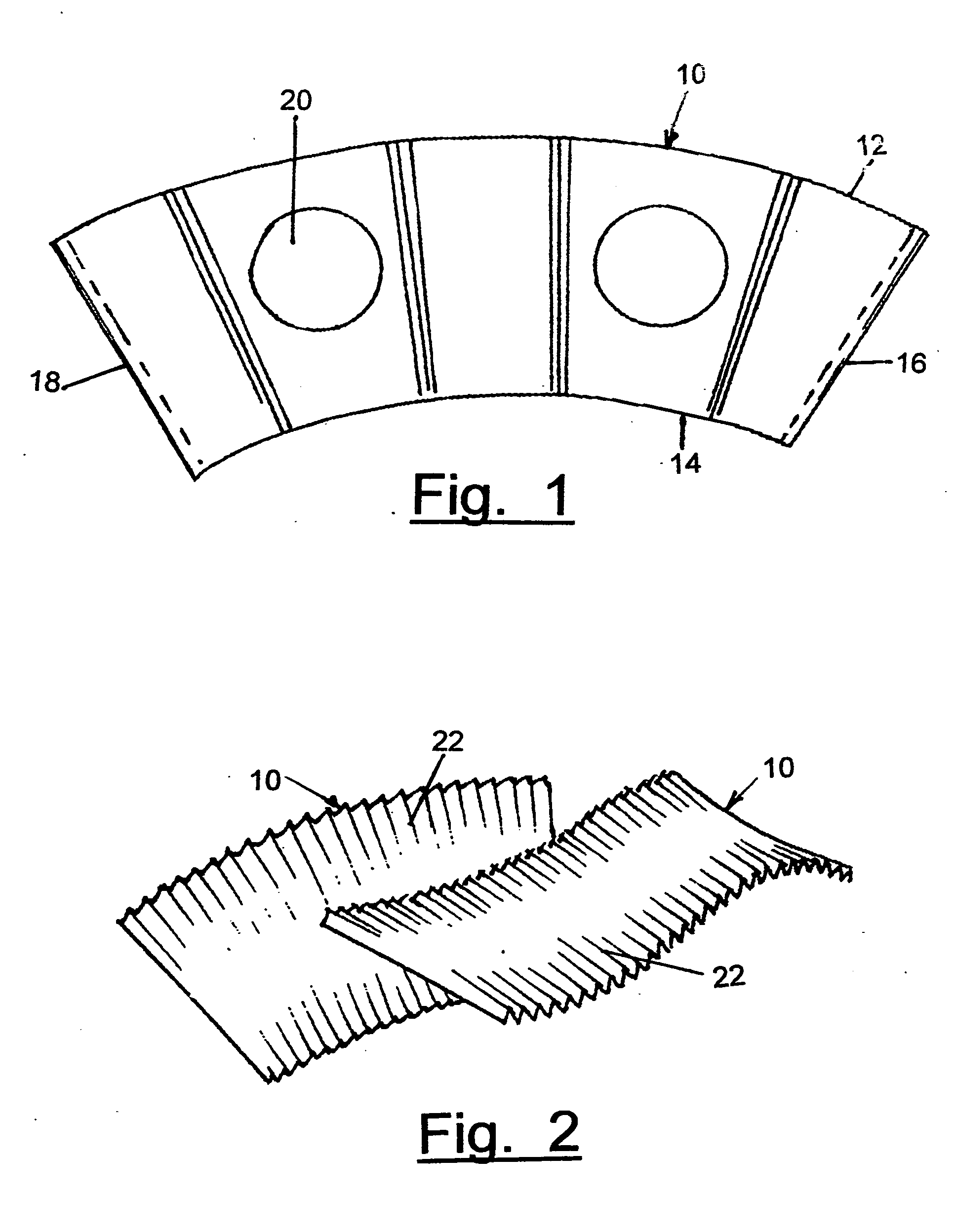

[0037]FIG. 1 represents pre-cut card stock that possibly may have a moisture-repellant wax layer on one side, that is, the side that is to be in contact with the content of the finished container. Such card stock is universally employed in the manufacture of disposable cups. The card stock may be punched into a trapezoidal sector shape. The exterior side of the pre-cut card stock is generally un-waxed so that decorative graphics or advertising can readily be printed thereon.

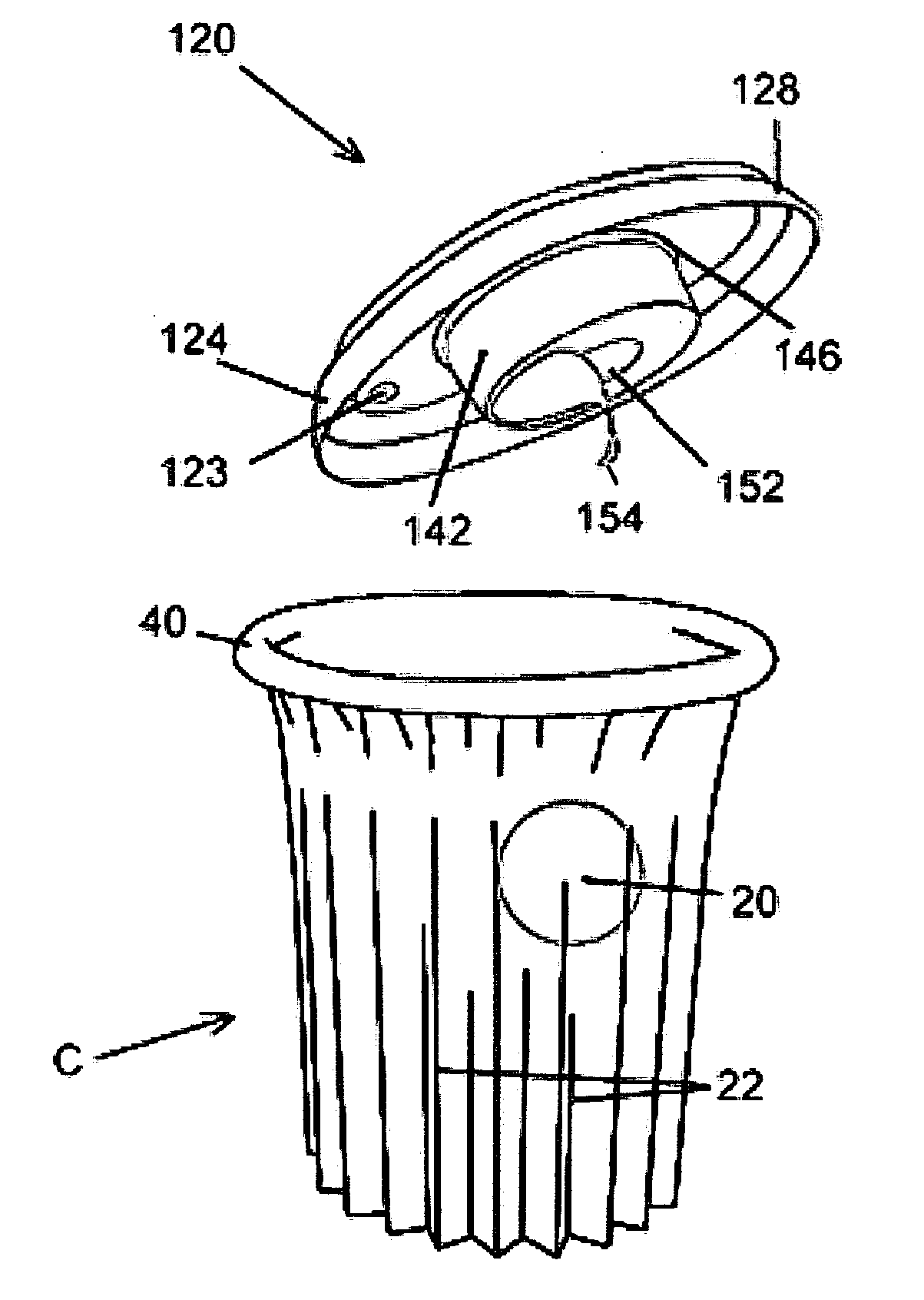

[0038] The cut blank 10 has an upper edge 12 and a lower edge 14 which edges 12 and 14 are spaced apart from one another by the width of the blank 10 which width yields the height of the container which is also referred to in assembly as container C. The blank 10 has lateral edges 16 and 18 that can be joined to one another so as to fashion the desired cylindrical or frusto-conical configuration of the cup or container 10. It is one feature of my container C that an area such as 20 is available for graphics or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com