Patents

Literature

37results about How to "Avoid hand injuries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-surface cleaning implement

A surface cleaning implement for use with an elongated handle is provided. The implement includes a largely rectangular and asymmetric body region with rounded outer edges, largely planar upper and lower surfaces, and upstanding contact material coextensively disposed thereon. The body region is a largely flattened structure having a first and second leading edge corner, the corners comprising where the leading edge of the body region transitions to the side edges. The first corner comprises a large, sweeping radius for cleaning curving and open surfaces. The second corner comprises a sharp corner having a small radius, chamfered, protuberant, or largely square corner wherein overly elongated and stiffened contact material extends therefrom for contacting surfaces within corners or within confined areas. The head region includes a back end having a handle receiving sheath and suitable support therefor, wherein an elongated handle is attached thereto for use away from the user's person.

Owner:PEREZ AMPARO DEL CARMEN

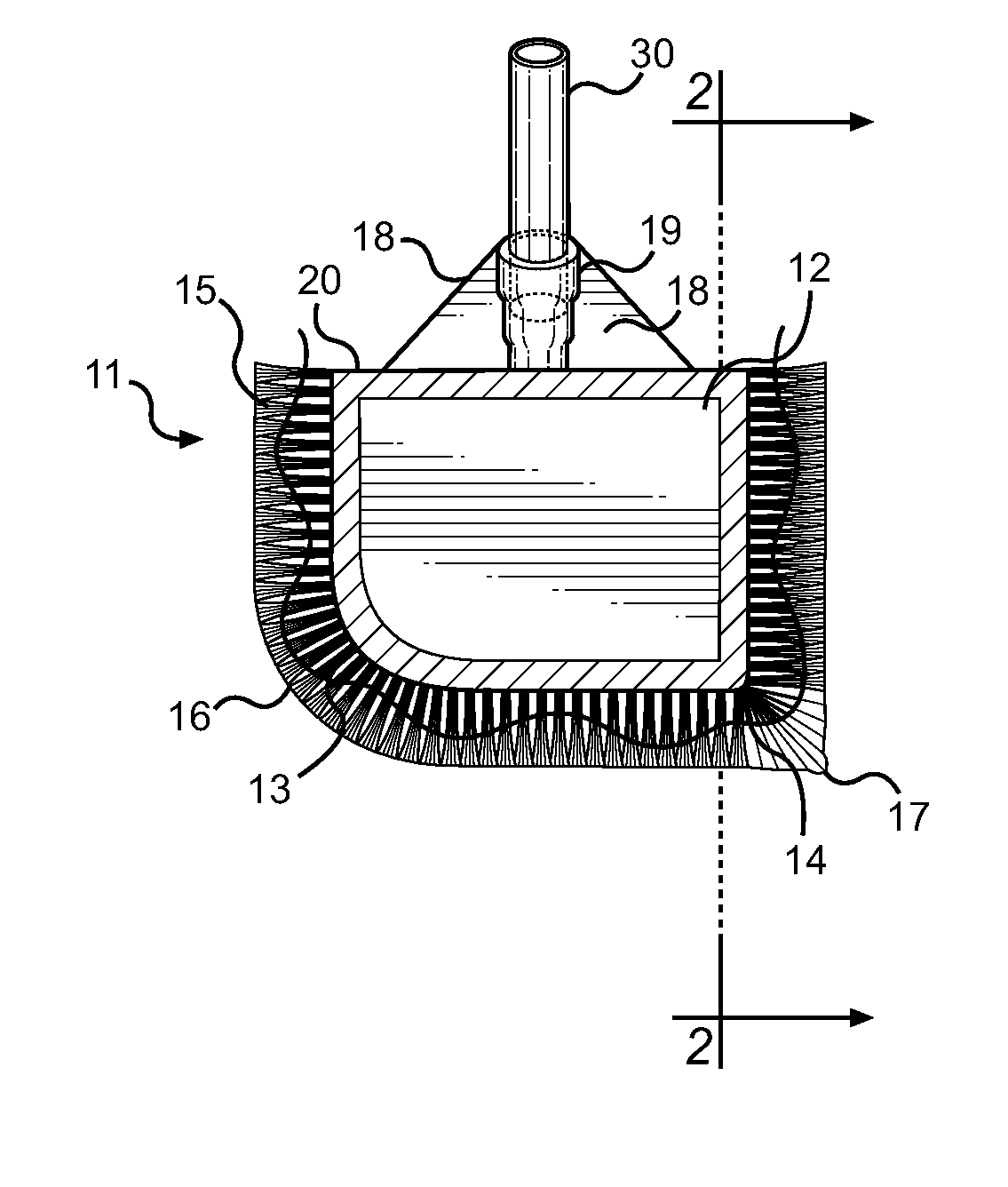

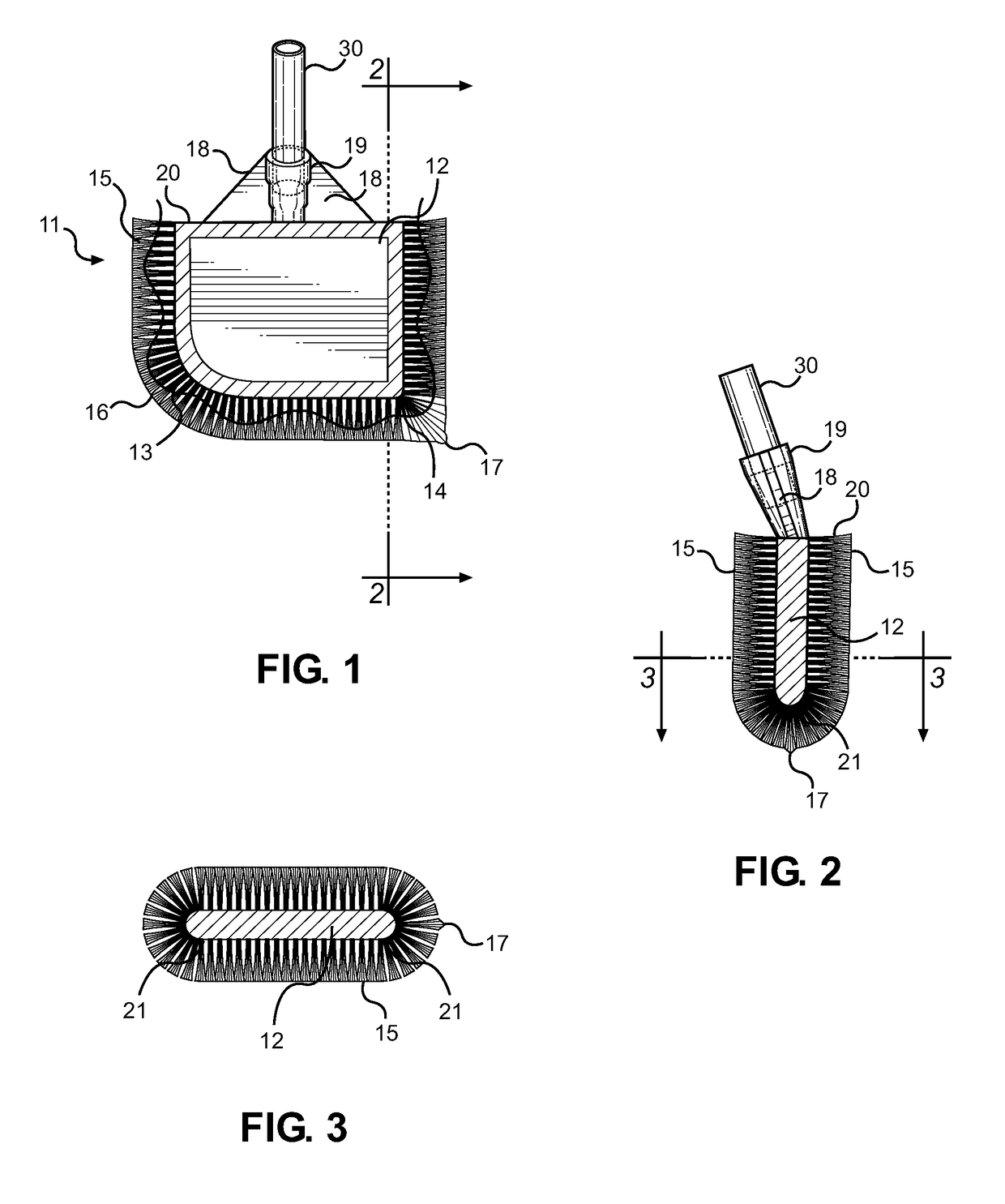

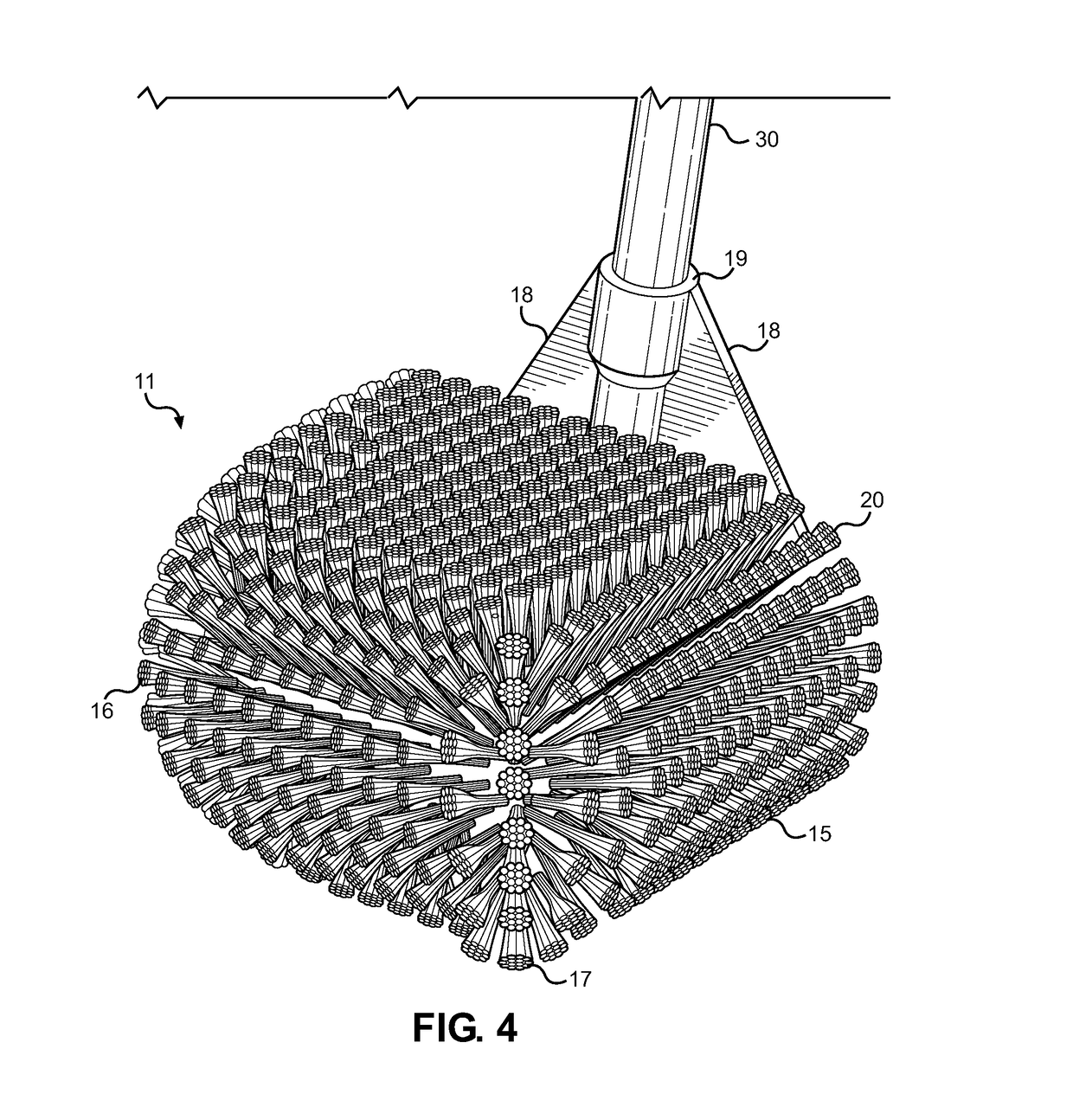

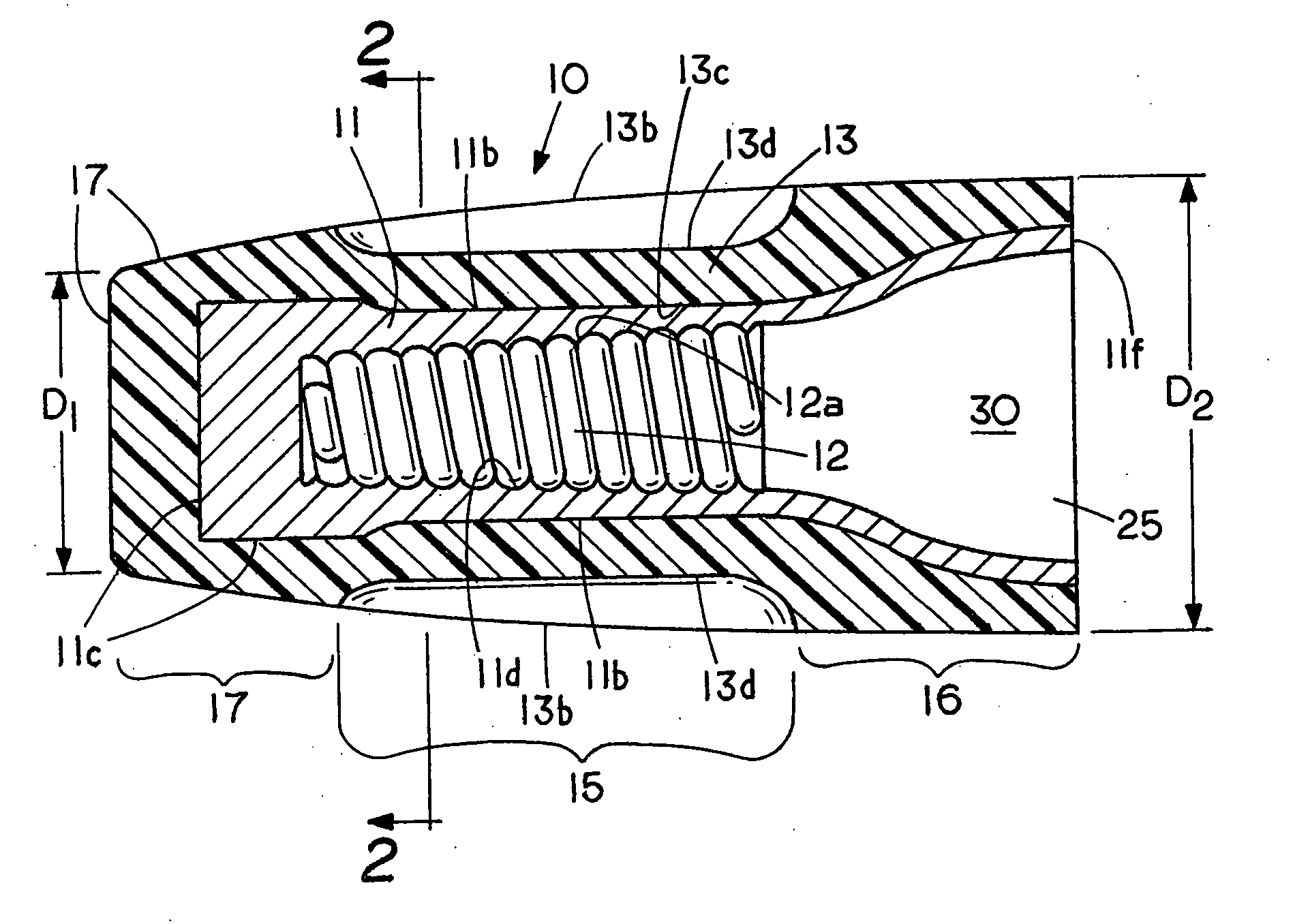

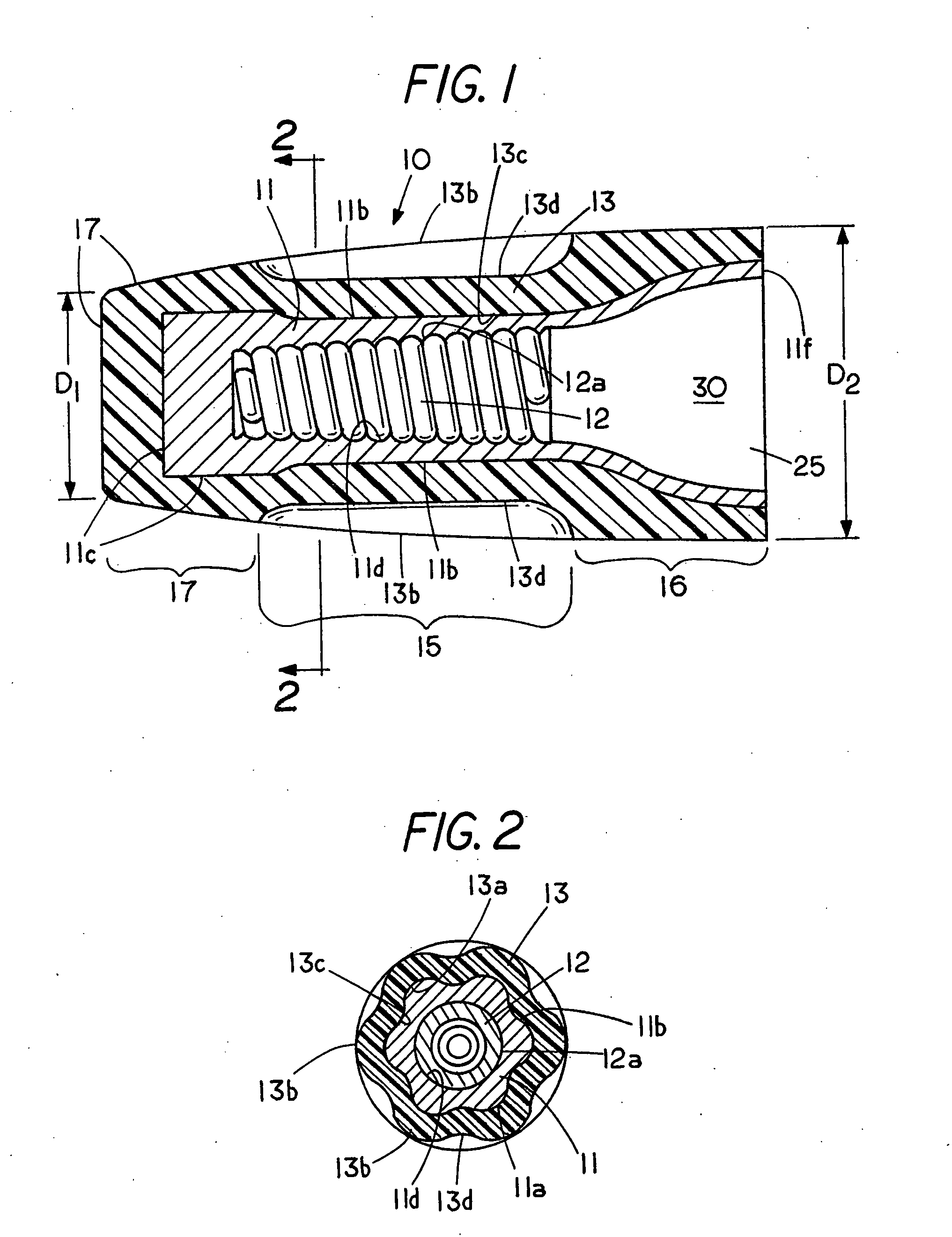

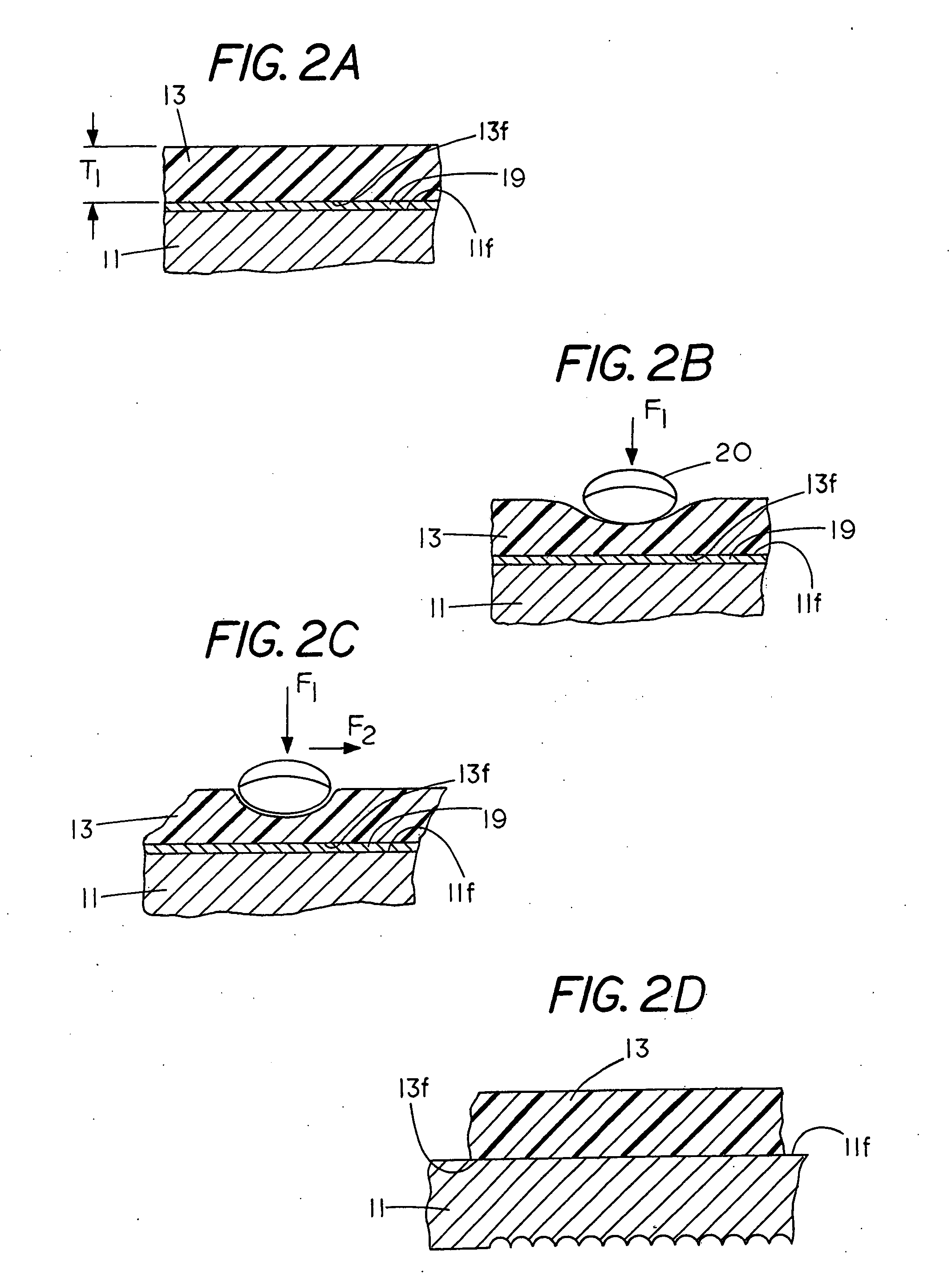

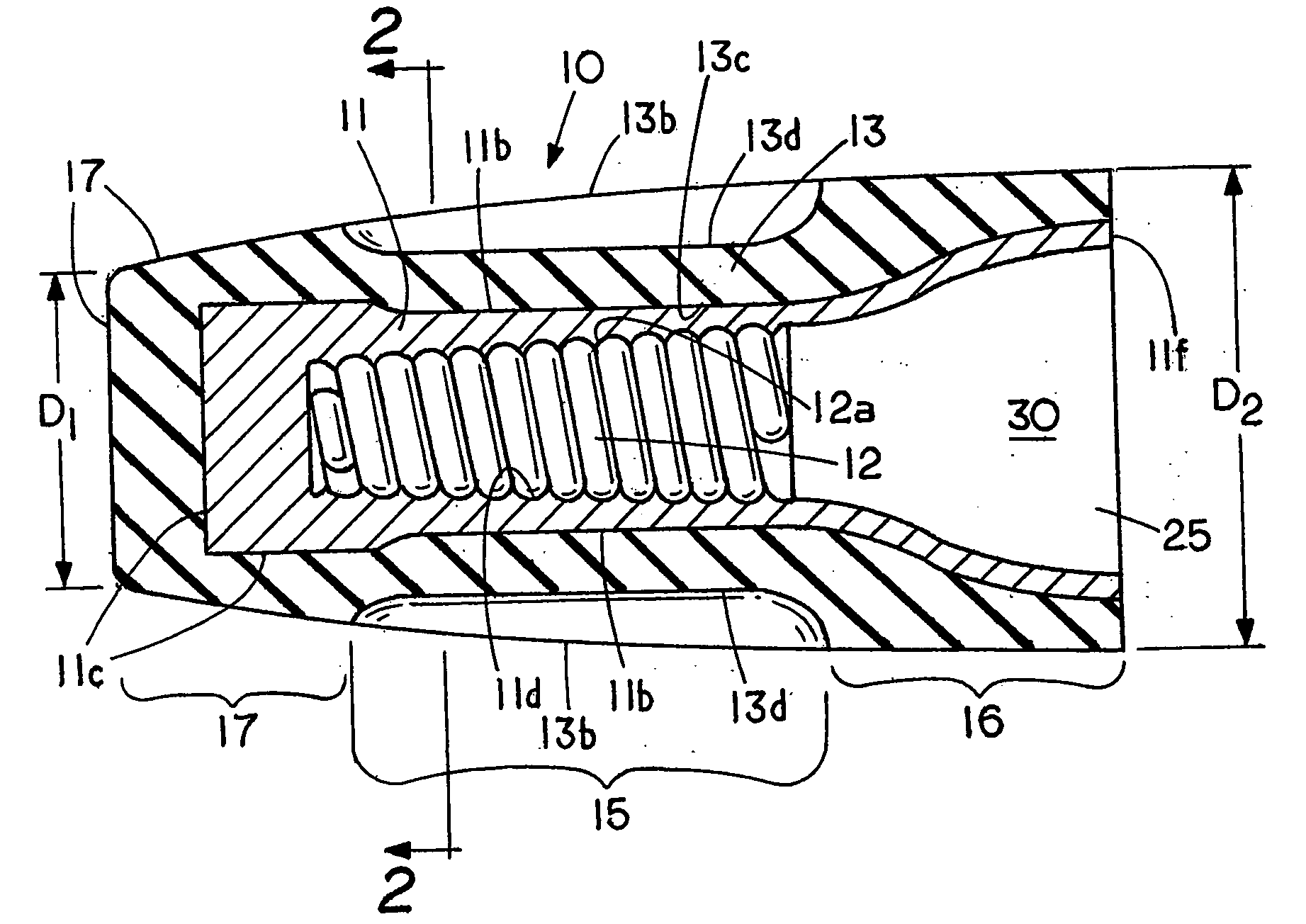

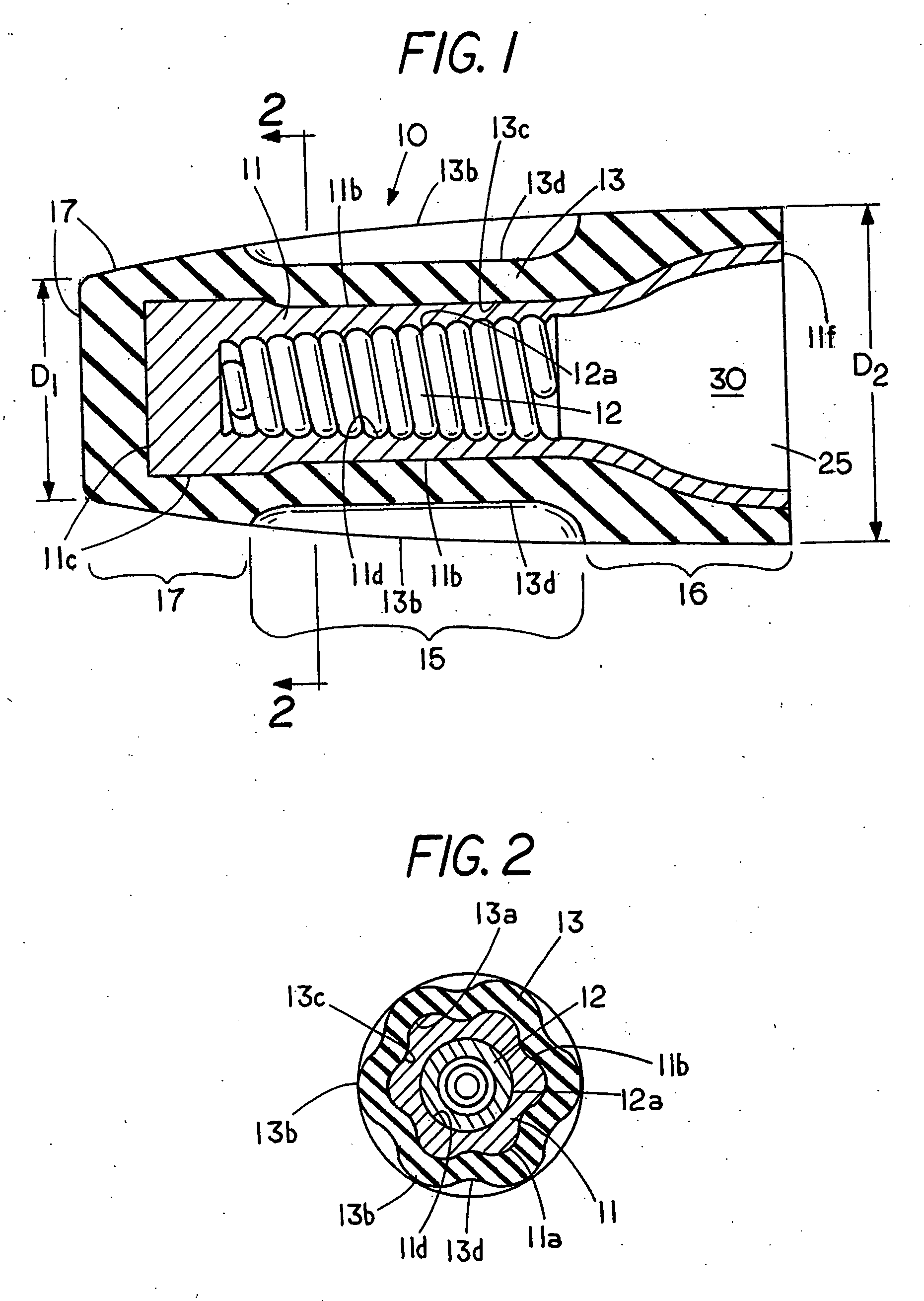

Cushion grip twist-on wire connector

ActiveUS20090283293A1Avoid fingersAvoid hand injuriesConnection end capsCable junctionsCushionGrip strength

A twist-on wire connector having a finger friendly cushion cover that covers not only the normal hand gripping region but at least part or all of the normal non-hand gripping region of the twist-on wire connector so that regardless of the way the twist-on wire connector is grasped the user fingers engage the cushion cover to inhibit finger and hand injury and fatigue from repeated securement of twist-on wire connectors as well as twist-on wire connector with enhanced gripping.

Owner:THE PATENT STORE

Twist-on wire connector

ActiveUS20070084620A1Avoid fingersAvoid hand injuriesCoupling device engaging/disengagingCoupling device detailsEngineeringMechanical engineering

A twist-on wire connector having a finger friendly unbiased cushioned cover that covers not only the normal hand gripping region but at least part or all of the normal non-hand gripping region of the twist-on wire connector so that regardless of the way the twist-on wire connector is grasped the user fingers engage the cushioned cover to inhibit finger and hand injury and fatigue from repeated securement of twist-on wire connectors to electrical leads and a method of making a twist-on wire connector with a cushioned cover by placing a soft to the touch material on the exterior surface of the twist-on wire connector.

Owner:THE PATENT STORE

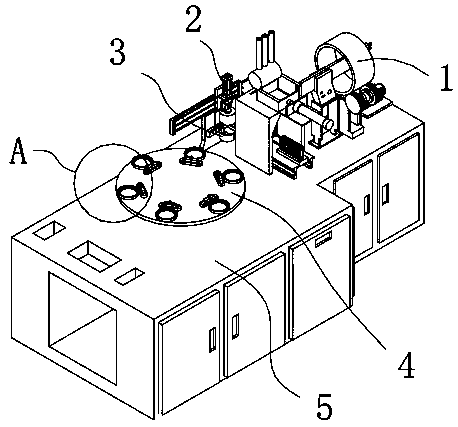

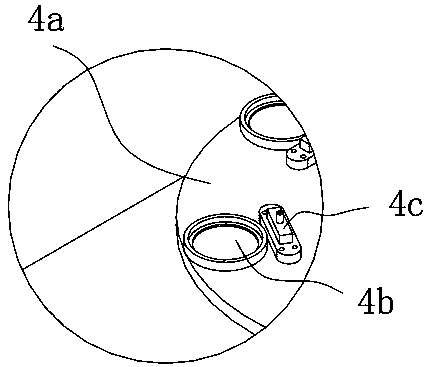

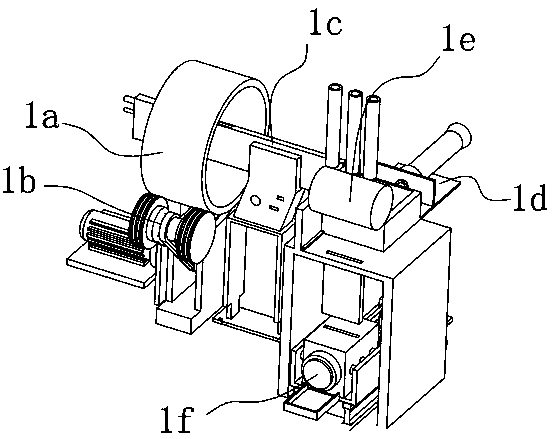

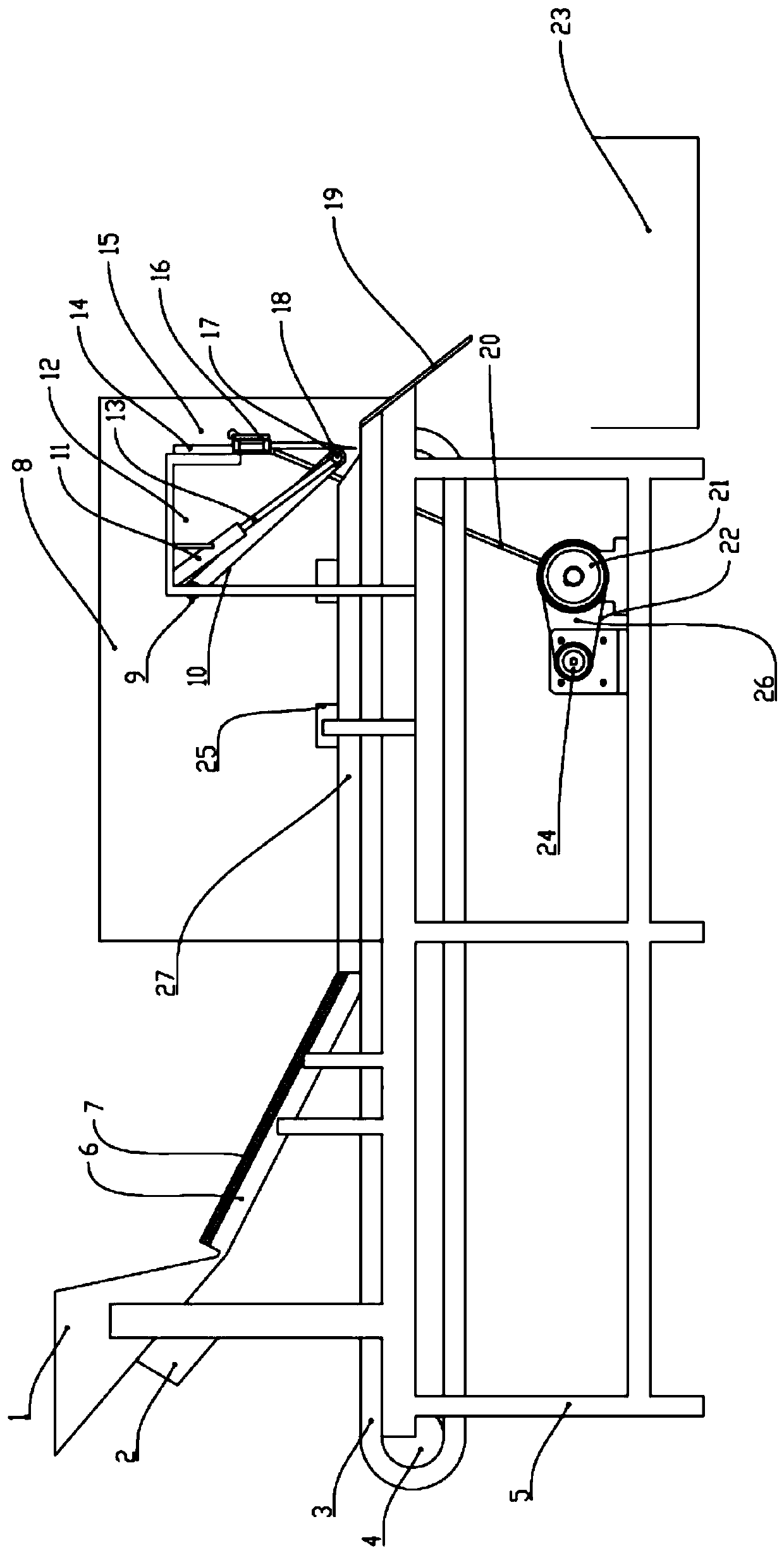

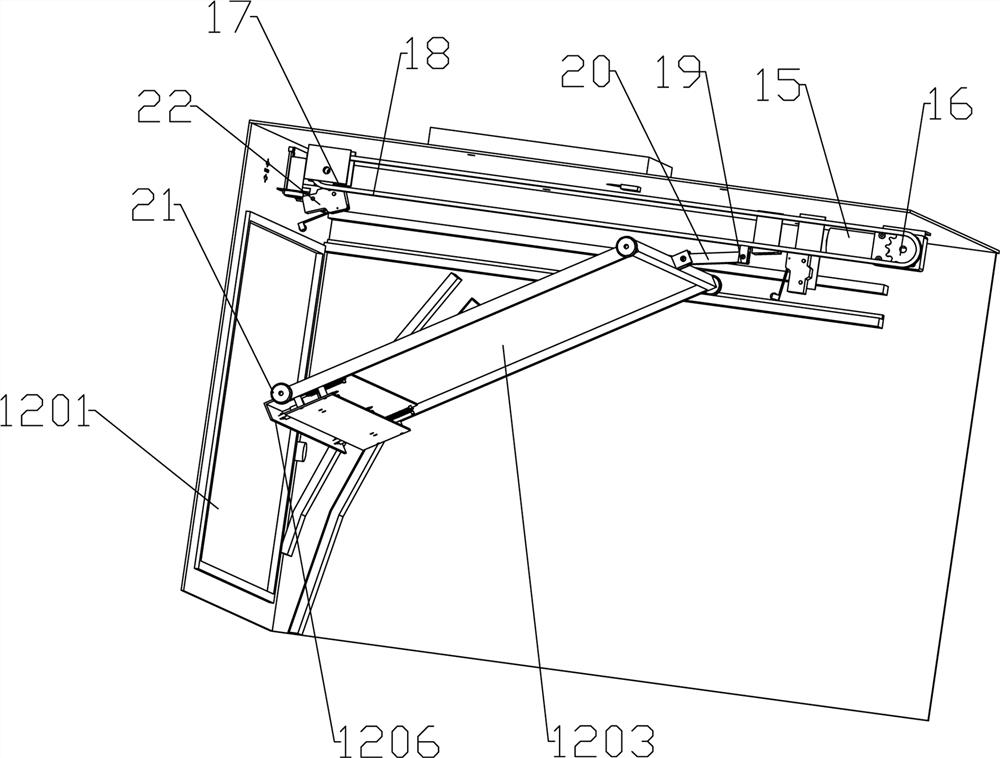

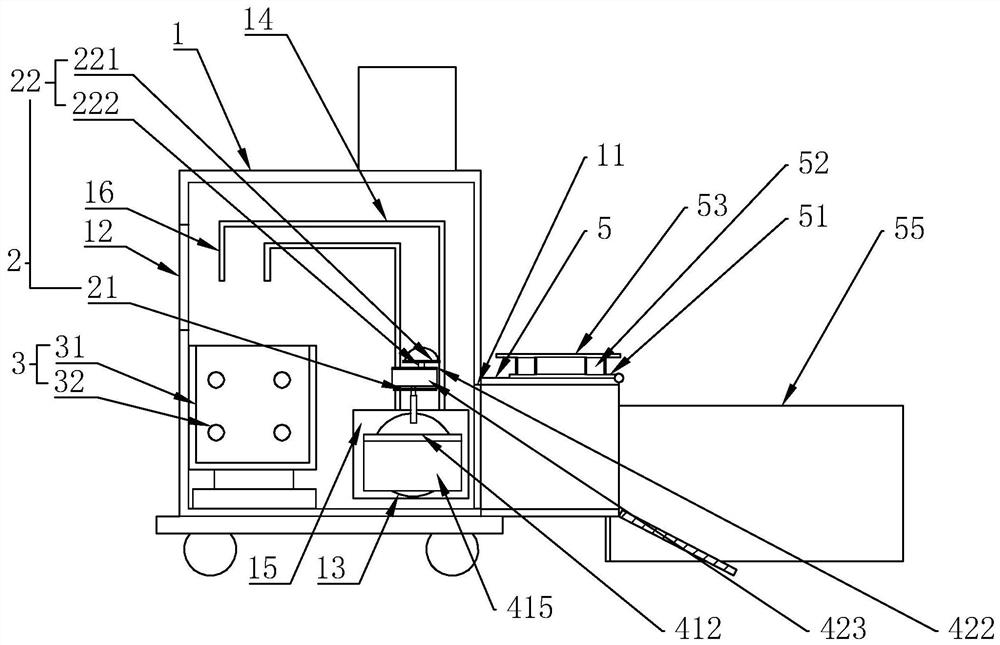

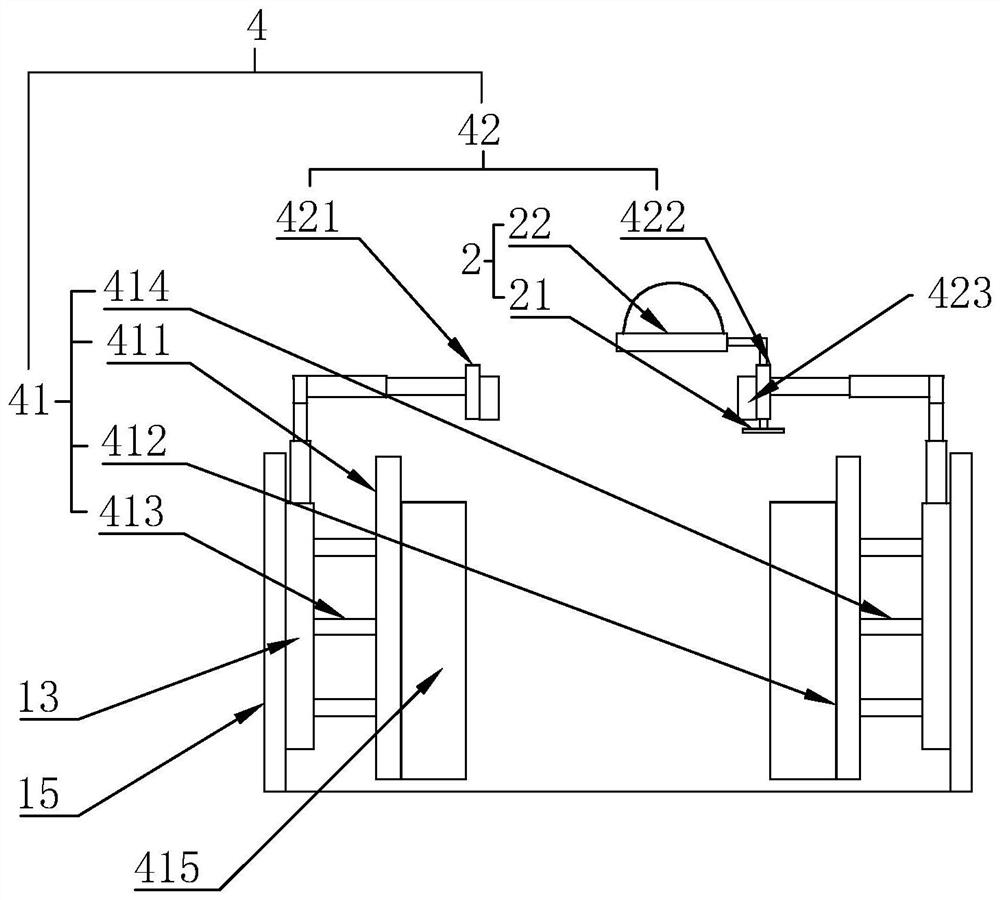

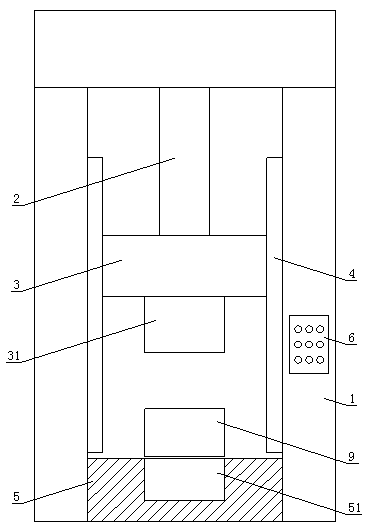

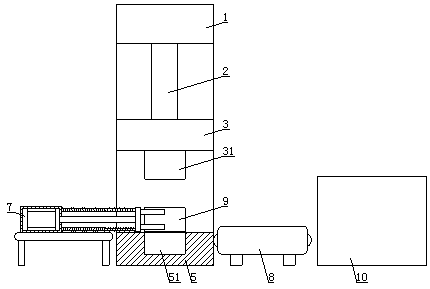

Automatic assembling equipment for automobile air conditioner O-shaped rings

ActiveCN111069892AImprove work efficiencyShorten the timeLiquid surface applicatorsCoatingsAutomotive air conditioningManual handling

The invention relates to the field of air conditioner compressor assembly, in particular to automatic assembling equipment for automobile air conditioner O-shaped rings. The automatic assembling equipment comprises an O-shaped ring feeding mechanism, an air conditioner compressor feeding mechanism, an O-shaped ring assembling mechanism, an air conditioner compressor positioning mechanism and a rack. The O-shaped ring feeding mechanism is used for providing the O-shaped rings to be assembled and carrying out feeding work and oil coating work of the O-shaped rings. The air conditioner compressorfeeding mechanism is arranged at the side portion of the O-shaped ring feeding mechanism and is used for providing air conditioner compressors to be assembled and conveying the air conditioner compressors to the output end of the O-shaped ring feeding mechanism. The O-shaped ring assembling mechanism is arranged at the side portion of the air conditioner compressor feeding mechanism. The air conditioner compressor positioning mechanism is arranged on the O-shaped ring assembling mechanism. The rack is used for mounting the O-shaped ring feeding mechanism, the air conditioner compressor feeding mechanism, the O-shaped ring assembling mechanism and the air conditioner compressor positioning mechanism. By means of a pneumatic feeding mode, the O-shaped rings are sent out one by one, feedingis achieved without manual operation, the working efficiency is improved, oil coating is carried out through an oil coating roller while the O-shaped rings are fed, and the working efficiency is greatly improved.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

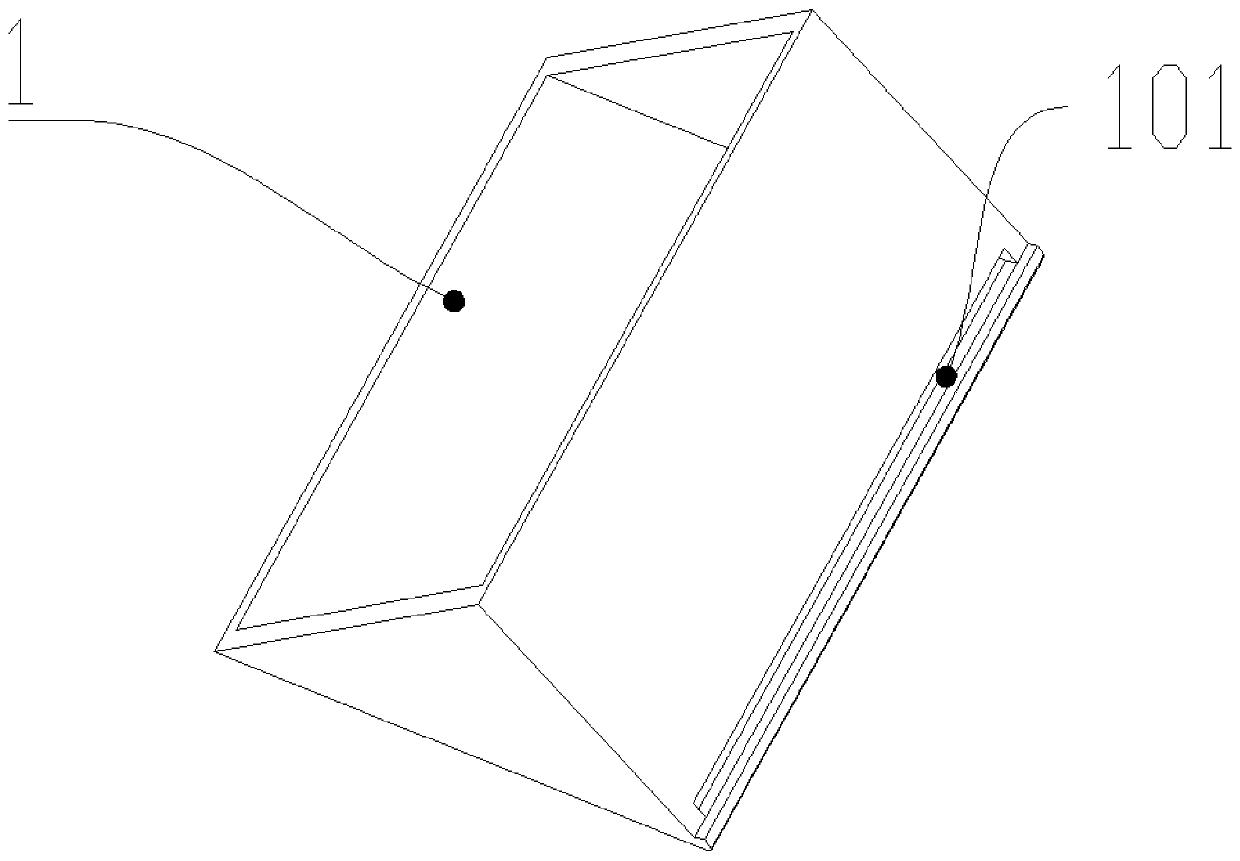

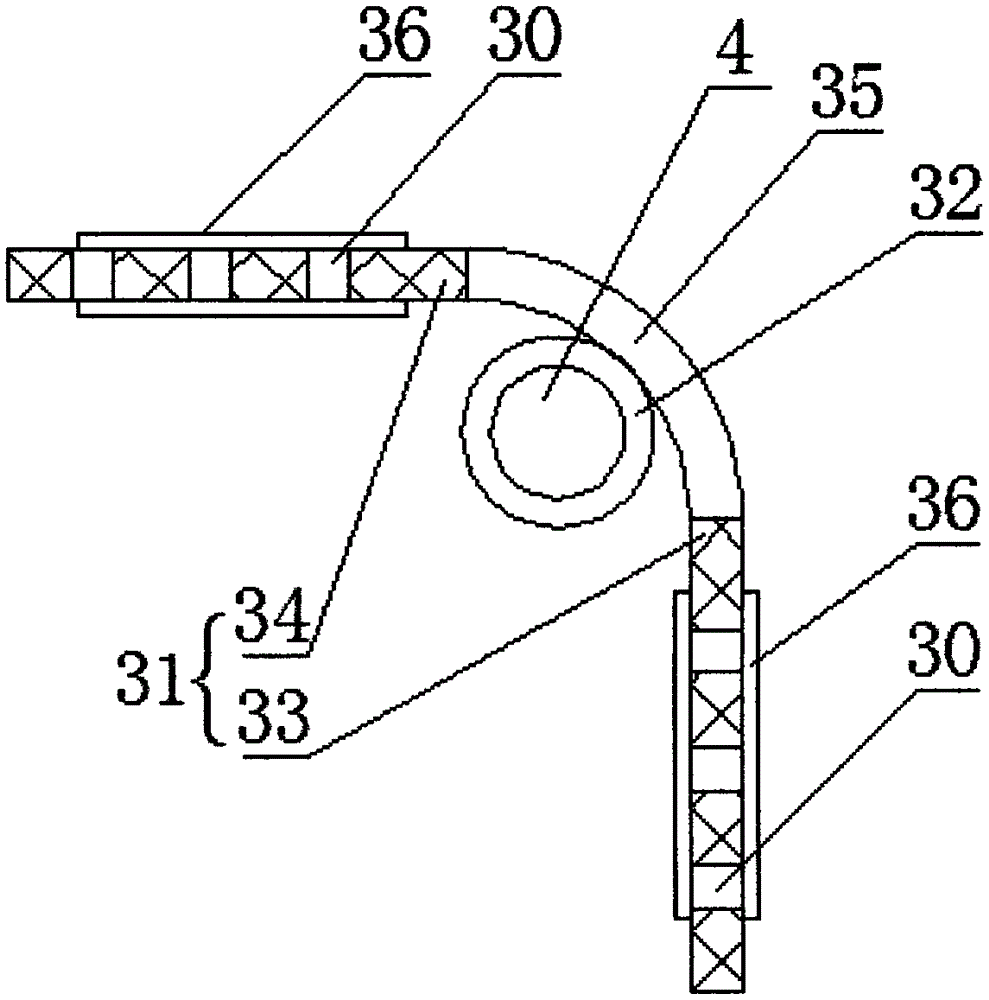

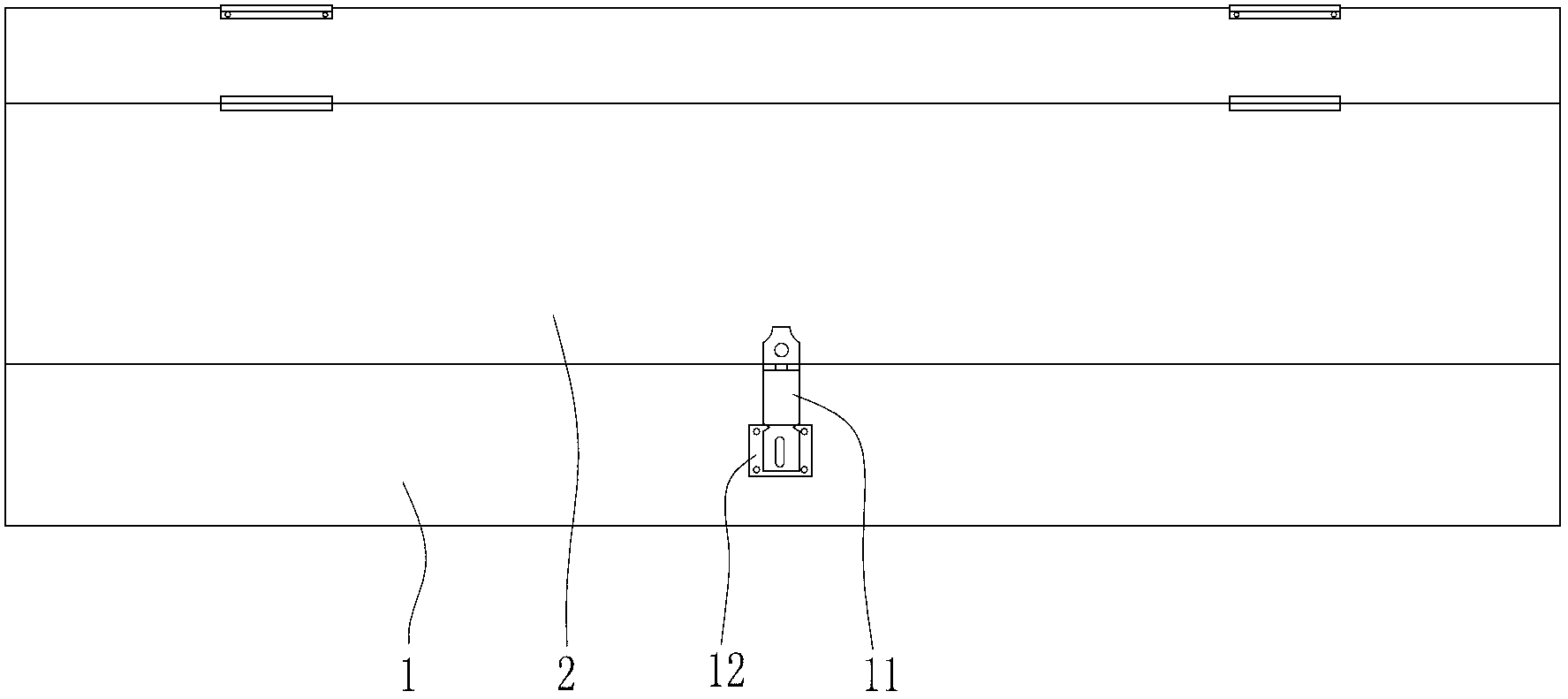

Automatic segmenting machine for capsicum frutescens

InactiveCN109807960ARealize automatic cuttingAvoid hand injuriesMetal working apparatusConveyor beltEngineering

The invention relates to the technical field of agricultural product processing, in particular to an automatic segmenting machine for capsicum frutescens. The machine comprises a feeding hopper and amachine frame, the feeding hopper is obliquely fixed on the machine frame, the bottom of the feeding hopper is connected with one end of a deflector, a plurality of pointed conical flow guiding blocksare fixed on the deflector, the other end of the deflector is connected to the starting end of a limiting module, the limiting module comprises a plurality of limiting blocks arranged in parallel andfixing blocks fixedly connected to the upper surfaces of the limiting blocks, the limiting module is parallel with a conveyor belt, the conveyor belt is arranged on the machine frame, a pressing mechanism is obliquely arranged above the conveyor belt, the tail end of the pressing mechanism is connected with the tail end of the limiting module, a cutting mechanism is vertically arranged above theconveyor belt, and the cutting mechanism is connected to a transmission mechanism located below the cutting mechanism through a connecting rod. Capsicum frutescens can be automatically and rapidly cutinto capsicum frutescens segments with the same length, labor is saved, and production efficiency is effectively improved.

Owner:寻乌县羊角园果蔬有限公司

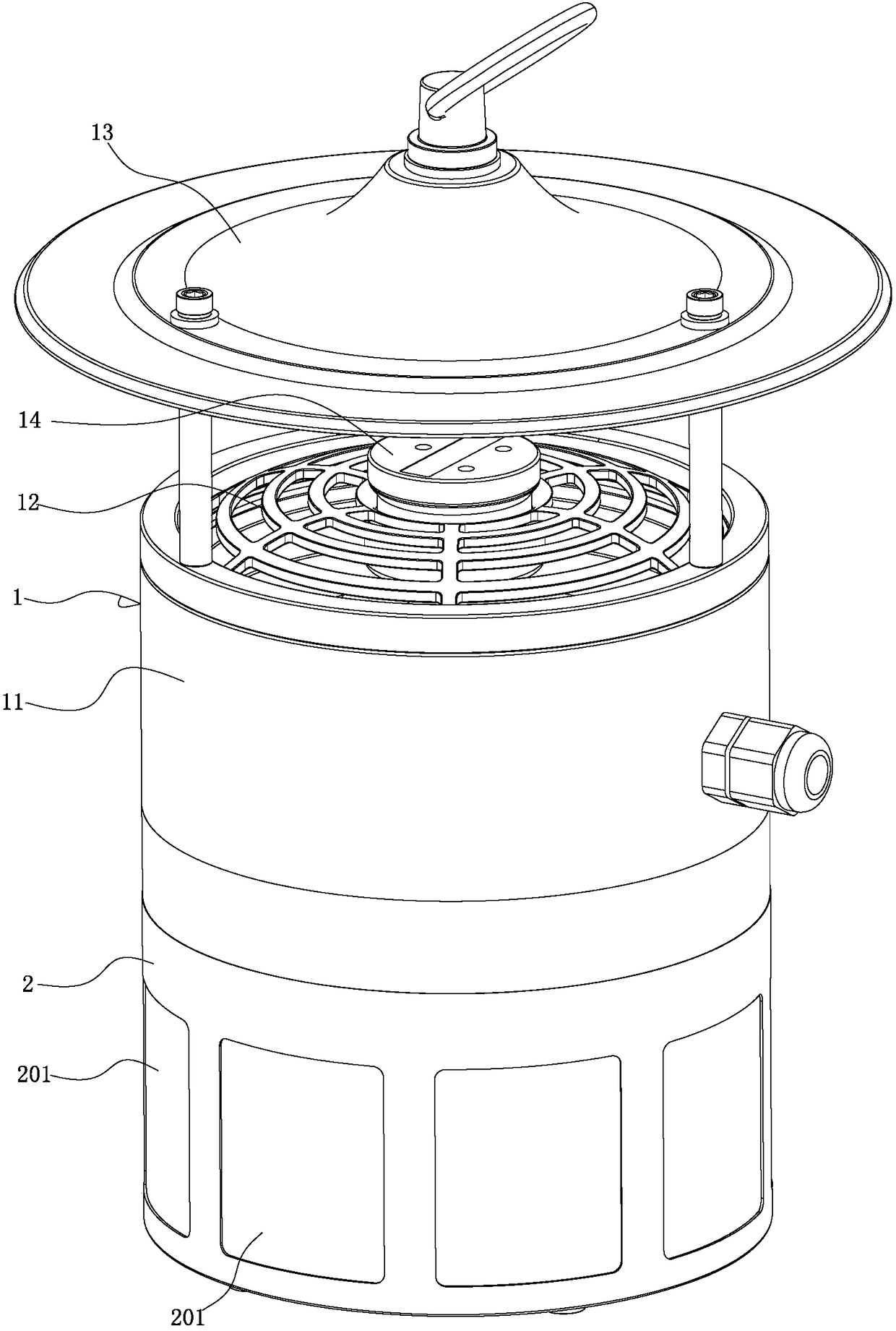

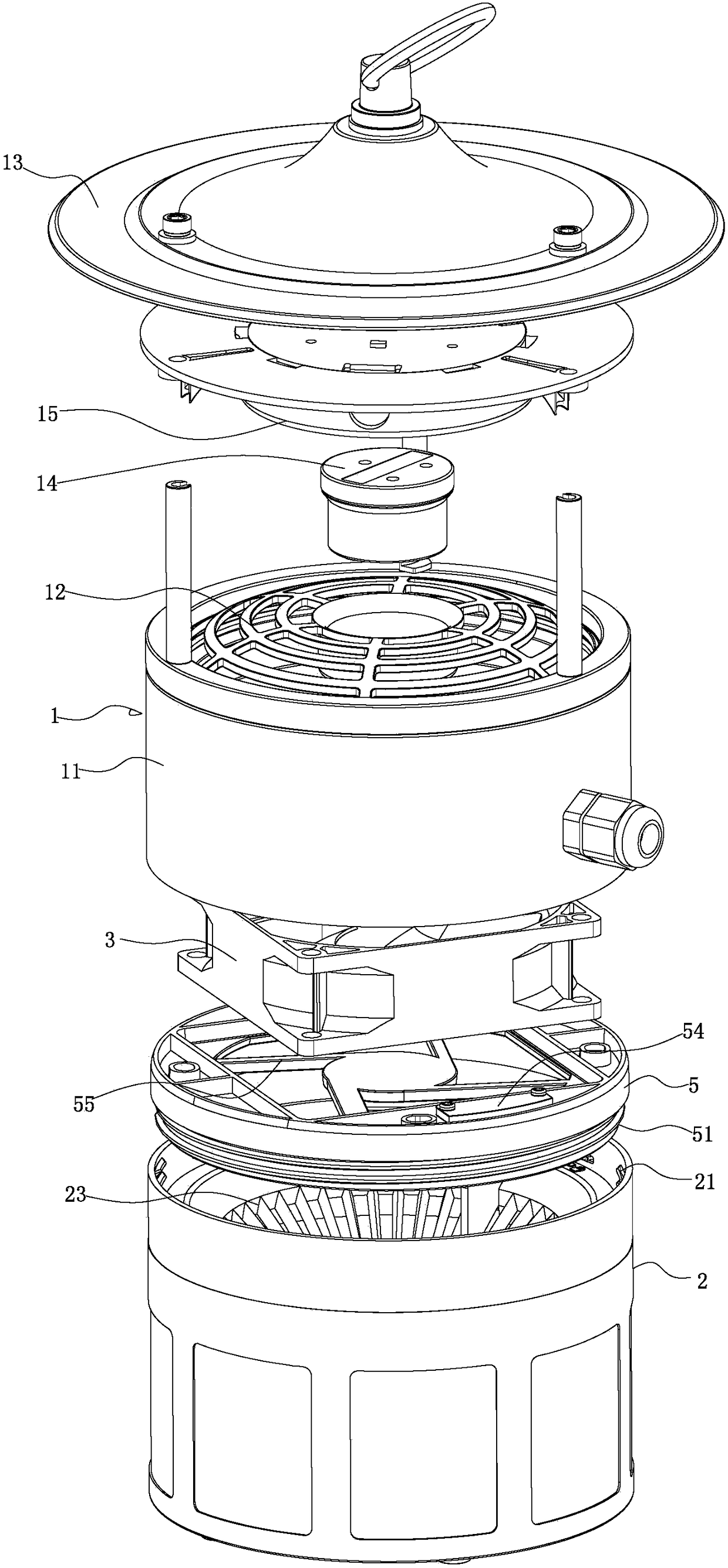

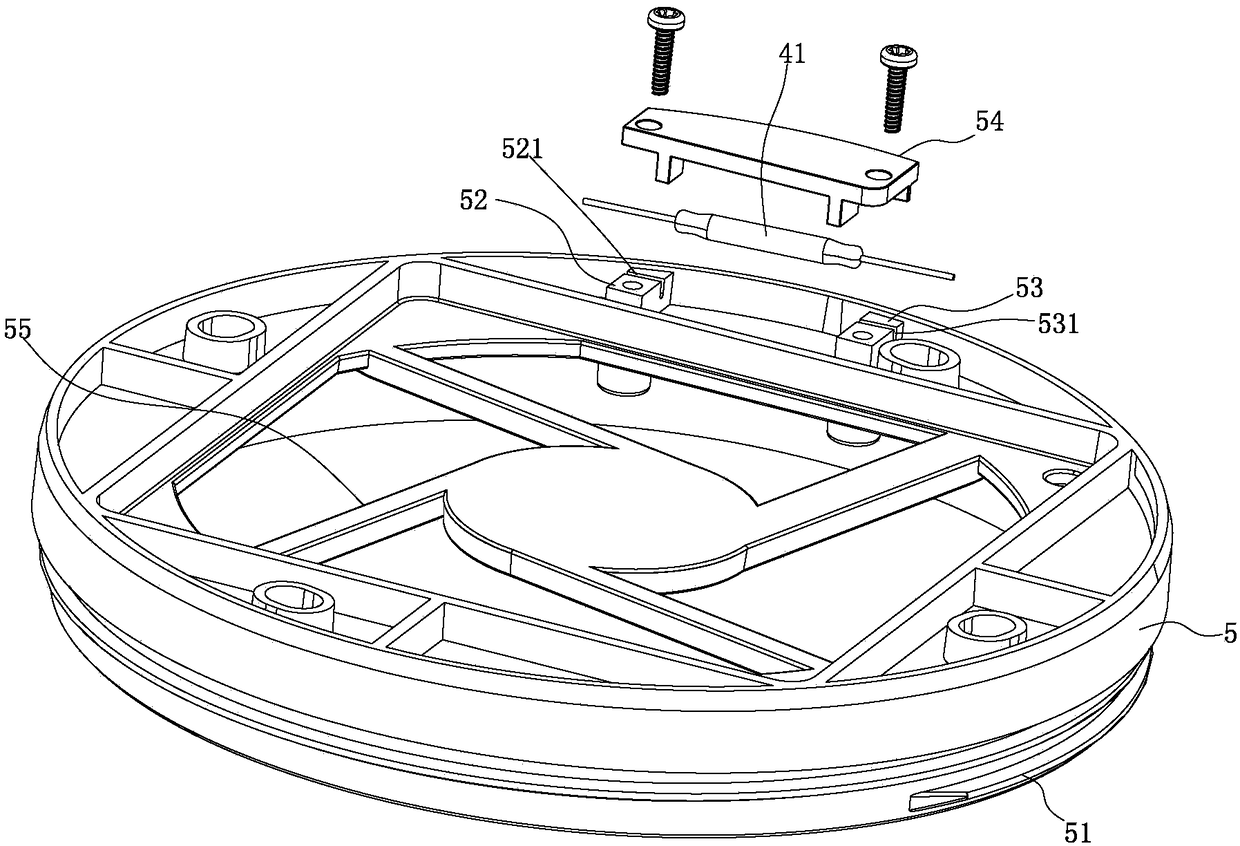

Insect trap with safeguard device

The invention discloses an insect trap with a safeguard device, comprising a trap body and a collection box releasably mounted at the lower end of the trap body. A fan is arranged in the trap body; the safeguard device is arranged between the trap body and the collection box and includes a switch module to control the fan to automatically start or stop. After the collection box is removed from thelower end of the trap body, the switch module is disconnected, the fan automatically stops operating, and then it can be avoided that the fan hurts the hand; the insect trap is safe and reliable to use, has no need for considering a protective net at the lower end of the trap body and considering the gap size of the protective net such that flies and other insects of large size may pass through and both large and small insects can be trapped, and meets national safety standards of China and safety standards of USA; after the collection box is re-mounted at the lower end of the trap body, theswitch module is on, the fan automatically starts, and the insect trap performs trapping.

Owner:东莞市方盛生物科技有限公司

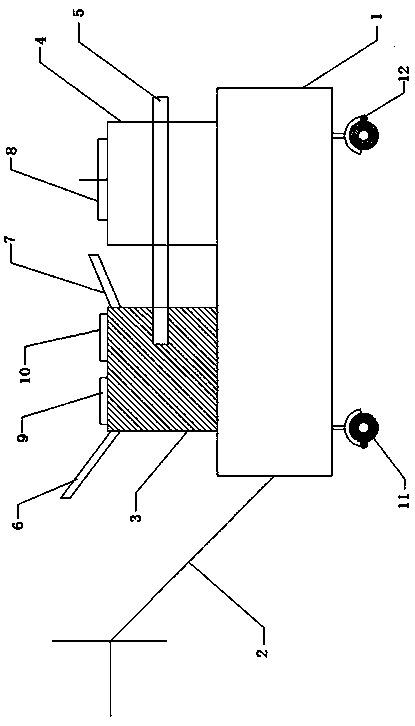

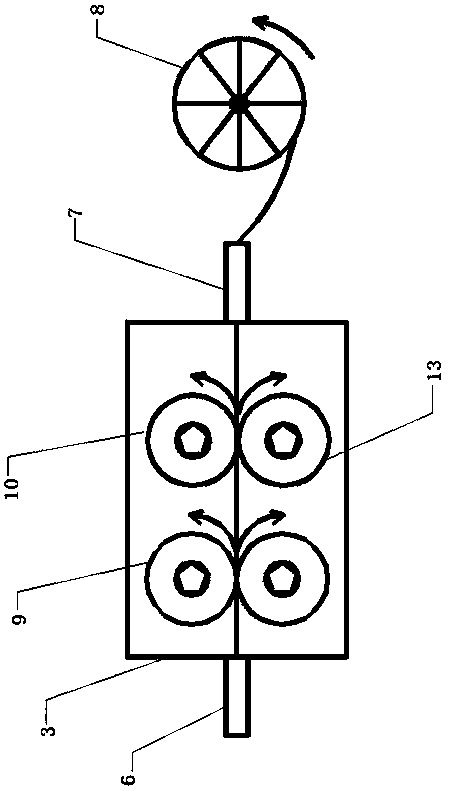

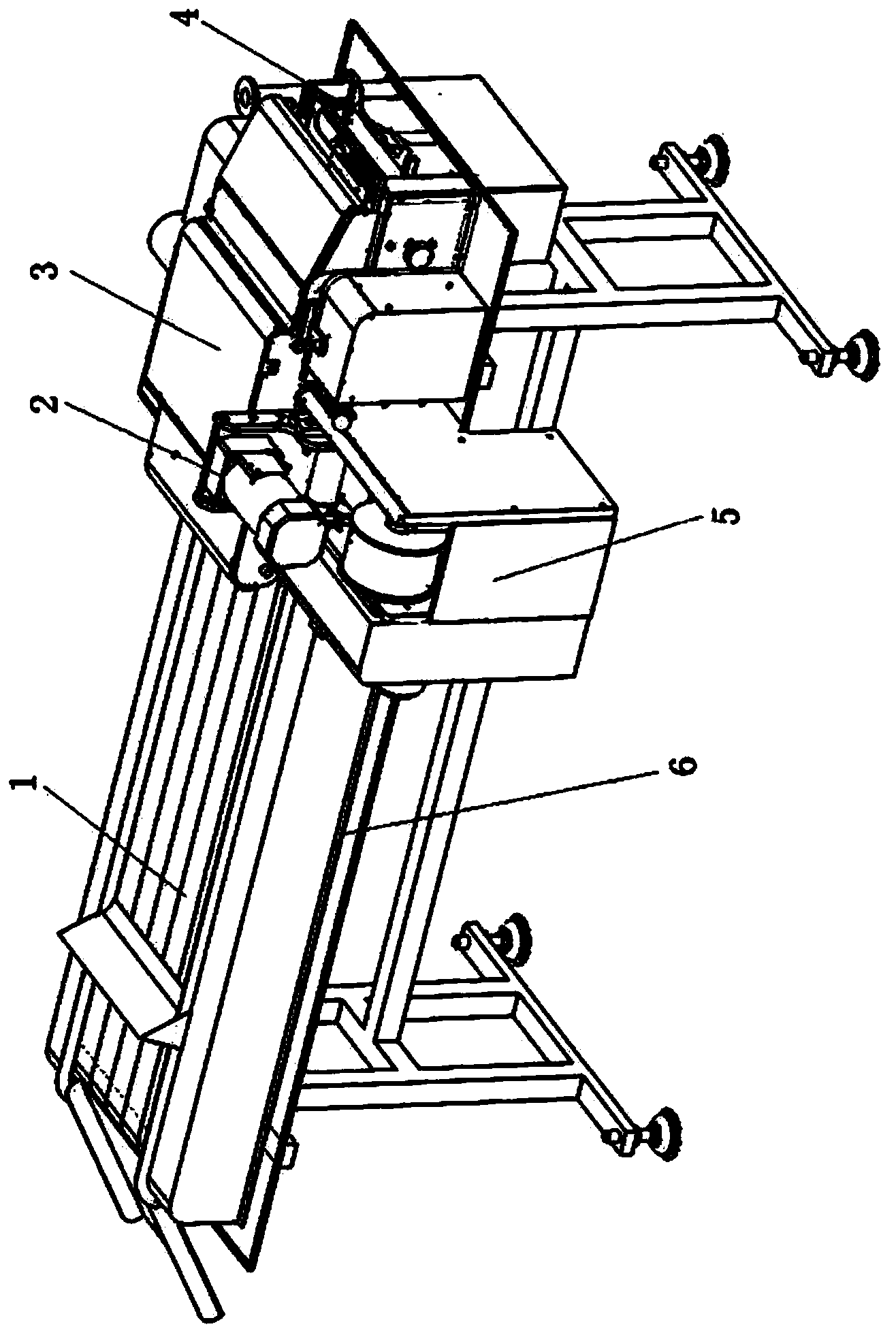

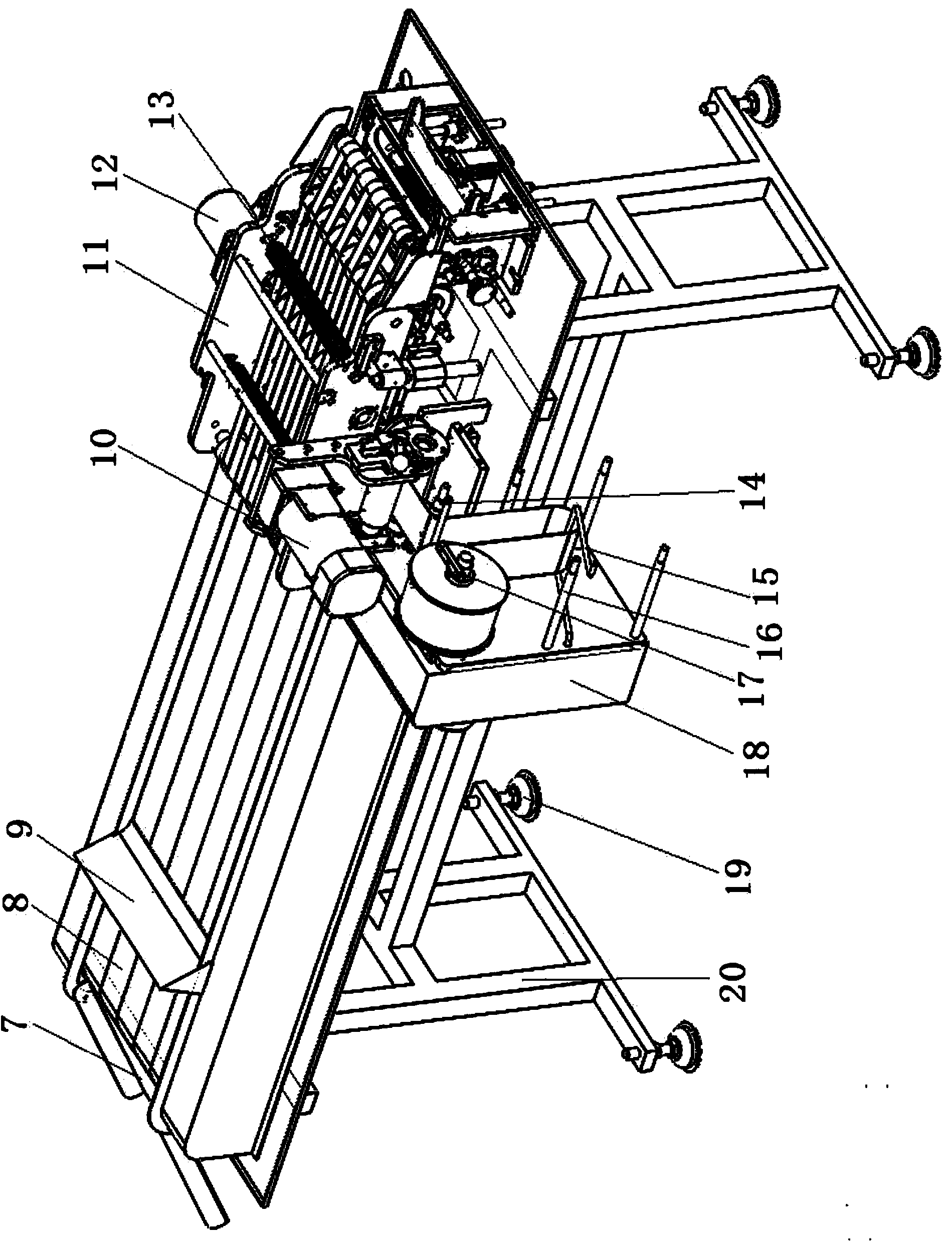

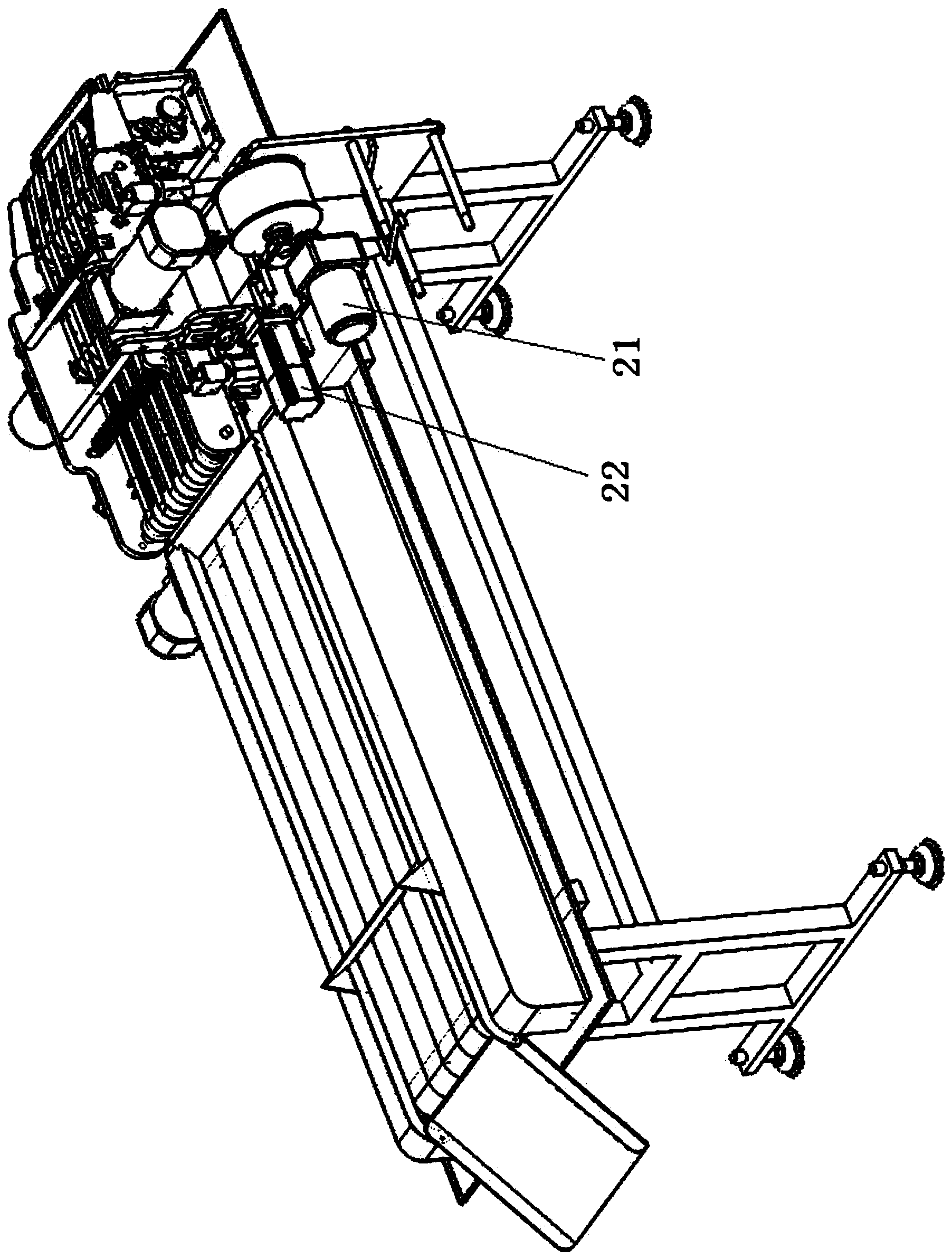

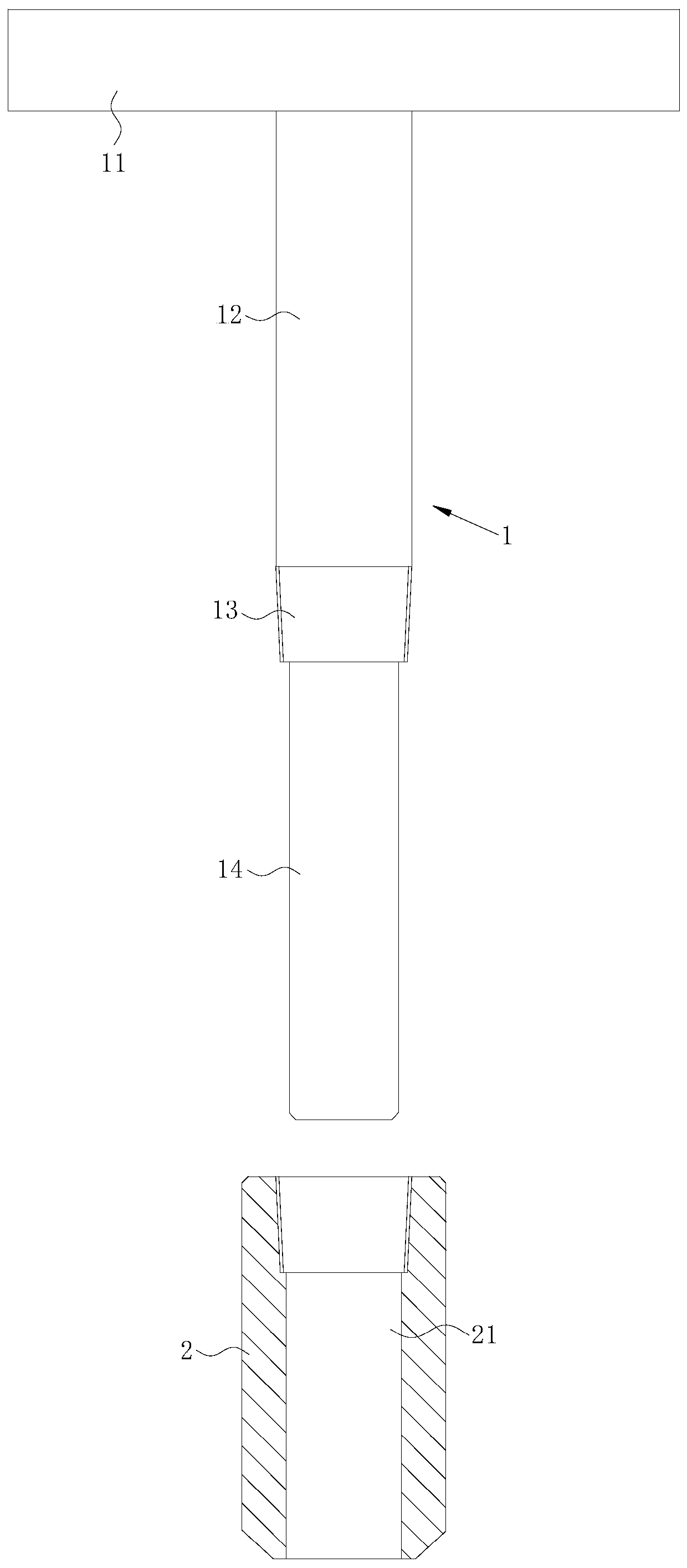

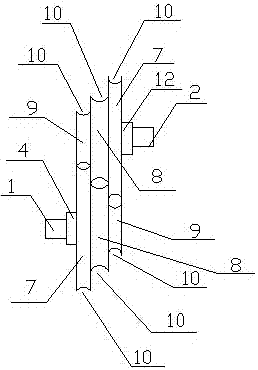

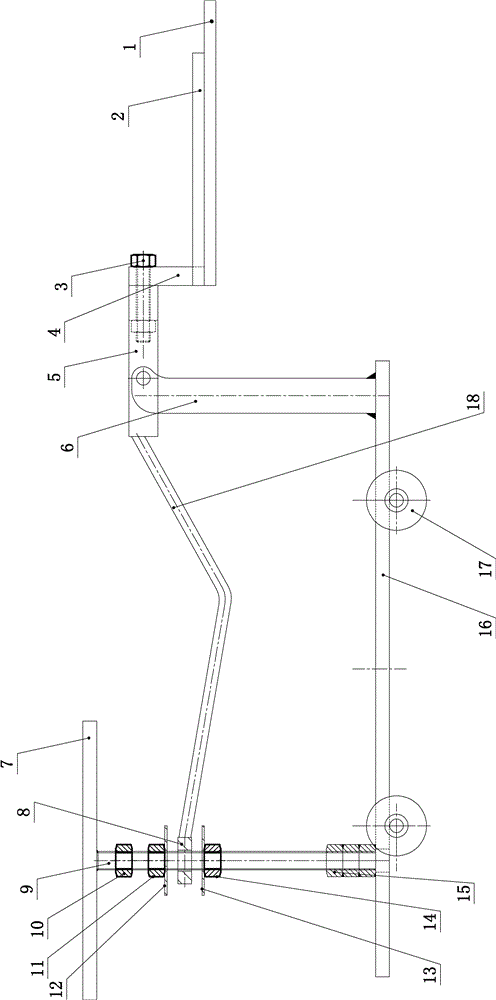

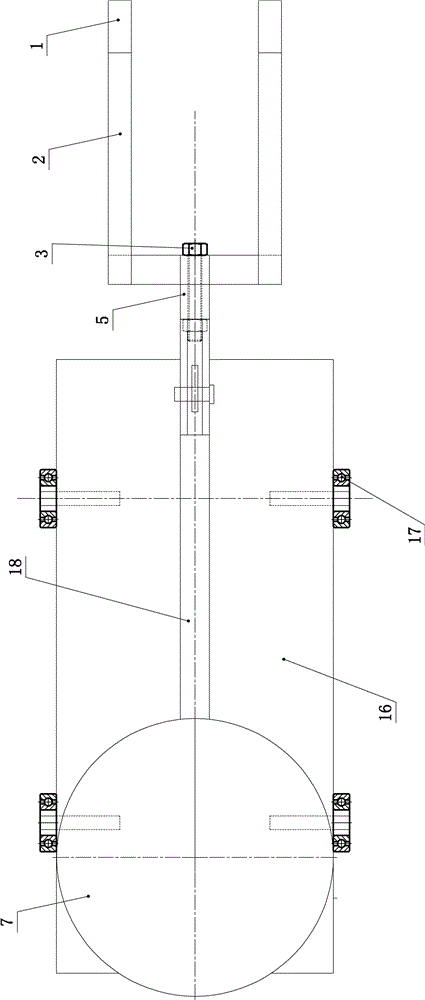

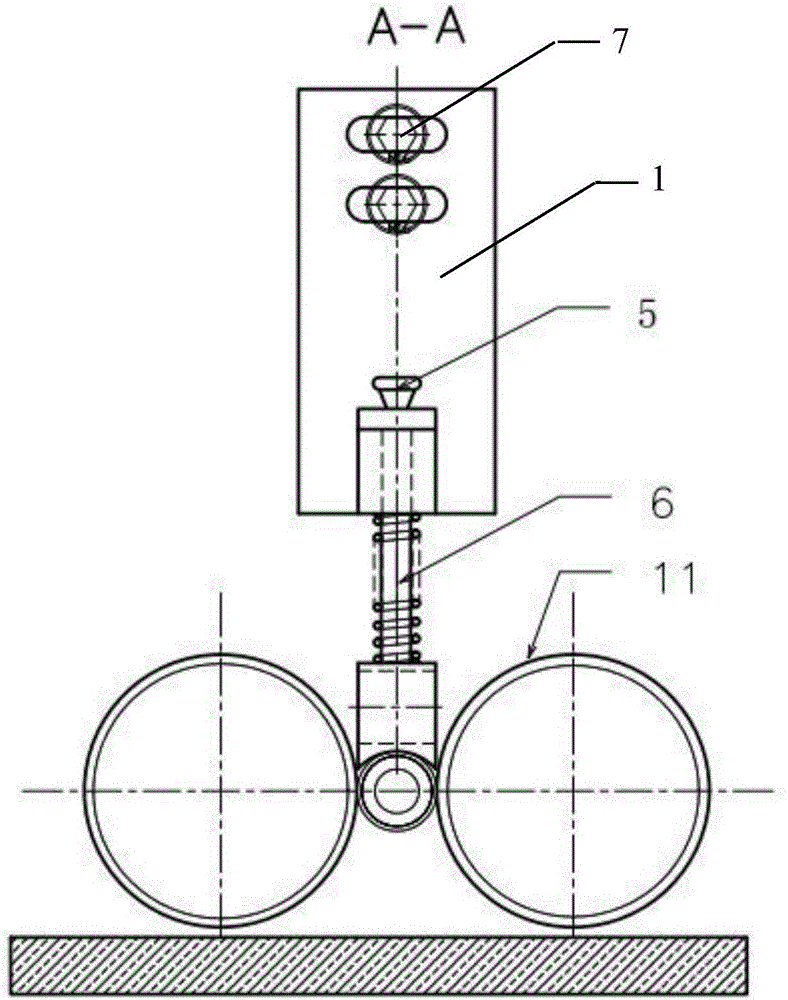

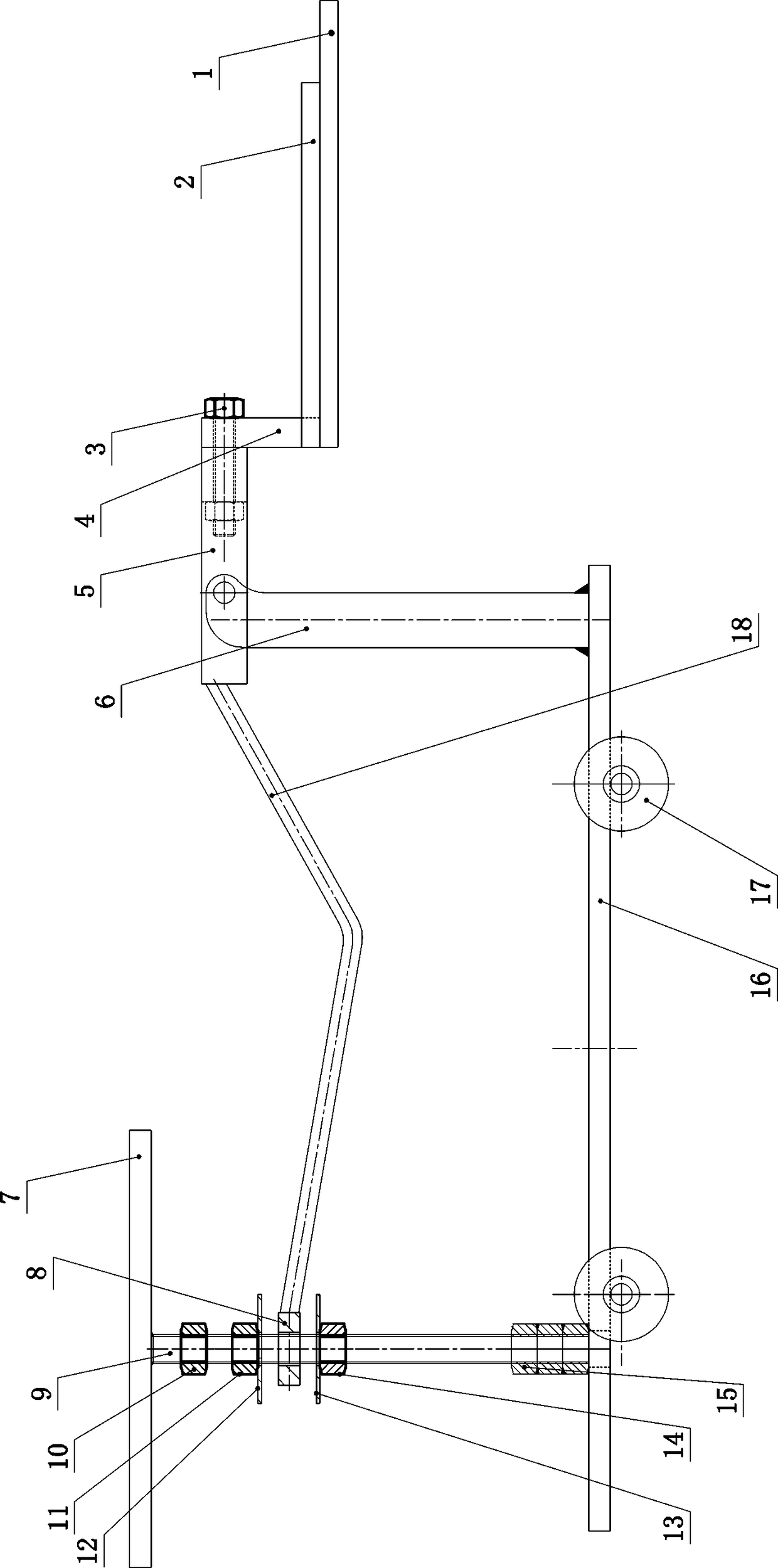

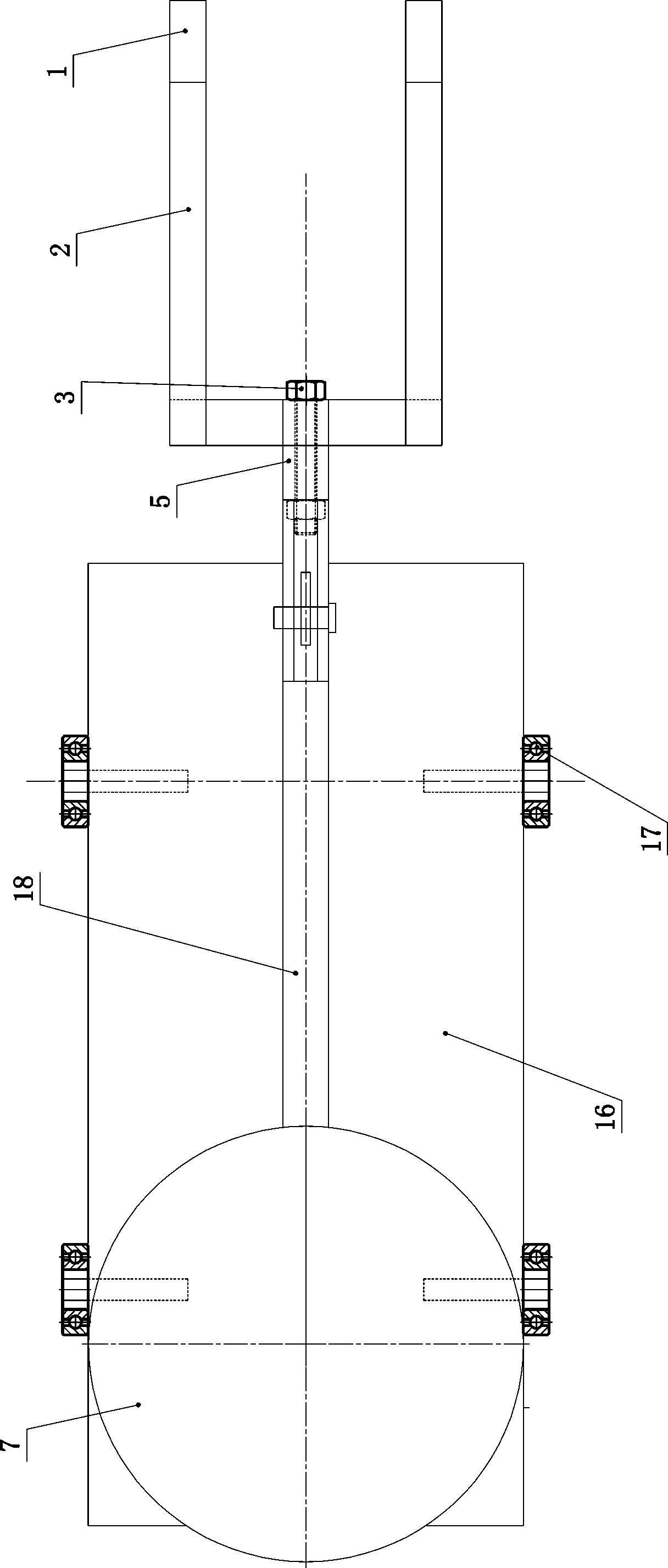

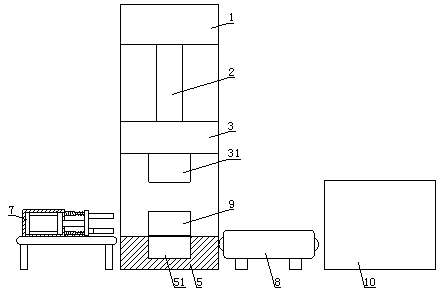

A threading power tool in a movable pre-buried tube

InactiveCN109066484AImprove work efficiencyEasy to operateApparatus for laying cablesElectric machineryPower tool

The invention discloses a threading power tool in a movable pre-buried tube which comprises a pre-buried tube threading power tool body; the movable pre-buried tube threading power tool body is provided with a base, A movable device is arranged below the base, A motor and a cable driving device are arranged above the base, The cable driving device comprises two groups of rotating structures, wherein the two groups of rotating structures are composed of two rotating wheels, the first rotating wheel and the second rotating wheel constitute a first group of rotating structures, the third rotatingwheel and the fourth rotating wheel constitute a second group of rotating structures, and a belt winding disk is arranged at the rear end of the cable driving device. The threading power tool in a movable pre-buried tube features that the manual dragging is replaced, and only one person is required to complete the threading work in the pipes, which greatly improves working efficiency and mechanization degree of operation, and achieves the purpose of artificial synergy. Machinery instead of manpower, multi-person operation changes into one person operation, greatly improves work efficiency. Workers can easily slip and hurt their hands when they use pliers to pull the wire. The use of electric machinery can avoid the occurrence of injuries.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

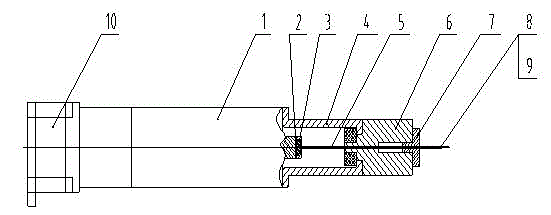

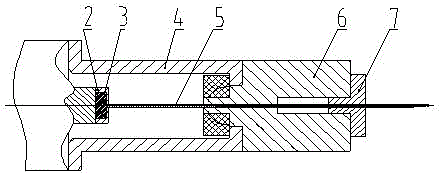

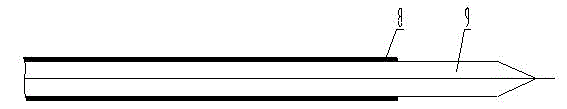

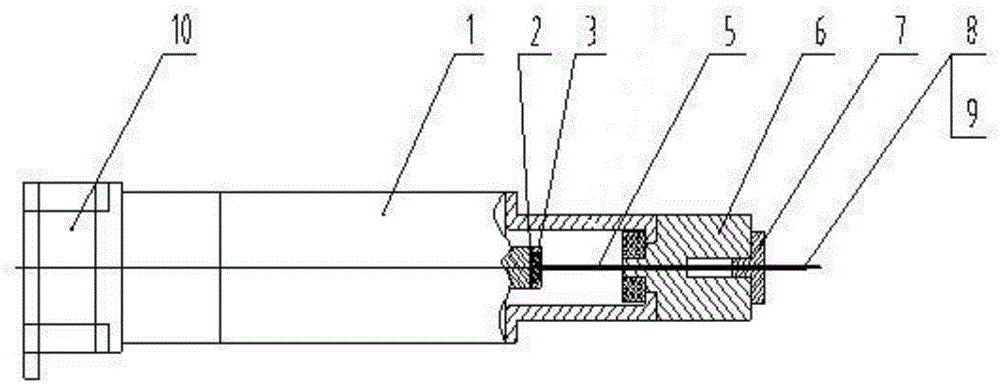

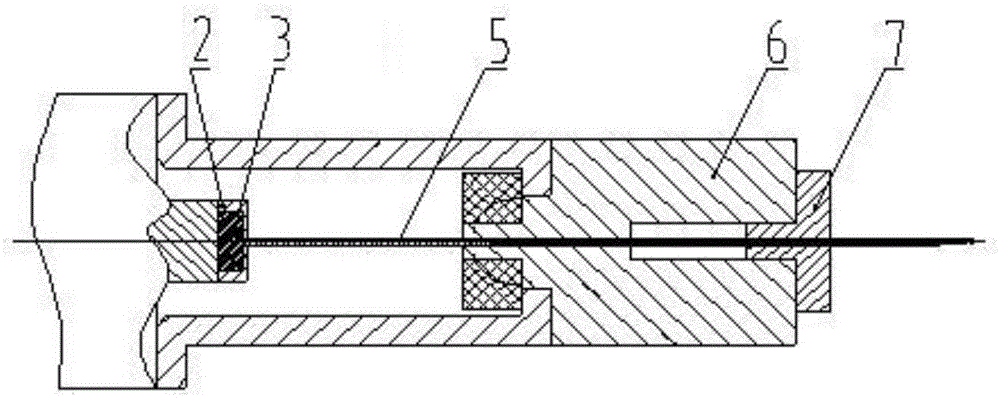

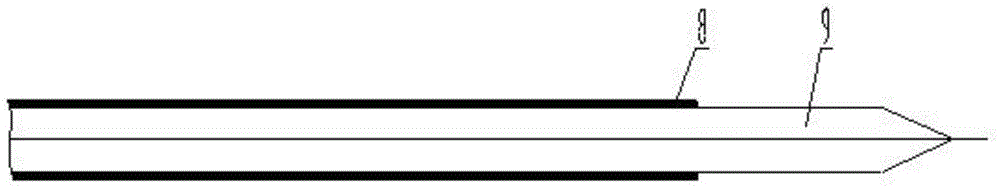

Mechanical intelligent needle thrusting device

ActiveCN102744921AAccurate speedAccurate distanceLayered productsSuturing needleUltimate tensile strength

The invention discloses a mechanical intelligent needle thrusting device, comprising an electric cylinder, a thimble, a guiding device, a guiding needle tubing and a suture needle. An input end of the electric cylinder is connected to a drive device arranged outside; a front end of an output end shell is connected to the guiding device; and the output end located within the shell is connected with the thimble. The guiding device, the guiding needle tubing and the suture needle are in sleeve joint from outside to inside; a front end of the guiding needle tubing is fixedly connected with the guiding device through a fastener; and the suture needle can move back and forth along the guiding needle tubing. A tail end of the thimble is connected with the electric cylinder; and a front of the thimble extends into the guiding needle tubing to support against the suture needle. The device of the invention has functions of adjusting speed and distance of needle thrusting, and can carry out accurate needle thrusting at a preset speed and distance parameters; besides, the device has characteristics of stable performance and high accuracy, substitutes manual needle thrusting process of a three-dimensional fabric for a related product, realizes intelligent mechanical needle thrusting, avoids hand injuries caused by manual needle thrusting, reduces labor intensity, and improves product quality and production efficiency.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

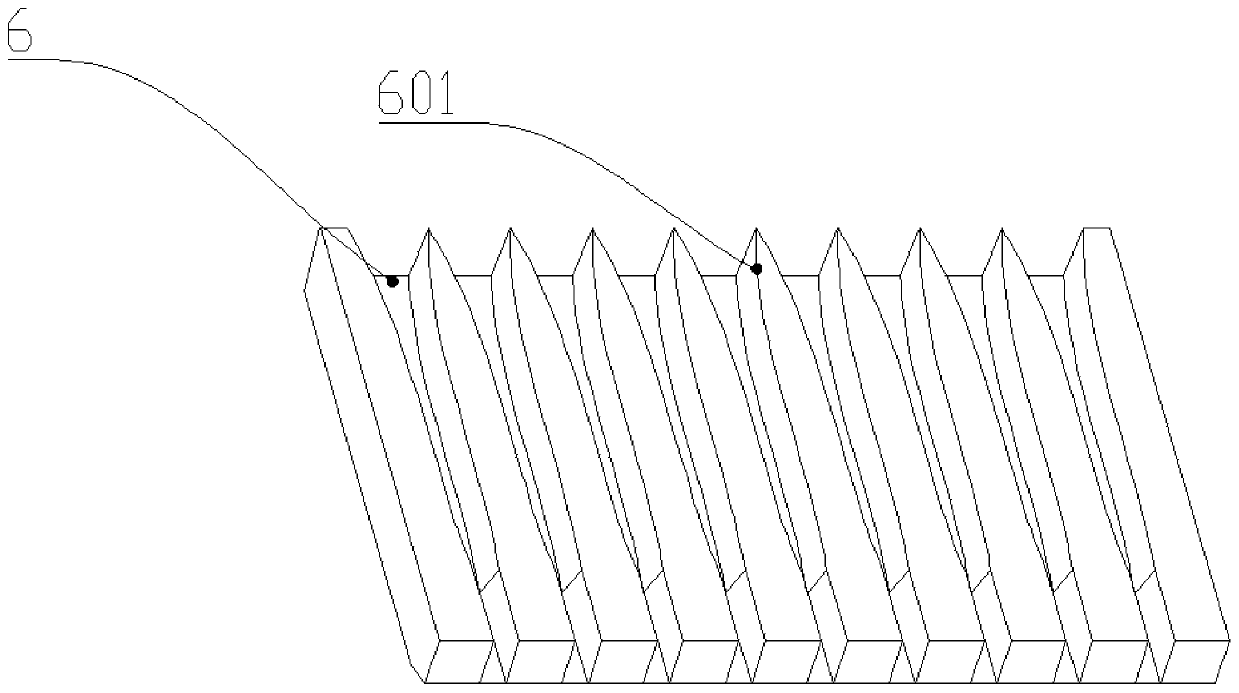

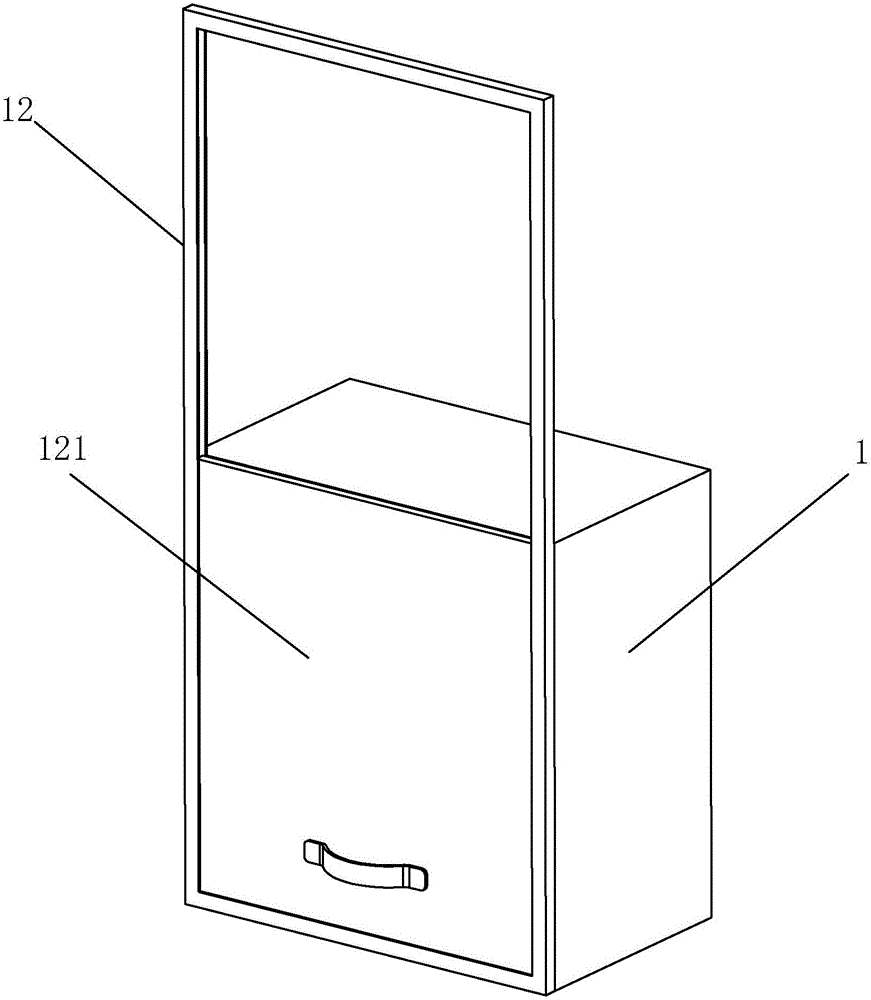

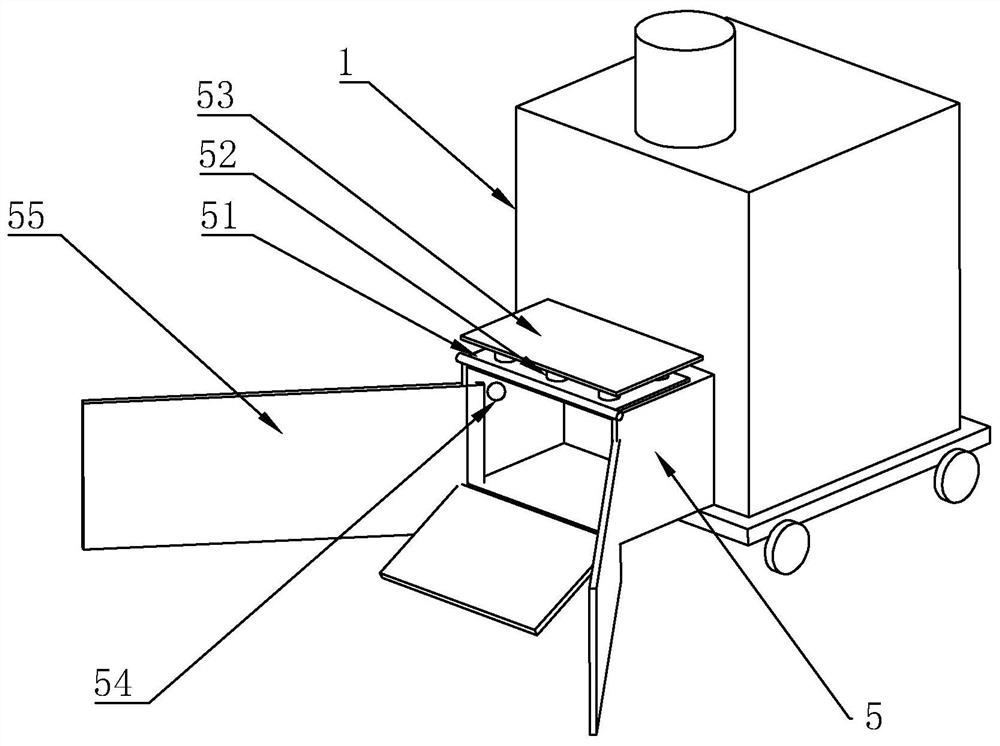

Automatic haw strip coiling and packaging machine

InactiveCN103708051AAvoid hand injuriesKeep clean and hygienicWrapping material feeding apparatusPaper cutEngineering

The invention relates to an automatic haw strip coiling and packaging machine. The automatic haw roll coiling and packaging machine comprises a workbench, a haw strip feeding device, a packaging paper feeding device, a packaging paper tensioning device, a packaging paper cutting device, a conveying device and a collecting device. The haw strip feeding device, the packaging paper feeding device, the packaging paper tensioning device, the packaging paper cutting device, the conveying device and the collecting device are arranged on the workbench. The automatic haw strip coiling and packaging machine is scientific in design, reasonable in structure and convenient to use. The automatic haw roll coiling and packaging machine achieves industrialization and automation of haw deep processing, fills in the blank of Chinese automatic haw strip coiling, solves the problem that manual packaging of haw strips is low in efficiency and poor in sanitary condition, and is quite high in use value and good in popularization prospect.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE +1

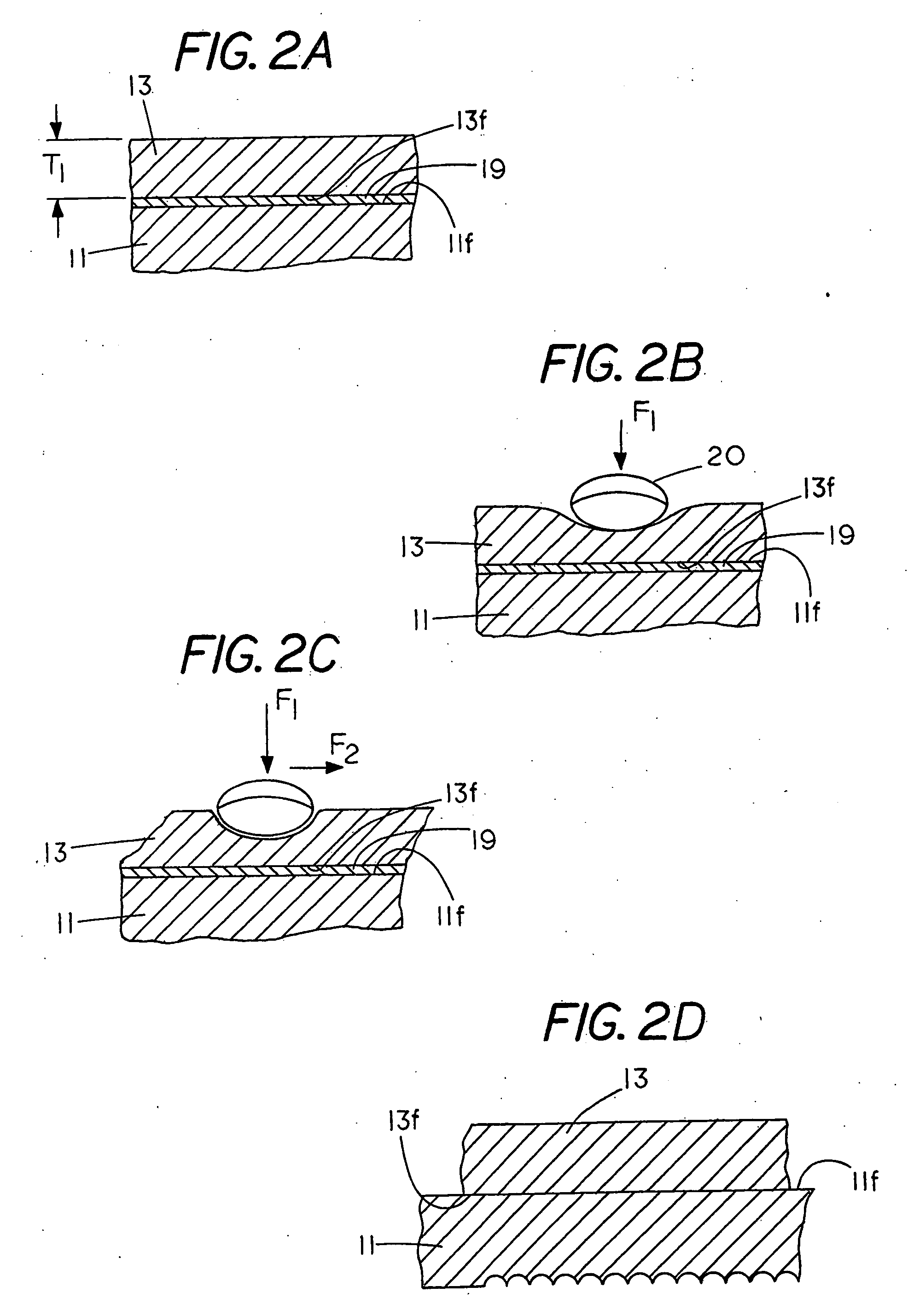

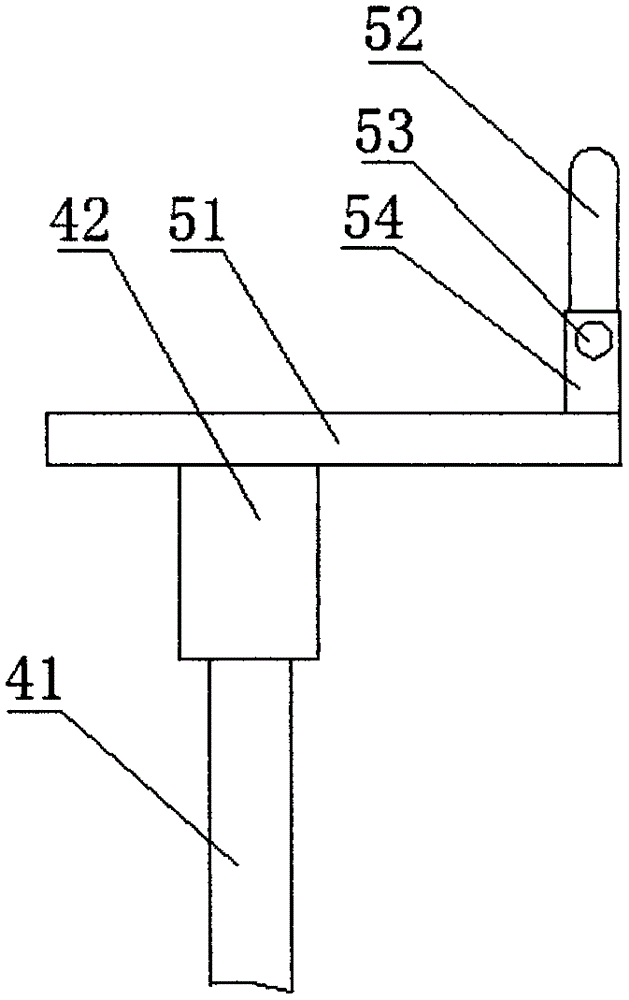

Shoe production process and upper heating device for shoe production process

The invention discloses a shoe production process and an upper heating device for the shoe production process. According to the technical scheme, the shoe production process includes the steps that a shoe last is sleeved with an upper, and the upper is heated and shaped; the upper obtained in the previous step is placed in the upper heating device to be preheated; the preheated upper in the previous step is placed in an injection molding machine to be subjected to injection molding, and a sole is manufactured at the bottom of the upper through injection molding; and demolding is conducted, and the upper subjected to injection molding is taken out of the injection molding machine. Before the upper is subjected to injection molding, the temperature of the upper is increased, so that plastic is prevented from being quickly cooled when the molten plastic makes contact with the upper due to the fact that the plastic and the upper are moderate in temperature, and the cooling time of the plastic is shortened; since the contact time between the molten plastic and the upper is prolonged, the connecting strength between the injection-molded sole and the upper is effectively improved; and the temperature of the upper is high when the sole makes contact with the upper, and thus the influence caused by heat expansion and cold contraction is lowered, and product quality is improved.

Owner:苏州同花盛鞋业有限公司

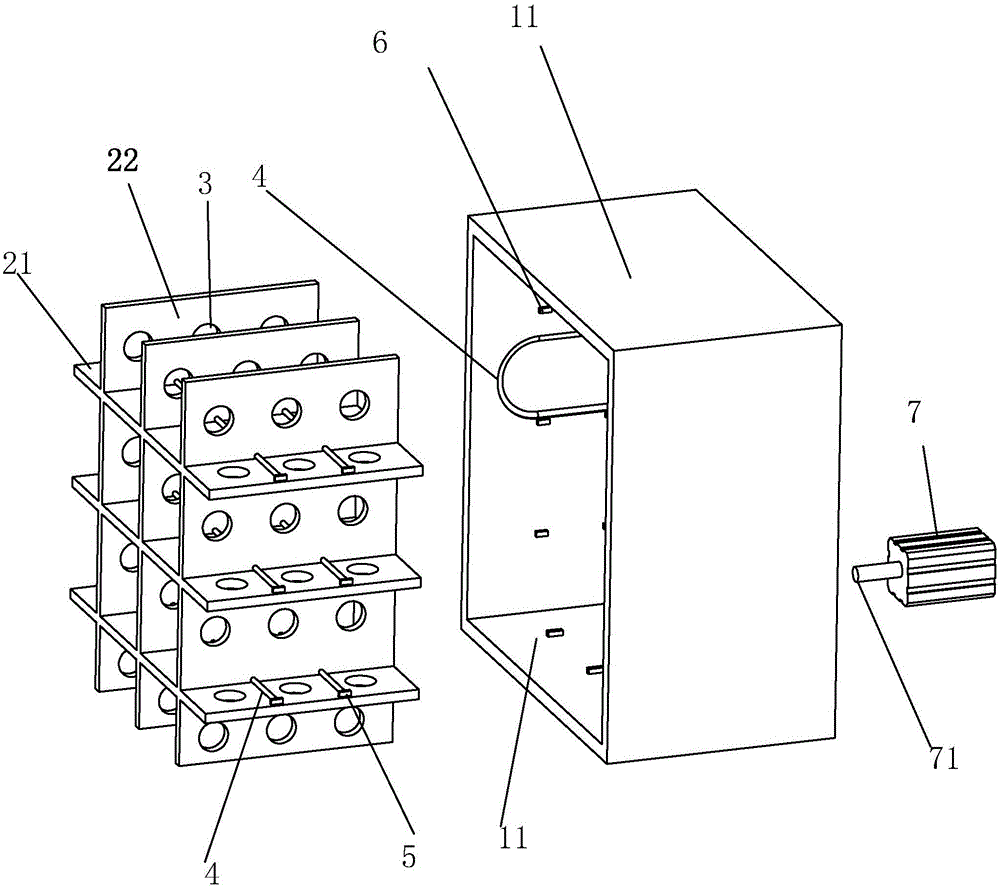

Lacquer bucket cover flanging device

The invention discloses a lacquer bucket cover flanging device. The lacquer bucket cover flanging device comprises a bracket and a die arranged on the bracket, wherein the die comprises a lower die (2) for containing a lacquer bucket cover (5) and an upper die having a guide groove and matching with the lower die (2); a round groove for containing the lacquer bucket cover (5) is formed in the upper surface of the lower die (2); an annular groove (4) is formed in the bottom surface of the upper die (1) and is located at the position corresponding to the edge of the round groove (3); the bottom surface of the annular groove (4) is arc-shaped. As the guide groove of the die can flange the lacquer bucket cover conveniently, the lacquer bucket cover flanging device can prevent a hand from being hurt by the edge of the lacquer bucket cover.

Owner:吴江区铜罗新世纪包装厂

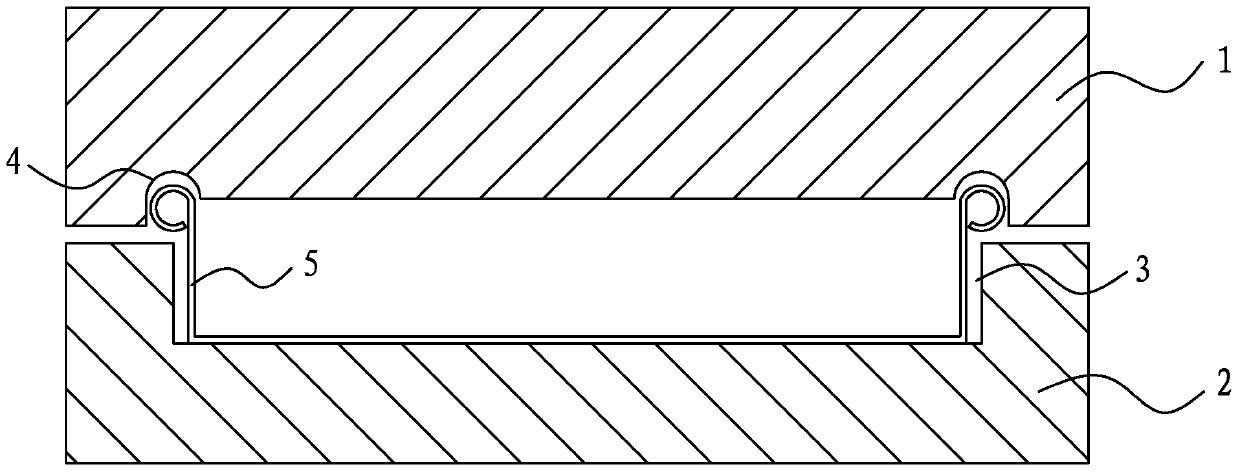

Hand-operated rice washer

The invention relates to a hand-operated rice washer which comprises a container box body and a box cover, wherein the box cover is fixedly connected to the container box body; a stirring component is arranged in the container box body and connected with a height-adjustable telescopic rod; the top end of the telescopic rod is arranged on the box cover in a penetrating manner; a handle is arranged on the telescopic rod; a water outlet is formed in the upper part of the container box body; and the diameter of the water outlet is less than the diameter of rice. The hand-operated rice washer provided by the invention has the following advantages: the stirring component is controlled to rotate by the handle, current situation of hand touching water and rubbing rice in rice washing is effectively improved, the washing speed is increased, the operation is convenient and the structure is simple; since the diameter of the water outlet is set to be less than the diameter of rice, the rice leakage is reduced, and the resource is saved; for rice washing in winter, the hand injury is avoided, and the application range is wide; and moreover, the handle is connected with the stirring component through the height-adjustable telescopic rod, thus the hand-operated rice washer can be adapted to different users, and the practical performance is good.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

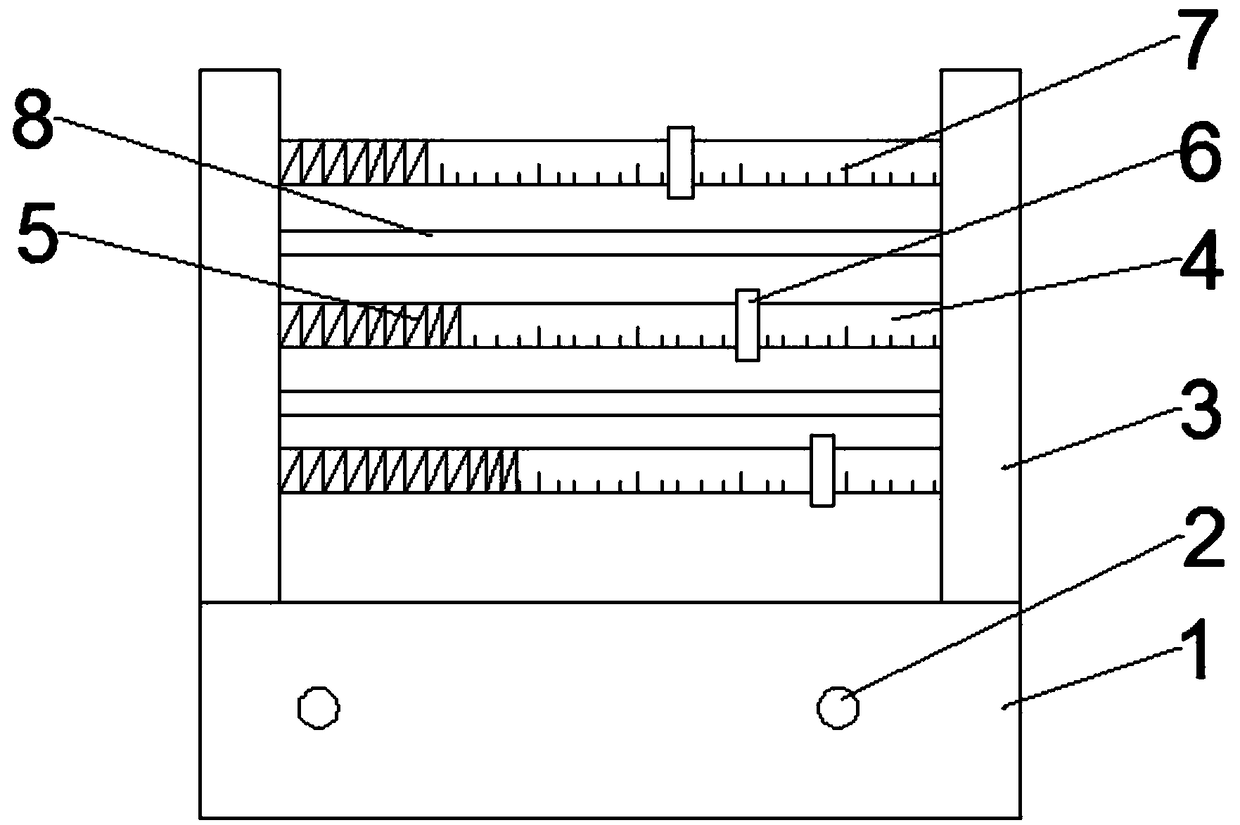

Electromagnet teaching experimental device

InactiveCN108806428AAvoid hand injuriesAvoid affecting the experimental resultsEducational modelsEngineeringElectromagnet

The invention discloses an electromagnet teaching experimental device, belonging to the field of teaching experimental aids. The electromagnet teaching experimental device comprises a hollow base, wherein a power supply is arranged in the base; two supporting plates are vertically arranged on the upper surface of the base; the two supporting plates are arranged at intervals; a plurality of connecting rods, which are horizontally arranged, are connected between the two supporting plates at intervals; coils are arranged on the surfaces of the connecting rods; each coil is arranged at one end ofthe corresponding connecting rod; and magnets are slidingly connected to the connecting rods. According to the electromagnet teaching experimental device, pins can be prevented from getting magnetizedin an electromagnet teaching experiment, so that influence to an experimental effect can be avoided.

Owner:王强

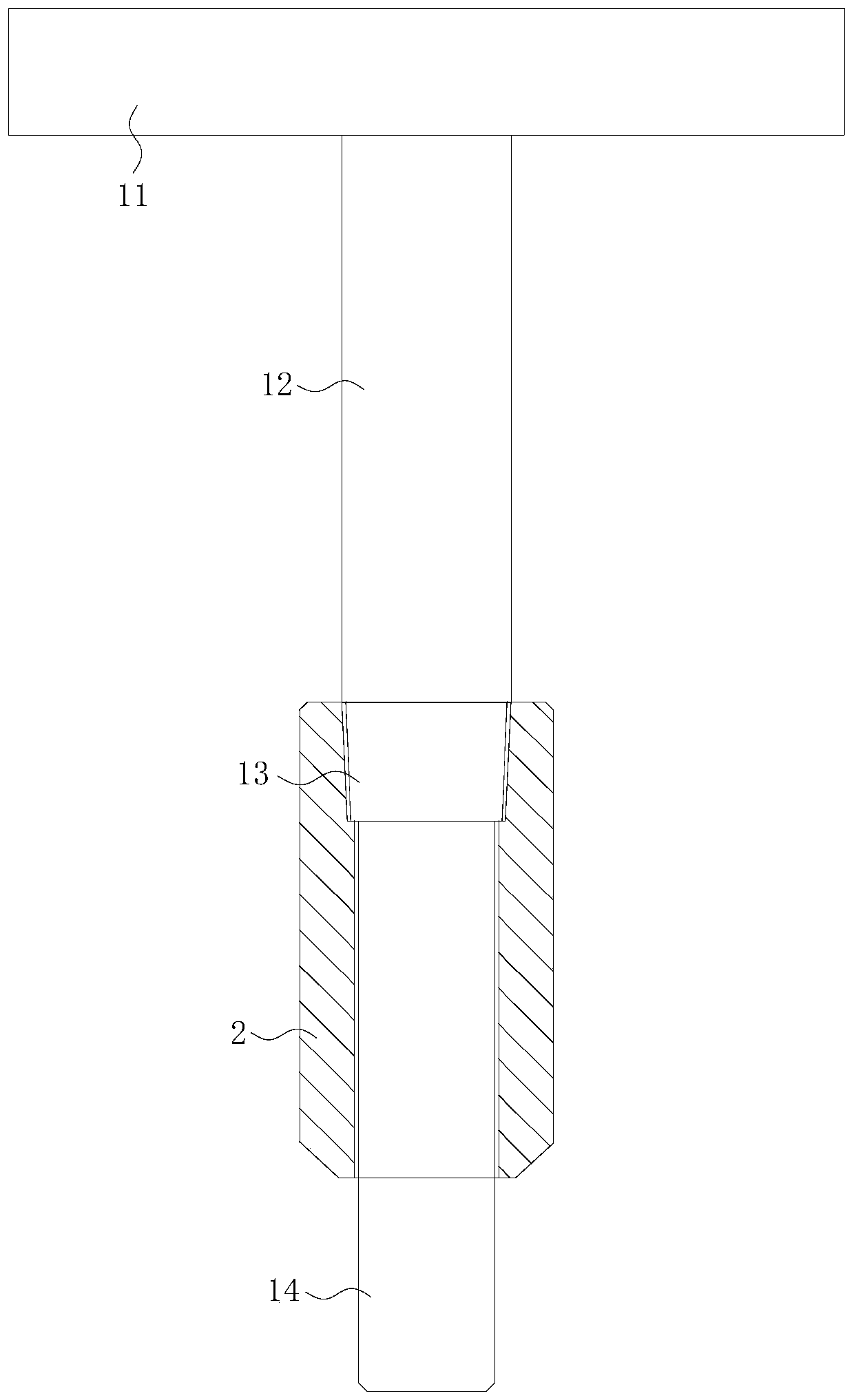

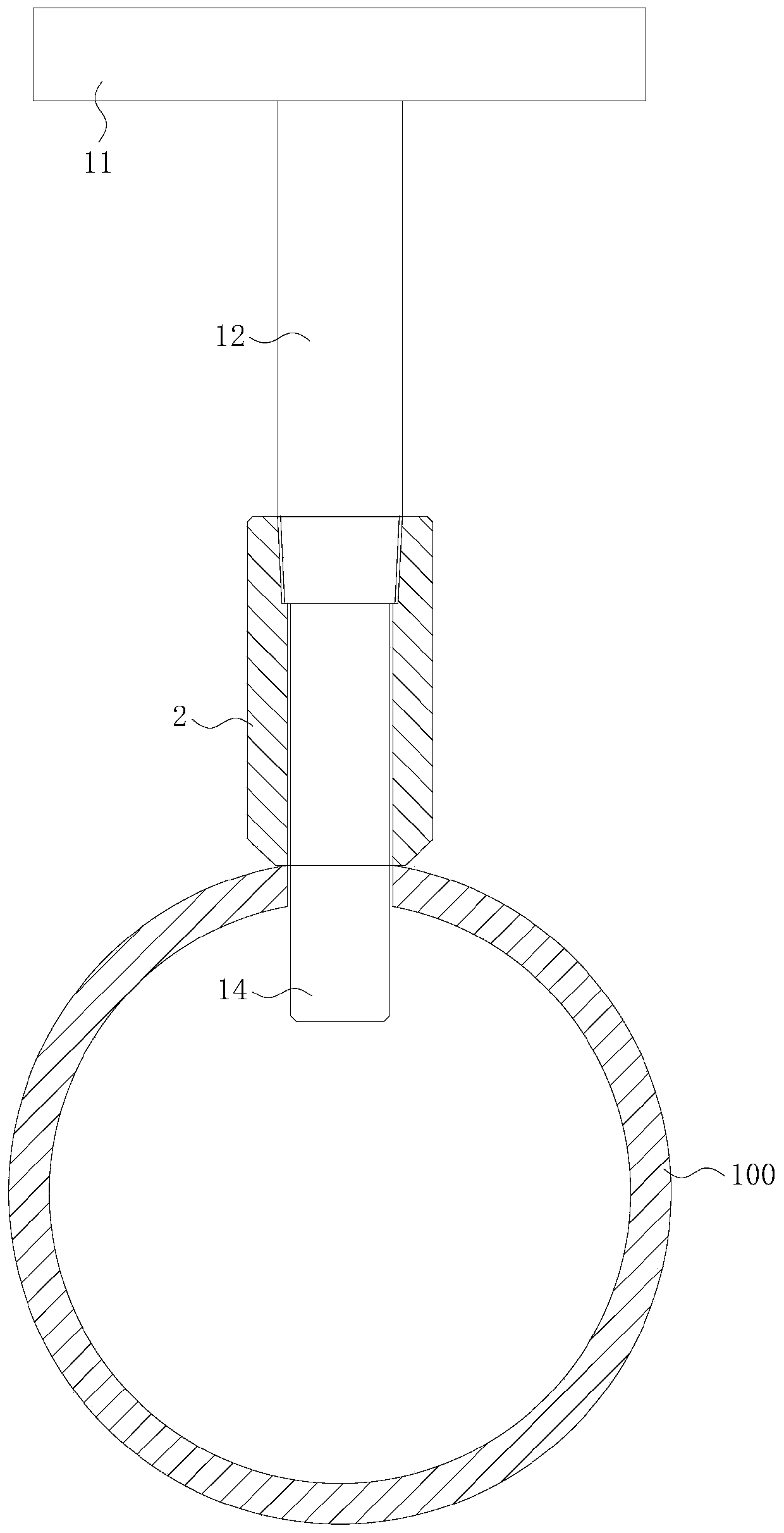

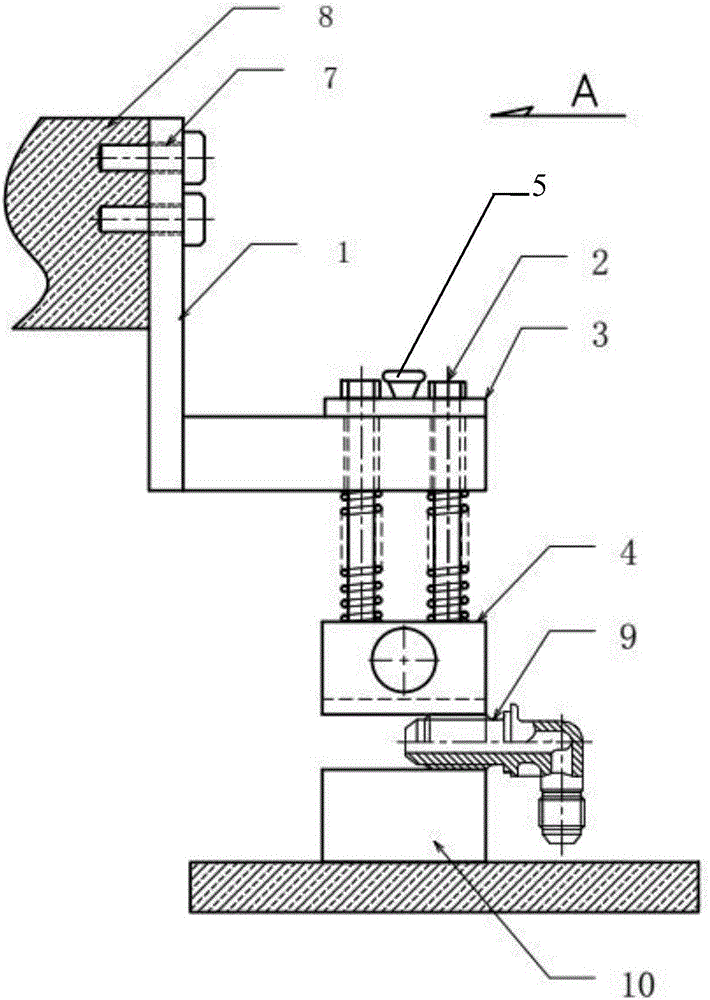

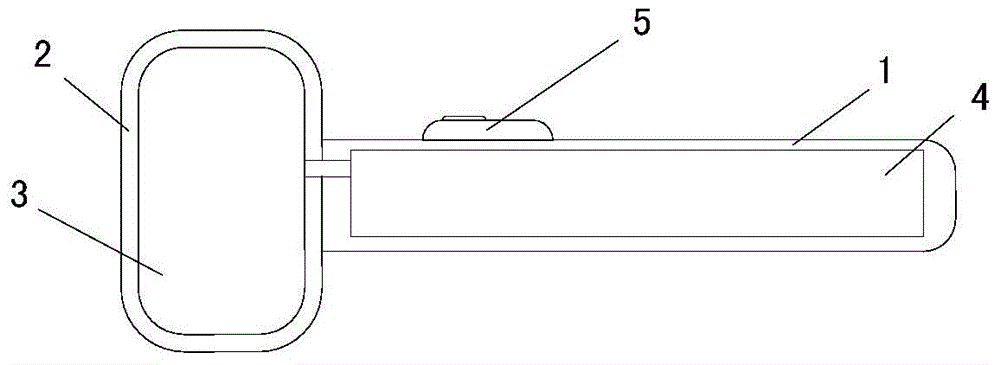

Welding auxiliary tool and welding method for instrument installation base

InactiveCN110561026AIncrease distanceAvoid hand injuriesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention discloses a welding auxiliary tool and a welding method for an instrument installation base. The welding auxiliary tool for the instrument installation base comprises a handrail, a connecting rod, a limiting part and a positioning rod, wherein the handrail is perpendicularly connected with the connecting rod; the limiting part is arranged between the connecting rod and the positioning rod; the positioning rod can be inserted into a through hole of the instrument installation base; the limiting part is connected with the instrument installation base; one end, far away from the limiting part, of the positioning rod stretches out of the through hole; and the positioning rod and the instrument installation base keep relative rest. According to the welding auxiliary tool for the instrument installation base provided by the invention, through a restricting effect of the limiting part, the positioning rod stretches out of the through hole of the instrument installation base, sothat the positioning rod can be inserted into an open hole of a pipeline, the instrument installation base is accurately positioned on the open hole of the pipeline, and the through hole in the instrument installation base aligns at the open hole of the pipeline. In addition, through arranging the connecting rod, the distance between a handle and a welding seam is effectively extended, and the occurrence of the phenomenon that a hand is injured in the welding process is prevented.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

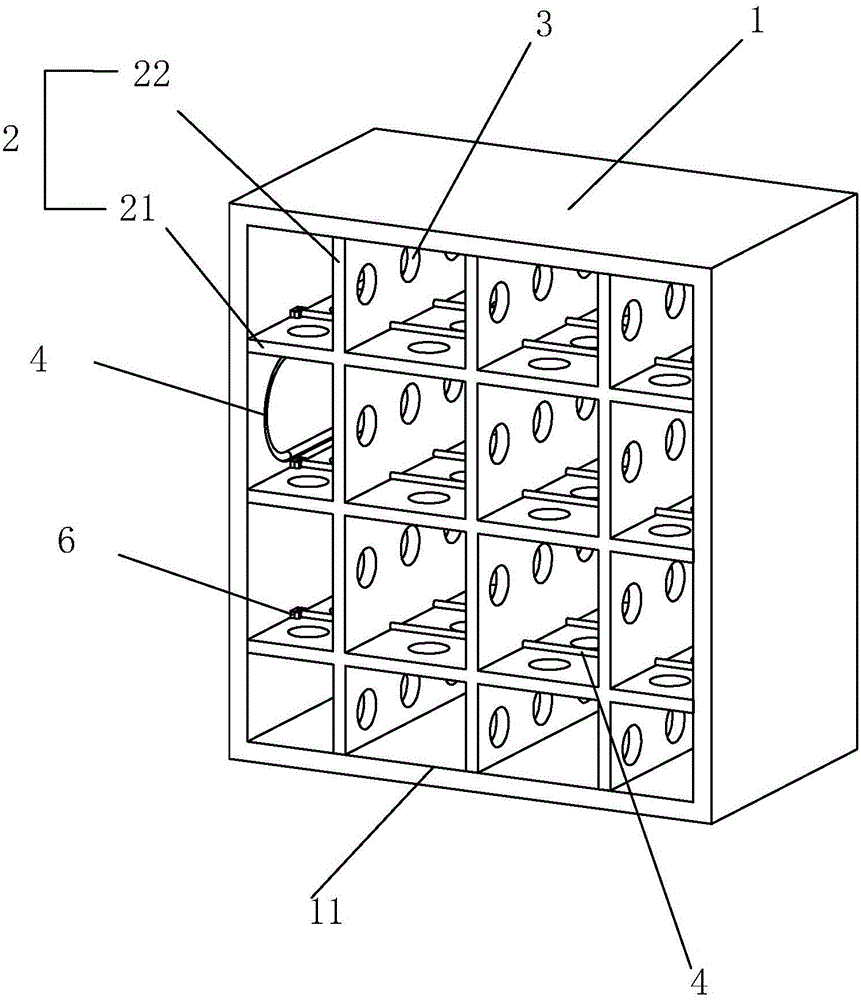

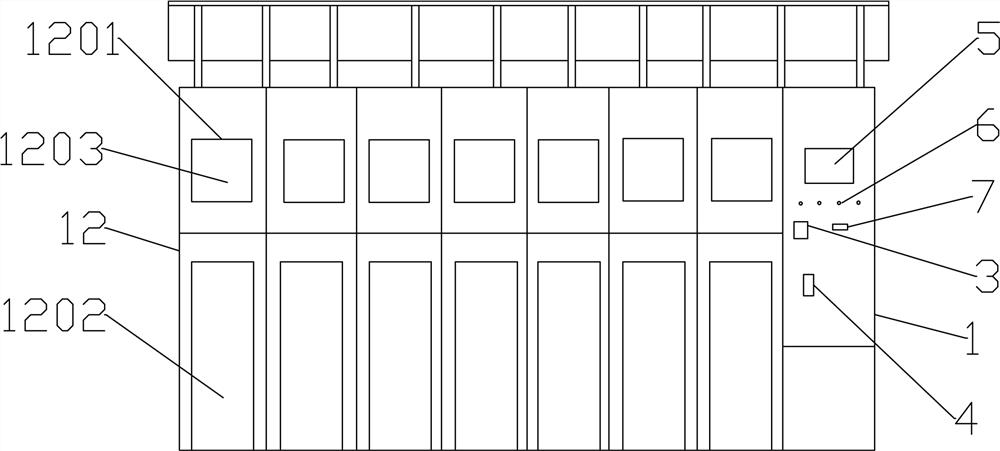

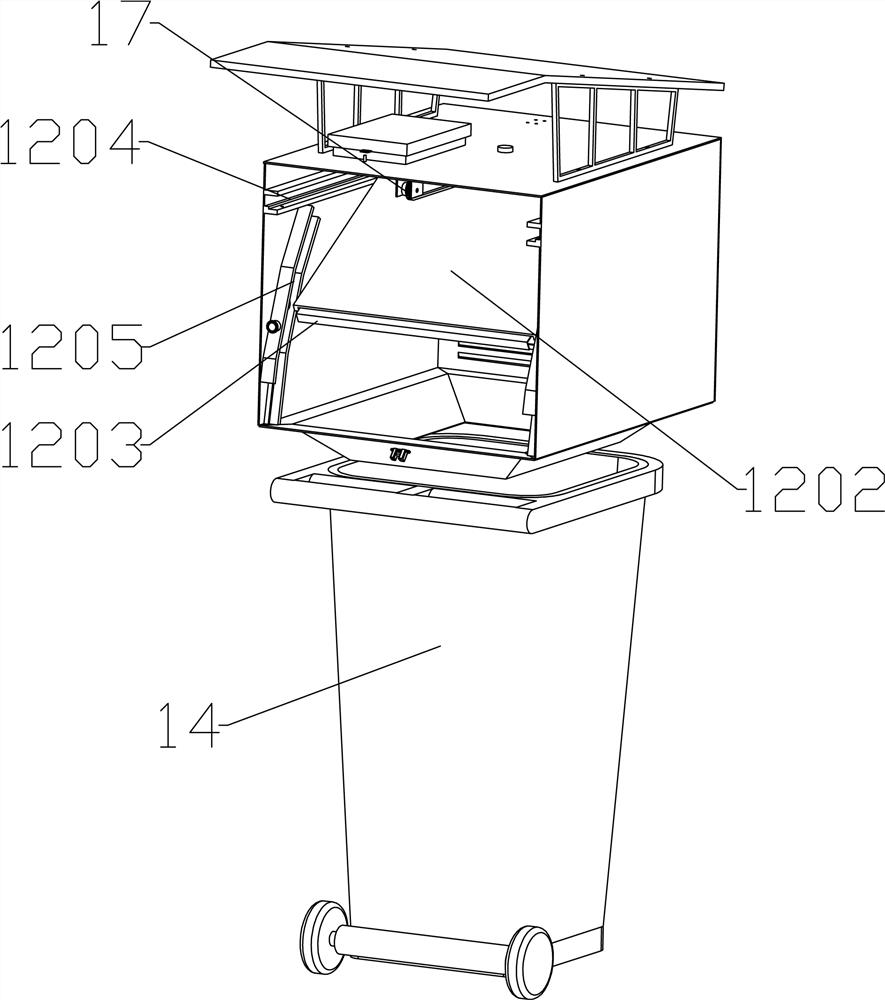

Traceable garbage classification throwing system and garbage throwing method

ActiveCN112093317AAchieve distinctionRealize traceabilityWaste collection and transferRefuse receptaclesKey pressingControl system

Owner:湖北云端互联网络科技有限公司

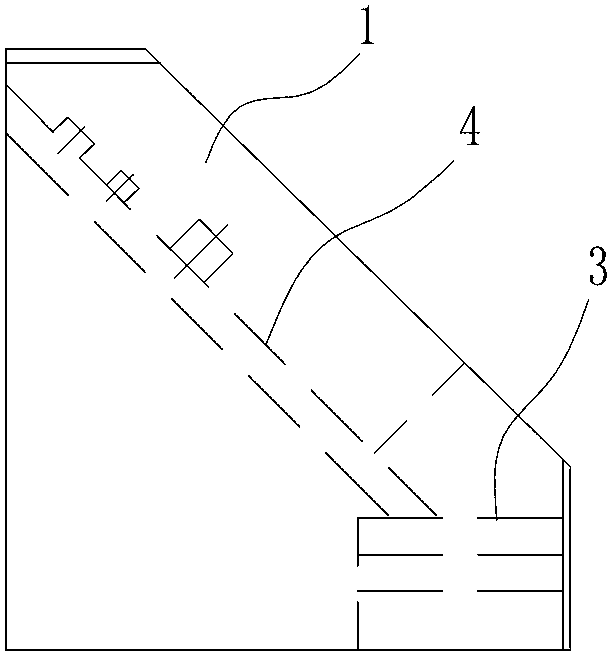

Tool box for repairing and debugging

The invention discloses a tool box for repairing and debugging. A flat plate (3) and an inclined plate (4) are fixed in a box body (1); at least one row of small positioning holes (5) and at least one row of intermediate positioning holes (6) are formed in the flat plate (3); the left part of the front plate surface of the inclined plate (4) is fixedly provided with a wrench positioning frame (7), and the right part of the front plate surface of the inclined plate (4) is fixedly provided with a row of first positioning blocks (8); the right side of the first positioning blocks (8) is provided with a row of positioning columns (9); and the upper side of the positioning columns (9) and the first positioning blocks (8) is provided with a row of second positioning blocks (10). According to the tool box for repairing and debugging, various tools for repairing and debugging are classified and arranged in the box body according to regions, and can be intuitively and clearly shown before workers, the workers can conveniently fetch specific tools as required, the time for searching the tools is saved, and the field management is facilitated.

Owner:力帆科技(集团)股份有限公司

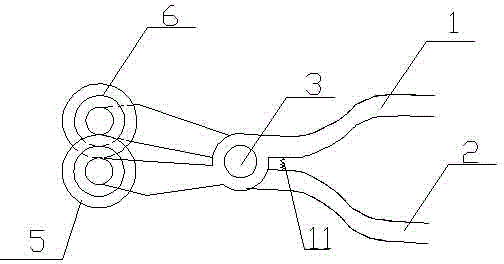

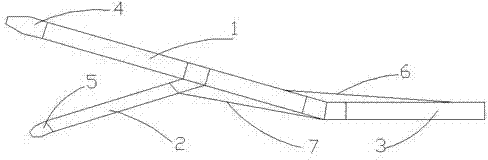

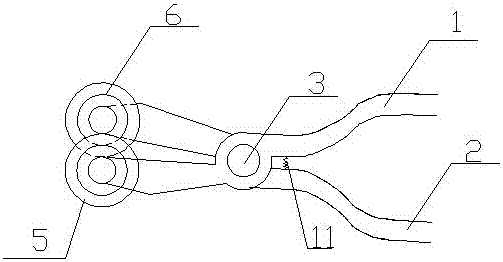

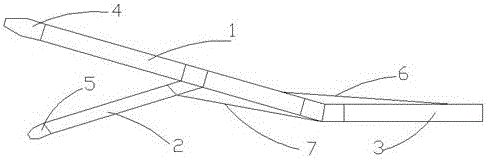

Correcting pliers for bent wires

The invention relates to the field of power tools, in particular to correcting pliers for bent wires, comprising a first handle and a second handle connected through a shaft. The front end of the first handle is connected with a first roller through a first rotary shaft. The first roller comprises at least two roller units which are coaxial and different in diameter; the front end of the second handle is connected with a second roller through a second rotary shaft; the second roller comprises roller units fitting the first roller; the sidewalls of the corresponding roller units are provided with grooves which are identical. The correcting pliers have the advantages that the correcting pliers are made according to the principle of pull and compression, the correcting pliers are suitable for correcting bent wires of different types, the wires are placed in the grooves of different types according to the different types of the wires, the wires in the grooves are compressed by pressing the first handle and the second handle, hand injury of workers caused by manual direct correcting of the wires is avoided during wiring, and work efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO WUDI COUNTY POWER SUPPLY CO

Small intelligent chicken killing device

InactiveCN112244065AImplementation intoAchieve plucking operationPoultry plucking mechanismsBlood collection/stirring apparatusAnimal scienceEngineering

The invention discloses a small intelligent chicken killing device which comprises a shell, a chicken killing mechanism, a feather plucking mechanism and a positioning mechanism, wherein the chicken killing mechanism, the feather plucking mechanism and the positioning mechanism are all installed in the shell, a chicken inlet and a chicken outlet are formed in the shell, the positioning mechanism is arranged at the position close to the chicken inlet, the feather plucking mechanism is arranged at the position close to the chicken outlet, a chicken inlet box is arranged at the chicken inlet, a chicken driving plate capable of being turned over up and down is arranged on the side edge, away from the chicken inlet, of the upper side surface of the chicken inlet box, telescopic chicken guidingplates are hinged to the left side edge and the right side edge, away from the chicken inlet, of the chicken inlet box, and a plurality of telescopic rods are fixed to the side surface, facing the chicken inlet box, of the chicken driving plate after the chicken driving plate is overturned downwards. According to the small intelligent chicken killing device, through the arrangement of the chickeninlet box and the chicken driving plate, chickens can be effectively driven into the shell, so that the situation that the chickens need to be grabbed firstly in the prior art is avoided.

Owner:温州鑫锐翔科技有限公司

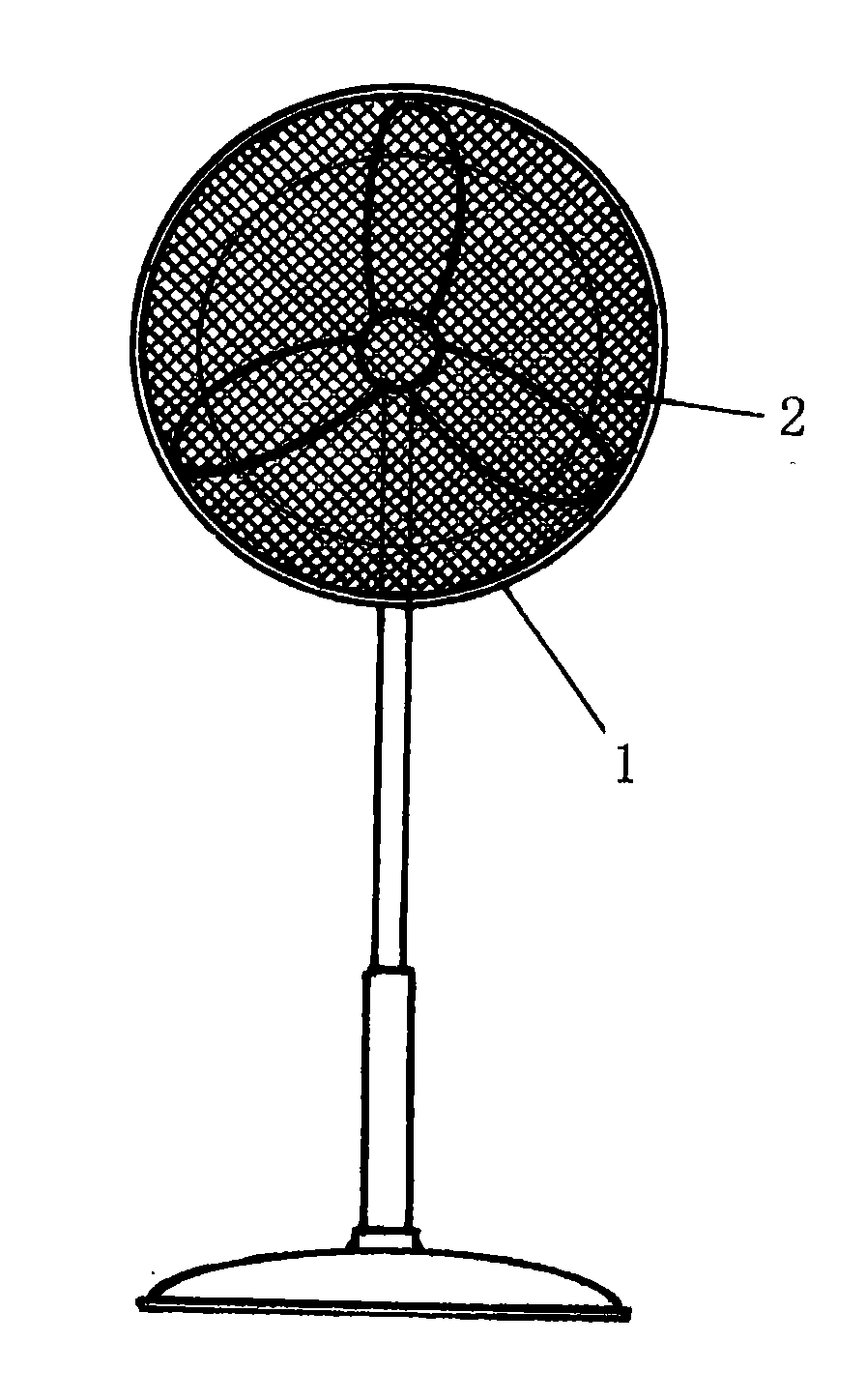

Protective cover of electric fan

InactiveCN101608635AImprove the protective effectPrevent hand injuriesPump componentsPump installationsEngineeringFan blade

Owner:严天笑

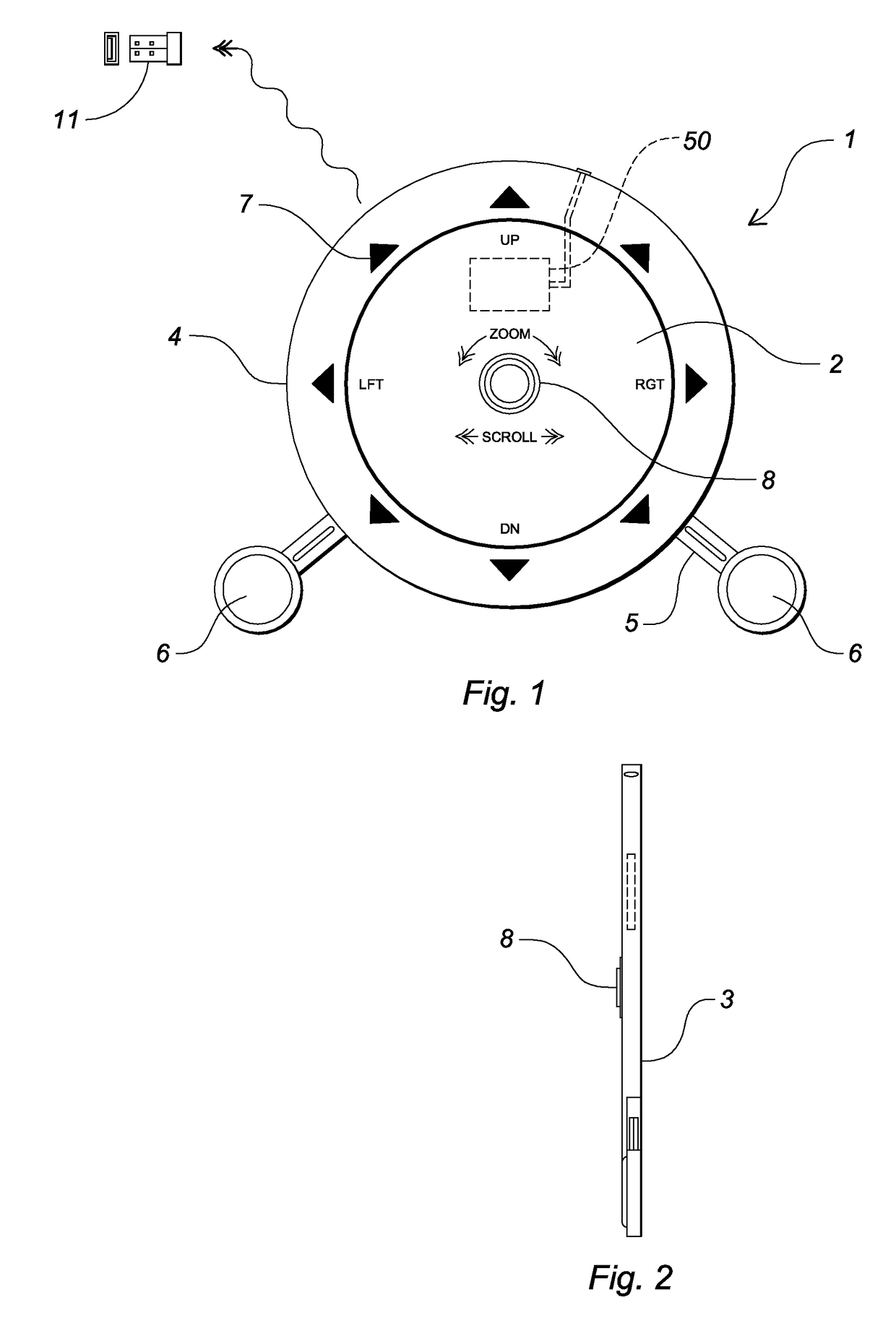

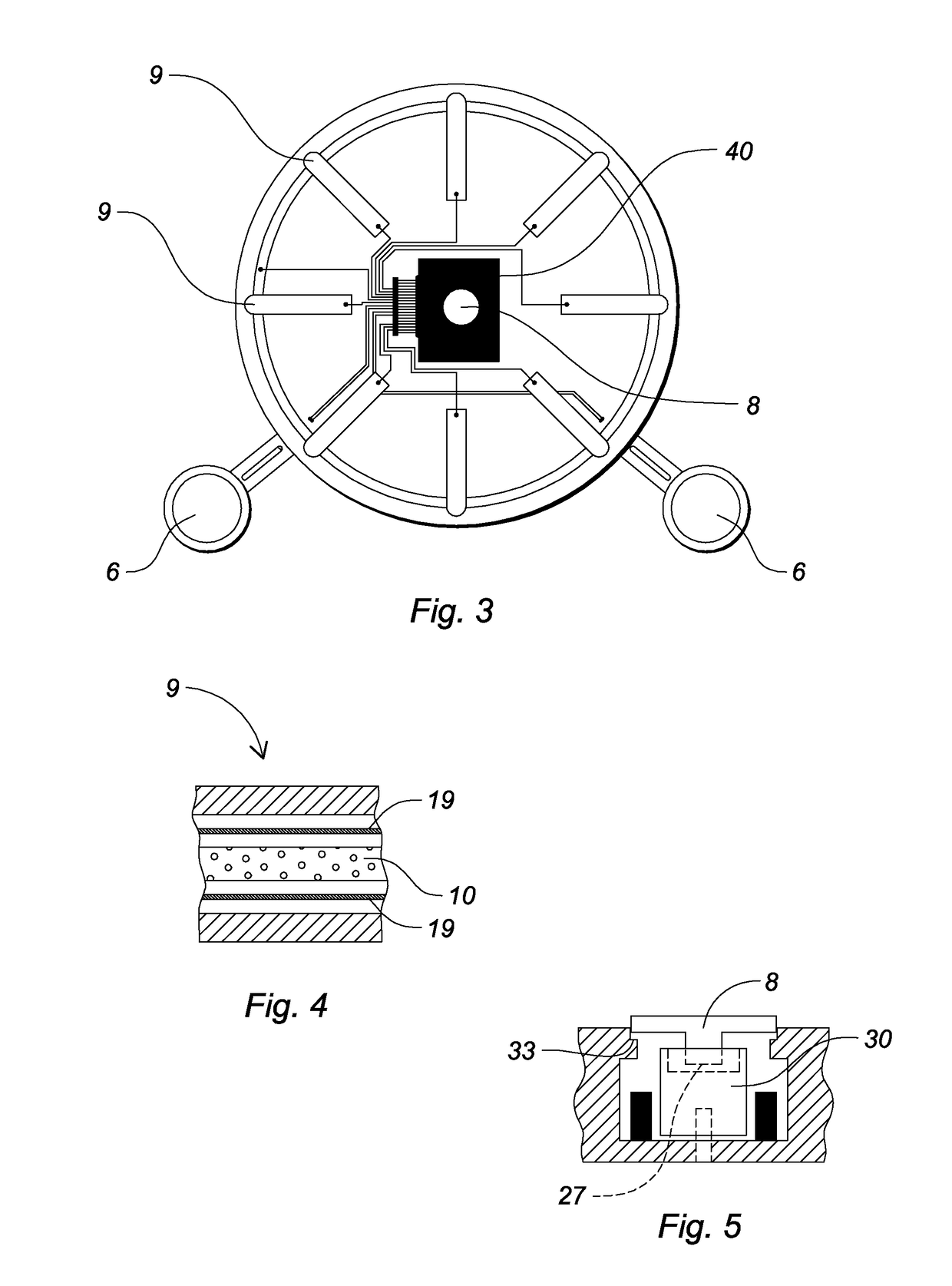

Ergonomic computer mouse

ActiveUS10061398B1Prevent wristAvoid hand injuriesCathode-ray tube indicatorsInput/output processes for data processingEngineeringWrist

An ergonomic computer mouse for comfortably accommodating a user's foot includes a substantially circular pad having a planar upper surface, a planar lower surface and at least one peripheral edge. Outwardly extending from the peripheral edge are a pair of arms, each having a control button at a distal end that functions as either a “left” or “right” button found on a conventional mouse. On the upper surface of the housing are a plurality of peripheral, multidirectional arrows that, when depressed with a foot, move a cursor in a corresponding direction on the screen. Likewise, a centrally disposed zoom button can be manipulated with a foot to enlarge, reduce or scroll through displayed screen content. Accordingly, a user can completely control all typical mouse functions with a foot to prevent wrist and hand stress or injury.

Owner:RUSSELL JONATHAN

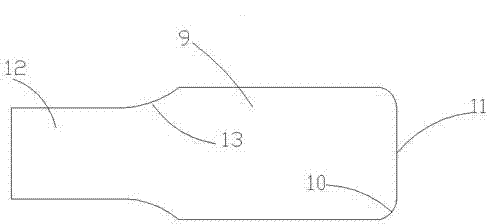

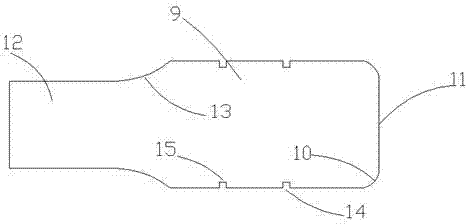

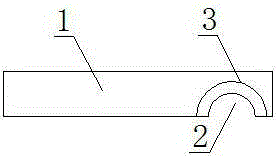

Anti-hand-cutting umbrella bone

The invention discloses an anti-hand-cutting umbrella bone, which comprises a first umbrella bone, wherein a second umbrella bone is arranged in the middle of the first umbrella bone, a third umbrella bone is arranged on one end of the first umbrella bone, a first pivot structure is arranged between the first umbrella bone and the second umbrella bone, and a second pivot structure is arranged between the first umbrella bone and the third umbrella bone; a first fixing piece is arranged on the other end of the first umbrella bone, and a second fixing piece is arranged on the other end of the second umbrella bone. The anti-hand-cutting umbrella bone has the advantages that the structure is simple and exquisite, a user is prevented from cutting a hand or being injured, and the safety coefficient in use is greatly improved.

Owner:ZHEJIANG TENGXIN UMBRELLA

Wire Bending Correction Pliers

The invention relates to the field of power tools, in particular to correcting pliers for bent wires, comprising a first handle and a second handle connected through a shaft. The front end of the first handle is connected with a first roller through a first rotary shaft. The first roller comprises at least two roller units which are coaxial and different in diameter; the front end of the second handle is connected with a second roller through a second rotary shaft; the second roller comprises roller units fitting the first roller; the sidewalls of the corresponding roller units are provided with grooves which are identical. The correcting pliers have the advantages that the correcting pliers are made according to the principle of pull and compression, the correcting pliers are suitable for correcting bent wires of different types, the wires are placed in the grooves of different types according to the different types of the wires, the wires in the grooves are compressed by pressing the first handle and the second handle, hand injury of workers caused by manual direct correcting of the wires is avoided during wiring, and work efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO WUDI COUNTY POWER SUPPLY CO

Device for quickly towing explosion-proof switch body

A device for quickly towing an explosion-proof switch body comprises a dismounting vehicle base. A moving wheel is installed relatively rotationally on the dismounting vehicle base. The front and the rear of the upper surface of the dismounting vehicle base are connected with a support rod and an adjusting rod respectively. The upper end of the support rod is hinged to a connecting arm. The front end of the connecting arm is fixedly connected with a horizontally arranged lifting support frame. The rear end of the connecting arm is fixedly connected with a pressing rod. The rear end of the pressing rod is fixedly connected with a movable card. The upper end of the adjusting rod is fixedly connected with a dismounting vehicle seat. The adjusting rod is in threaded connection with an upper stopping nut and a lower stopping nut which are arranged correspondingly. The adjusting rod passes through the center of the movable card located between the upper stopping nut and the lower stopping nut. The lifting support frame is in a U shape with a forward opening. The upper surface of the center of the lifting support frame is fixedly connected with a connecting block fixedly connected to the front end of the connecting arm. The pressing rod is in a V shape with an upward opening. An intersection angle between the two sections of the pressing rod is an obtuse angle. The movable card is in a circular or U shape.

Owner:枣庄矿业(集团)有限责任公司柴里煤矿

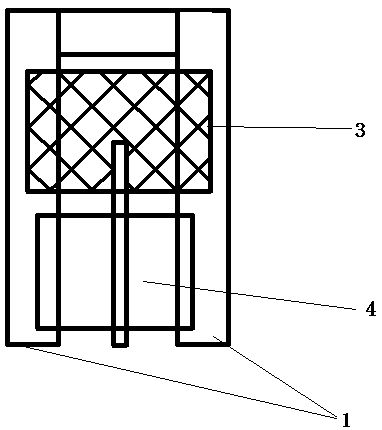

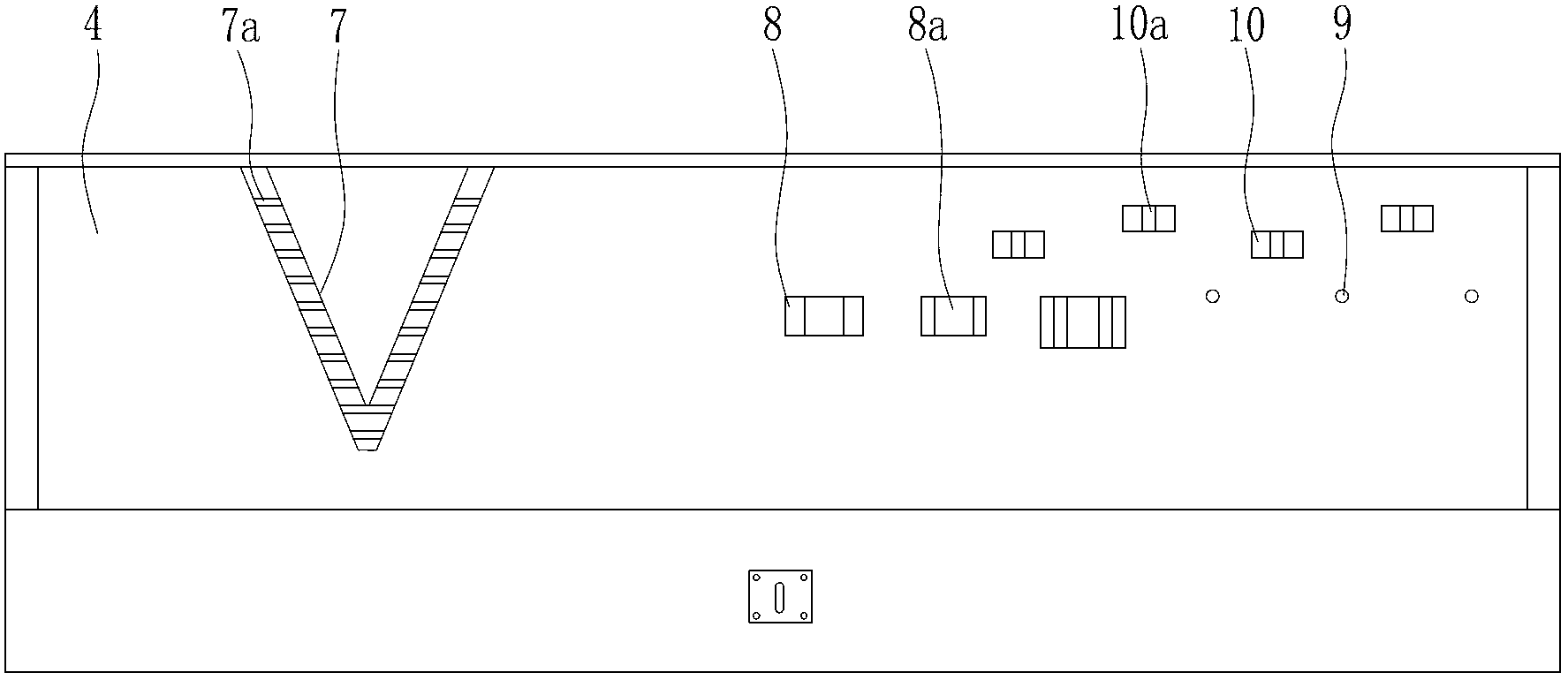

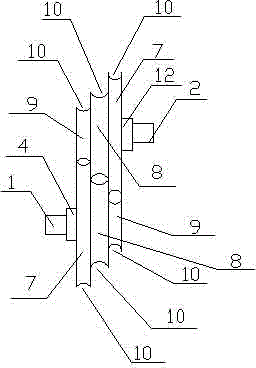

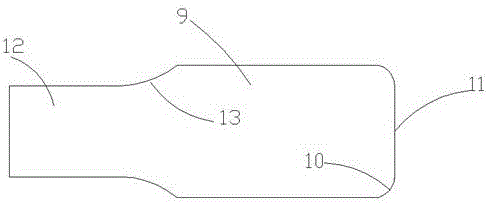

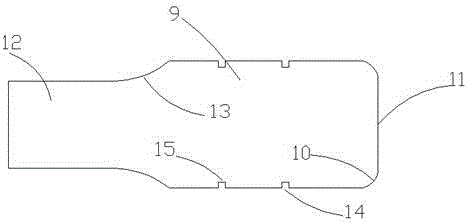

Feeding protection mechanism for horizontal thread rolling machine

InactiveCN105935731AAvoid hand injuriesPrevent jumpingMetal-working feeding devicesScrew-threads articlesProtection mechanismEngineering

The invention discloses a feeding protection mechanism for a horizontal thread rolling machine. The feeding protection mechanism for the horizontal thread rolling machine comprises a support, guide pillars, a movable plate, a star handle, springs and a pressing block, wherein the support is 'L'-shaped; a vertical side of the support is fixed to a thread rolling machine body; cylindrical through holes in the vertical direction are formed in a horizontal side of the support; the upper ends of the guide pillars penetrate through the cylindrical through holes of the support and are connected with the movable plate; the lower ends of the guide pillars are connected with the pressing block; one spring sleeves the outer surface of each guide pillar; the star handle is mounted on the movable plate; and a round hole is formed in the middle of the pressing block. A thread rolling station of an existing thread rolling machine does not have a feeding protection mechanism, and a worker needs to press a workpiece with hands in a thread rolling process, and is injured easily. After the feeding protection mechanism disclosed by the invention is additionally arranged on the thread rolling machine, the following effects can be achieved: firstly, jumping of the workpiece is prevented during thread rolling of the workpiece, particularly in a few seconds at the beginning of thread rolling; and secondly, the possible circumstance that the hands of the worker are pinched and the worker is injured is avoided. Feeding protection is realized by a simple connection assembly and an elastic fixing assembly, and the structure is quite simple.

Owner:DALIAN SUNNY TITANIUM IND

Cut-resistant umbrella ribs

ActiveCN103027452BImprove connection strengthIncrease productivityWalking sticksBiochemical engineeringSafety coefficient

The invention discloses an anti-hand-cutting umbrella bone, which comprises a first umbrella bone, wherein a second umbrella bone is arranged in the middle of the first umbrella bone, a third umbrella bone is arranged on one end of the first umbrella bone, a first pivot structure is arranged between the first umbrella bone and the second umbrella bone, and a second pivot structure is arranged between the first umbrella bone and the third umbrella bone; a first fixing piece is arranged on the other end of the first umbrella bone, and a second fixing piece is arranged on the other end of the second umbrella bone. The anti-hand-cutting umbrella bone has the advantages that the structure is simple and exquisite, a user is prevented from cutting a hand or being injured, and the safety coefficient in use is greatly improved.

Owner:ZHEJIANG TENGXIN UMBRELLA

Explosion-proof switch body fast dragging device

A device for quickly towing an explosion-proof switch body comprises a dismounting vehicle base. A moving wheel is installed relatively rotationally on the dismounting vehicle base. The front and the rear of the upper surface of the dismounting vehicle base are connected with a support rod and an adjusting rod respectively. The upper end of the support rod is hinged to a connecting arm. The front end of the connecting arm is fixedly connected with a horizontally arranged lifting support frame. The rear end of the connecting arm is fixedly connected with a pressing rod. The rear end of the pressing rod is fixedly connected with a movable card. The upper end of the adjusting rod is fixedly connected with a dismounting vehicle seat. The adjusting rod is in threaded connection with an upper stopping nut and a lower stopping nut which are arranged correspondingly. The adjusting rod passes through the center of the movable card located between the upper stopping nut and the lower stopping nut. The lifting support frame is in a U shape with a forward opening. The upper surface of the center of the lifting support frame is fixedly connected with a connecting block fixedly connected to the front end of the connecting arm. The pressing rod is in a V shape with an upward opening. An intersection angle between the two sections of the pressing rod is an obtuse angle. The movable card is in a circular or U shape.

Owner:枣庄矿业(集团)有限责任公司柴里煤矿

Mechanical intelligent needle thrusting device

ActiveCN102744921BAccurate speedAccurate distanceLayered productsSuturing needleUltimate tensile strength

The invention discloses a mechanical intelligent needle thrusting device, comprising an electric cylinder, a thimble, a guiding device, a guiding needle tubing and a suture needle. An input end of the electric cylinder is connected to a drive device arranged outside; a front end of an output end shell is connected to the guiding device; and the output end located within the shell is connected with the thimble. The guiding device, the guiding needle tubing and the suture needle are in sleeve joint from outside to inside; a front end of the guiding needle tubing is fixedly connected with the guiding device through a fastener; and the suture needle can move back and forth along the guiding needle tubing. A tail end of the thimble is connected with the electric cylinder; and a front of the thimble extends into the guiding needle tubing to support against the suture needle. The device of the invention has functions of adjusting speed and distance of needle thrusting, and can carry out accurate needle thrusting at a preset speed and distance parameters; besides, the device has characteristics of stable performance and high accuracy, substitutes manual needle thrusting process of a three-dimensional fabric for a related product, realizes intelligent mechanical needle thrusting, avoids hand injuries caused by manual needle thrusting, reduces labor intensity, and improves product quality and production efficiency.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

A safety percussion device

The invention discloses a safety percussion device, which comprises a hand-held part, a high-hardness metal percussion part is fixed at the front end of the hand-hold part, an electromagnet is arranged inside the percussion part, and the electromagnet is connected to the hand-held part through a wire. battery, and the electromagnetic sticker is also provided with a control switch on the handle. In the present invention, by setting an electromagnet in the striking part, the power supply can be turned on and off through the control switch during use, so as to exert its adsorption function, which is convenient for control, and can be used for items such as hammers, and can be used to fix nails when used for hammers. Effectively prevent hand injury caused by holding nails.

Owner:XIAN YONGCHENG ELECTRONICS SCI & TECH

Auxiliary device applied to electric screw press and used for getting cylindrical finished product

InactiveCN111230020AAvoid hand injuriesImprove securityUpsetting pressesSwagging pressesMachine pressScrew press

The invention discloses an auxiliary device applied to an electric screw press and used for getting a cylindrical finished product. The auxiliary device comprises a rack; one side of the rack is provided with a push component; the other side of the rack is provided with a conveying component; the push component comprises a support platform, a cylinder fixing base, a cylinder, a telescopic guide rod, a fixing plate, a first clamping part and a second clamping part; and the conveying component comprises a first bracket, a second bracket, a driving shaft, a driven shaft and a conveying belt. According to the auxiliary device applied to the electric screw press and used for getting the cylindrical finished product disclosed by the invention, the cylinder acts to drive the fixing plate, the first clamping part and the second clamping part to synchronously move close to the cylindrical finished product until the cylindrical finished product is pushed to the conveying component so as to prevent injuries of a worker due to machine faults when the worker takes the cylindrical finished product with hands; high safety is achieved; afterwards, the cylindrical finished product is conveyed by the conveying belt into a cylindrical finished product storage region and is stored; and thus the labor intensity of the worker for transferring the cylindrical finished product is alleviated.

Owner:新沂市宜新生物科技有限公司

Nail fixing device

InactiveCN105313075AAvoid hand injuriesMeet the needs of useDispensing apparatusNail dispensersBiomedical engineeringMagnet

The invention relates to the technical field of hardware equipment, in particular to a nail fixing device. According to the nail fixing device, a handle is provided with a groove, and a magnet is arranged inside the groove. When the nail fixing device is used, a nail is put into the groove, the nail is fixed through the magnet, then the nail fixing device is held with a hand to put the nail in the use position, and the nail is fixed through a hammer, so that the hammer is prevented from injuring the hand, and the use requirements are met.

Owner:CHANGZHOU XINER SPEED REDUCER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com