A threading power tool in a movable pre-buried tube

A technology of electric tools and pre-embedded pipes, which is applied in the direction of cable laying equipment, etc., can solve the problems of manual operation, worker injury, and efficiency decline, and achieve the effect of improving work efficiency, high safety factor, and avoiding hand injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

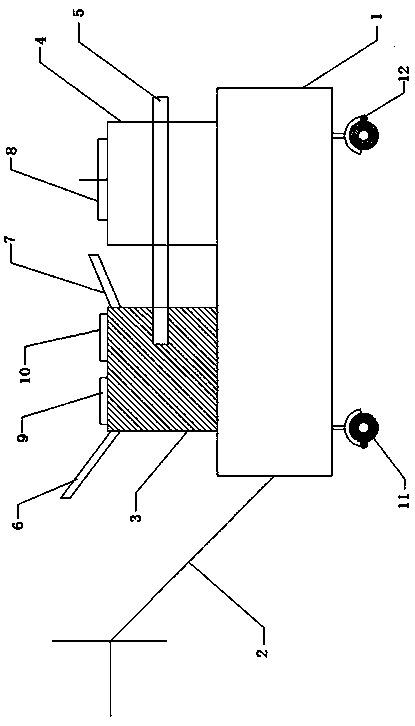

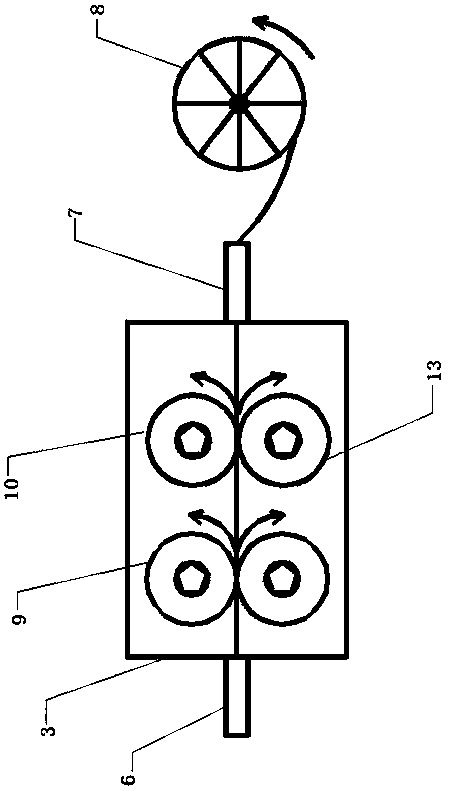

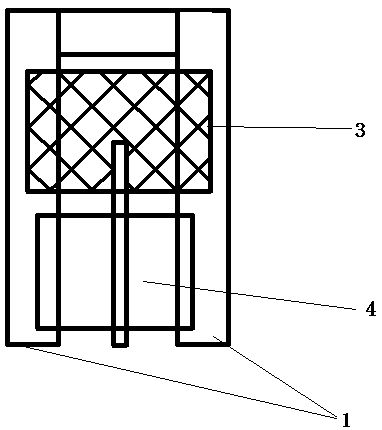

[0027] see Figure 4 It can be seen that the operation process of the present invention is: before the device works, one end of the belt line 14 is connected with the cable, the other end has been fixed on the belt line winding disc 8, the universal wheel 11 of the device is locked, the device is started, and the cable Drive the pulling force of the device 3 to the belt line 14. At this time, the belt line 14 will drive the cable at the other end of the pre-embedded wire tube to go into the wire tube. When you see that it is now 10-15cm out of the wire box at the other end, stop the device from rotating. , and then the belt line 14 is separated from the cable, and the threading in the wire tube is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com