Shoe production process and upper heating device for shoe production process

A production process and heating device technology, applied in footwear, applications, household appliances, etc., can solve problems such as low connection strength and falling soles, and achieve the effect of improving thermal insulation, avoiding damage, and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A shoe production process. Firstly, the shoe upper is put on the shoe last, and then the shoe last is heated in a dryer to heat and set. Since the heating and setting of the shoe upper belongs to the prior art, it will not be described here. Before being sent into the injection molding machine, put the upper into the upper heating device for heating. After the upper is heated to 100°C, take the upper out of the heating device, and then immediately put the upper into the mold of the injection molding machine. The mold is designed according to the shape of the sole. After the injection molding is completed, wait for the mold to cool down, take the upper out of the injection molding machine, and perform demoulding operation to complete the processing of the upper and upper.

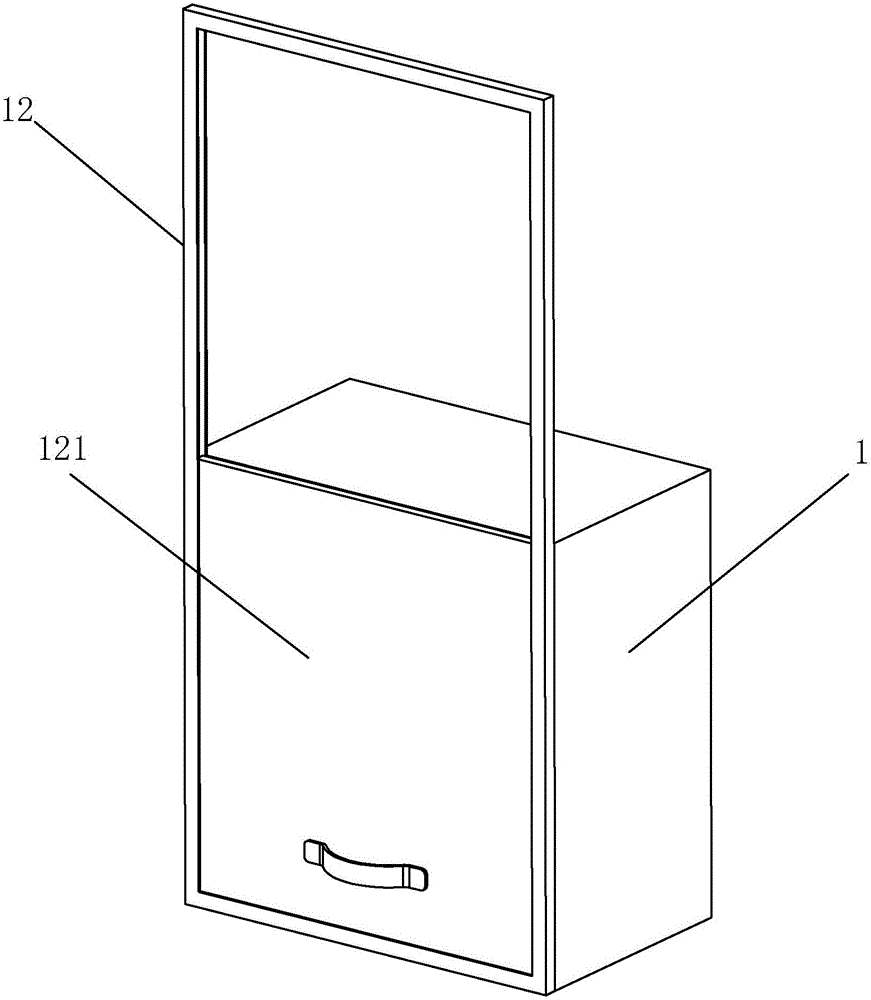

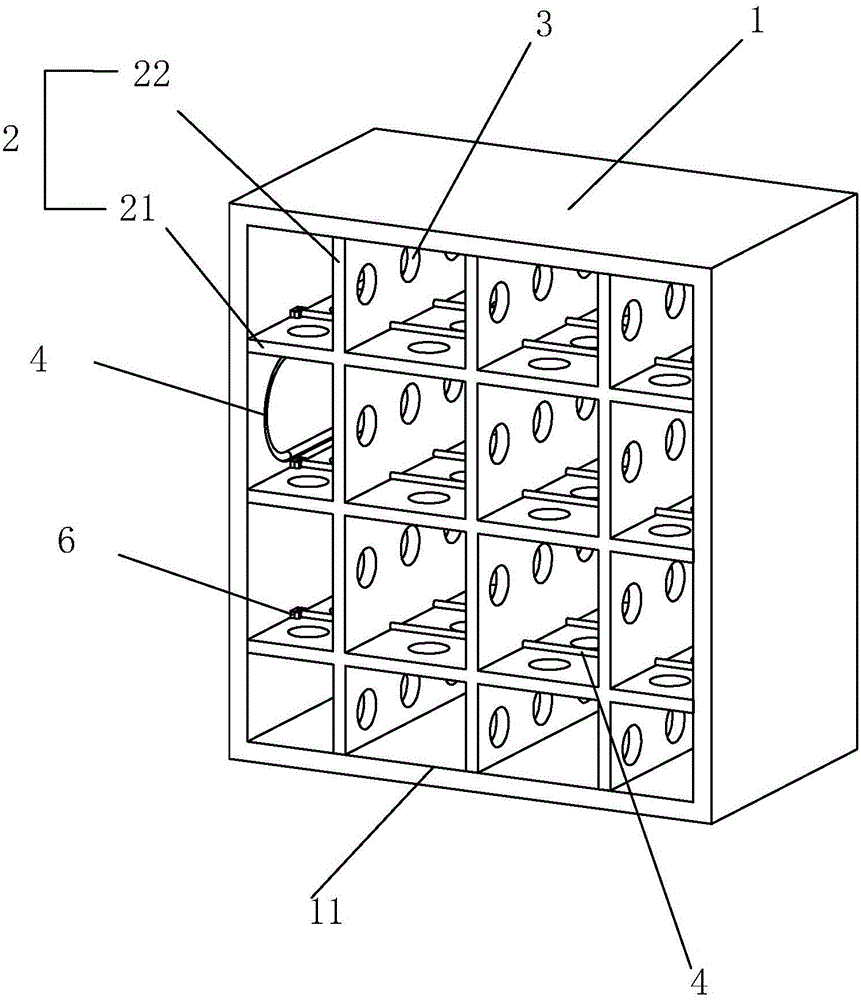

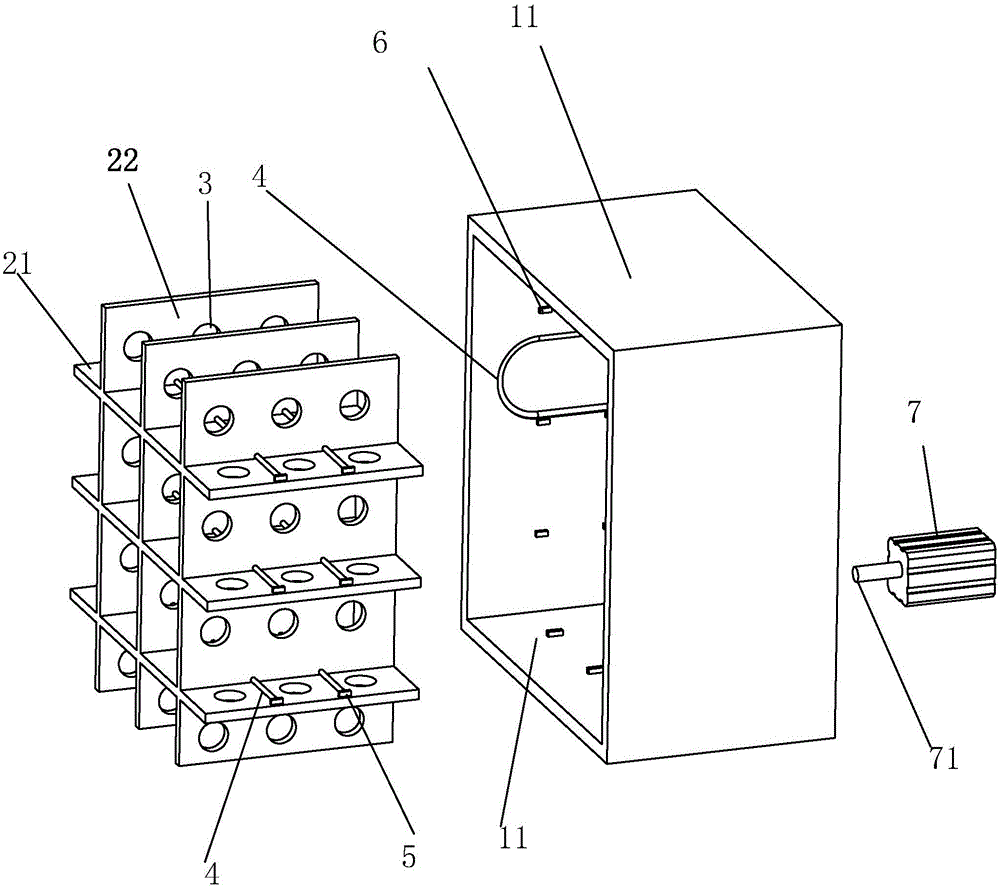

[0043] A shoe upper heating device used in the above-mentioned shoe production process, mainly including a box body 1, a cavity 11 is provided in the box body 1, when heating, the shoe upper is placed ...

Embodiment 2

[0048] The difference from Embodiment 1 is that in this embodiment, the shoe upper is preheated to 120°C. In addition, in this embodiment, the screw rod 81 is selected as the ejector part, and the screw rod 81 is threadedly connected with the separator 2. In this embodiment, Among them, there are two screw rods 81, which are respectively rotated and arranged at both ends of the spacer 2. The two screw rods 81 can ensure that the force on the spacer 2 is even when sliding, and can prevent the spacer 2 from being stuck in the cavity 11. Dead phenomenon, the screw rod 81 is rotationally connected with the box body 1, and the screw rod 81 extending into the box body 1 is threadedly connected with the transverse partition plate 21. When working, the motor 8 rotates, driving the screw rod 81 to rotate, and the separation can be realized through screw transmission. Piece 2 of the slide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com