Automatic haw strip coiling and packaging machine

A fruit tan peel and automatic technology, applied in the field of fruit tan peel automatic roll packaging machine, can solve the problems of high labor intensity of staff, unable to meet sales demand, large demand for operators, etc., to enhance market competitiveness, meet market demand, reduce The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

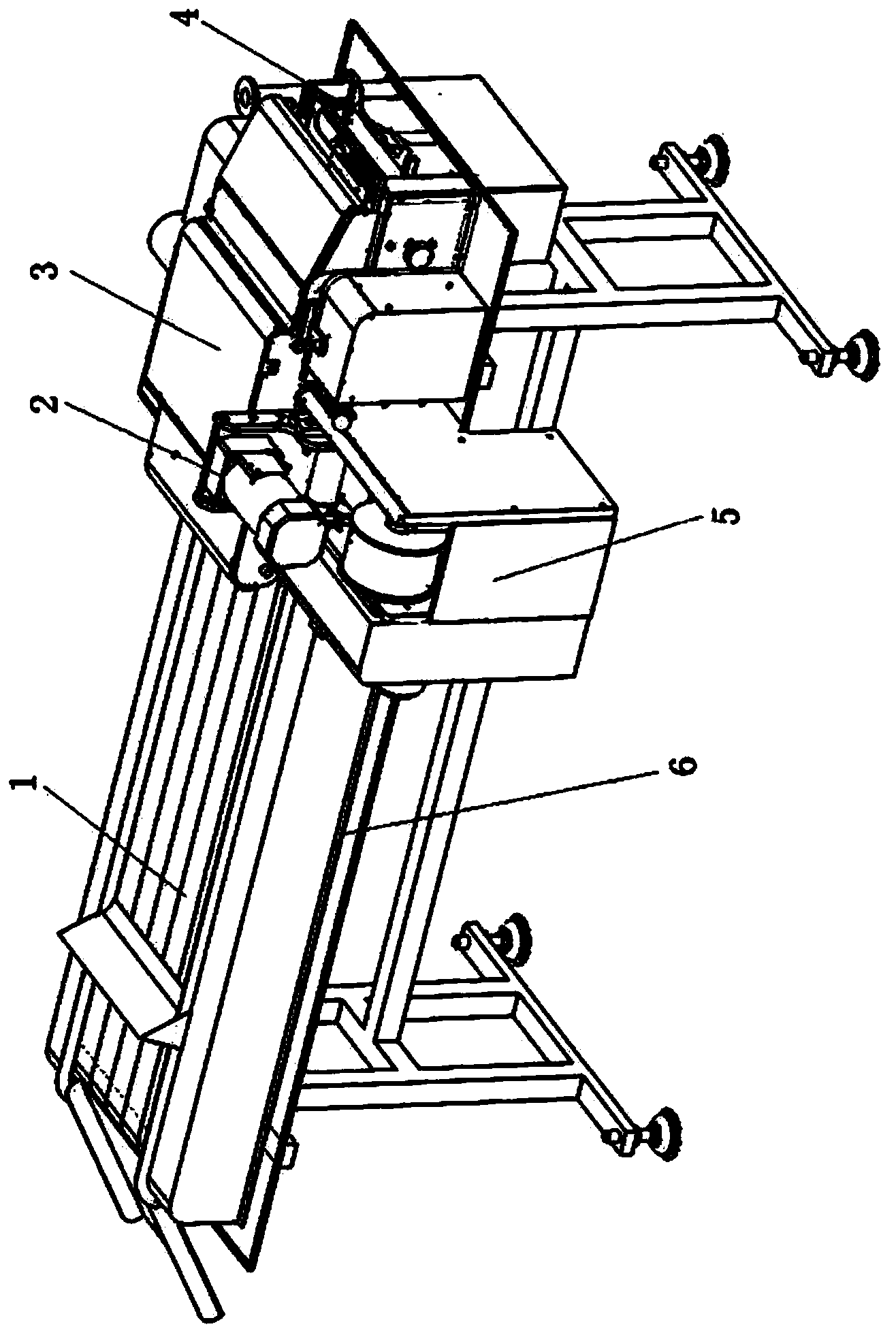

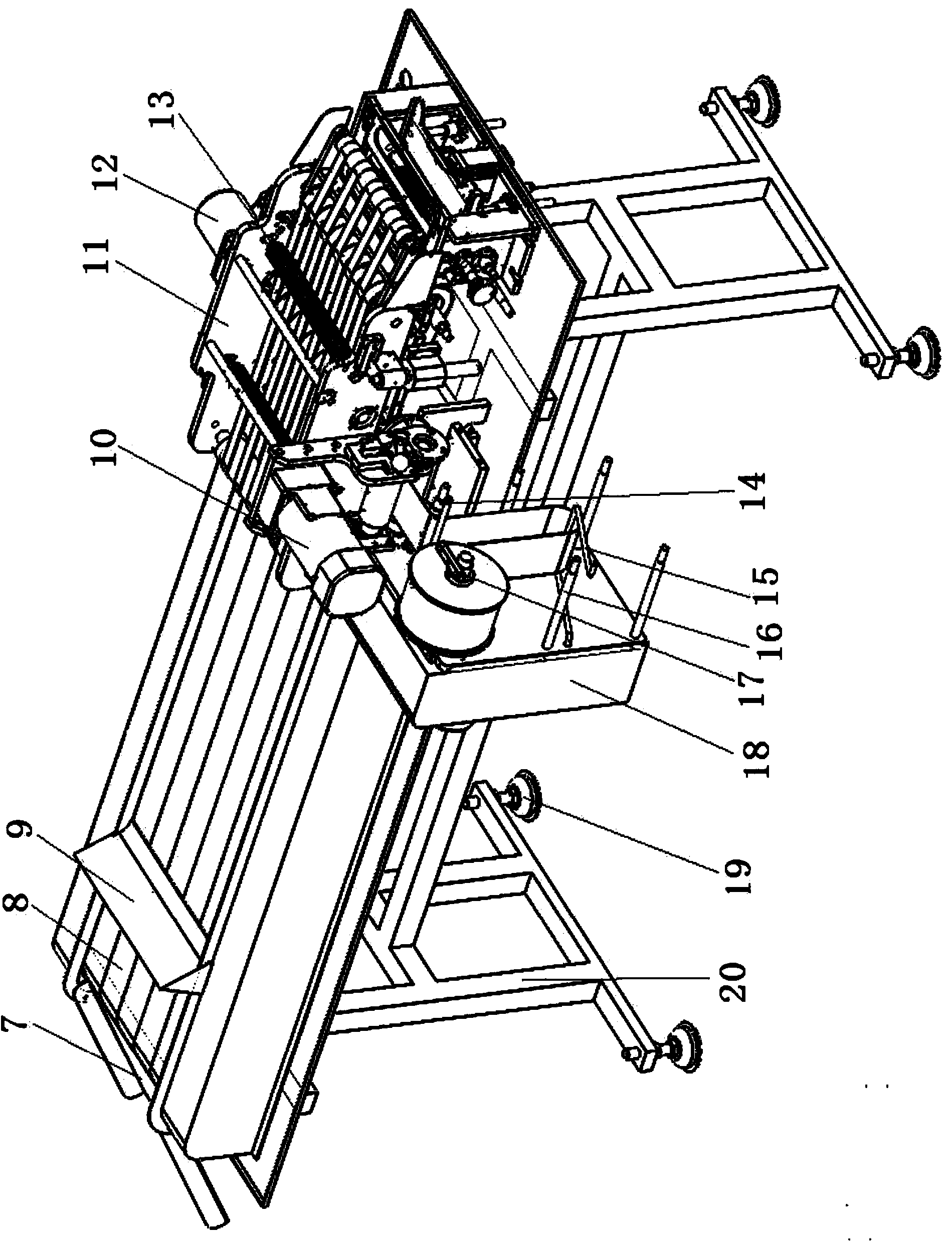

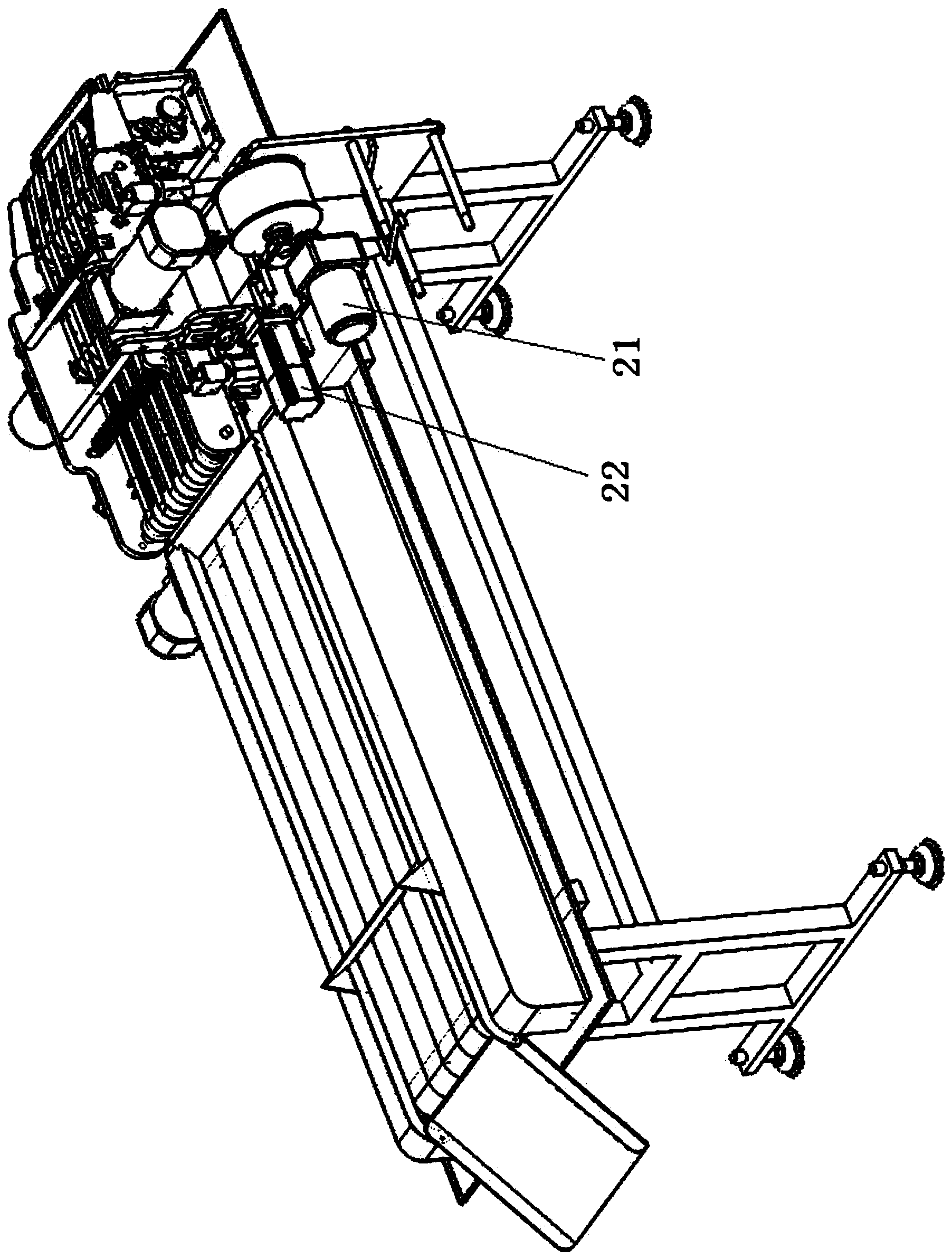

[0036] An automatic rolling packaging machine for fruit skin, comprising a workbench 6, a fruit skin feeding device 4, a wrapping paper feeding device 5, a wrapping paper pulling device, a wrapping paper cutting device 2, a conveying device 3 and a receiving device 1, the fruit skin The feeding device, the wrapping paper feeding device, the wrapping paper pulling device, the wrapping paper cutting device, the conveying device and the receiving device are all arranged on the workbench, the support frame 20 is installed on the lower part of the workbench, and the outrigger 19 is installed on the bottom of the support frame . The following is a detailed description of each part of the device;

[0037] 1. Fruit pee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com