Welding auxiliary tool and welding method for instrument installation base

A technology of auxiliary tooling and mounting seat, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of hand injury in welding, close welding seam distance, difficult to judge and ensure installation accuracy, etc., to prevent hand injury , the effect of extending the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

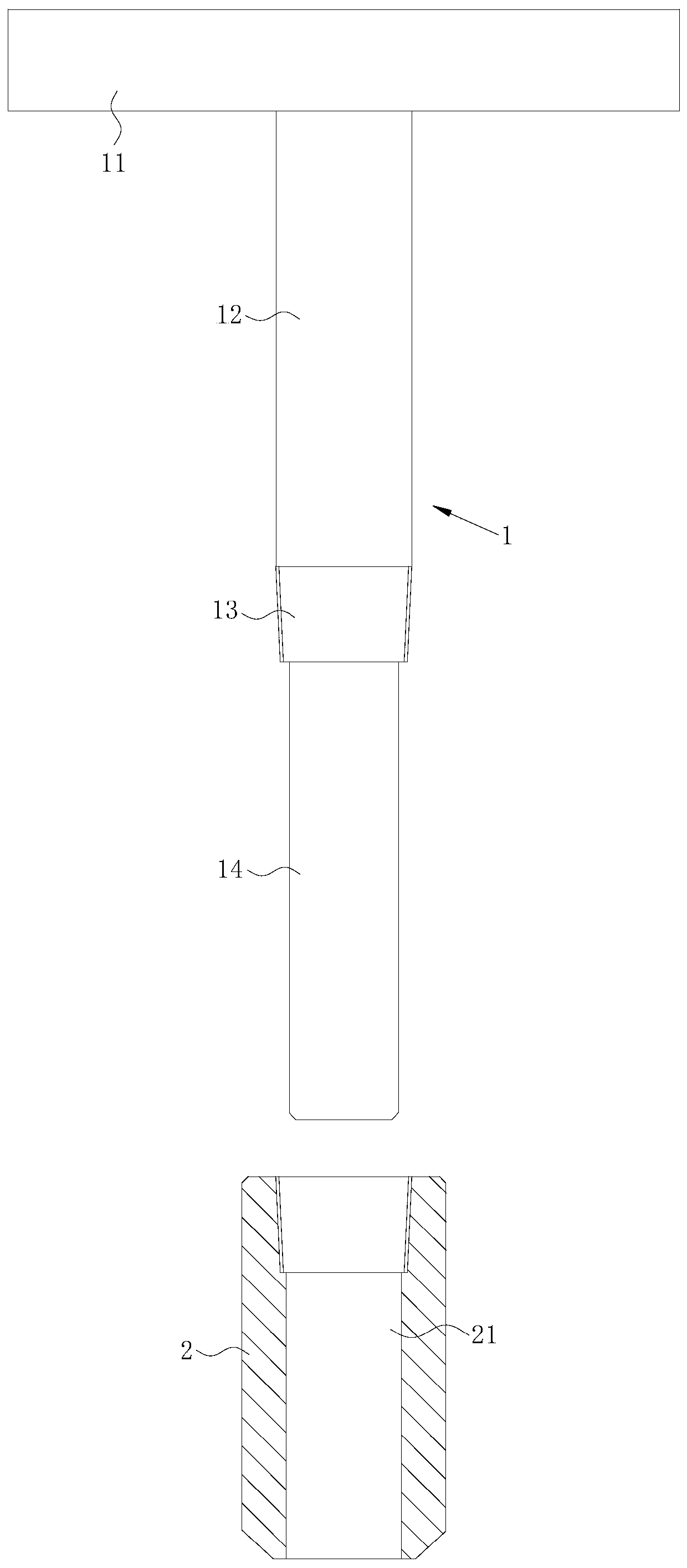

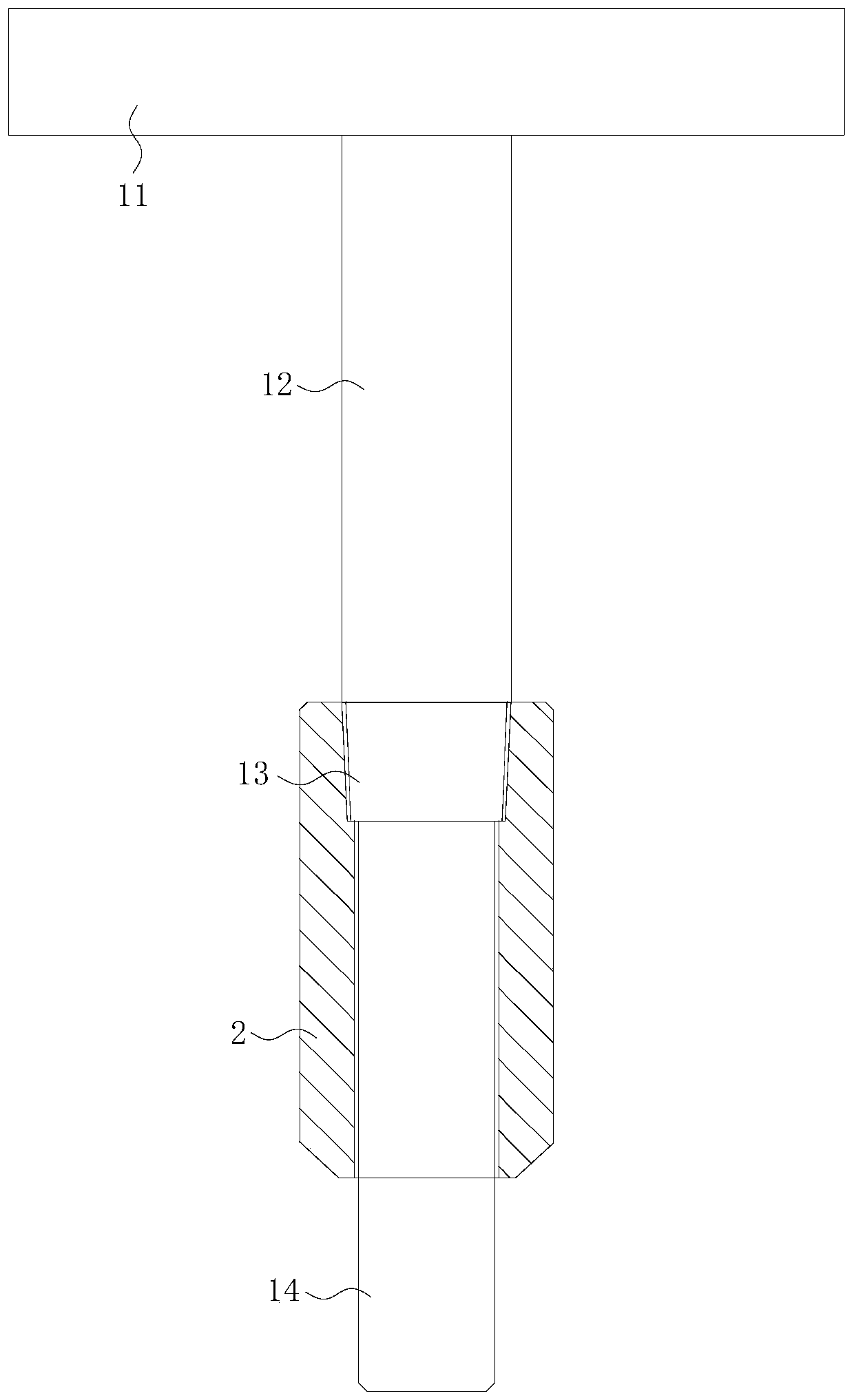

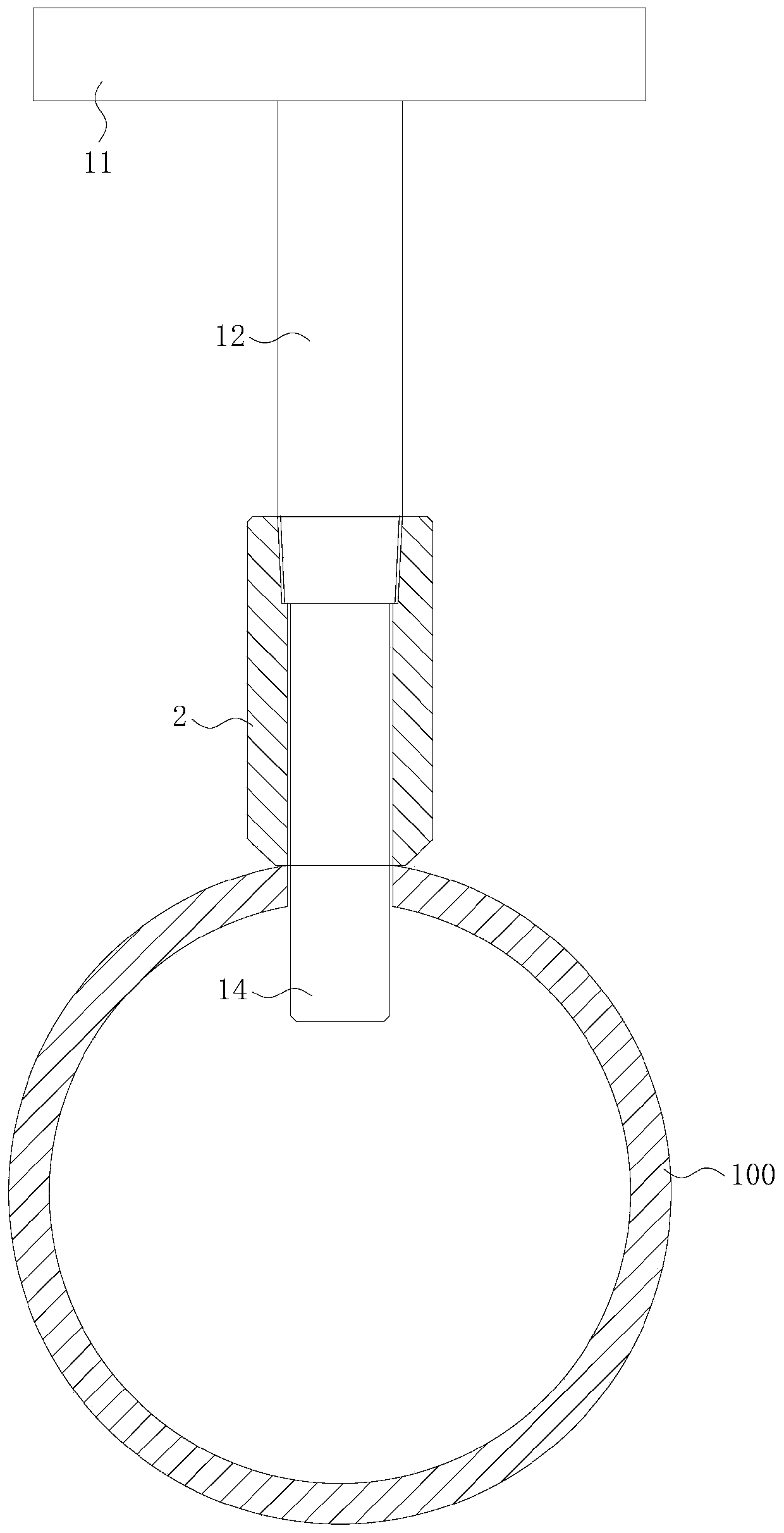

[0034] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

[0035] In the present invention, unless otherwise expressly specified and limited, a first feature "on" or "under" a second feature may include the first and second features in direct contact, or may include the first and second features Not directly but through additional features between them. Also, a first feature being "above" a second feature includes that the first feature is directly above and obliquely above the second feature, or simply means that the first feature is at a higher level than the second feature. The first feature being "below" the second feature includes that the first feature is directly below and diagonally below the second feature, or simply means that the first feature is at a lower level than the second feature.

[0036] like Figure 1 to Figure 4 As shown, the welding auxiliary toolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com