Automatic segmenting machine for capsicum frutescens

A cutting machine, millet pepper technology, applied in the direction of metal processing, can solve the problems of a large number of labor, hand injury, low efficiency, etc., to achieve the effect of improving production efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

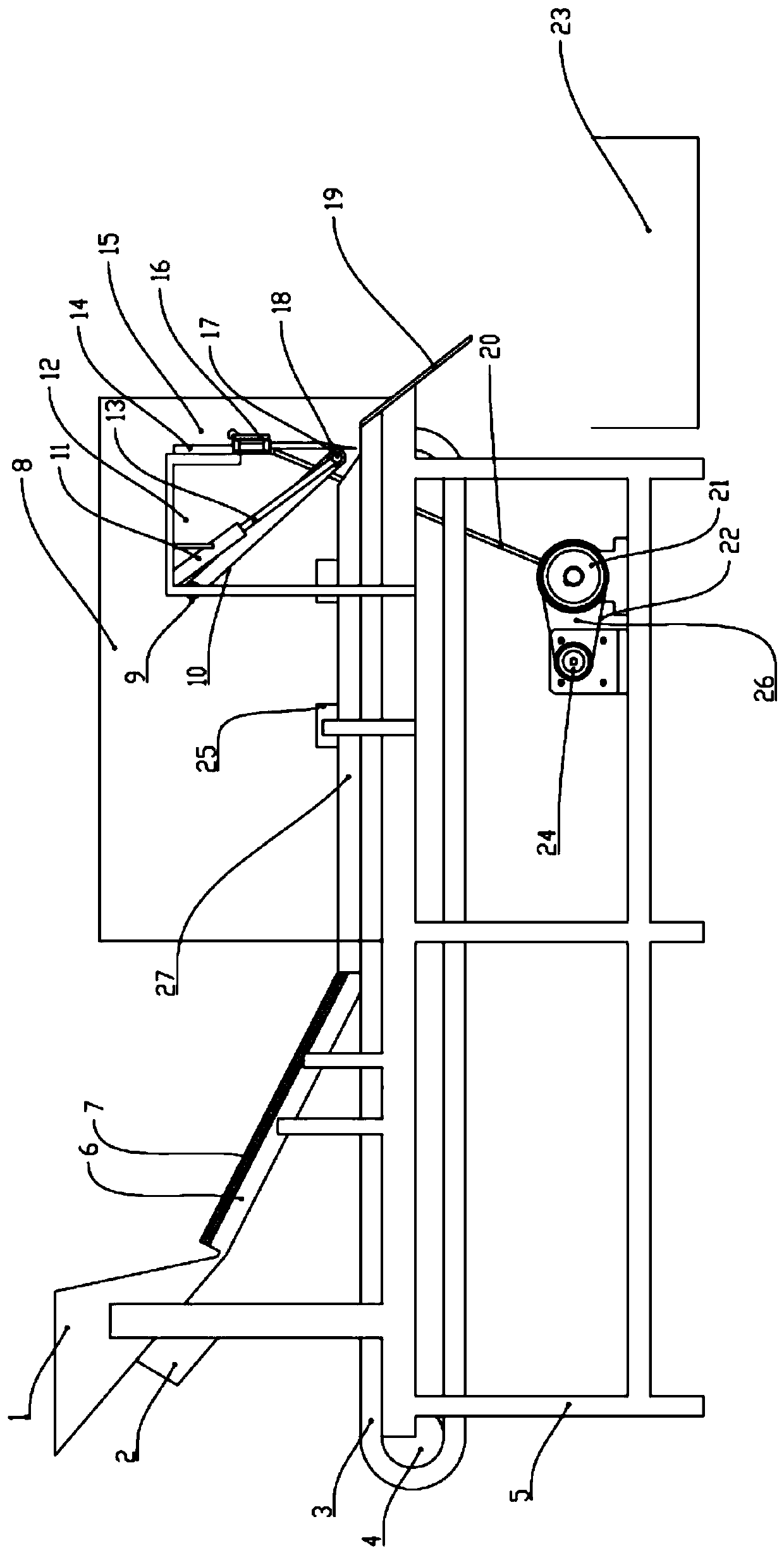

[0028] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

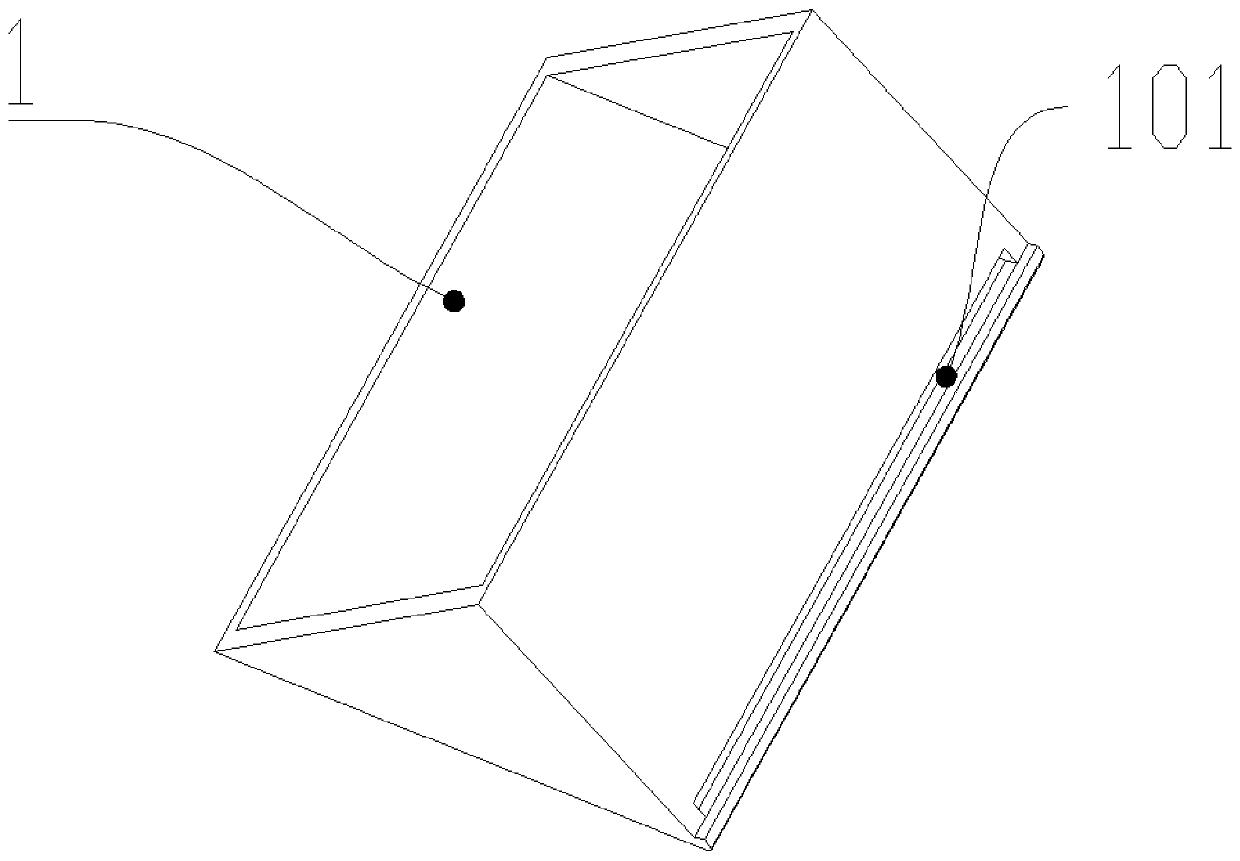

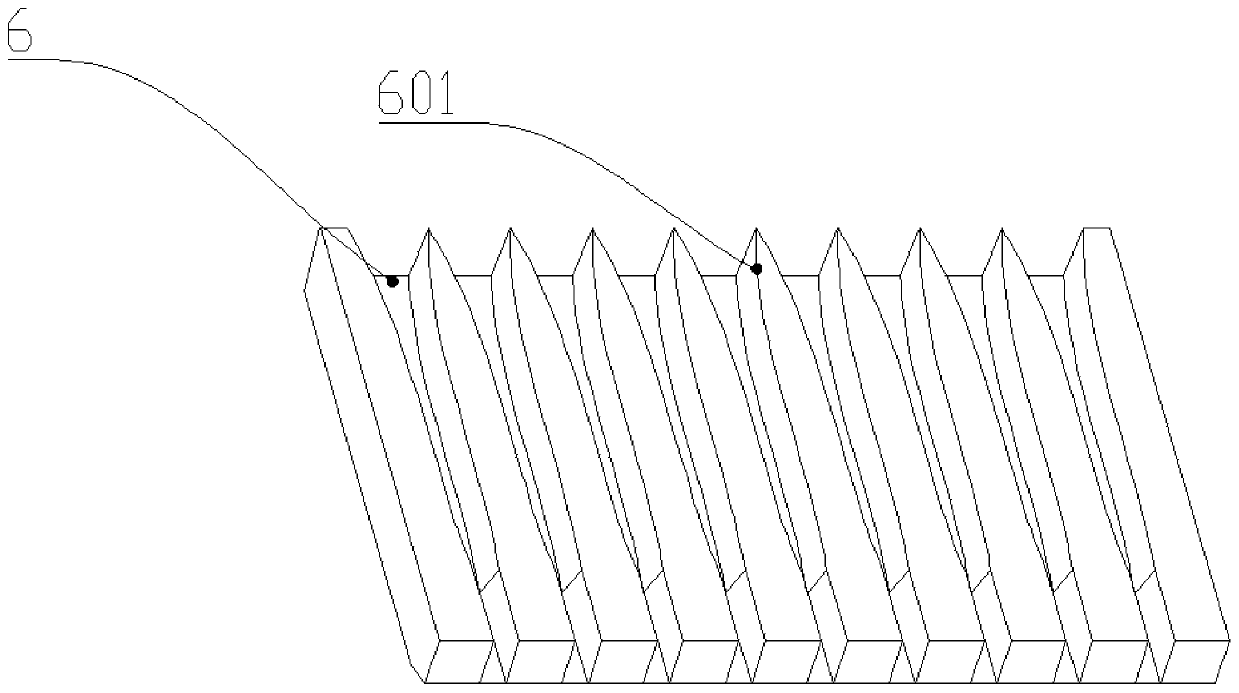

[0029] Such as Figure 1 to Figure 8 As shown, the present invention discloses a millet pepper automatic cutting machine, which includes a feeding hopper 1 and a frame 5, the feeding hopper 1 is fixed on the frame 5 obliquely, and the bottom of the feeding hopper 1 is connected with one end of the deflector 6 , the deflector 6 is fixed with a plurality of tapered deflector blocks 601, the other end of the deflector 6 is connected with the starting end of the limit module 27, and the limit module 27 includes a plurality of limit blocks 271 arranged in parallel and connected with the limit block. The fixed block 25 fixedly connected to the upper surface of the bit block 271, the limit module 27 is arranged in parallel with the conveyer belt 3, the conveyer belt 3 is arranged on the frame 5, and the vegetable press mechanism 12 is also arranged obliquely above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com