Feeding protection mechanism for horizontal thread rolling machine

A technology of protection mechanism and thread rolling machine, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of unsolved feeding protection, no error-proofing function, complicated device structure, etc., and achieve fast and effective Worker safety, guaranteed wire rolling quality, and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

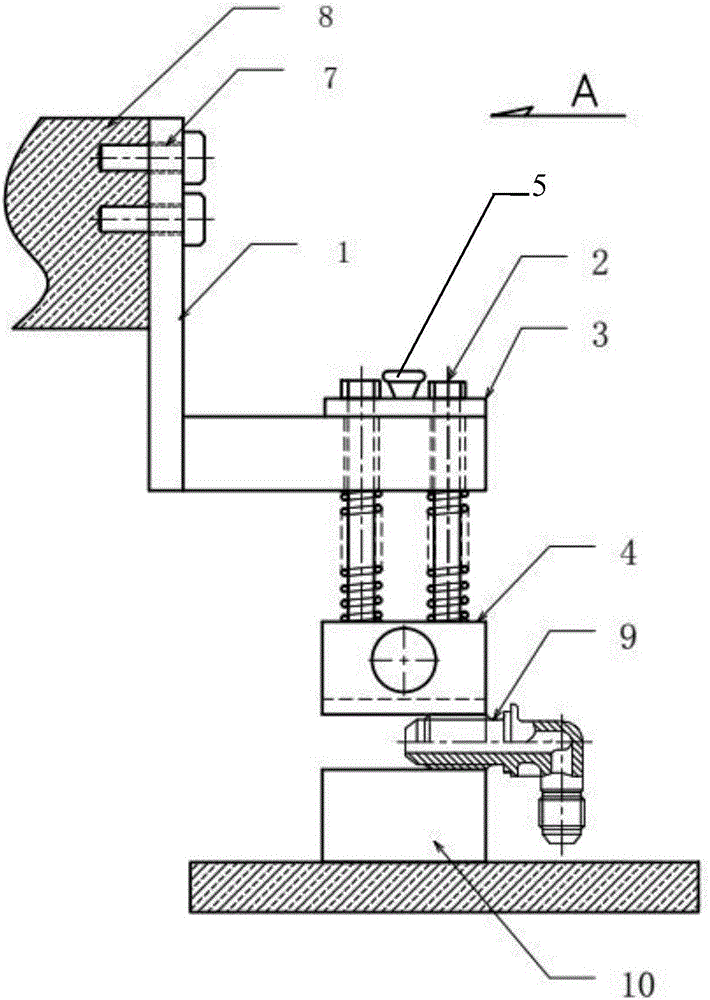

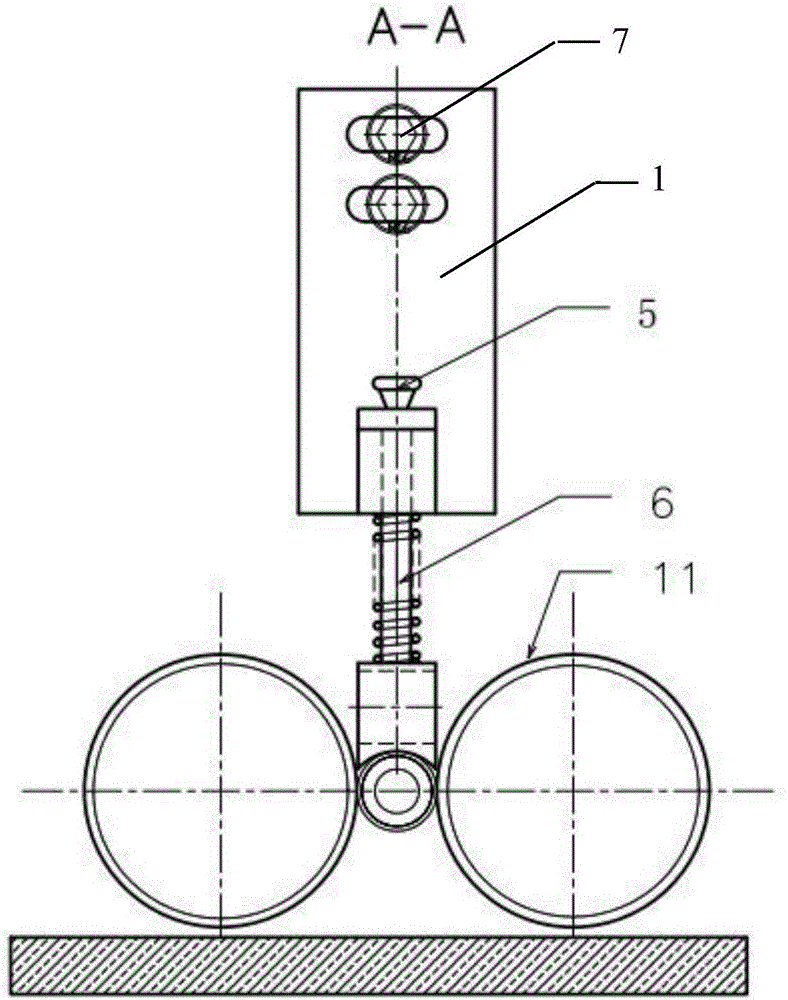

[0018] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-2 As shown, a feeding protection mechanism of a horizontal thread rolling machine includes a bracket 1, a guide column 2, a moving plate 3, a star handle 5, a spring 6 and a pressing block 4; the shape of the bracket 1 is "L" , its vertical side is fixed with the thread rolling machine body 8, and the horizontal side has a cylindrical through hole in the vertical direction, the upper end of the guide post 2 passes through the cylindrical through hole of the support 1 and is connected with the moving plate 3, and the lower end is connected with the pressing block 4 Connection; the outer surface of the guide post 2 is covered with a spring 6; the star handle 5 is installed on the moving plate 3; the pressure block 4 has a round hole in the middle.

[0019] Further, the upper end of the guide post 2 has a round cap with a diameter larger than the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com