Mechanical intelligent needle thrusting device

A pin insertion device and mechanical technology, applied in the field of mechanical intelligent pin insertion device, can solve the problems of poor stability of finished products, labor-intensive, manual pin insertion, etc., and achieve stable performance, reduced labor intensity, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

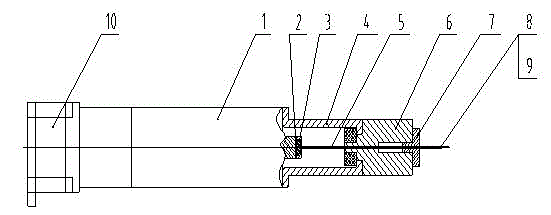

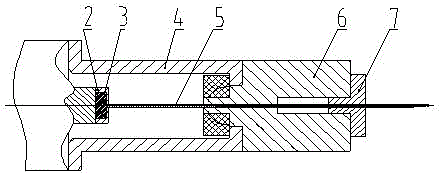

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

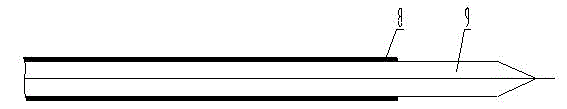

[0015] Such as figure 1 As shown, the present invention includes an electric cylinder 1, a thimble 5, a guide 6, a guide needle tube 8 and a suture needle 9; the input end of the electric cylinder 1 is connected to an external driving device, and the front end of the output shell is connected to the guide 6, The output end located in the shell is connected to the thimble 5 through the clamping nut 2; the clamping nut 2 is also provided with a magnetic ring 3, and the thimble 5 is magnetized and adsorbed by the magnetic ring 3 to absorb the suture needle 9; the guide 6, the guide needle tube 8, the suture The needles 9 are sequentially socketed from the outside to the inside, the front end of the guide needle tube 8 is fixedly connected with the guide 6 through a fastener, and the suture needle 9 can move back and forth along the guide needle tube 8; the tail end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com