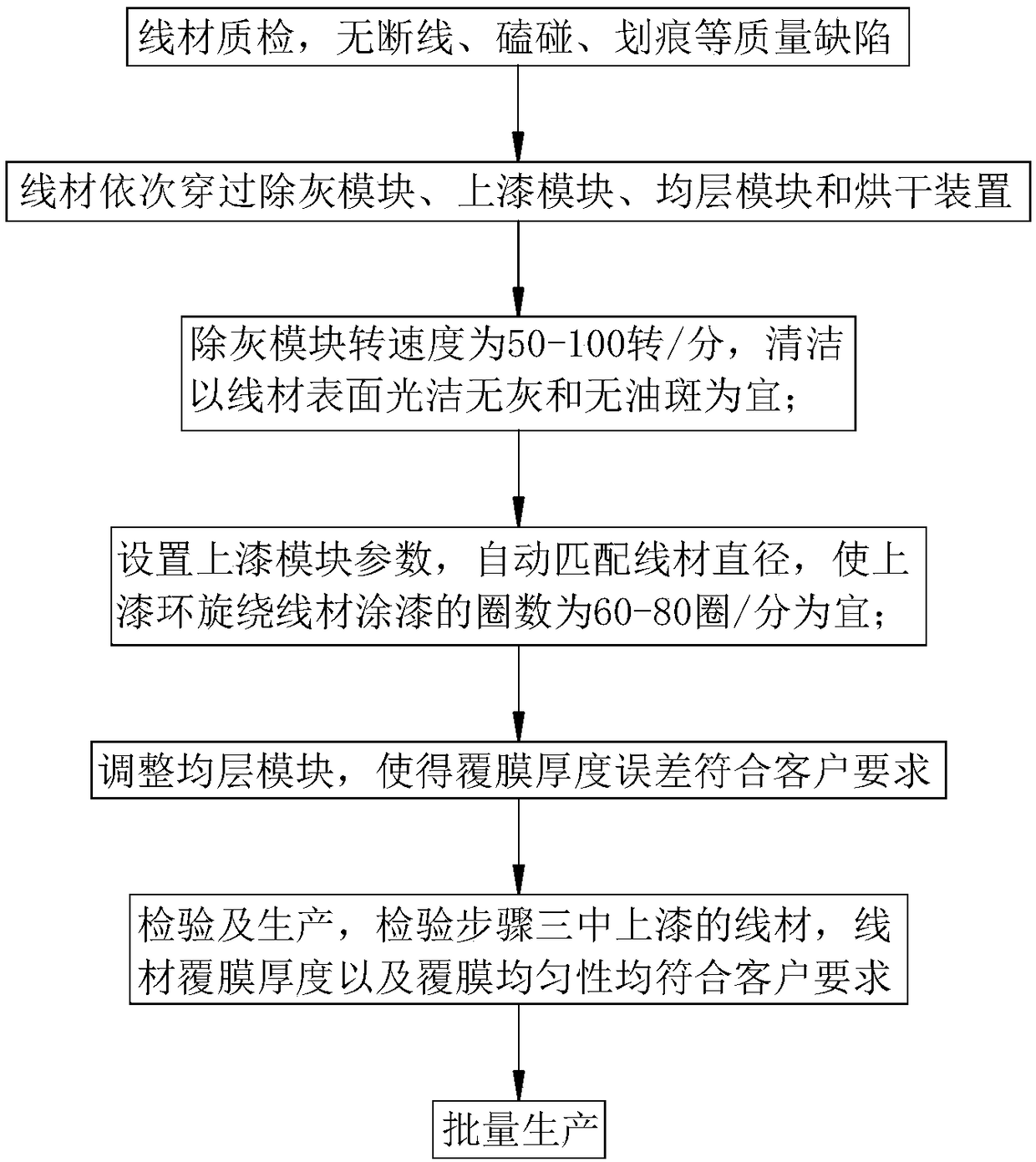

Automatic varnishing method for wire rods of enameled wires

An enameled wire and wire technology, which is applied to electrical components, circuits, and conductor/cable insulation, etc., can solve the problems of difficult to achieve uniform paint film thickness, restrict wire insulation performance, low production efficiency, etc., to avoid uneven painting, Improve paint quality and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

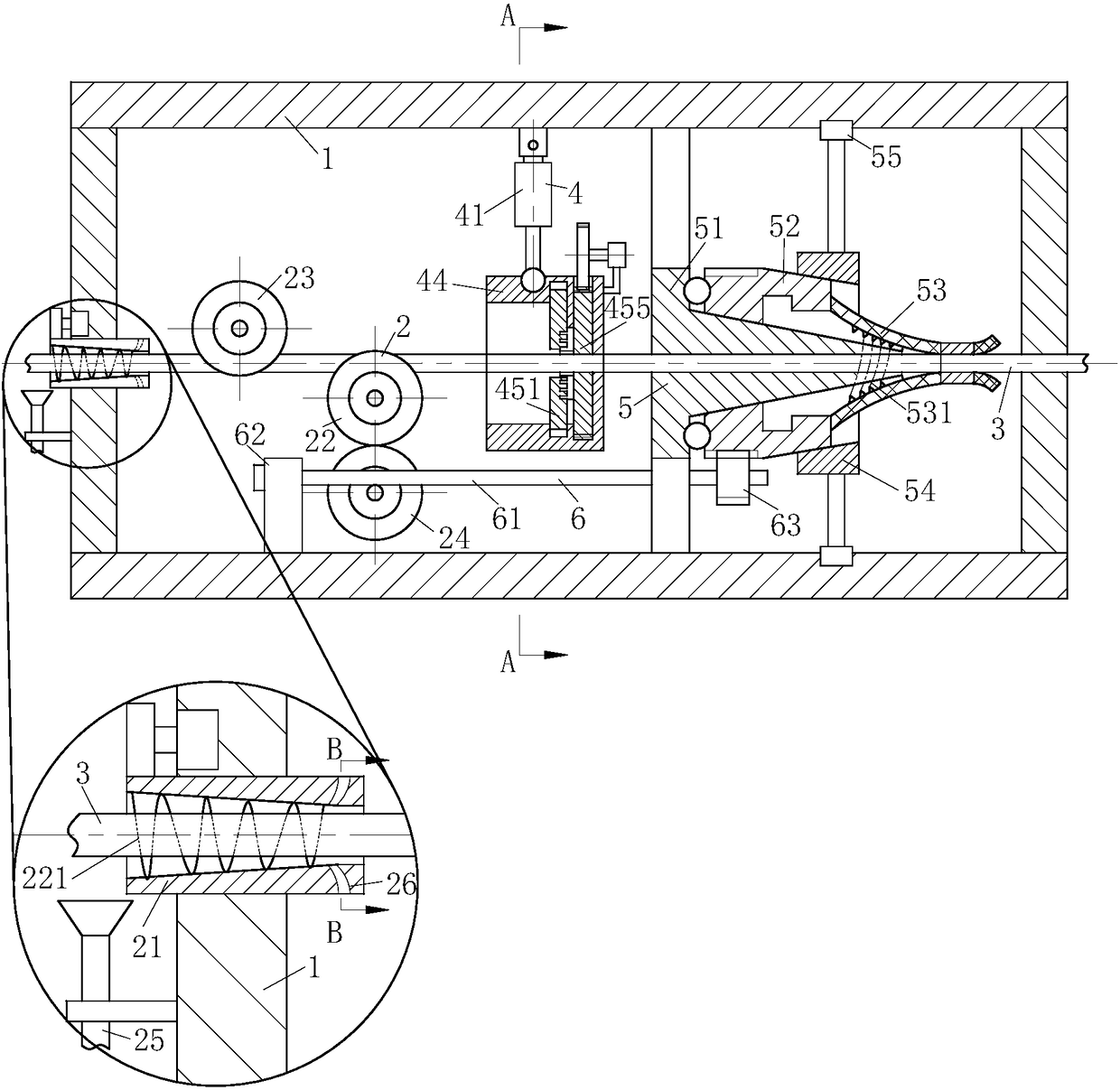

[0038] As an embodiment of the present invention, the inner side of the tensioning sheet 53 is provided with a helical protrusion 531 ; the helical protrusion 531 is disposed in contact with the fixing ring 51 ; the helical protrusion 531 is used to scrape the tensioning sheet 53 The removed insulating paint is discharged; when the rotating ring 52 rotates and scrapes the paint, the excess paint is removed to one side through the spiral bump 531, so as to avoid paint accumulation and stretch the tension sheet 53, resulting in uneven thickness of the paint layer, improving the wire rod. 3 cladding quality.

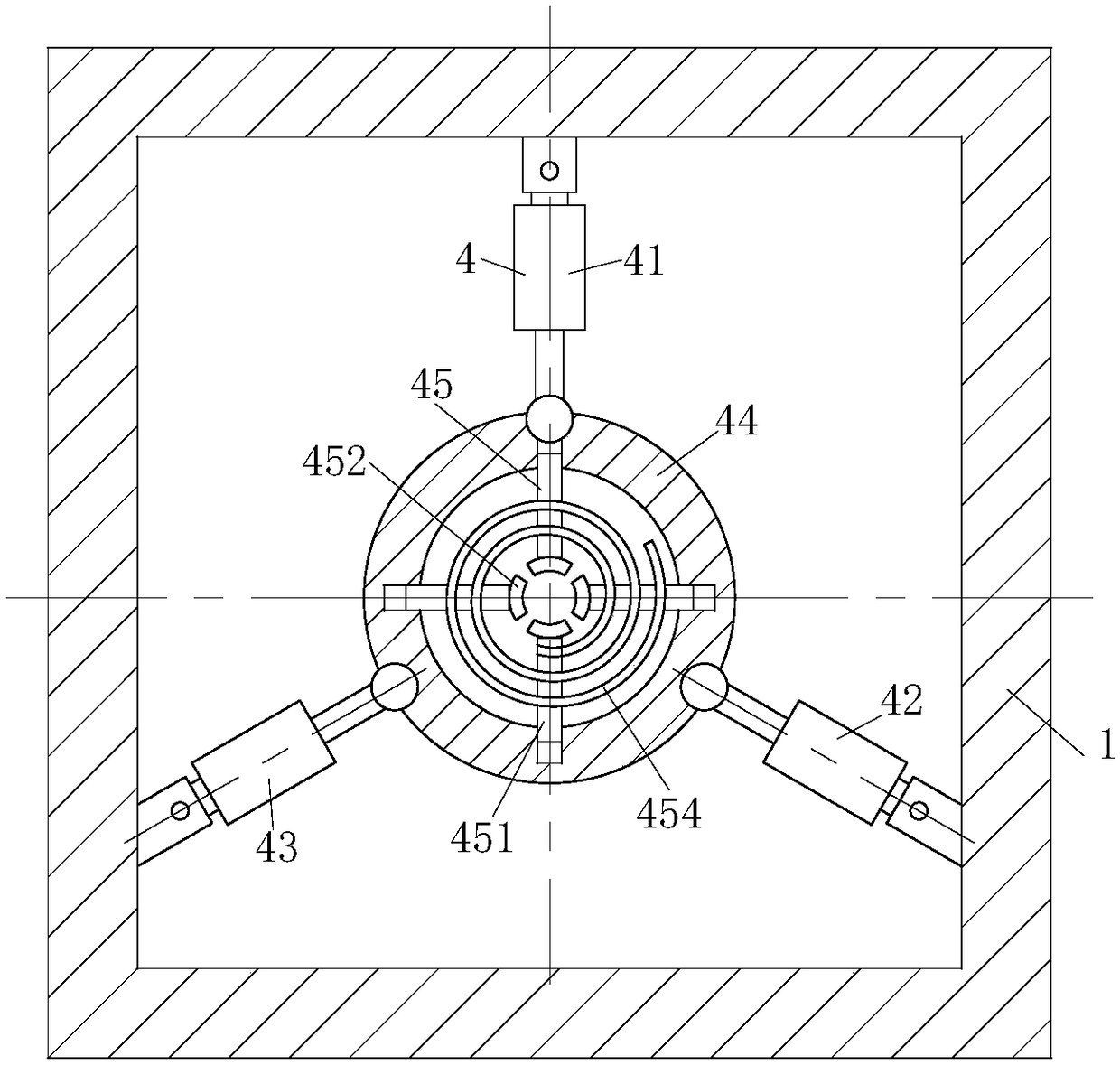

[0039] As an embodiment of the present invention, the painting module 4 includes a No. 1 lever 41, a No. 2 lever 42, a No. 3 lever 43, a painting ring 44, an adjustment unit 45 and a controller; the No. 1 lever The control rod 41, the second control rod 42 and the third control rod 43 are arranged in a triangle on the outside of the paint ring 44; The ring 44 is ball-joine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com