Mechanical thermal insulation type horizontal well steam injection string

A technology for steam injection string and horizontal well, which is used in isolation devices, sealing/packaging, wellbore/well components, etc., and can solve the problems of inability to heat insulation devices, to ensure that they are coaxial with each other, and difficult to obtain a sealing effect. , to simplify the heat insulation operation, reduce the cost of heat insulation, and improve the quality of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

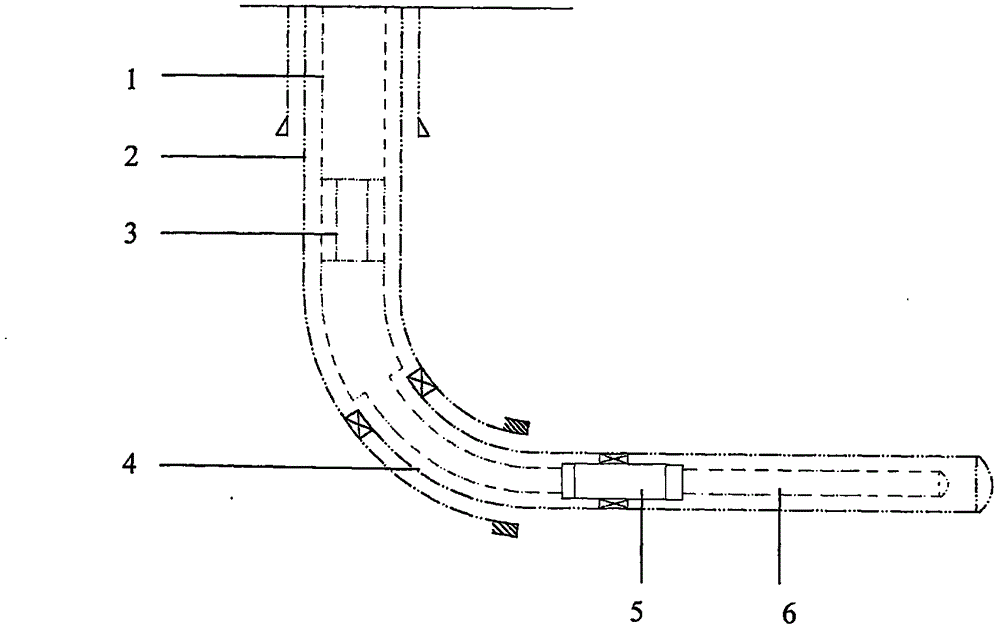

[0010] figure 1 One embodiment of the present invention is given. It can be seen from the figure that it includes the existing steam injection pipe string, which is composed of heat insulation pipe 1, telescopic pipe 3, oil pipe 6, etc. It is characterized in that the oil pipe sections of the steam injection pipe string are connected in series Heat-insulating steam injection device 5, which consists of a thermal packer and a radial positioning mechanism for a ball-blocking blocker arranged on its center pipe.

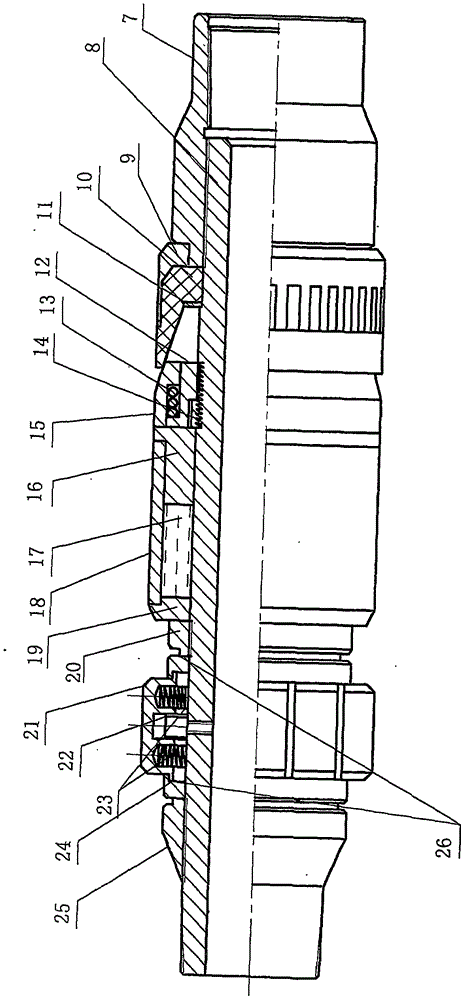

[0011] Depend on figure 2 It can be seen that the basic structure of the above-mentioned thermal packer is exactly the same as that of the prior art. It is composed of a central tube 8, etc., and a soft expansion ring 10 and its axial positioning parts are arranged outside the right side of the central tube. A thermodynamic hydraulic cylinder is arranged outside through a locking ring 20, and the thermodynamic hydraulic cylinder is composed of a cylinder body, a pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com