Method for laying vertical cables for extra-high building

A technology for vertical cables and high-rise buildings, applied in the construction field of vertical cable laying methods for super high-rise buildings, can solve the problems of too much effort and difficulty in ensuring construction safety, and achieve the effects of labor saving, extensive promotion of use value, and free control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

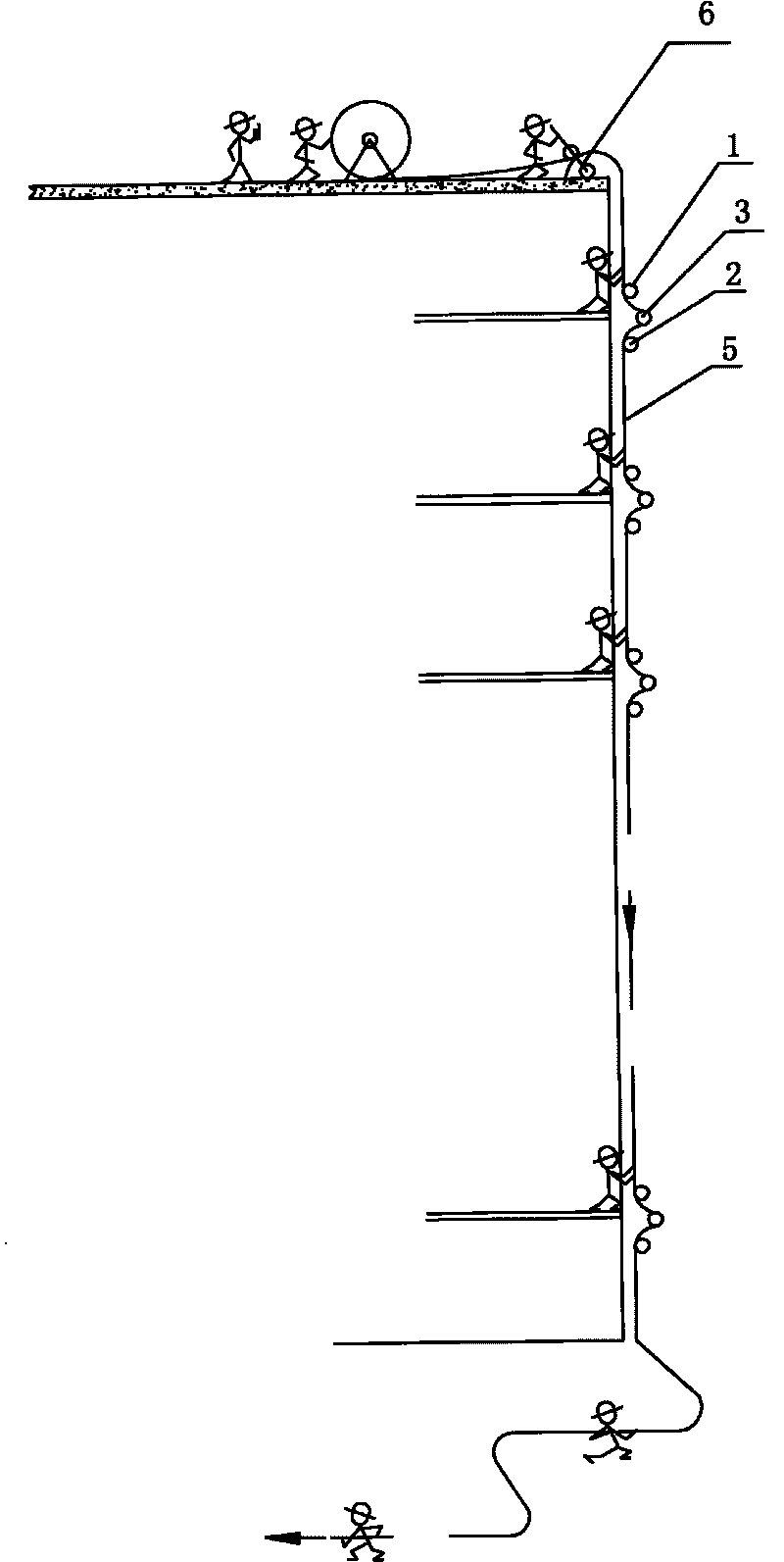

[0020] refer to figure 1 , the super high-rise building vertical cable laying method, comprises the following steps:

[0021] (1) Conduct necessary on-site measurements on the site, and install cable trays along the direction of the cables.

[0022] Among them, in the field measurement of this step, it includes compiling the cable table according to the drawing, mastering the cable specification, length, start and end positions, and all the cable bridges (brackets) along the direction of the cable 5 should be installed.

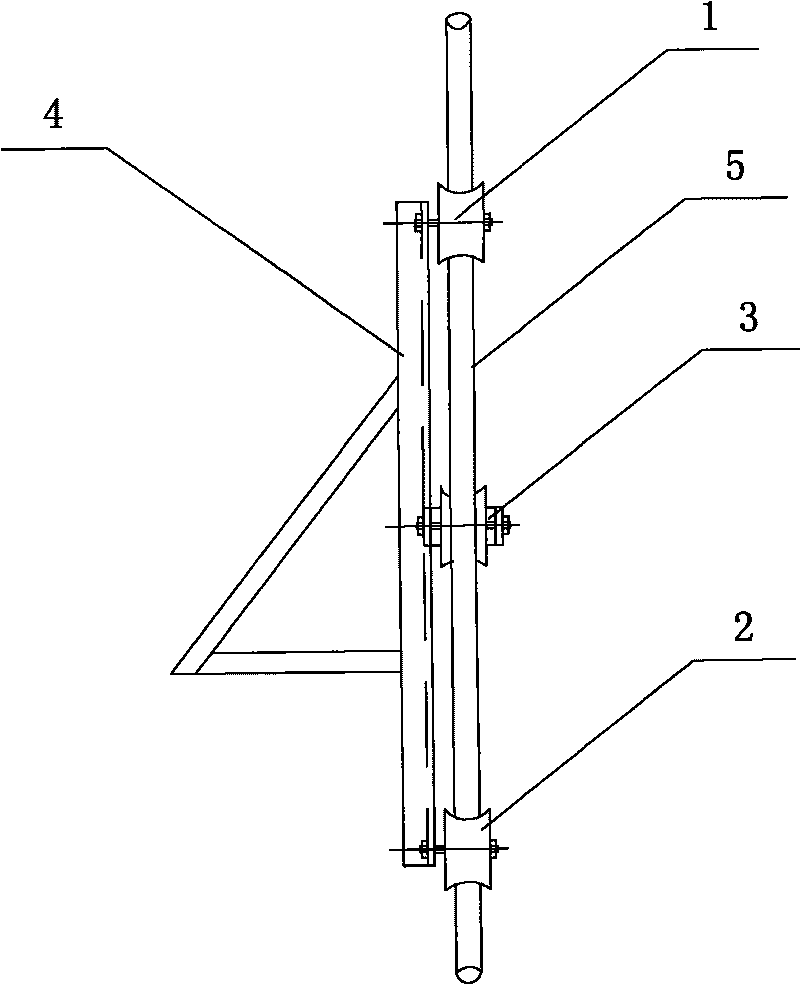

[0023] (2) Determine the number of damping retarders.

[0024] Wherein, the subsection load-bearing capacity of the damping retarder is calculated according to the total height of the vertical section and the gravity of the cable 5 with the largest section, so as to determine the number of devices.

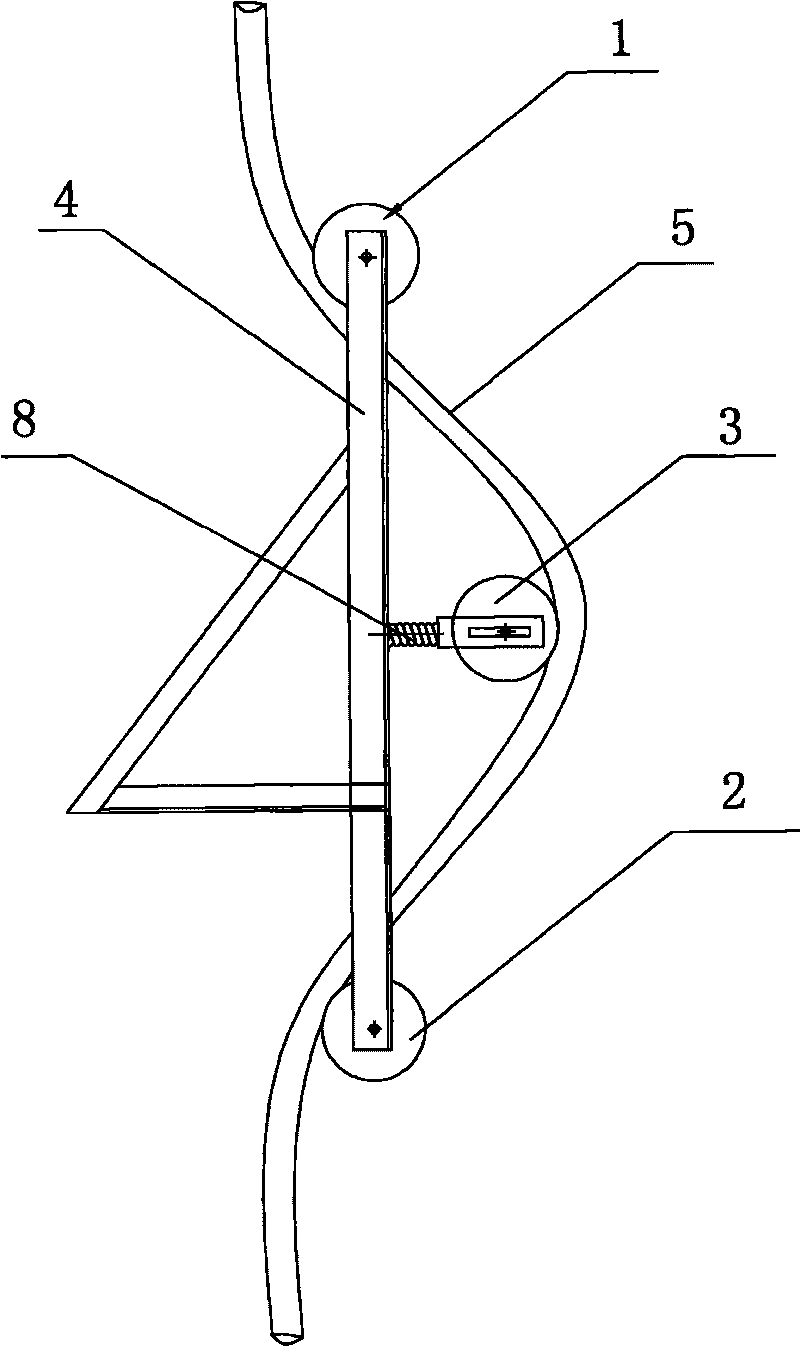

[0025] Among them, refer to figure 2 , 3 , 4, the damping buffer includes a bracket 4 and an upper guide wheel 1, an intermediate guide wheel 3 and a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com