Anti-corrosion chimney and anti-corrosion method for chimney

A chimney and flue gas technology, used in combustion methods, combustion product treatment, exhaust gas devices, etc., can solve the problems of long downtime, slow construction, and insufficient ash joints in the factory, and achieve excellent anti-corrosion effect and construction. Convenient and simple, the effect that meets the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

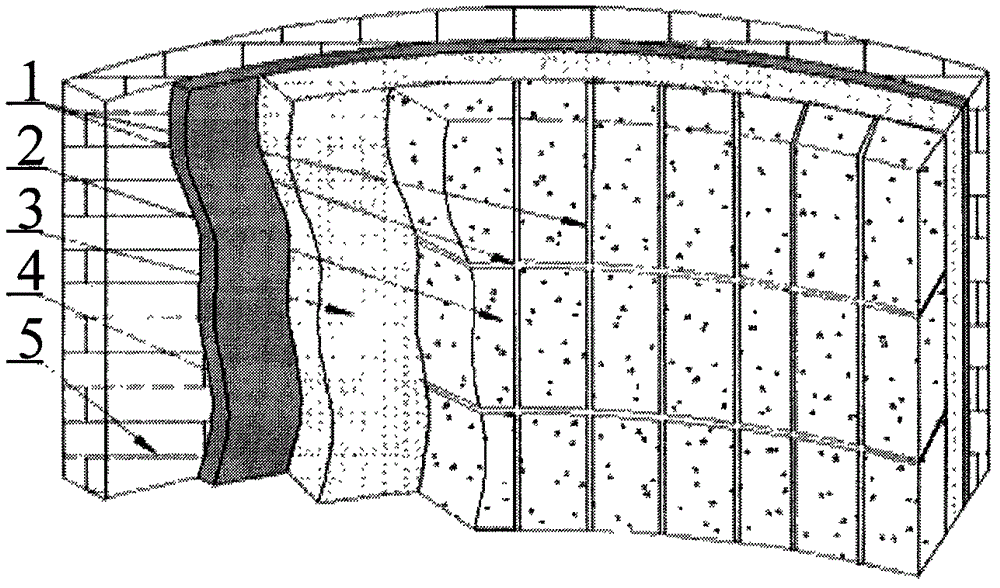

[0062] For existing chimneys such as figure 1 For the single-tube chimney of the structure shown, the anti-corrosion modification method is as follows:

[0063] (1) First, the inner surface of the single-tube chimney, that is, the surface of the ceramic tile layer, is pretreated. The pretreatment mainly includes removing dirt such as smoke and dust deposited on the surface, and exposing the body of the ceramic tile layer to facilitate subsequent treatment. Subsequently, the surface of the ceramic tile layer is processed, and the potholes produced by cracks, shedding, and corrosion of the ceramic tile are repaired to make the surface as smooth as possible. Said repair can choose concrete, viscous material of the same material as ceramic tiles or the material with physical properties similar to ceramic bricks, preferably the material with physical properties similar to ceramic bricks, so as to obtain the same thermal expansion and contraction properties as ceramic bricks.

[006...

Embodiment 2

[0075] The chimney shown in this embodiment is a newly built chimney, and its structure includes: a reinforced concrete cylinder body, an insulation layer, and a glass fiber reinforced plastic lining in sequence from outside to inside.

[0076] The new chimney is built according to the conventional process, and only the original anti-corrosion inner layer of the chimney in the prior art is replaced with a fiberglass lining. The material replacement does not change the construction process, so its construction is simple.

[0077] The newly-built chimney has no obvious corrosion marks and cracks after one year of operation in the coal-fired power plant. Compared with Comparative Example 1, the anti-corrosion effect of the chimney of the present invention is greatly improved after adding the glass fiber reinforced plastic lining, and its anti-corrosion effect is difficult to predict by those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com