Multiple head small diameter long screw drilling wall forming machine

A small-diameter, long-spiral technology, used in sheet pile walls, water conservancy projects, embankments, etc., can solve the problems of lack of anti-seepage effect, difficult construction quality control, insufficient pile strength, etc., to avoid uneven mixing of cement and soil. , to avoid the limited depth of the city wall, the effect of guaranteed pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

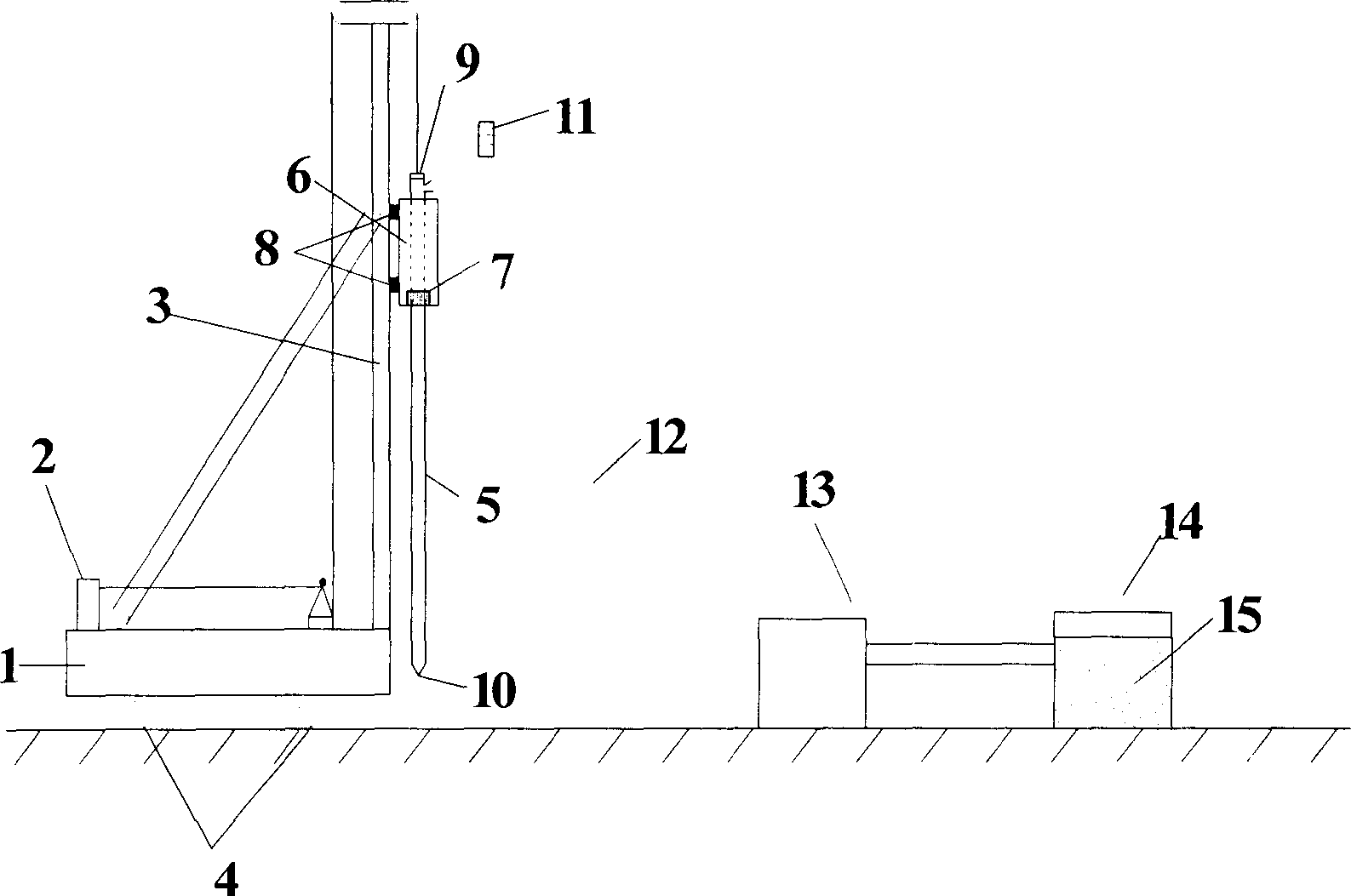

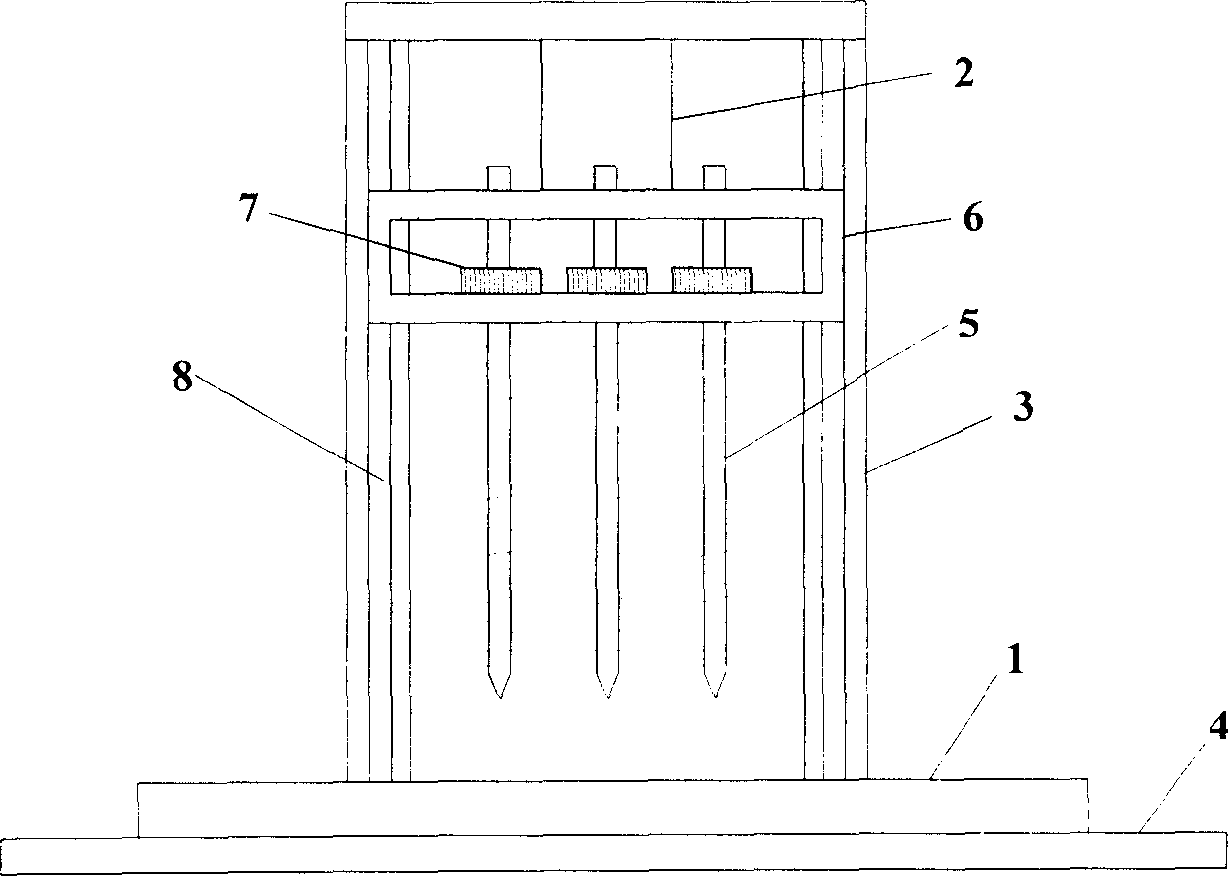

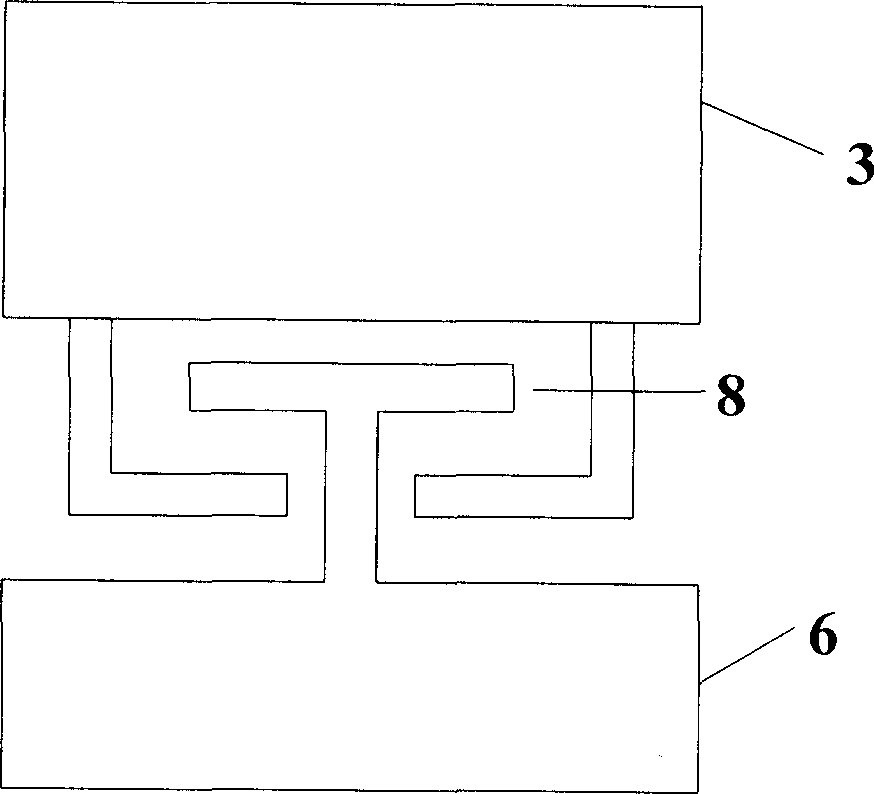

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the chassis 1 is connected with the hoist 2, the gantry pile frame 3 is installed on the chassis 1, and the guide rail 4 is arranged below the chassis 1; the hoist 2 is connected with at least two auger rods 5 through the gantry pile frame 3, that is, two or two More than root, in this example, it is connected with three auger rods 5 side by side, and the upper parts of the three auger rods 5 are connected with the rectangular positioning frame 6, and the rectangular positioning frame 6 is slidingly connected with the gantry pile frame 3 through the contact device 8, and the inside of the rectangular positioning frame 6 Rotary power device 7 is set; exhaust valve 9 is arranged at the top of each auger rod 5, and one-way valve 10 is provided at the lower end; the upper part of each auger rod 5 is connected with concrete delivery pipe 12 through elbow 11, and concrete delivery pipe 12 is connected with conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com