Drill-buried type prefabricated pipe pile for electric transmission line

A technology of power transmission lines and prefabricated pipe piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of difficulty in ensuring the quality of pile bodies, large noise pollution, and large manpower consumption, so as to reduce construction safety hazards, The effect of high safety and less manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

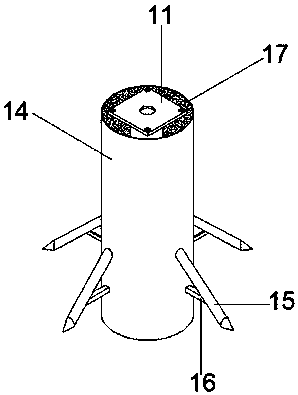

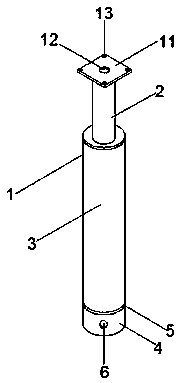

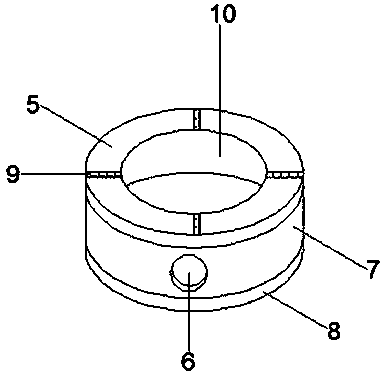

[0016] Such as figure 1 , figure 2 , image 3 As shown, a drilled and buried prefabricated pipe pile for a transmission line includes: a drilled and buried prefabricated pipe pile for a power transmission line, including an internal flow guide member 1, a flow guide steel pipe 2, a prefabricated micro pipe pile 3, a grouting head 4, Grouting head top plate 5, grouting hole 6, grouting steel pipe 7, grouting head bottom plate 8, reinforcing rib 9, opening 10, top plate 11, hole 12, bolt hole 13, external positioning nesting member 14, fork foot 15 , angle steel 16, mortar 17, the inner guide member 1 and the outer positioning nested member 14 are connected by the poured mortar 17, the inner guide member 1 includes guide steel pipe 2, prefabricated micro pipe pile 3, grouting head 4. The diversion steel pipe 2 is welded on the top of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com