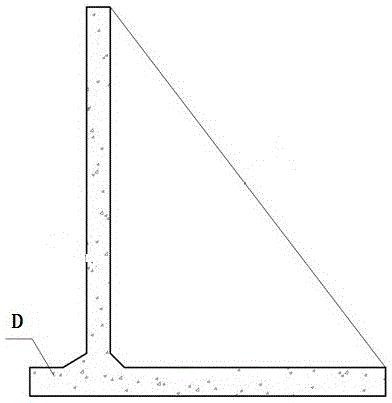

a retaining wall

A retaining wall and front wall technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the large stress difference between the front toe and heel of the floor, increase the engineering volume of the working face, increase the engineering volume of the retaining wall, etc. problems, to achieve the effect of improving anti-sliding, reducing engineering cost, and improving the stress condition of foundation and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

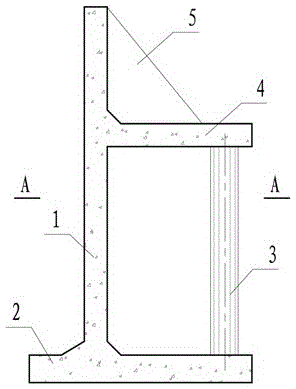

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

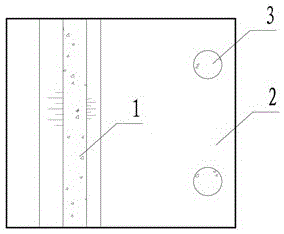

[0013] Such as figure 1 As shown, the retaining wall includes a front wall 1, a base plate 2, a column 3 and an unloading platform 4, the bottom edge of the front wall is fixedly connected with the base plate, the unloading platform 4 is connected horizontally with the upper side of the front wall, and the column is vertical It is arranged on the bottom plate and the upper end is supported and connected with the lower side of the unloading platform. The unloading platform can choose to use some ribs 5 to connect with the front wall according to the size of the upper load; the column 3 is a column or a square column (circle is better). The unloading platform 4 transmits the upper load to the bottom plate 2 through the column 3 to reduce the horizontal pressure of the upper load on the front wall 1 .

[0014] The front wall 1 is generally desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com