Clearance control method for adhesion of tube target

A tube target and bonding technology, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems such as difficult and poor consistency of the gap between the back tube and the tube target, and the expansion and cracking of the tube target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

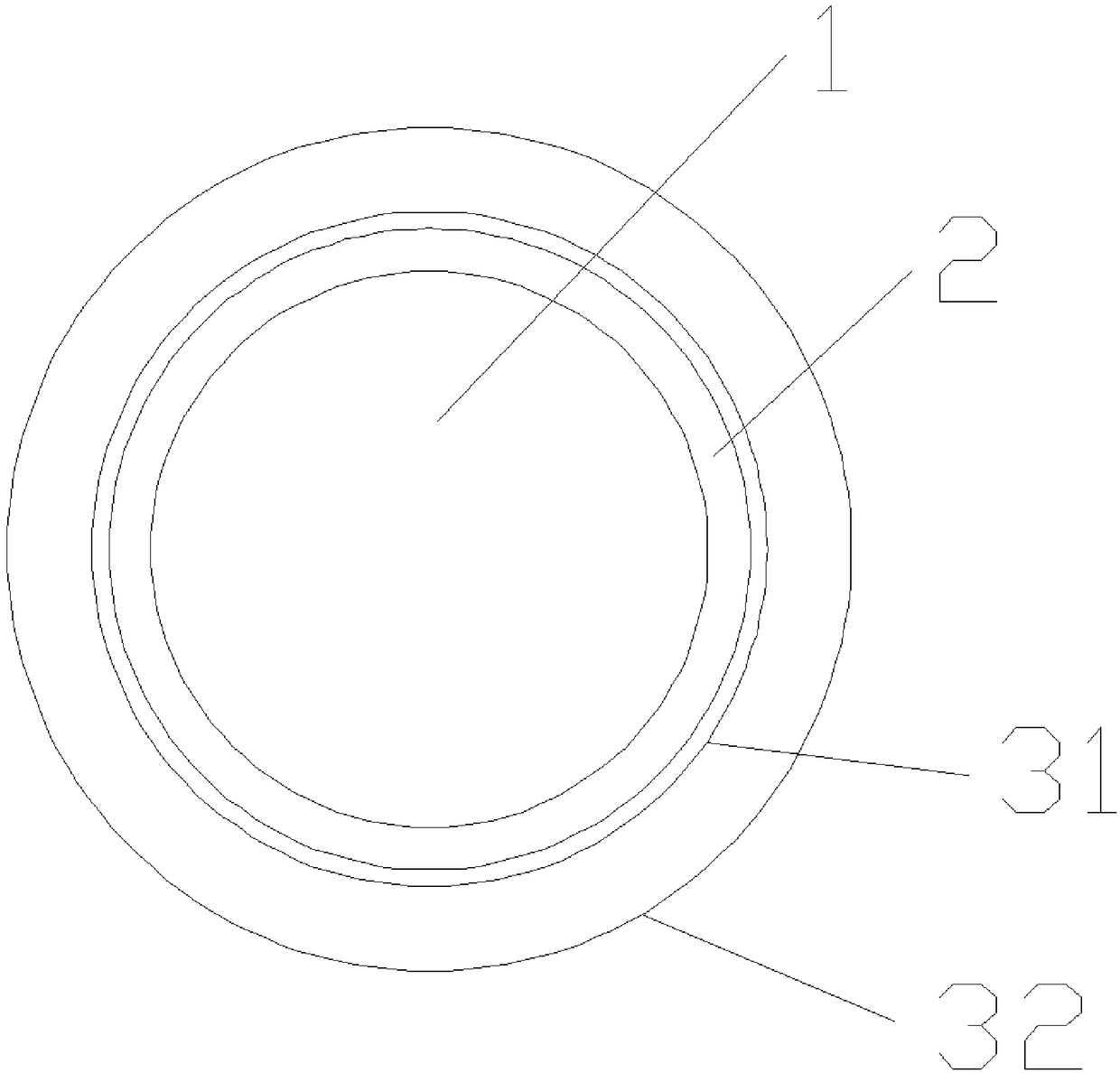

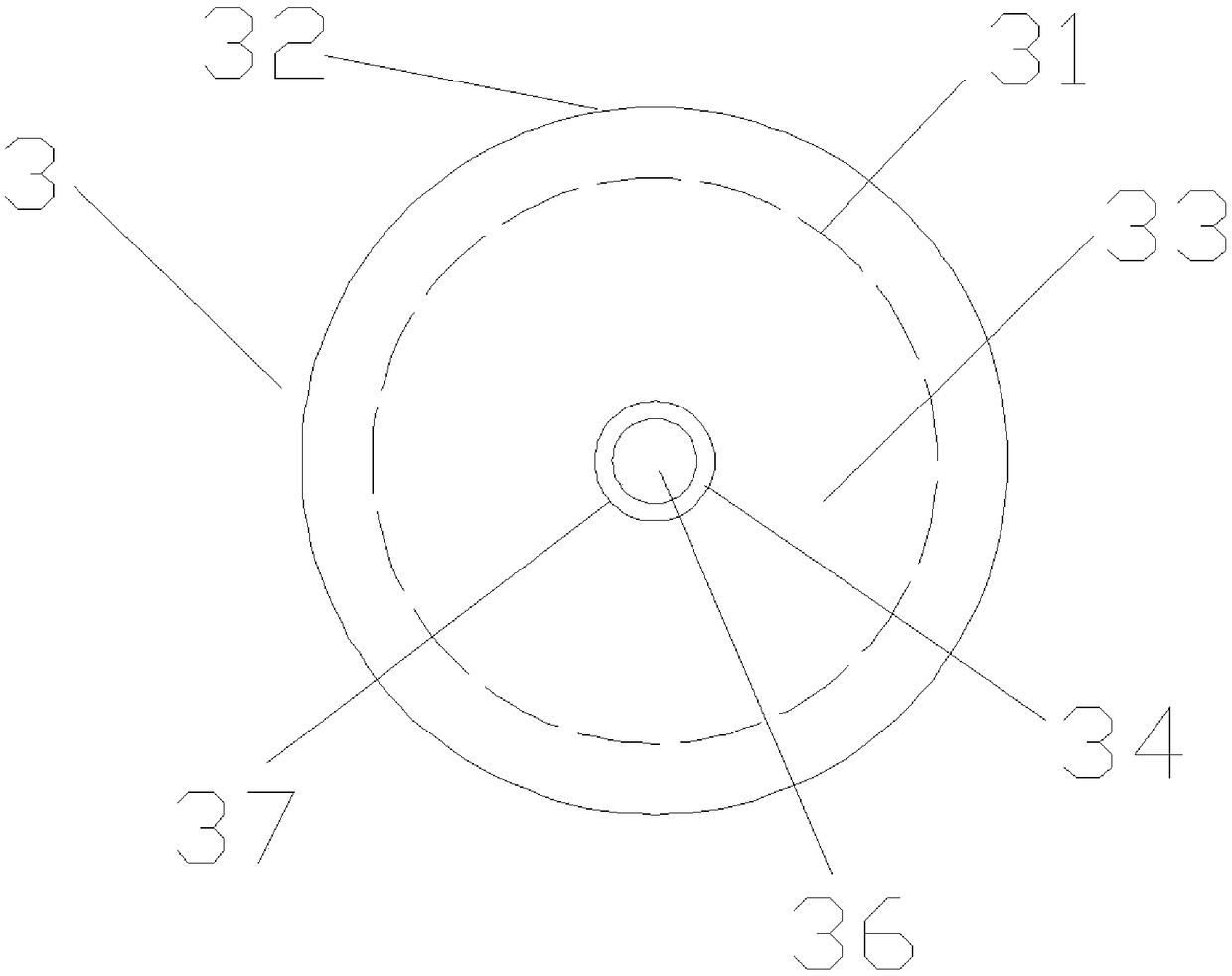

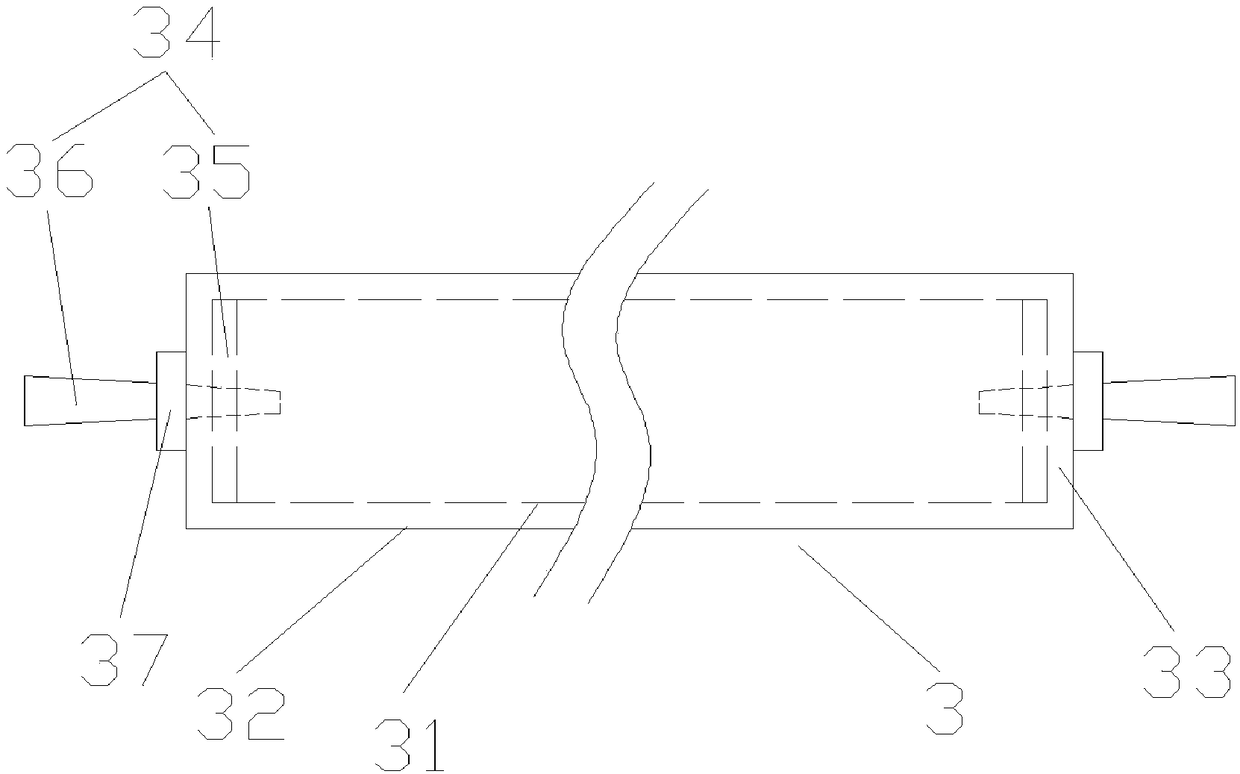

[0021] The present invention provides a method for controlling the gap between pipe targets, such as Figure 1-4 As shown, it includes a back tube 1 and a tube target 2 that are bonded to each other, the back tube 1 is made of titanium or stainless steel, the tube target 2 is made of metal or ceramics, and the outside of the tube target 2 is set There is an adjustment ring 3, which covers the tube target 2 and the back pipe 1, and the adjustment ring 3 includes an inner ring 31, an outer ring 32 and sealing flanges 33 arranged on both ends, and the sealing flange 33 at one end An adjustment part 34 is provided on the flange 33, and the adjustment part 34 is used to adjust the same-diameter distance from the inner ring 31 to the outer ring 32. The inner surface of the inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com