Method for controlling gaps of laser fusion weld plates of aluminum alloy vehicle bodies

A control method, laser melting technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as quality defects, and achieve the effect of low processing cost, simple process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

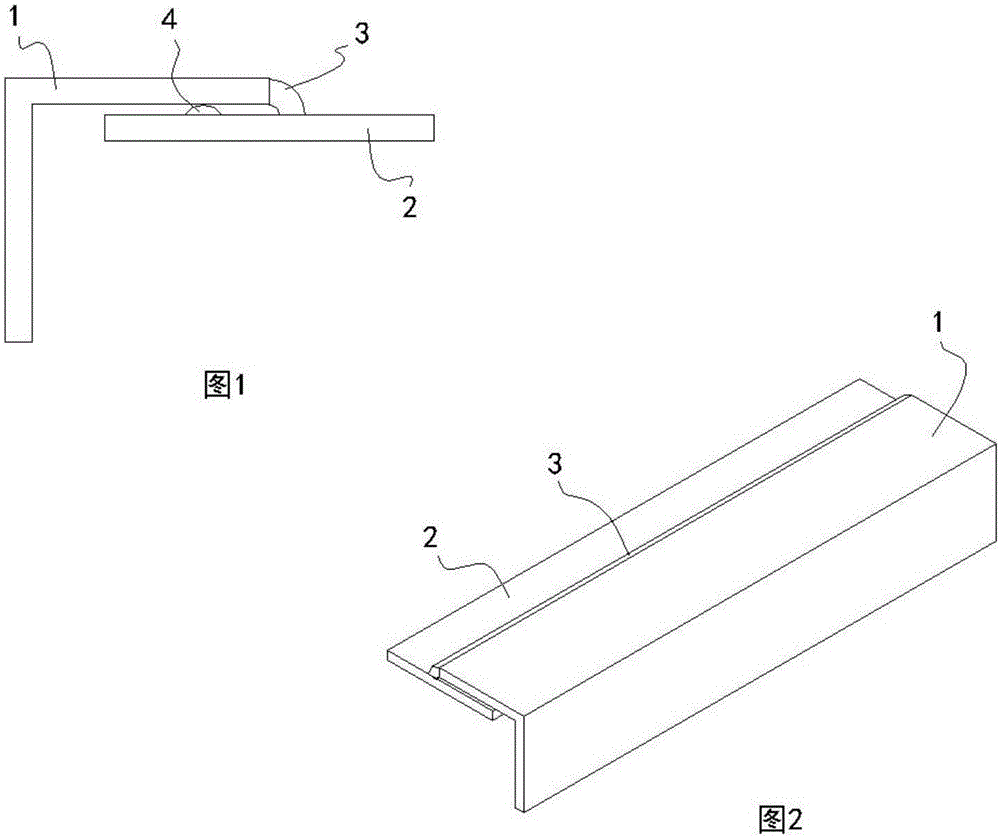

[0020] see figure 2 In this embodiment, the laser welding plate is formed with an overlapping area between the outer plate 1 and the inner plate 2, and the laser welding seam 3 is formed between the edge of the outer plate and the outer surface of the inner plate along the edge of the outer plate.

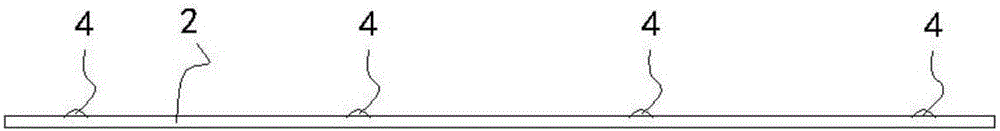

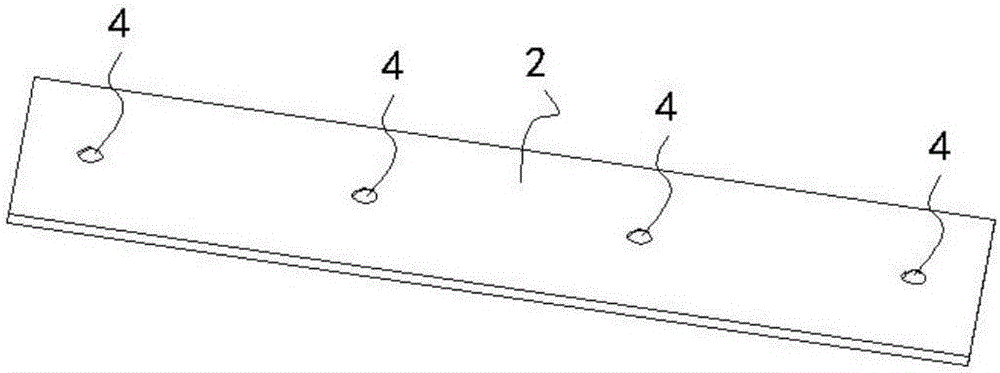

[0021] see figure 1 In this embodiment, the method for controlling the gap between the laser welding panels of the aluminum alloy vehicle body is: in the overlapping area, a protrusion 4 is formed on the outer surface of the inner panel 2, and the outer surface of the inner panel 2 refers to the position where the outer panel 1 is located. On the surface of the inner plate on the side, the protrusion 4 is used to maintain a gap in the overlapping area between the clamped outer plate 1 and the inner plate 2 during the laser welding process, and the height of the gap is the height of the protrusion 4 .

[0022] In specific implementation, such as Figure 4 As shown, the protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com