LED optical structure for car lamps

An optical structure, LED light source technology, applied in the direction of headlights, optical signals, light sources, etc., can solve the problem of difficult to achieve complete continuous lighting, and achieve the effect of continuous lighting effect, continuous lighting effect, and saving placement space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

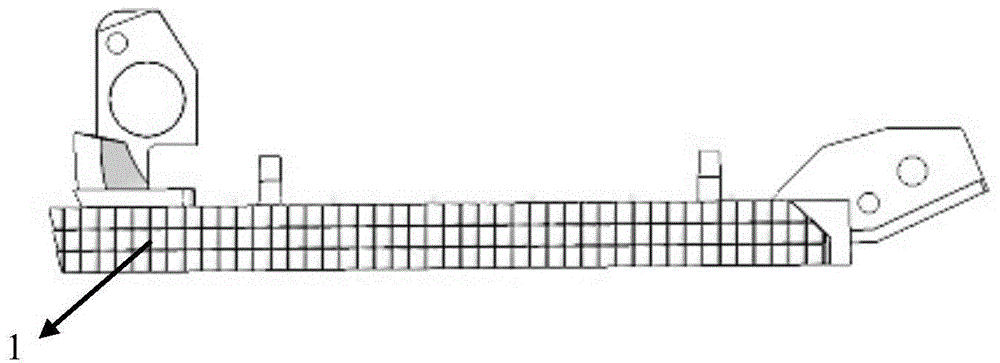

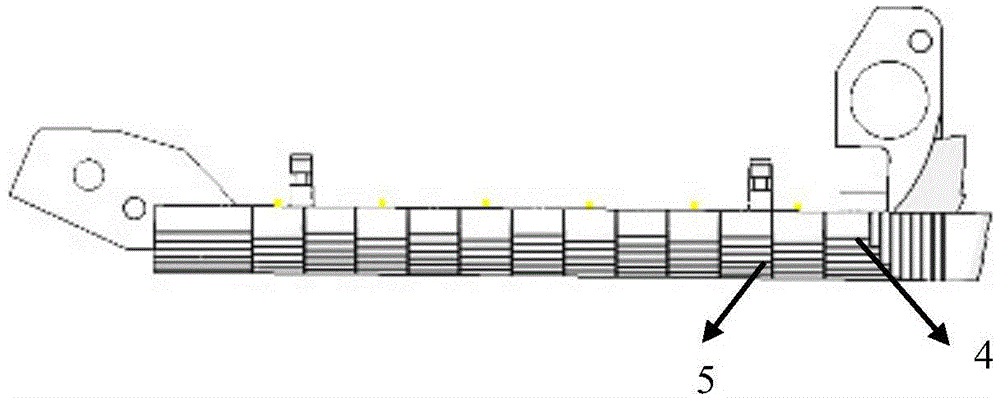

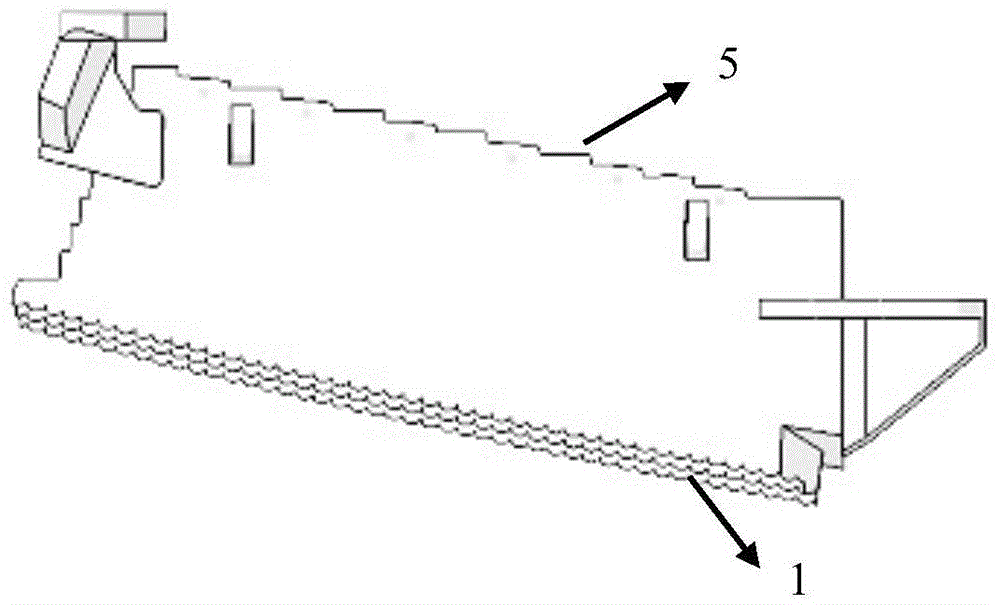

[0050] An LED optical structure for a car lamp, comprising a pattern structure surface arranged on the front of an LED lamp body for diffusing light, and an LED light source arranged behind the pattern structure surface of the LED lamp body. The inner light distribution mirror of the light guide is arranged directly behind the pattern structure surface of the LED lamp body, and the entire thick-walled light guide inner light distribution mirror is injection molded with PC or PMMA at one time.

[0051] An LED light source is arranged on one side of the light distribution mirror in the light guide, that is, the LED light source is arranged on the rear side of the pattern structure surface of the LED lamp body, and a free-form surface is formed on the side of the light distribution mirror in the light guide corresponding to the LED light source The reflective mirror surface of the LED light source, so that the light from the LED light source is fully emitted on the reflective mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com