Ultrasonic cavitation shot peening method and its application device

An ultrasonic and shot peening technology, which is applied in the field of ultrasonic cavitation shot peening method and its use device, can solve the problems of limited application and inability to apply to metal surfaces with complex shapes, and achieve the effects of high processing efficiency, overcoming attenuation phenomenon, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

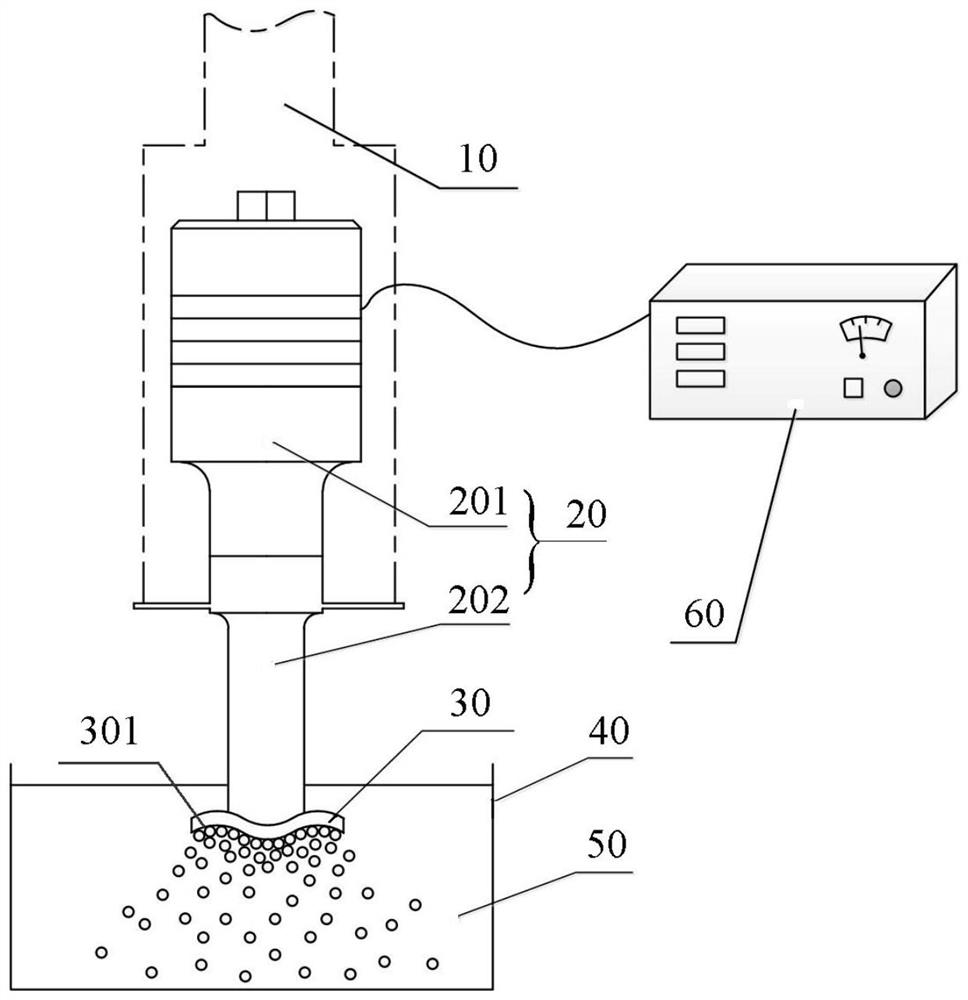

[0026] Such as figure 1 As shown, the ultrasonic cavitation shot peening method provided in this embodiment includes:

[0027] An ultrasonic assembly 20 is provided, the ultrasonic assembly 20 includes an ultrasonic transducer 201 and an ultrasonic horn 202 connected to the ultrasonic transducer;

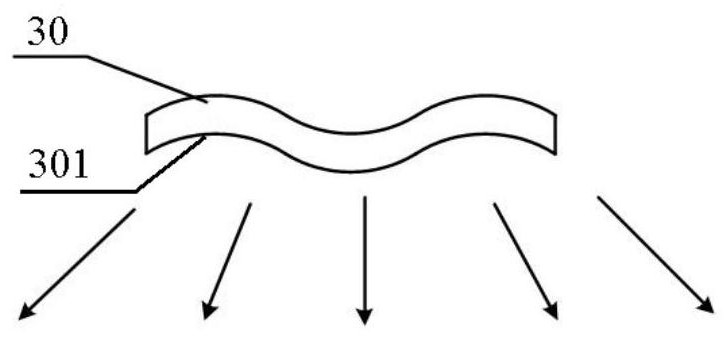

[0028] A first workpiece 30 is provided, the first workpiece 30 includes a first surface to be treated 301, the first workpiece 30 is detachably connected to the ultrasonic horn 202 and exposes the first surface to be treated 301;

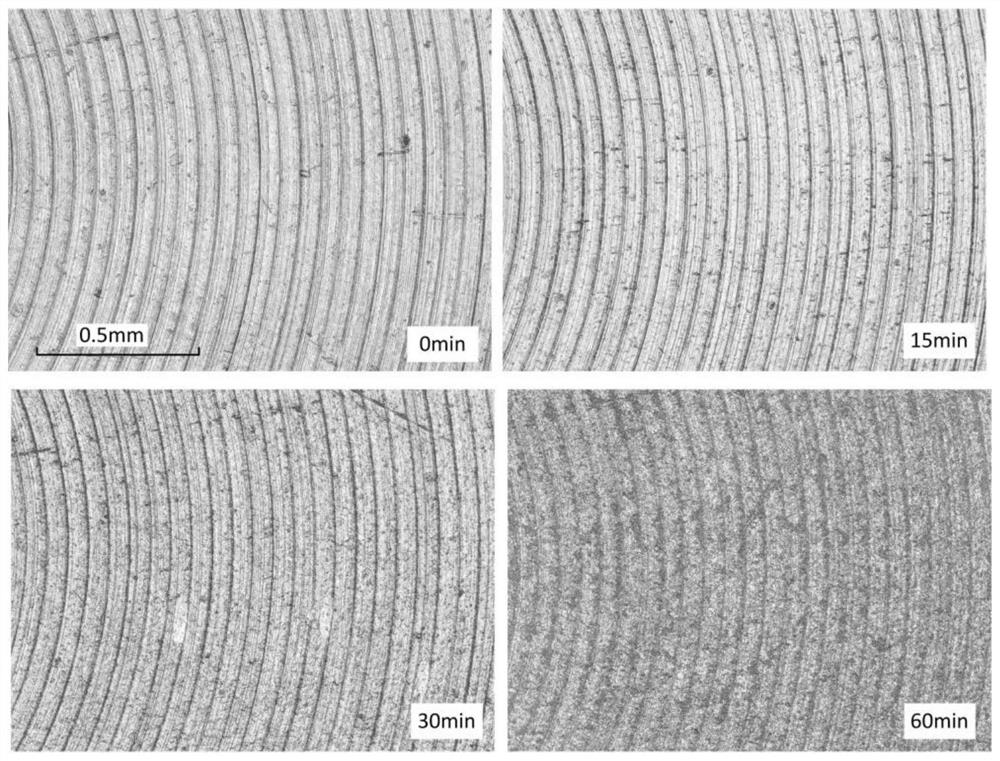

[0029] The ultrasonic component 20 is communicated with the ultrasonic power supply 60, and the first surface to be treated 301 is immersed in the liquid medium 50, so that the ultrasonic waves generated by the ultrasonic component 20 are transmitted through the first surface to be treated 301 into the liquid medium 50, the cavitation bubbles in the liquid medium 50 are collapsed to produce micro jets and shock waves to act on the first surface to be tr...

Embodiment 2

[0045] Such as Figure 4 As shown, on the basis of Embodiment 1, this embodiment further includes providing an acoustic wave reflector 70, the acoustic wave reflector 70 includes an acoustic wave reflective surface 701, and the acoustic wave reflector 70 is placed in the liquid medium 50 .

[0046] Specifically, the sound wave reflecting surface 701 is set facing the first surface to be treated 301 . The first surface to be treated 301 radiates high-intensity ultrasonic waves, which are transmitted to the acoustic wave reflecting surface 701 through the liquid medium 50, and the ultrasonic waves are reflected to the first surface to be treated 301 through the acoustic wave reflecting surface 701, so that the first surface to be treated 301 The intensity of ultrasonic waves is further enhanced, thereby improving the ultrasonic cavitation effect of the first surface to be treated 301, enhancing the intensity of ultrasonic cavitation shot peening, and obtaining a surface with ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com