Silicon-carbon composite material as well as preparation method and application thereof

A technology of silicon-carbon composite material and negative electrode material, which is applied in the preparation/purification of carbon, nanotechnology for materials and surface science, silicon, etc., and can solve the problems of cumbersome process, consumption of electrolyte, discharge of toxic chemicals, etc. Achieve high electrochemical lithium storage capacity, volume expansion mitigation, and volume expansion inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

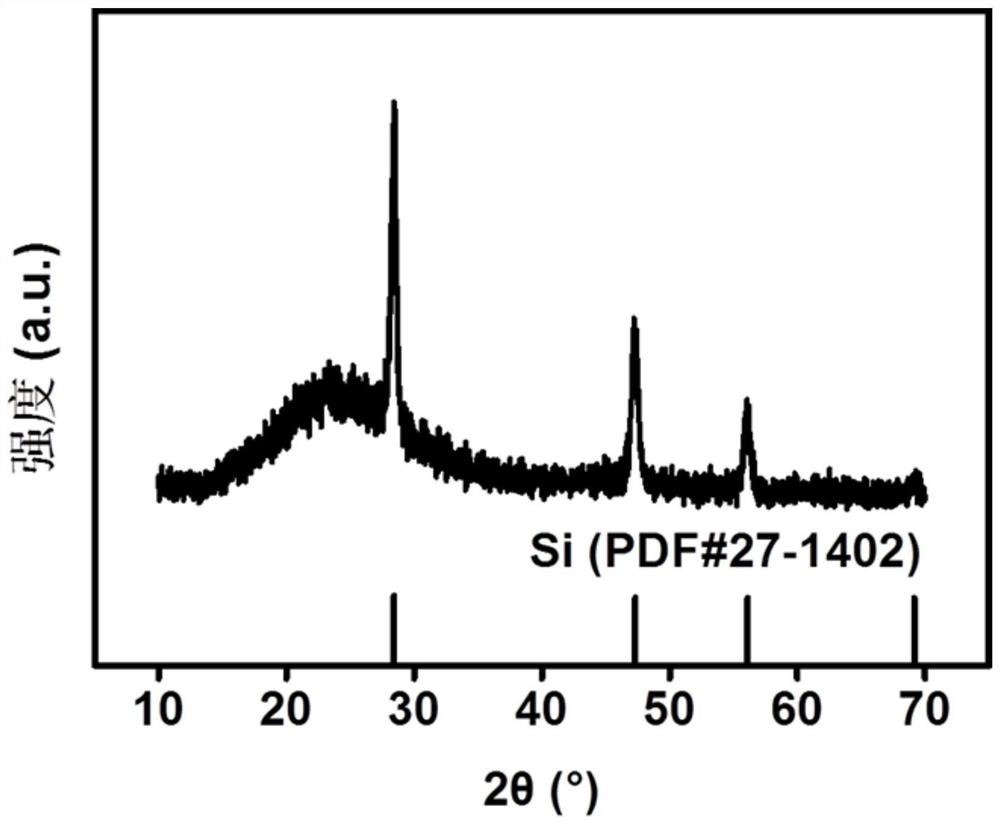

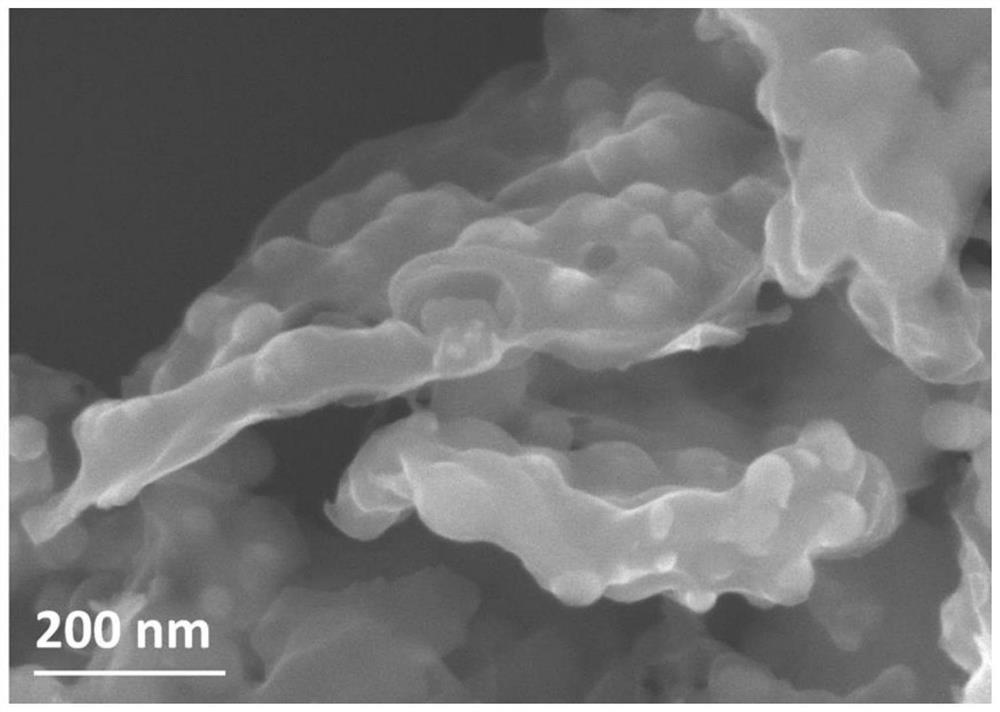

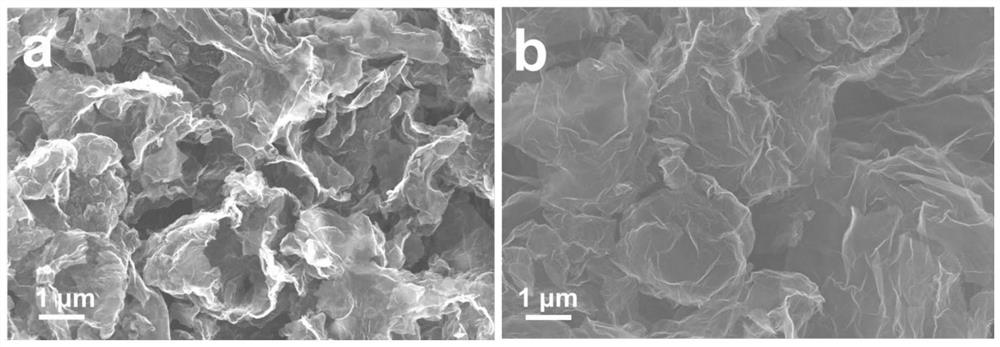

[0081] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0082] (1) Annealing the petroleum pitch at 400° C. for 4 hours in an inert atmosphere to obtain a mesophase pitch (that is, a graphene-like carbon nanosheet precursor), and then fully ultrasonically dissolving 225 mg of the mesophase pitch in 15 ml of toluene solution;

[0083] (2) The organic solution containing mesophase pitch prepared by 10g of LiCl-KCl (59%:41% (mol%)), 200mg of nano-silicon powder and step (1) is added successively in the planetary ball mill tank, ball milled for 2h, and the speed 600rpm;

[0084] (3) Vacuum drying the ball-milled slurry obtained in step (2) at 100° C., and grinding it into a uniform powder to obtain a mixed precursor powder;

[0085] (4) Anneal the mixed precursor powder obtained in step (3) in a tube furnace with argon flow at 5 °C min -1 The speed is increased to 360°C for 1h, and then at 10°C·min -1 The temperature was raised to 700°C and...

Embodiment 2

[0087] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0088] (1) Annealing the petroleum pitch at 400° C. for 4 hours in an inert atmosphere to obtain a mesophase pitch (that is, a graphene-like carbon nanosheet precursor), and then fully ultrasonically dissolving 225 mg of the mesophase pitch in 15 ml of toluene solution;

[0089] (2) Add 10g of CaCl 2 -NaCl (55%:45% (mol%)), 200mg of nano-silica powder and the organic solution containing mesophase pitch prepared in step (1) were successively added to the planetary ball mill tank, ball milled for 2h, and the rotating speed was 600rpm;

[0090] (3) Vacuum drying the ball-milled slurry obtained in step (2) at 100° C., and grinding it into a uniform powder to obtain a mixed precursor powder;

[0091] (4) The mixed precursor powder obtained in step (3) is annealed in a tube furnace with an argon gas flow at 8°C min -1 The rate is increased to 550 ° C for 2 hours, the temperature is lowere...

Embodiment 3

[0093] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0094] (1) Annealing the petroleum pitch at 400° C. for 4 hours in an inert atmosphere to obtain a mesophase pitch (that is, a graphene-like carbon nanosheet precursor), and then fully ultrasonically dissolving 225 mg of the mesophase pitch in 15 ml of toluene solution;

[0095](2) The organic solution containing mesophase pitch prepared by 10g of NaCl-KCl (50%:50% (mol%)), 200mg of nano-silicon powder and step (1) is added successively in the planetary ball mill tank, ball milled for 2h, rotating speed 600rpm;

[0096] (3) Vacuum drying the ball-milled slurry obtained in step (2) at 100° C., and grinding it into a uniform powder to obtain a mixed precursor powder;

[0097] (4) Anneal the mixed precursor powder obtained in step (3) in a tube furnace with argon flow at 8°C min -1 The rate is increased to 700°C for 1h, the temperature is lowered to room temperature, and 1mol·L -1 Dil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com