Long-distance curing water-based LED blue-light UV wood coating and preparation method thereof

A wood coating and long-distance technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as difficult curing of heterogeneous and large parts, difficulty in LED promotion, and inability to meet the needs of curing heterogeneous and large furniture. , to achieve the effect of not affecting performance, overcoming oxygen resistance and light attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

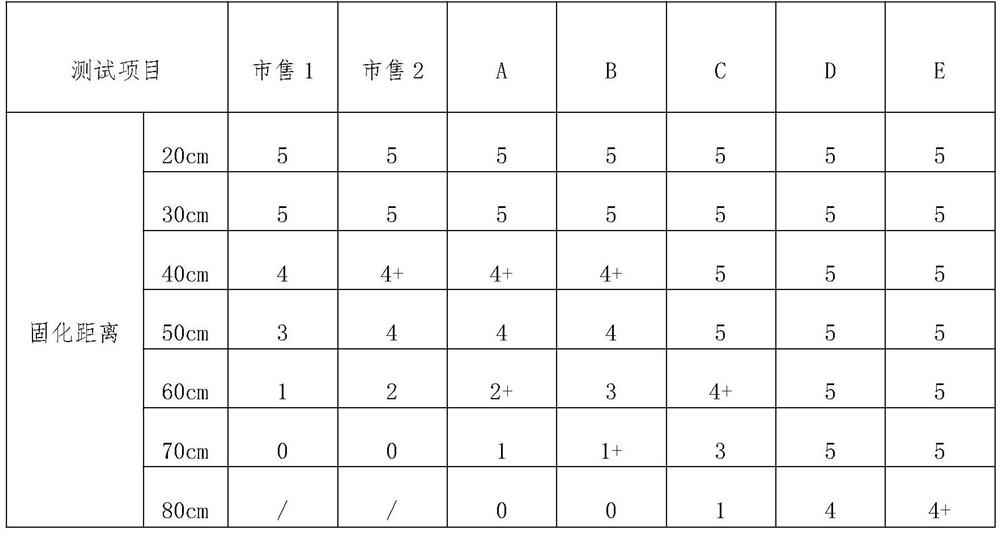

Examples

Embodiment 1

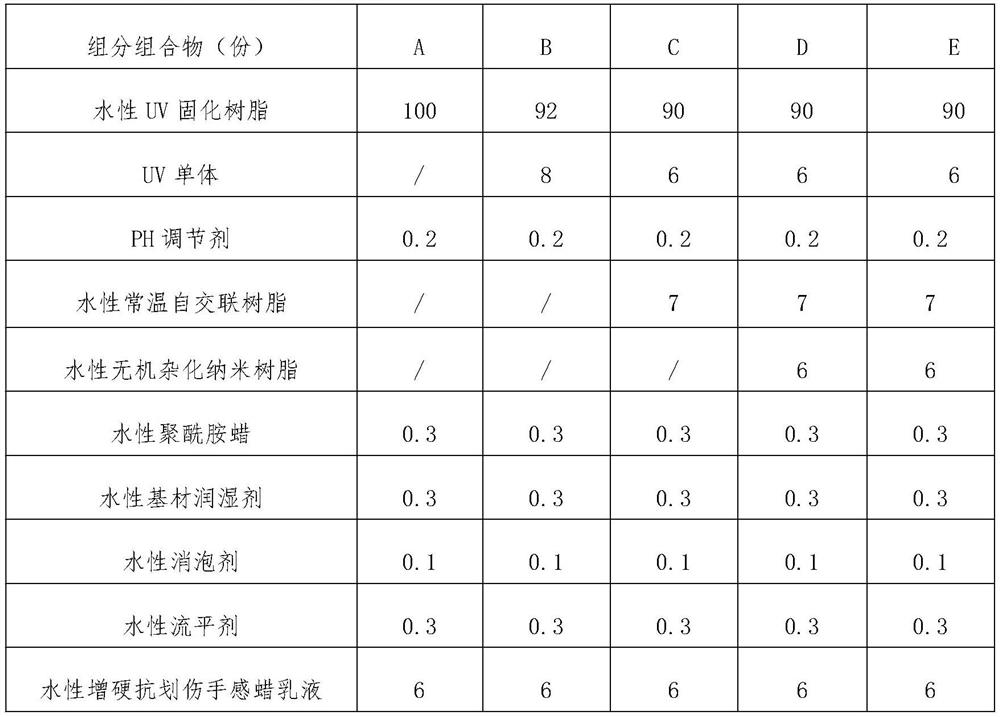

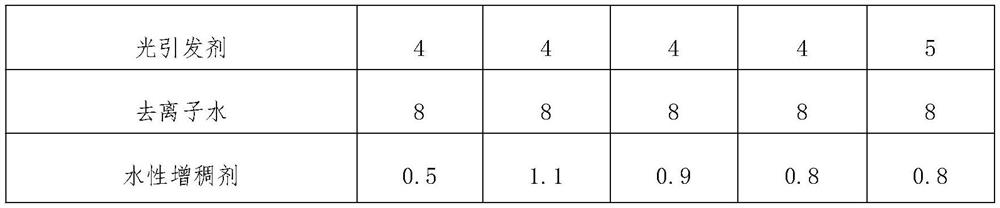

[0031] The preparation of embodiment 1 long-distance curing water-based LED blue light UV wood coating A

[0032] (1) At room temperature, put 100 parts of water-based UV curable resin into the material tank, put in 0.2 part of pH regulator while stirring, adjust the pH value to 7-8, then put in 0.3 part of water-based polyamide wax, high-speed 1000- Disperse at 1200 rpm for 10-20 minutes.

[0033] (2) At room temperature, add 0.3 parts of water-based substrate wetting agent, 0.1 part of water-based defoamer, 0.3 parts of water-based leveling agent, 6 parts of water-based hardening and anti-scratch hand wax, and 4 parts of photoinitiator while stirring. 8 parts of deionized water, dispersed at 600-800 rpm at medium speed for 10-15 minutes.

[0034] (3) At room temperature, add 0.3 part of water-based thickener while stirring, disperse at 1000-1200 rpm at high speed for 20-30 minutes, and adjust the paint viscosity to 65-70KU / 23°C.

Embodiment 2

[0035] The preparation of embodiment 2 long-distance curing water-based LED blue light UV wood coating B

[0036] (1) At room temperature, put 92 parts of water-based UV curable resin into the material tank, put in 8 parts of UV monomer and 0.2 part of pH adjuster while stirring, adjust the pH value to 7-8, and then put into water-based polyamide wax 0.3 part, disperse at high speed 1000-1200 rpm for 10-20 minutes.

[0037] (2) At room temperature, add 0.3 parts of water-based substrate wetting agent, 0.1 part of water-based defoamer, 0.3 parts of water-based leveling agent, 6 parts of water-based hardening and anti-scratch hand wax, and 4 parts of photoinitiator while stirring. 8 parts of deionized water, dispersed at 600-800 rpm at medium speed for 10-15 minutes.

[0038] (3) At room temperature, add 1.1 part of water-based thickener while stirring, disperse at high speed 1000-1200 rpm for 20-30 minutes, and adjust the paint viscosity to 65-70KU / 23°C.

Embodiment 3

[0039] The preparation of the water-based LED blue light UV wood coating C of embodiment 3 long-distance curing

[0040] (1) At room temperature, put 90 parts of water-based UV curable resin into the material tank, put in 6 parts of UV monomer while stirring, 7 parts of water-based normal temperature self-crosslinking resin, 0.2 part of pH regulator, adjust the pH value to 7- 8. Then add 0.3 part of water-based polyamide wax, and disperse at 1000-1200 rpm at high speed for 10-20 minutes.

[0041] (2) At room temperature, add 0.3 parts of water-based substrate wetting agent, 0.1 part of water-based defoamer, 0.3 parts of water-based leveling agent, 6 parts of water-based hardening and anti-scratch hand wax, and 4 parts of photoinitiator while stirring. 8 parts of deionized water, dispersed at 600-800 rpm at medium speed for 10-15 minutes.

[0042] (3) At room temperature, add 0.9 part of water-based thickener while stirring, disperse at 1000-1200 rpm at high speed for 20-30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com