Patents

Literature

73results about How to "No stuck issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for locating ultrahigh circular sand core

ActiveCN103418752AUnique methodHigh strengthFoundry mouldsFoundry coresMaterials scienceMolding sand

The invention relates to a method for locating a ring product, a sand core, in particular to a method for locating an ultrahigh circular sand core. The method comprises the following steps that two guide rods with the shapes the same as the shapes of mold cavity locating grooves are manufactured; a die sample with the shape the same as that of a mold cavity is placed in a sand box, the position is adjusted well, and molding sand flows into the sand box; after the molding sand is hardened, the die sample is lifted out to form the mold cavity and the mold cavity locating grooves; a sand core body with locating grooves is manufactured; in the mold cavity, the guide rods are placed along the mold cavity locating grooves; the sand core locating grooves are made to correspond to the guide rods, and core setting is started along the guide rods; after the core setting is completed, the guide rods are lifted out, and the cavities defined by the mold cavity locating grooves and the sand core locating grooves are filled with the molding sand. The method is unique, and through the method of adopting the guide locating rods, in the core setting process, the operation is convenient, and the problem of locating damage is avoided.

Owner:KOCEL STEEL

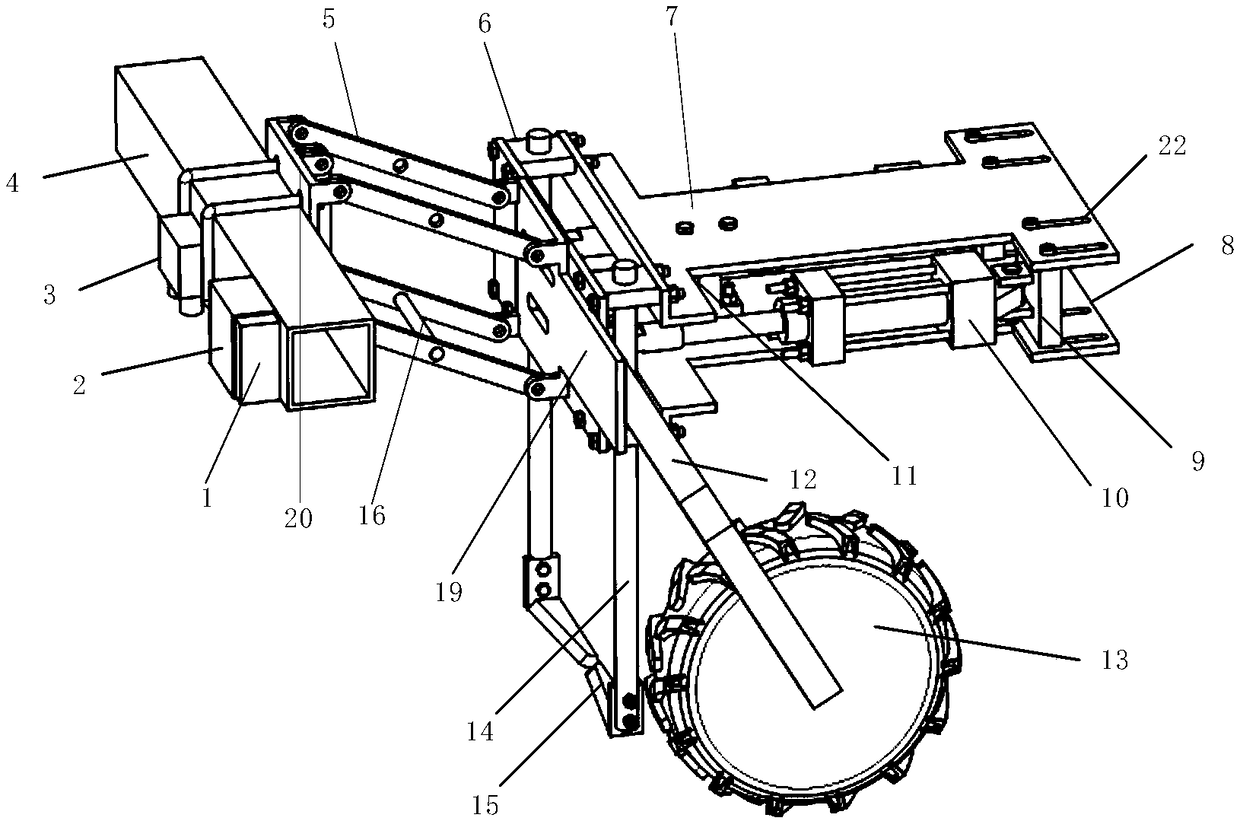

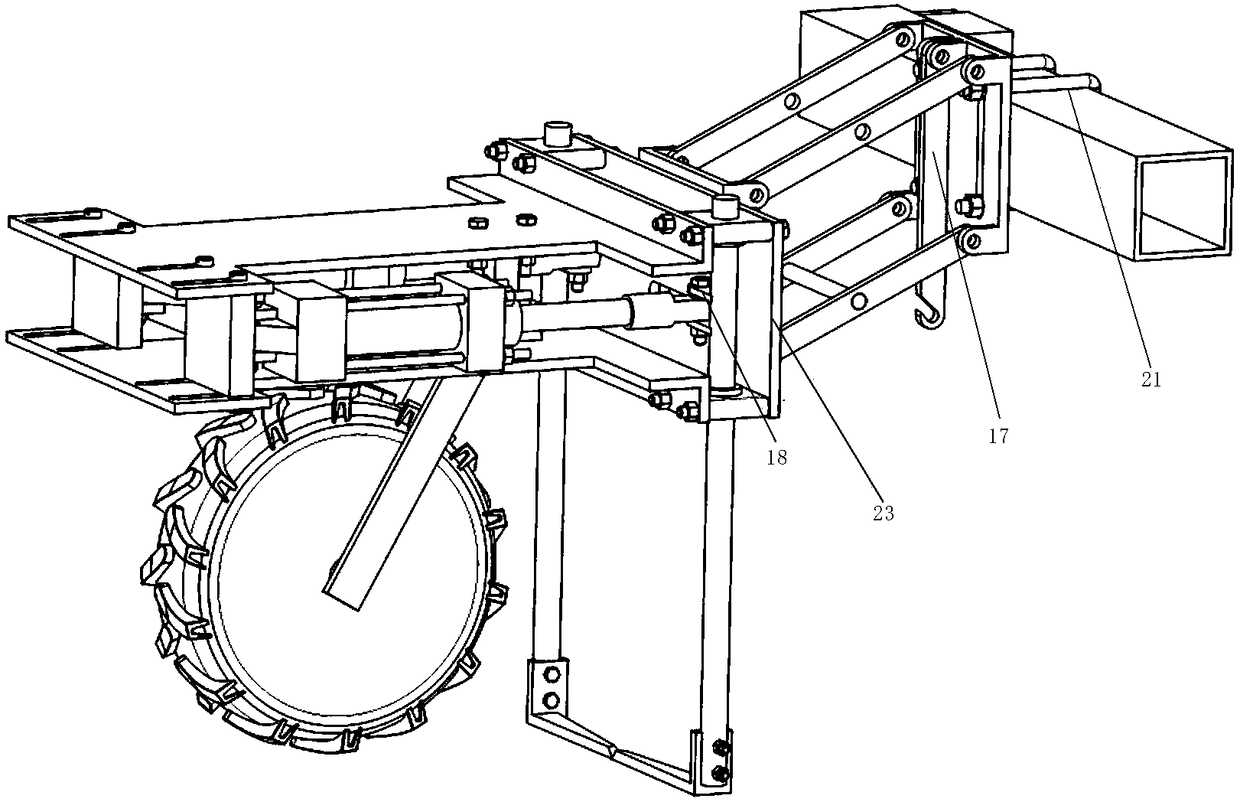

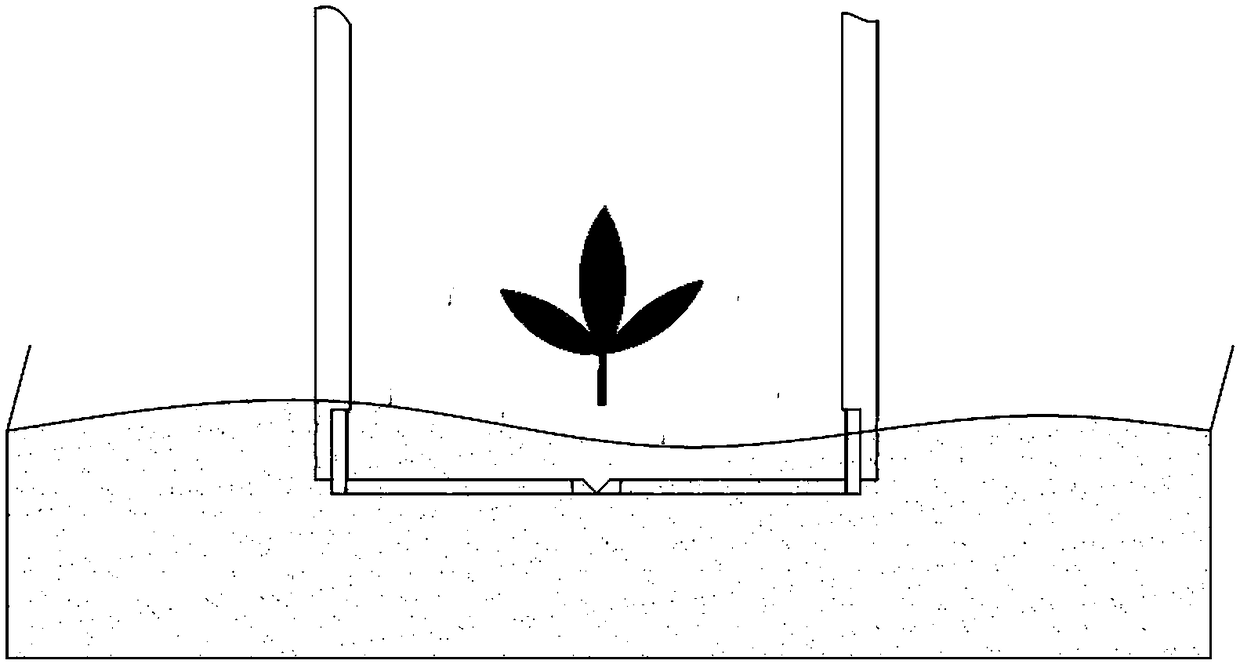

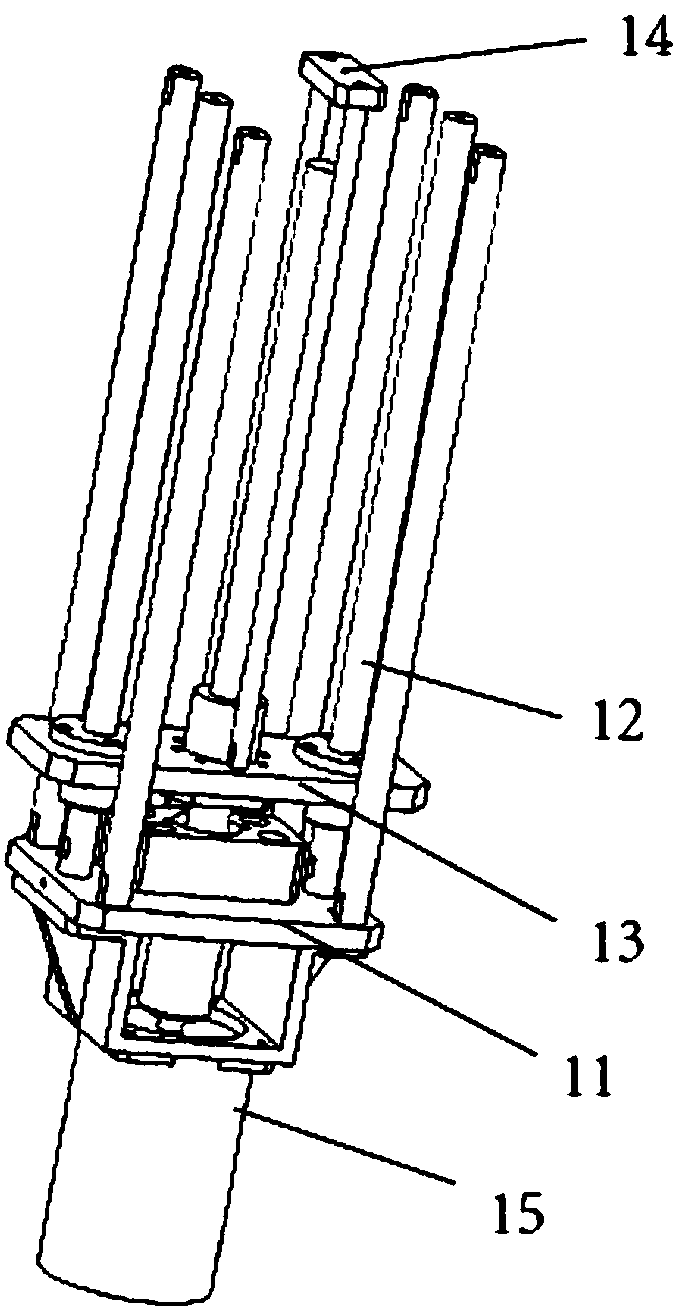

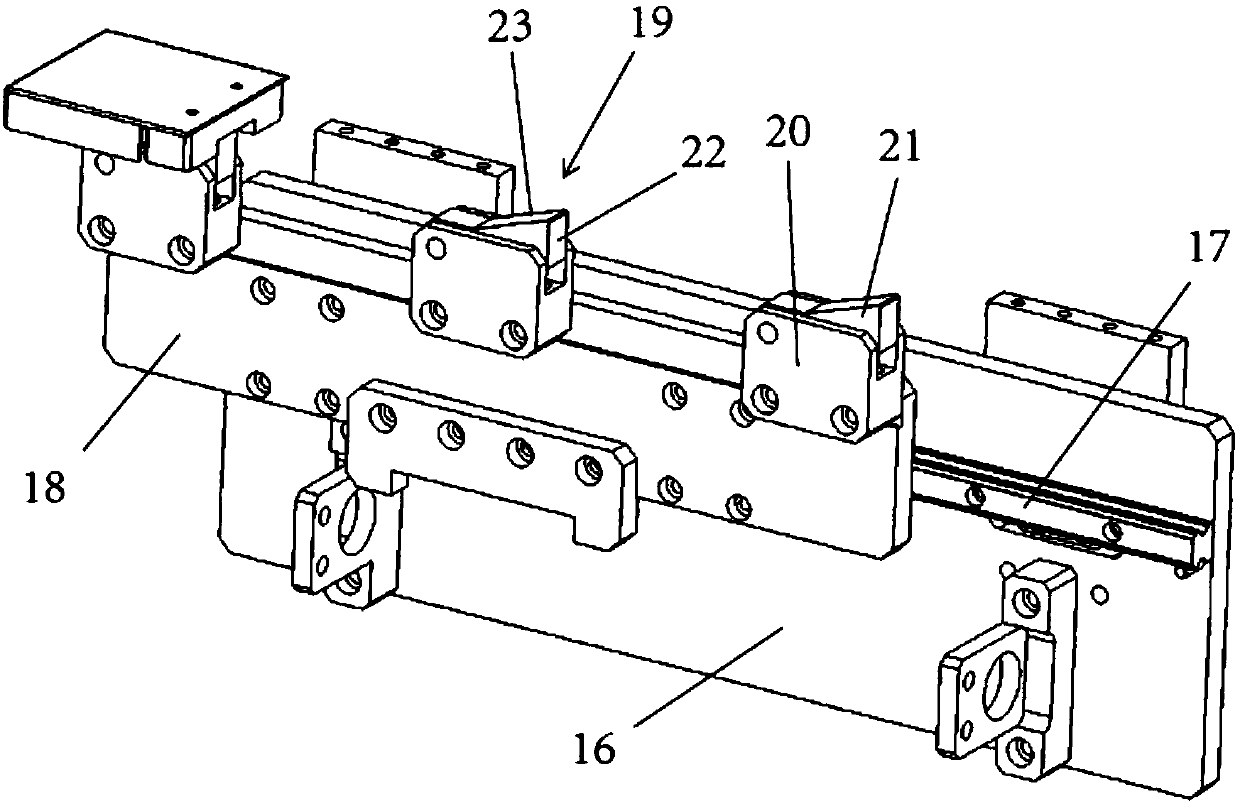

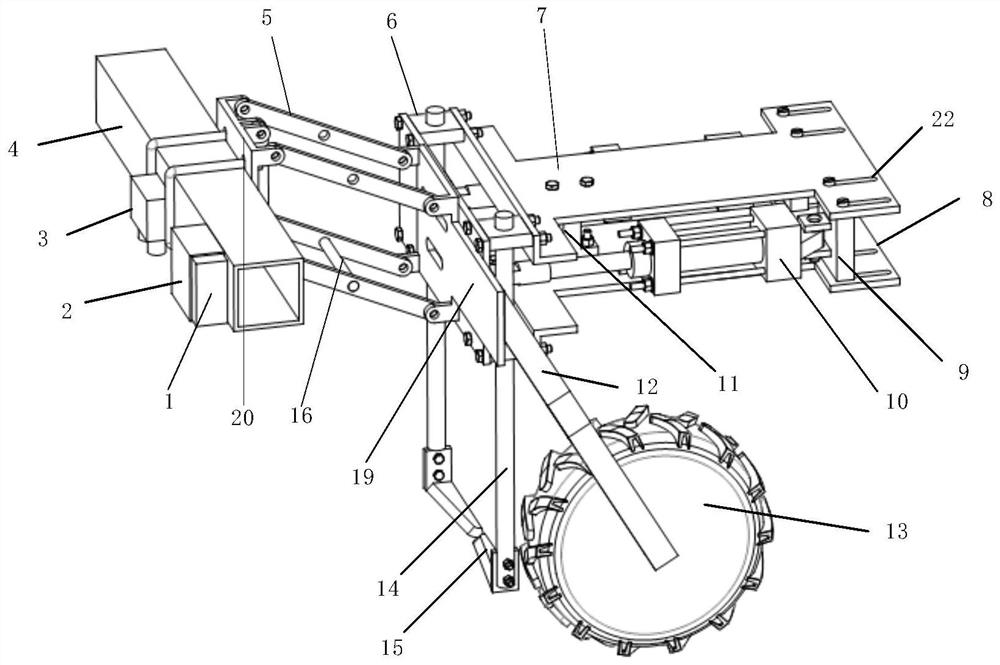

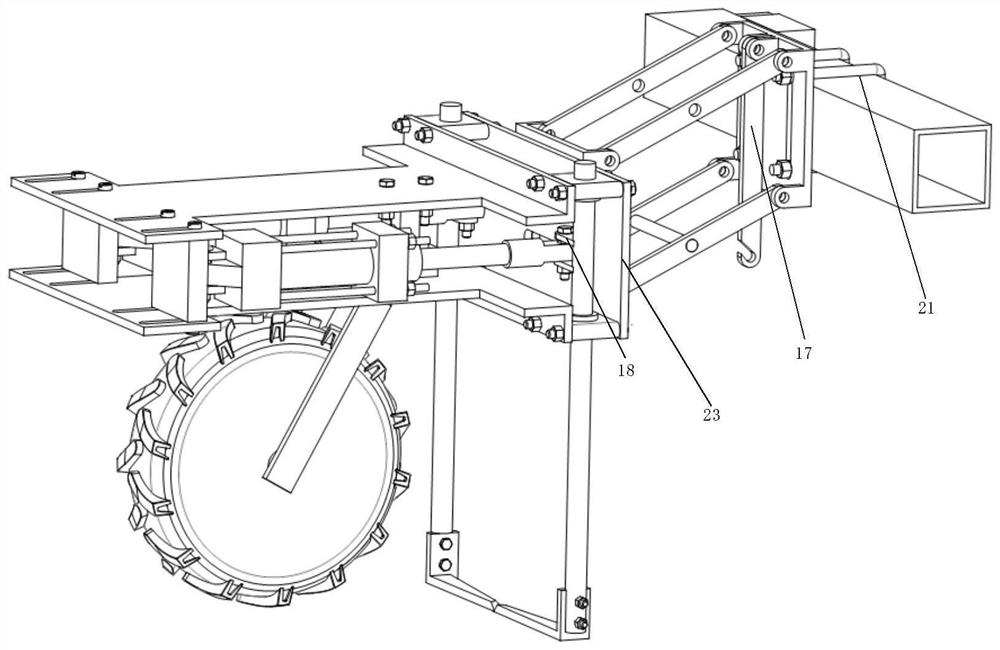

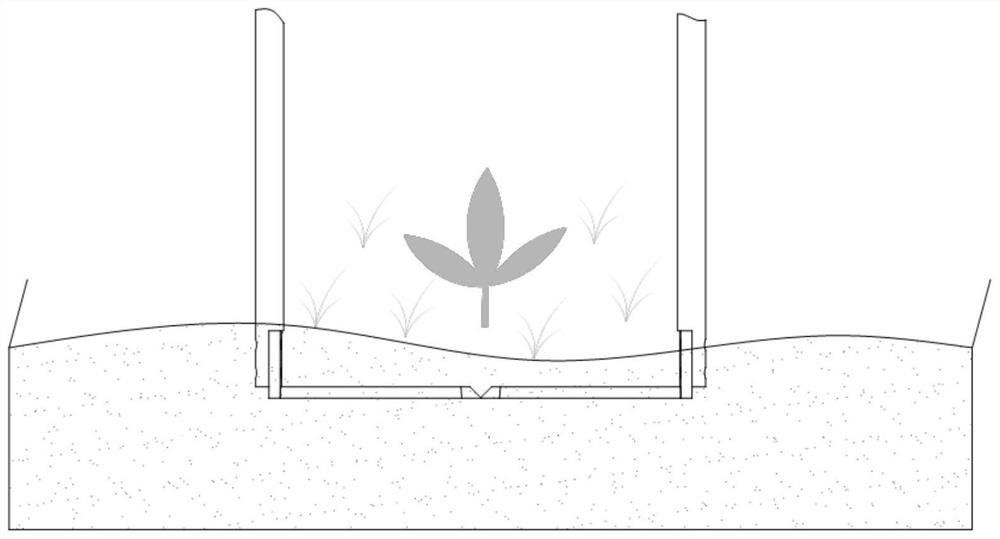

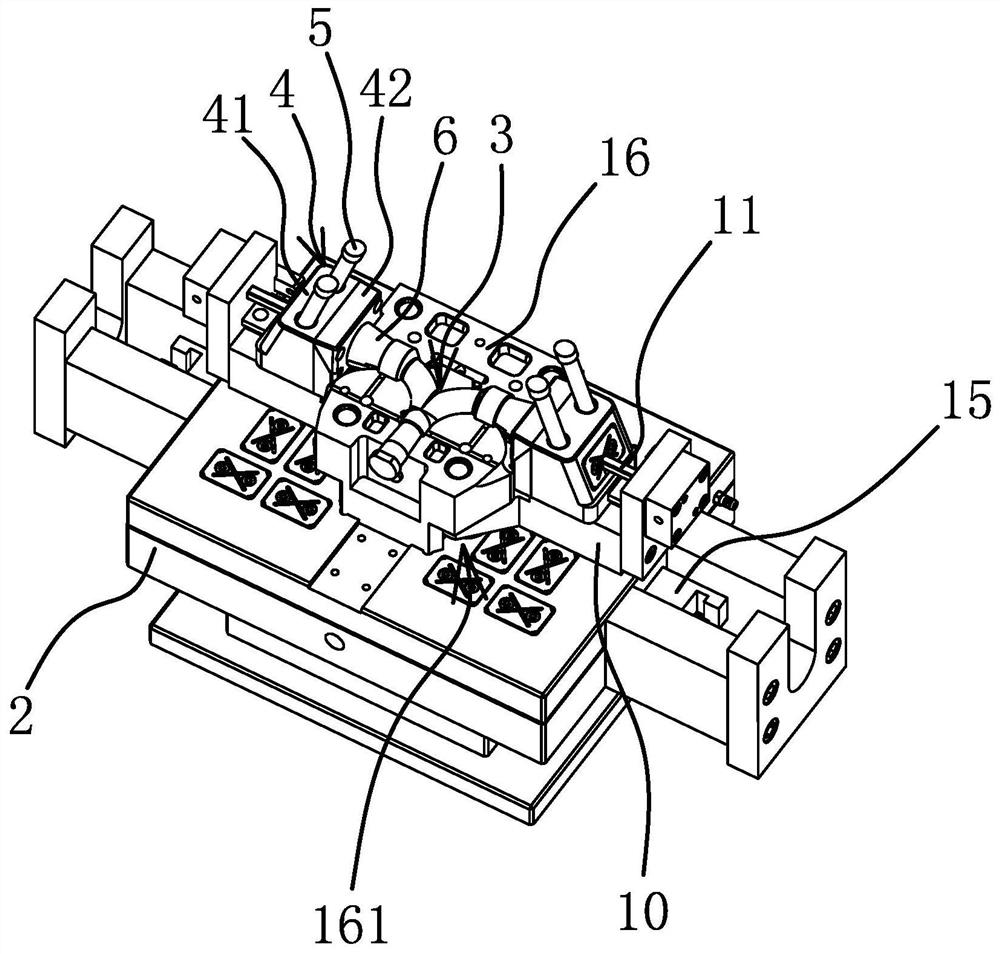

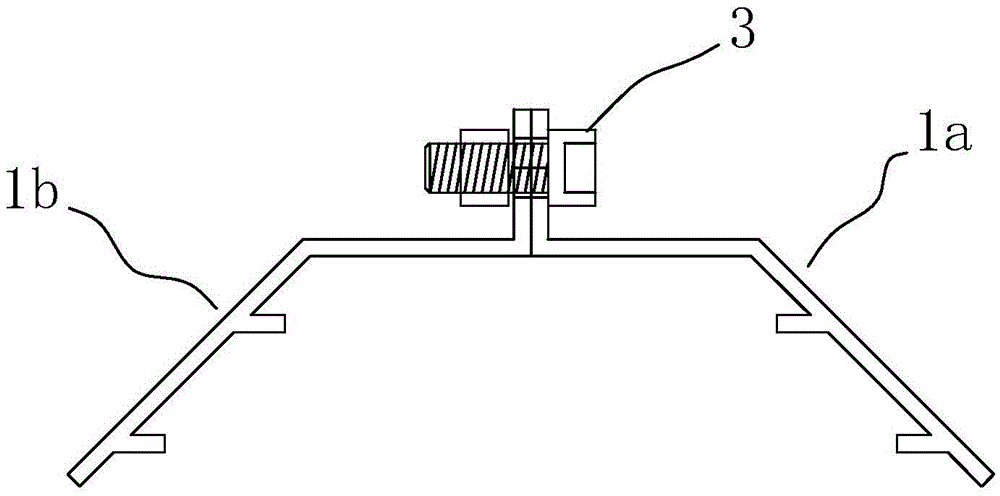

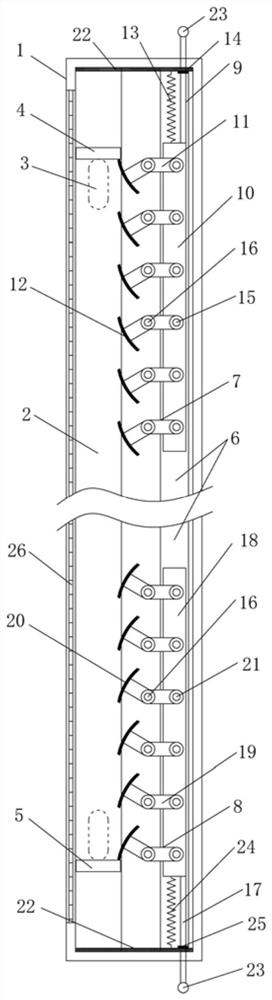

Opening-closing type intelligent weeding device for acquiring seedling and grass information based on binocular vision

ActiveCN109005693AImprove accuracySimple control algorithmTelevision system detailsSoil-working equipmentsAgricultureControl system

The invention belongs to the technical field of agricultural equipment, in particular to an opening-closing type intelligent weeding device for acquiring seedling and grass information based on binocular vision. The device is fixedly connected to a horizontally arranged cross beam which is perpendicular to the heading direction. The weeding device comprises a binocular vision servo control system,an inter-strain grass removing end executor and a parallel four-rod profile modeling unit. The binocular vision servo control system comprises a binocular camera, a single chip microcomputer and a servo controller. The binocular camera is fixed on the front end face of the cross beam and used for acquiring seedling and grass information of a big field. The single chip microcomputer has an image processing function. The parallel four-rod profile modeling unit comprises a parallel four-rod mechanism, a land wheel rod and a land wheel. The parallel four-rod mechanism comprises an upper pull rod,a lower pull rod, a front installation plate, a back installation plate, a hanging rod and a hook. The inter-strain grass removing end executor comprises a top plate, a base plate, a hydraulic cylinder, a hoe rod and a hoe. According to the invention, the weeding device is compact in structure, high in weeding efficiency, high in accuracy, high in transportability, widely applicable and suitablefor various kinds of large-field working conditions.

Owner:CHINA AGRI UNIV

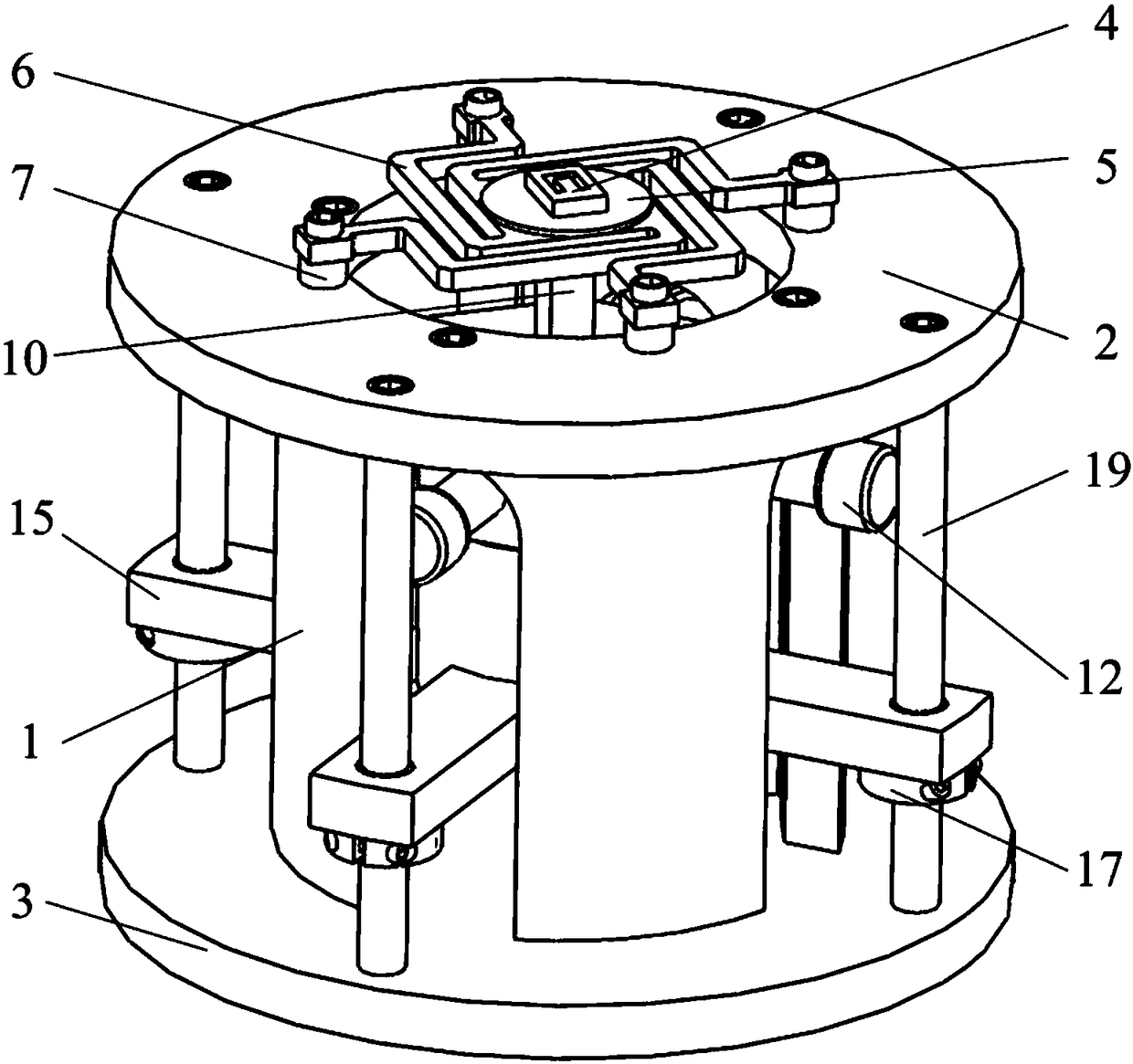

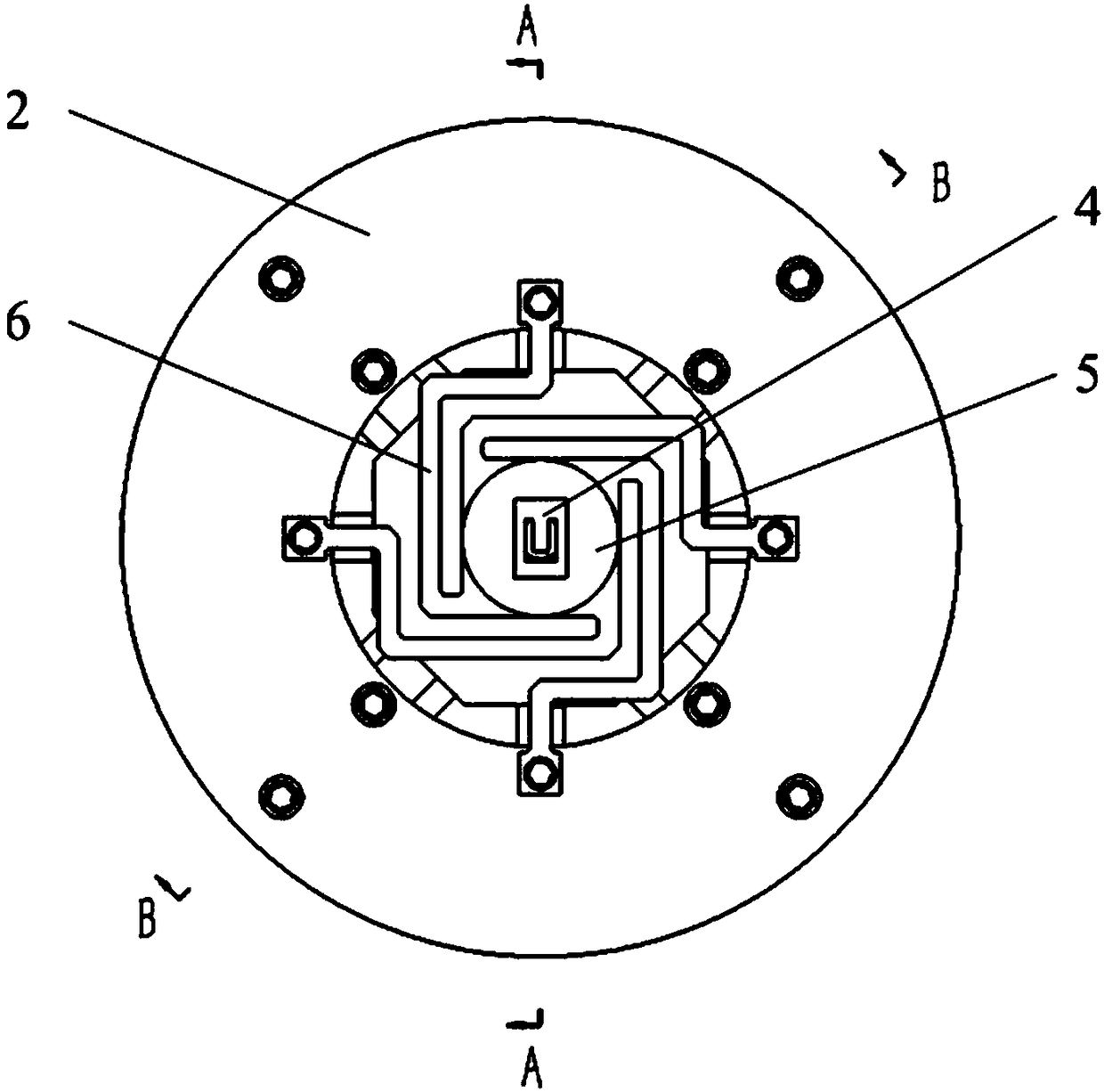

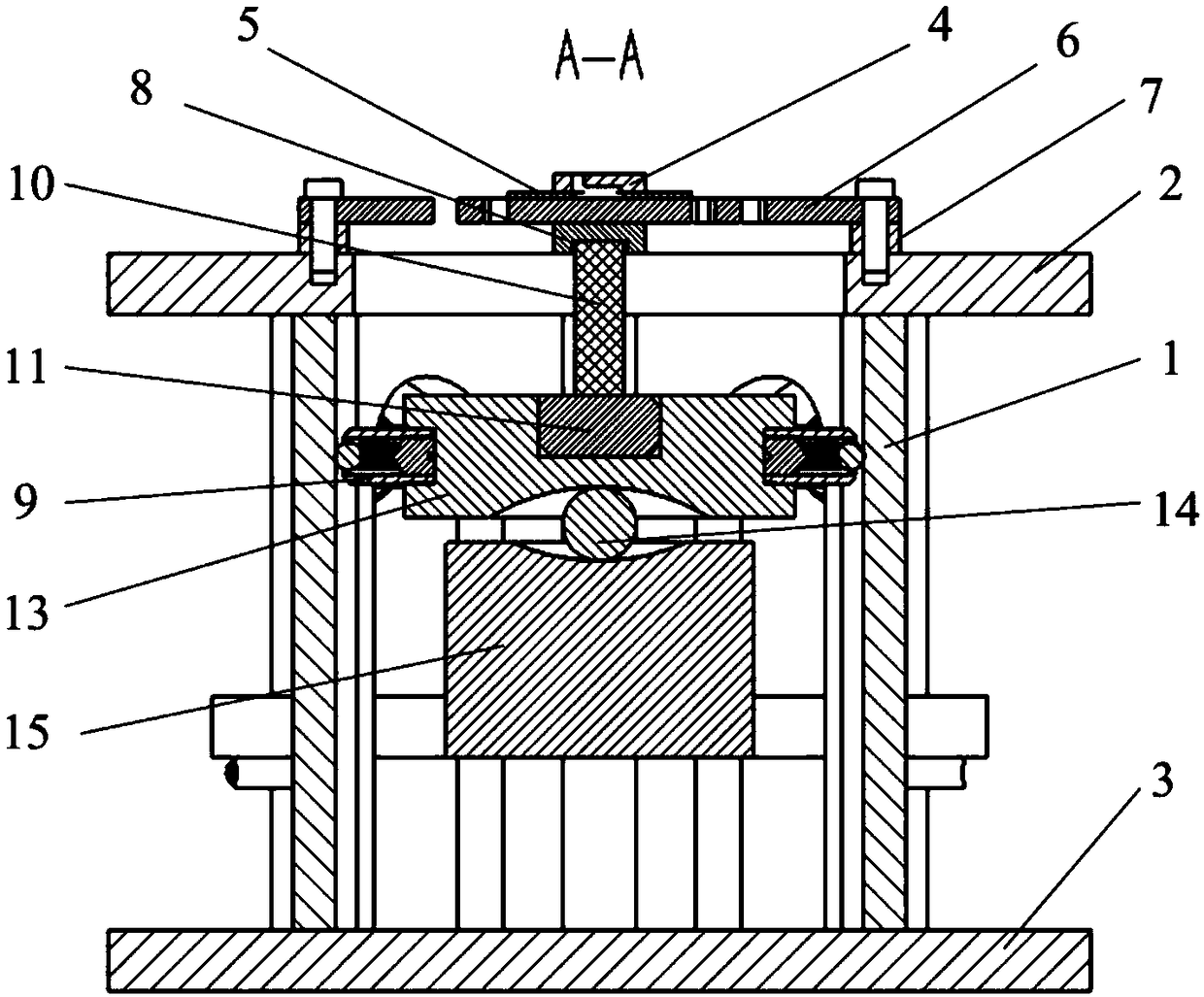

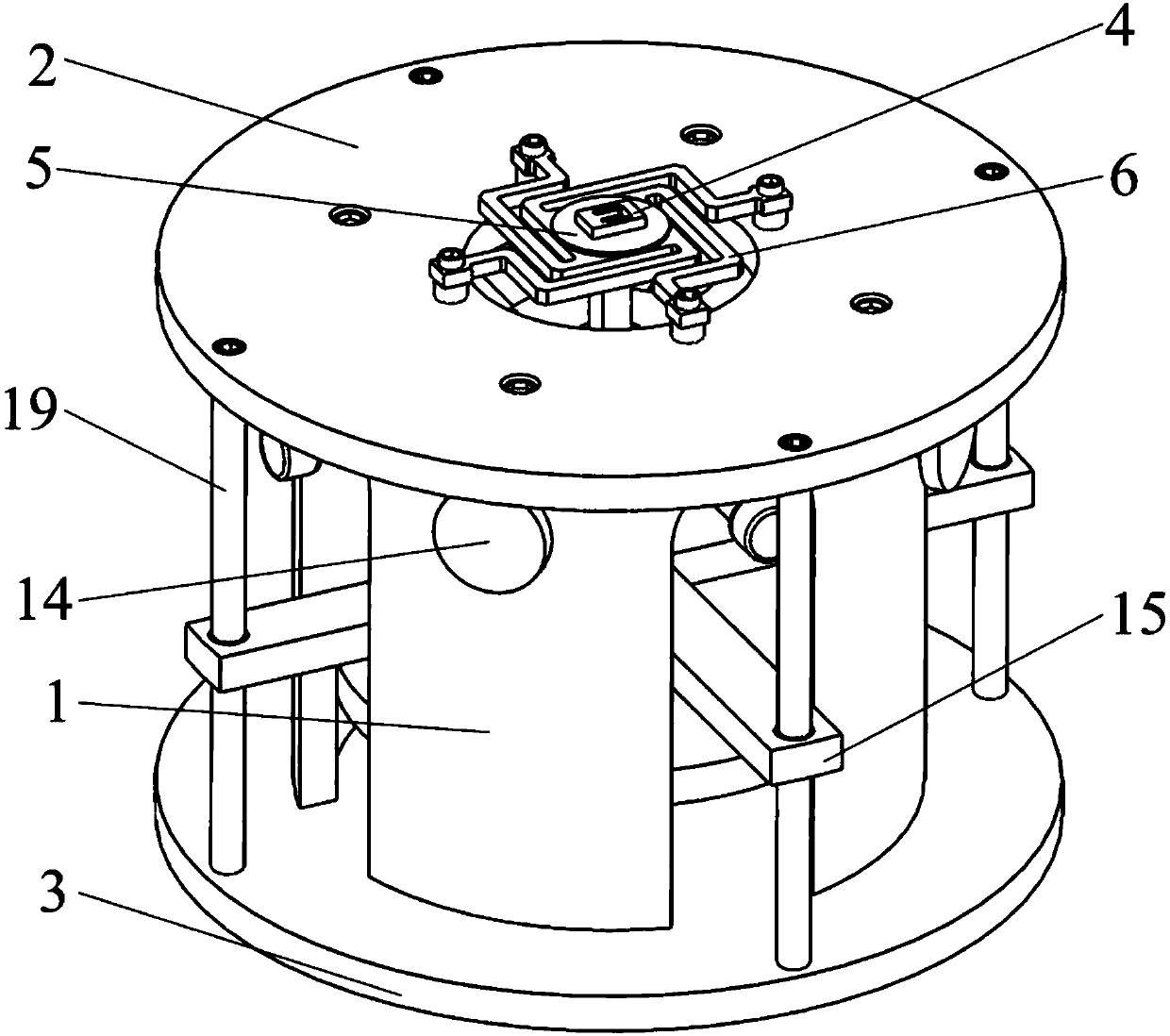

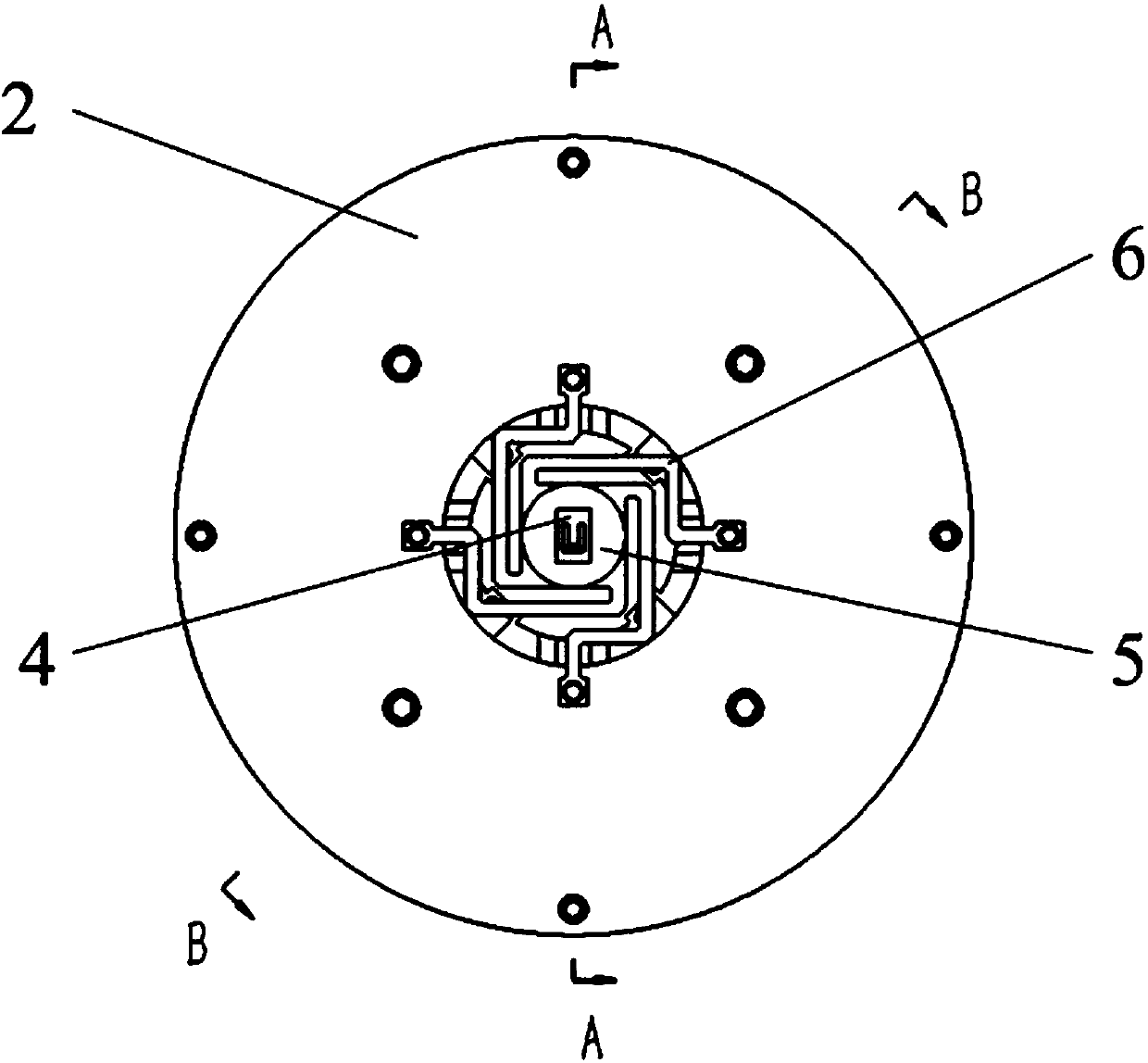

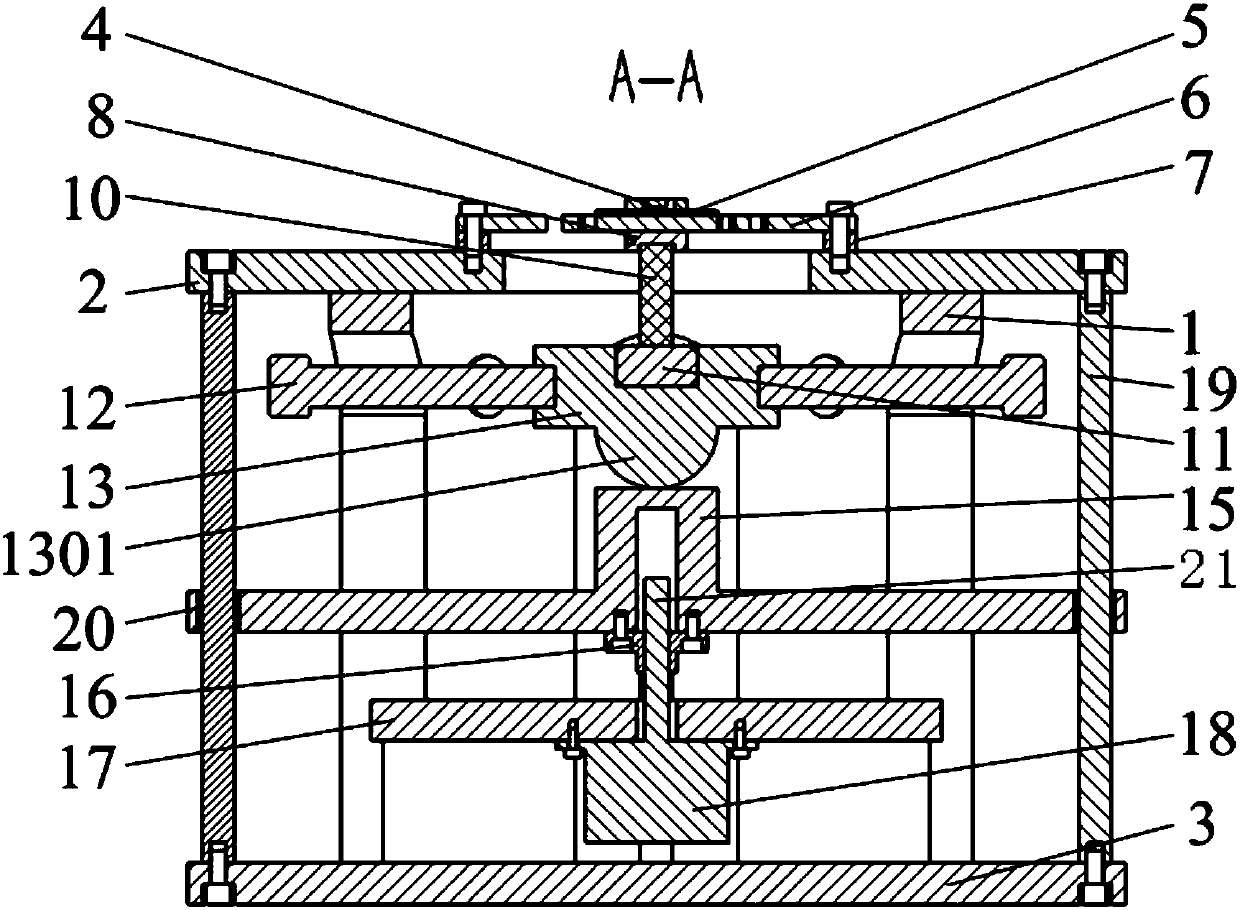

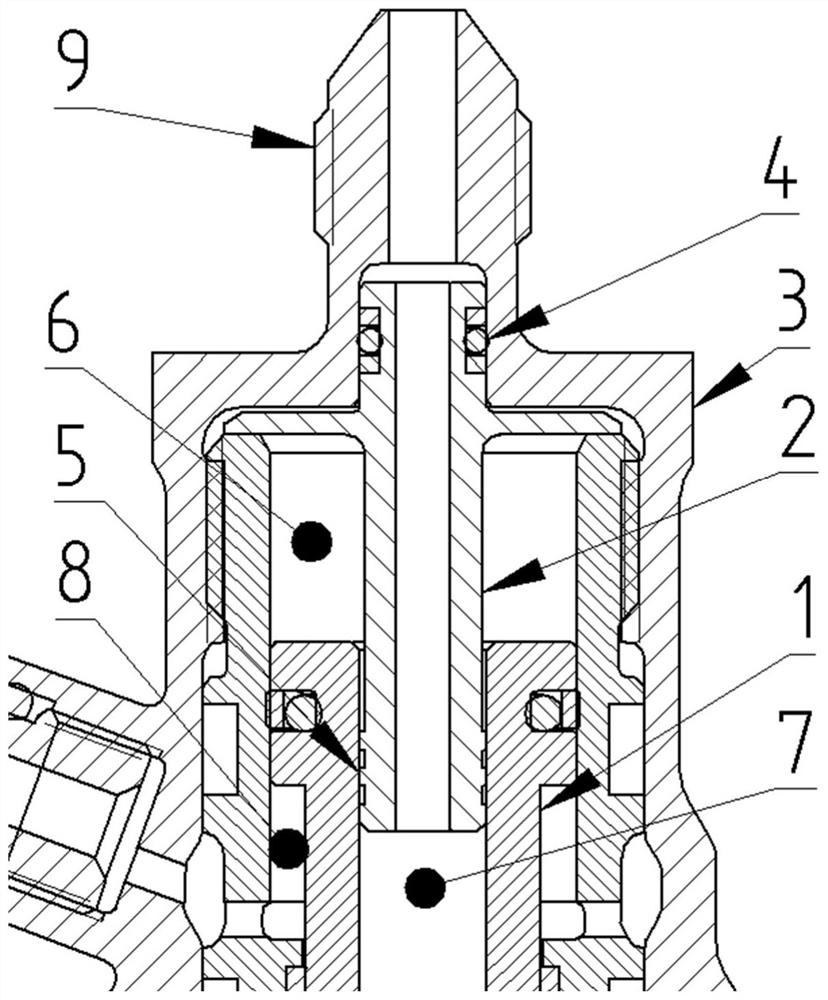

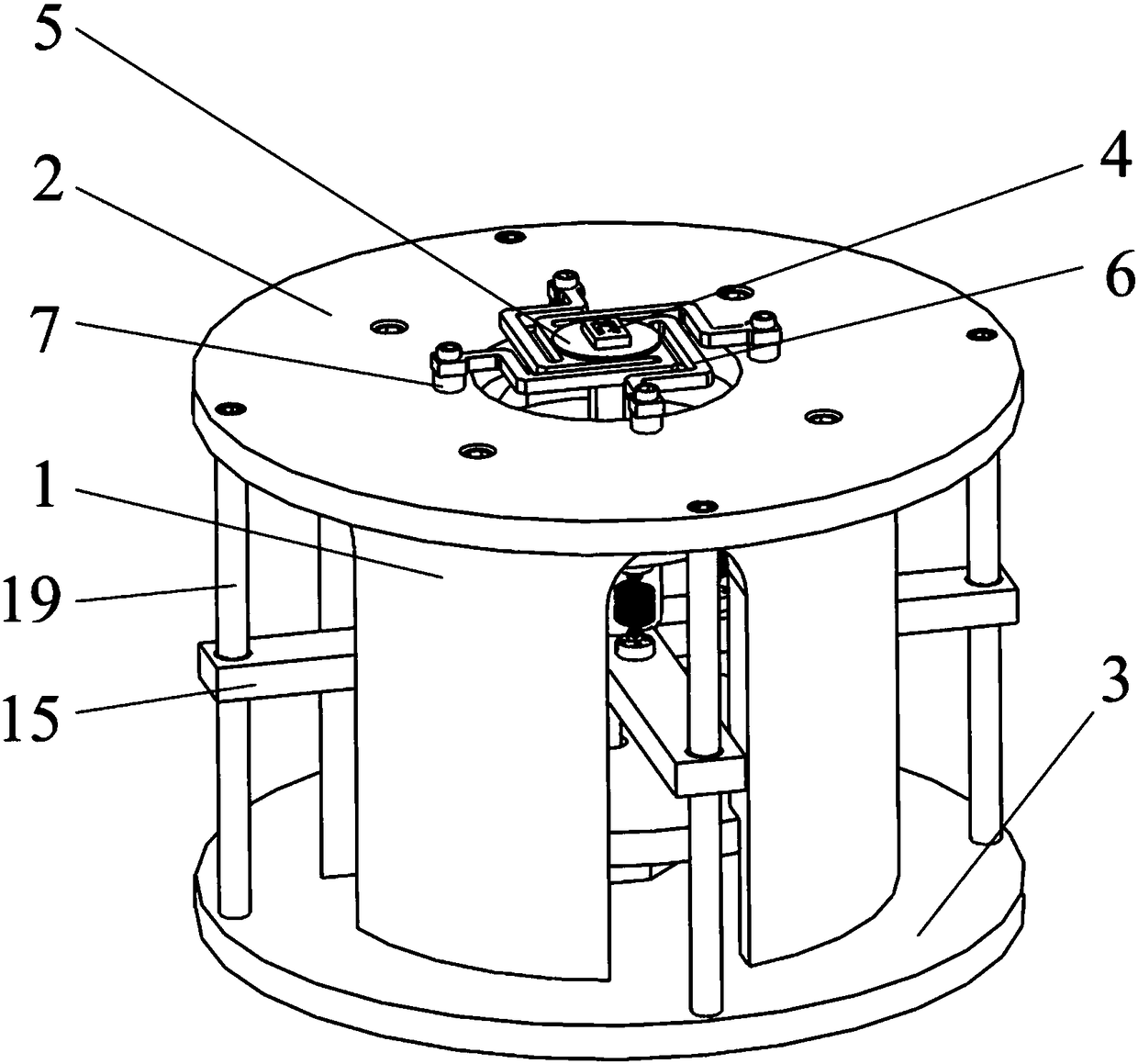

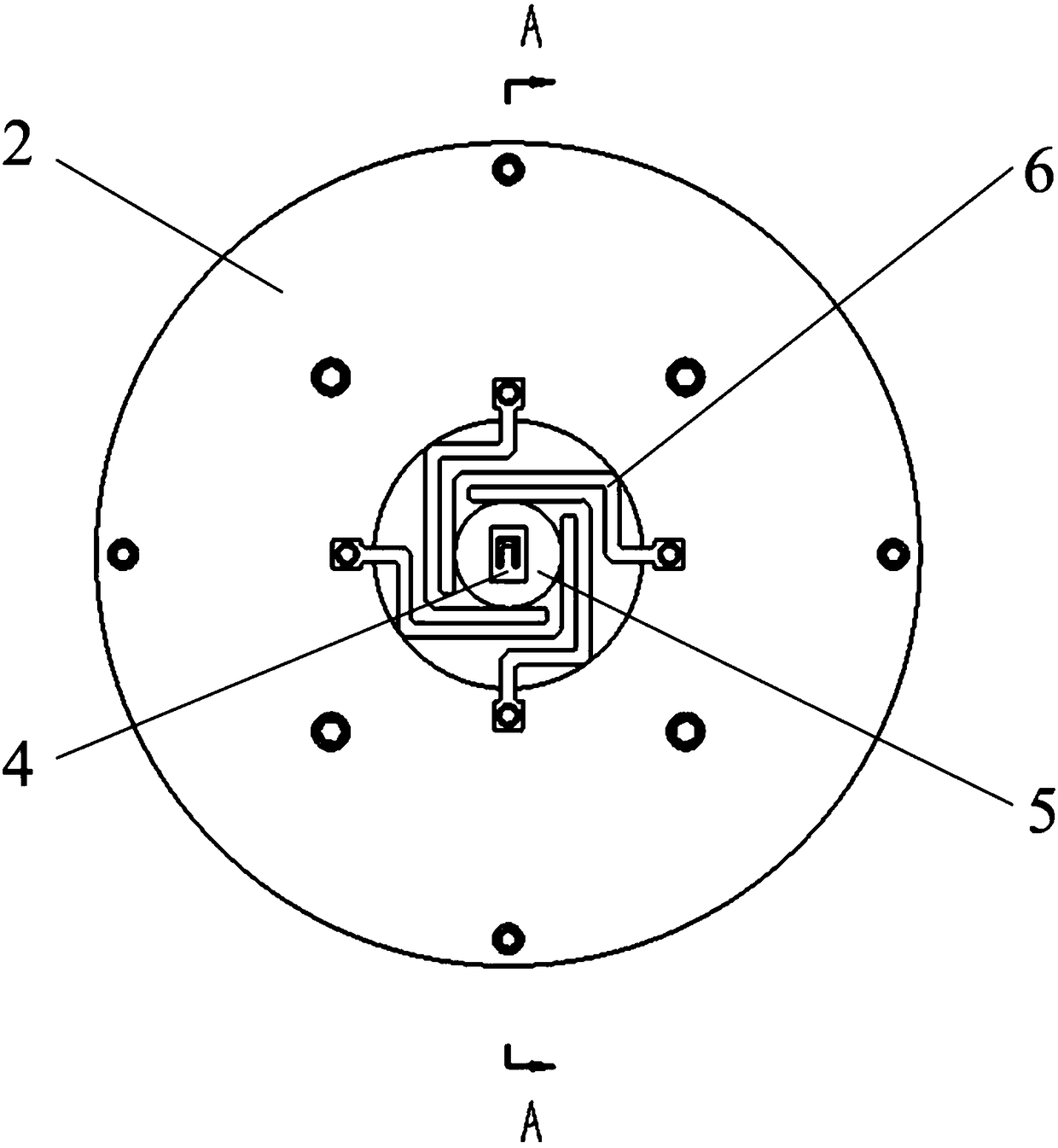

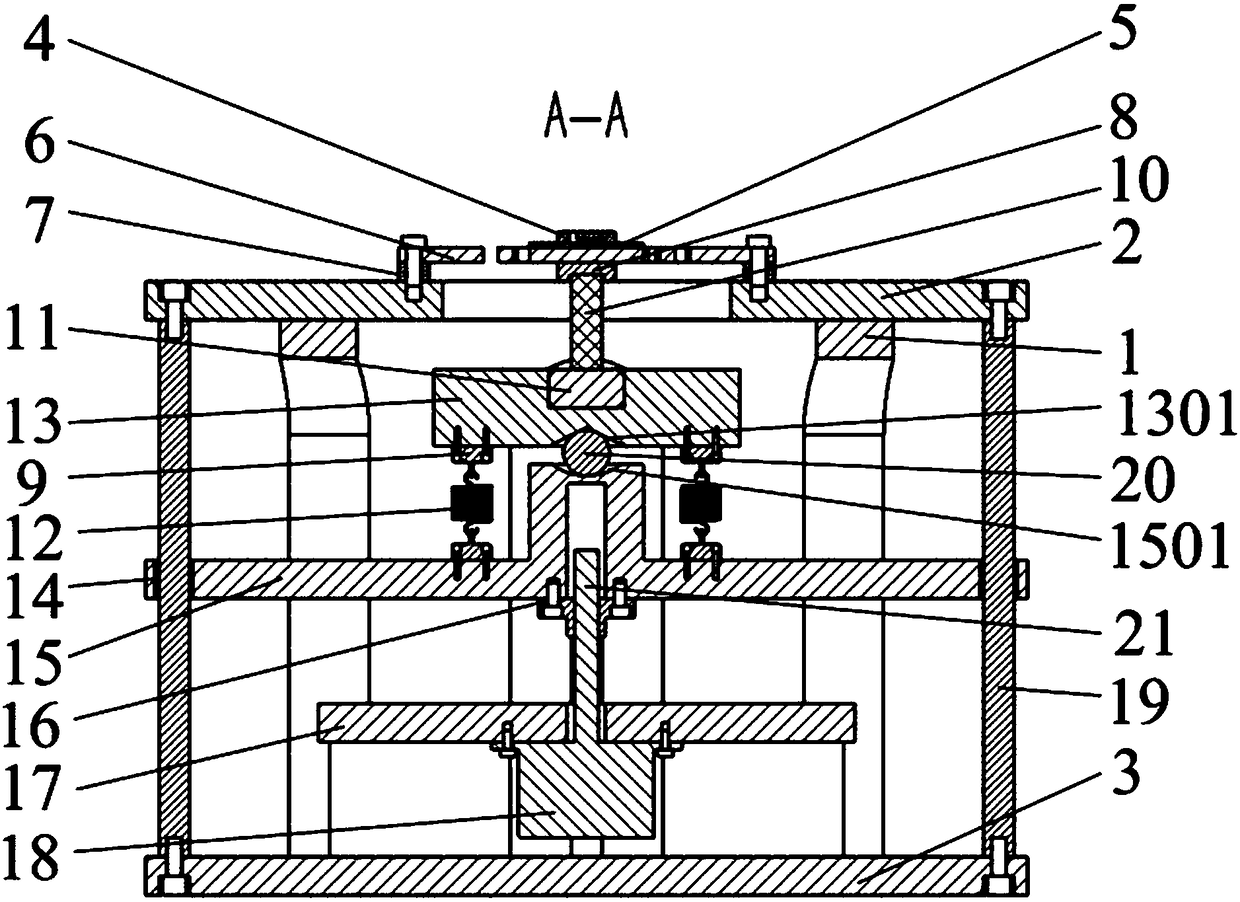

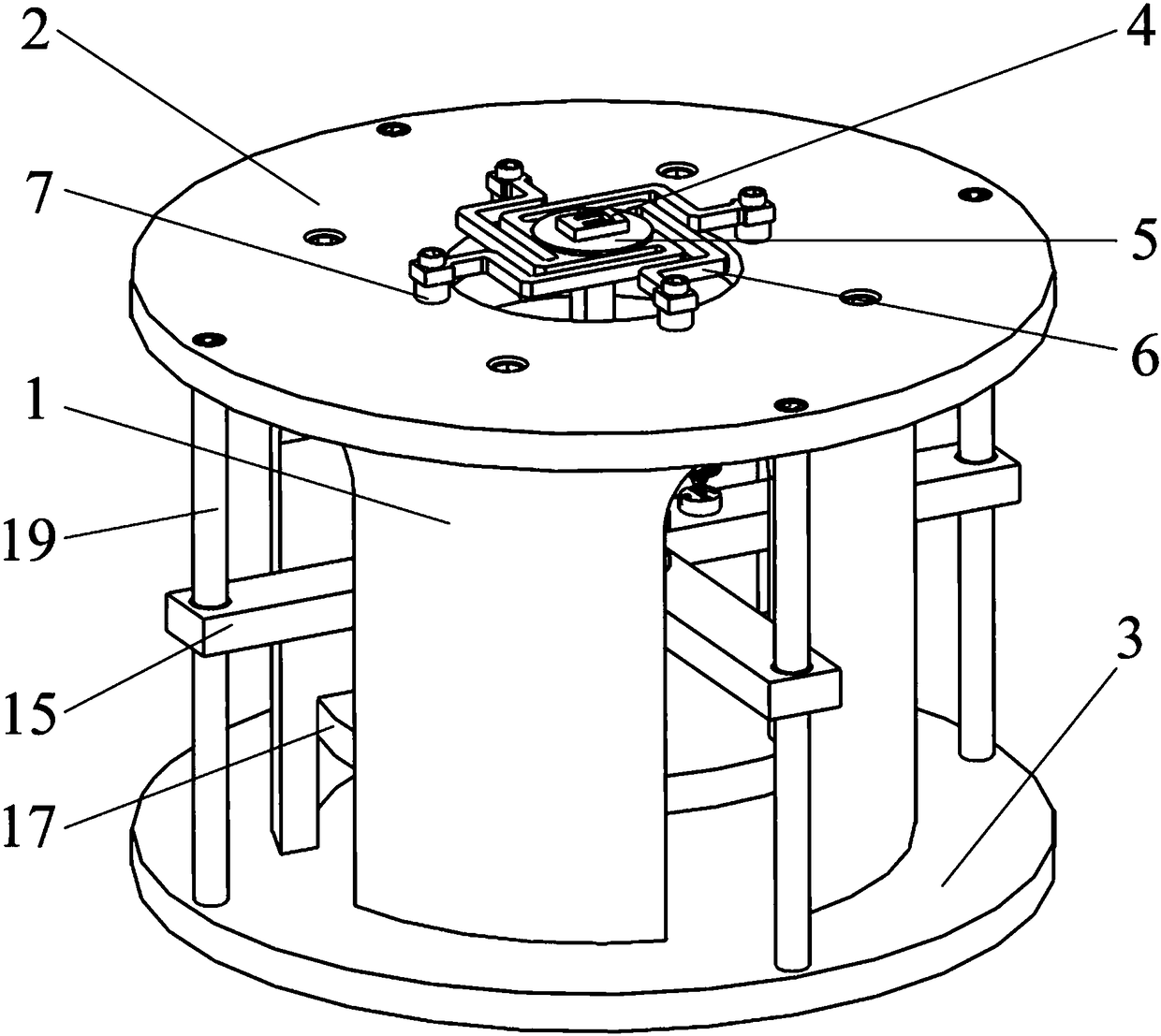

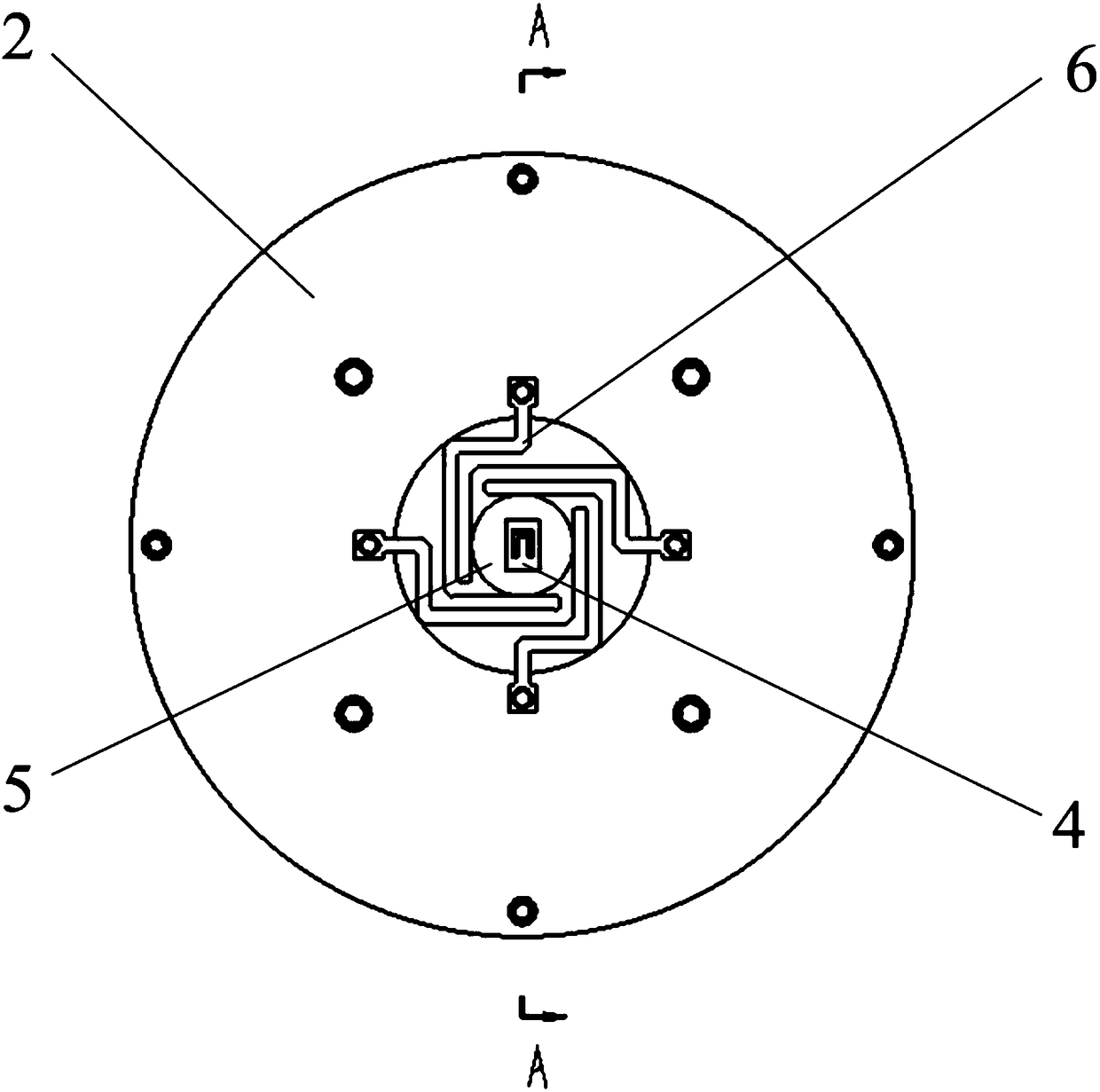

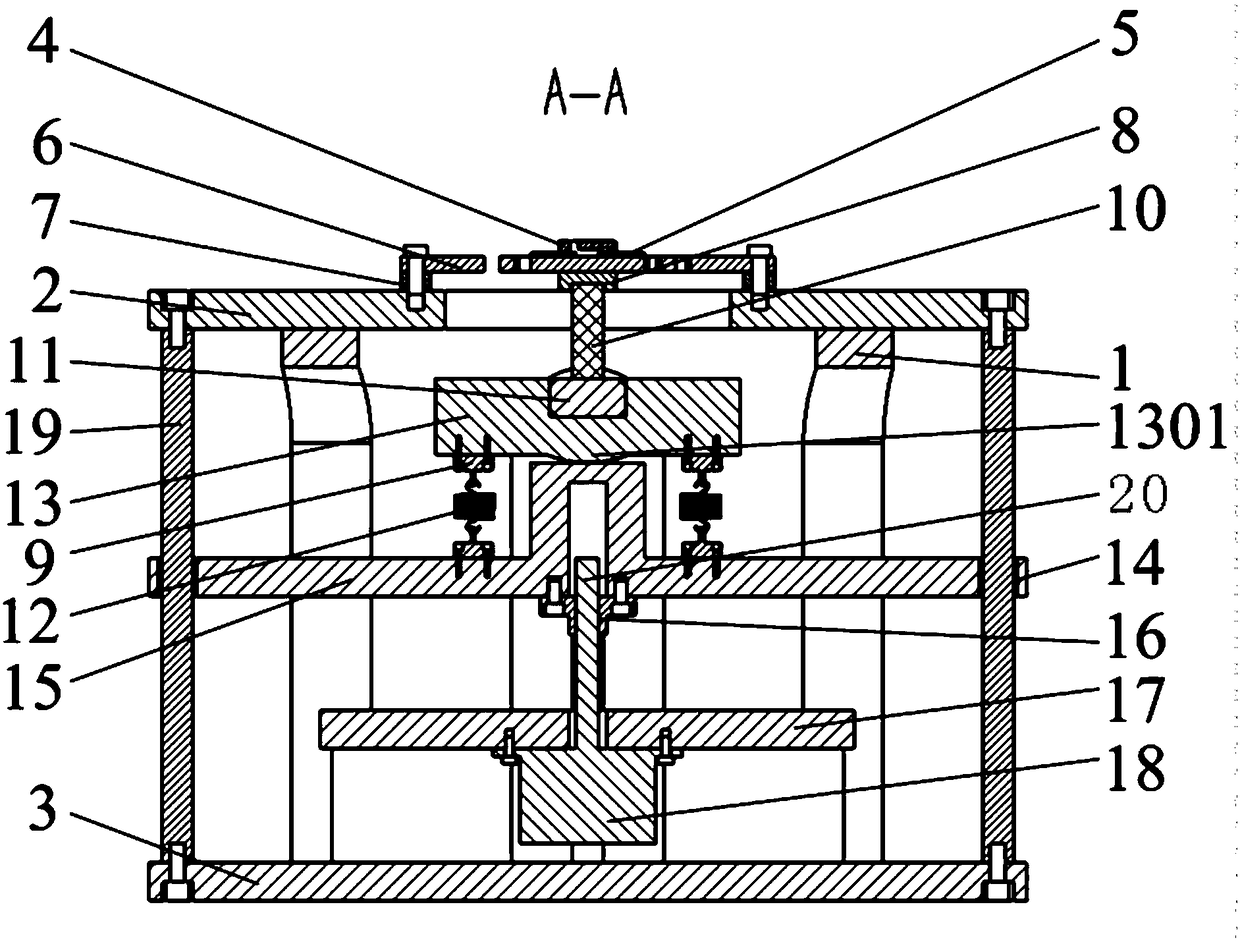

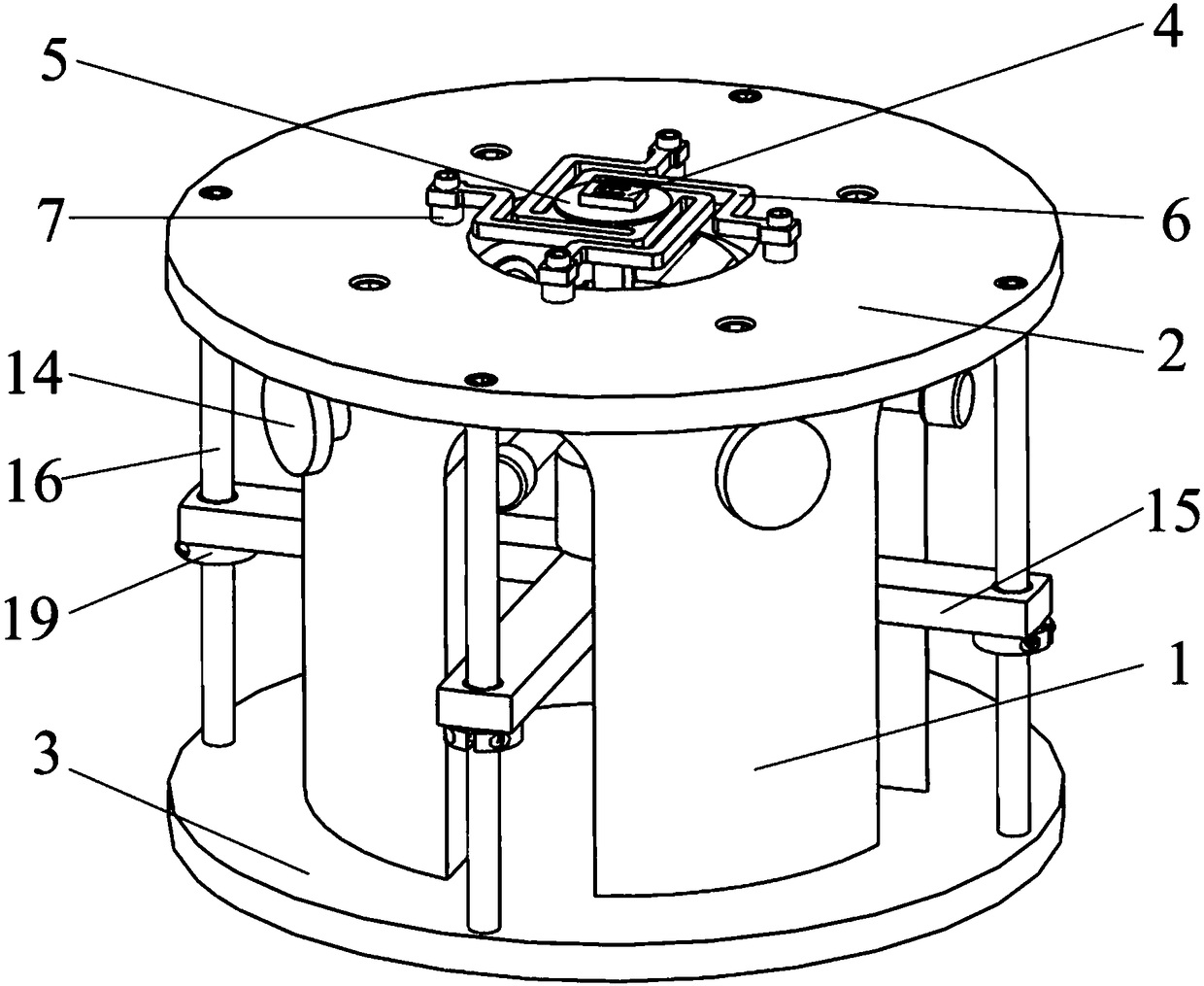

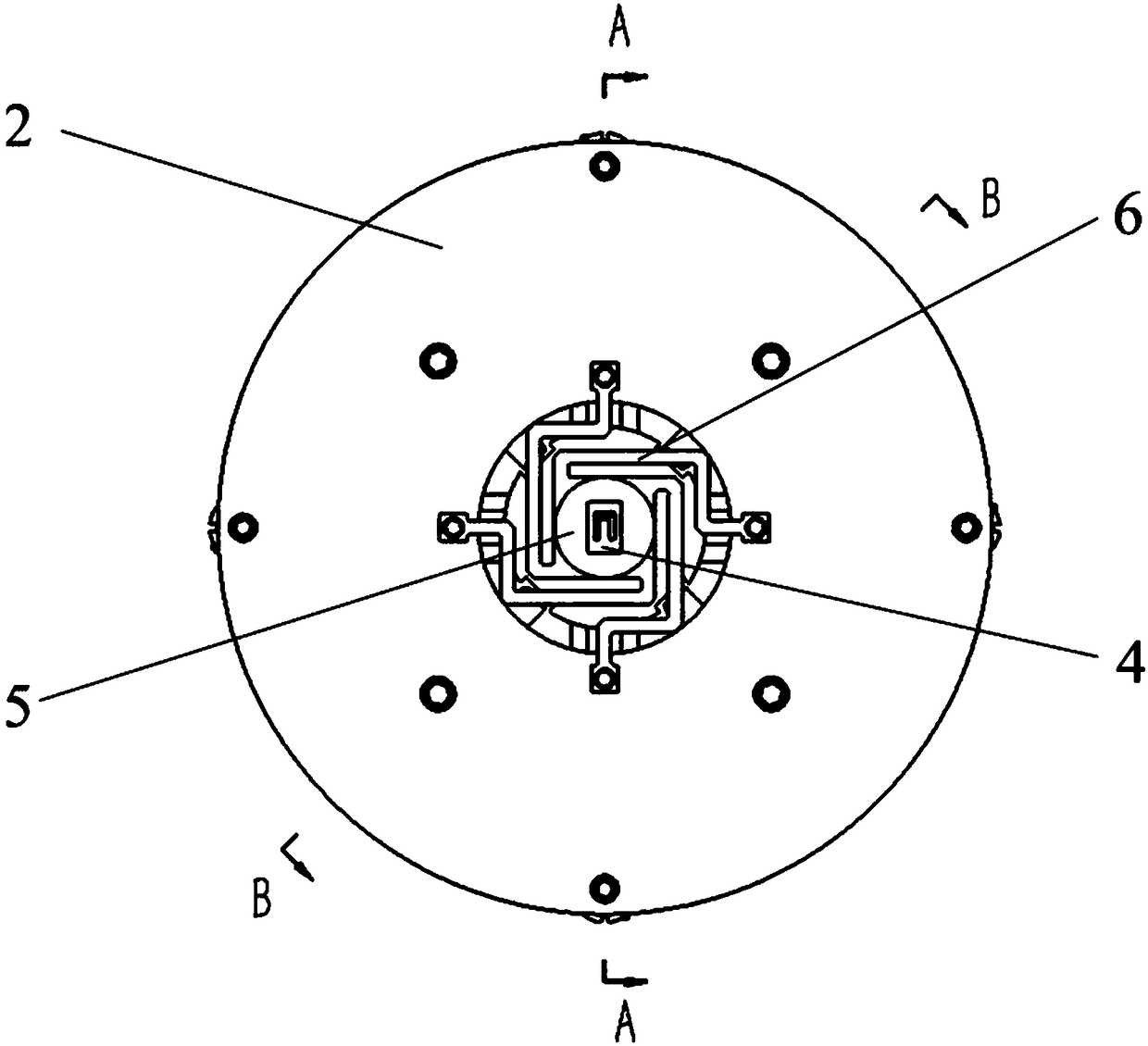

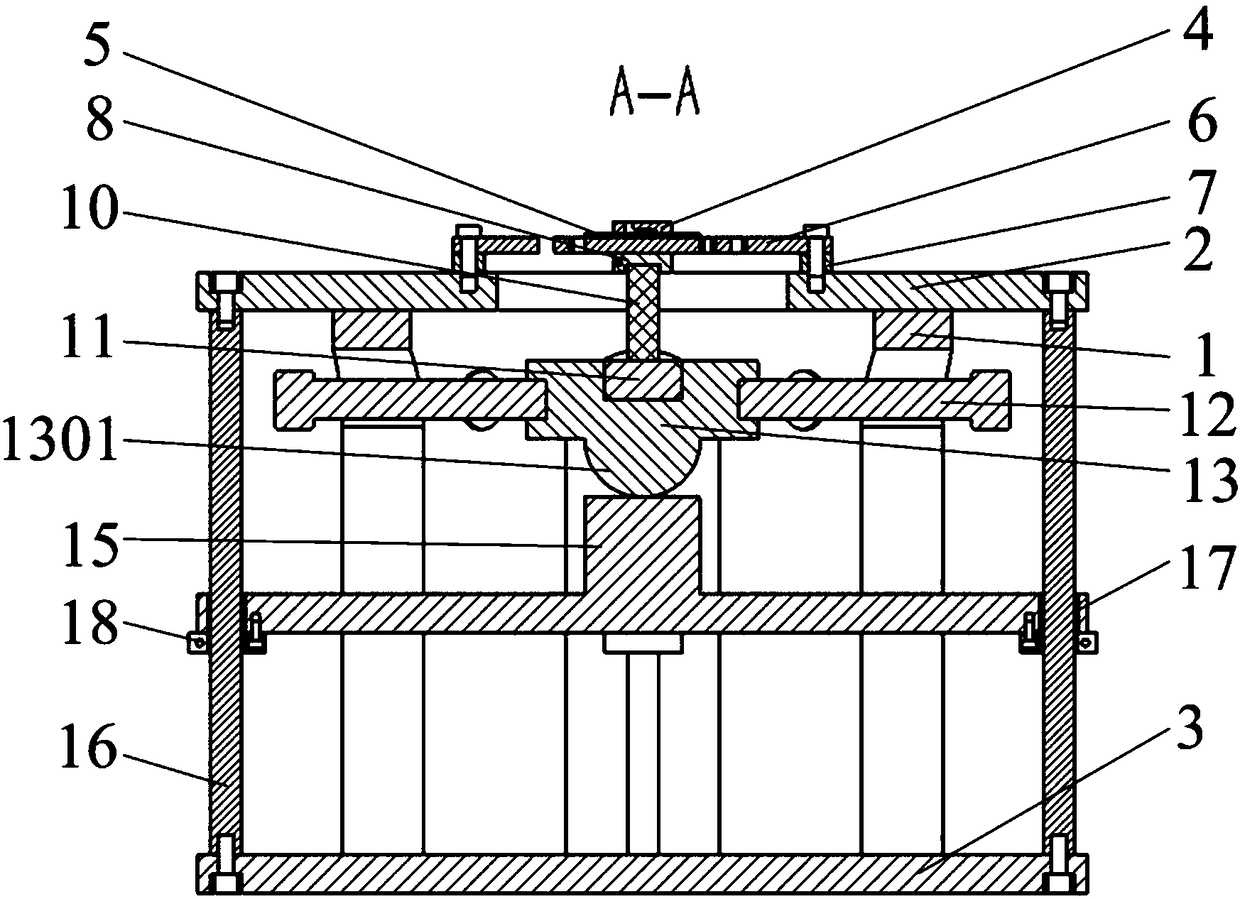

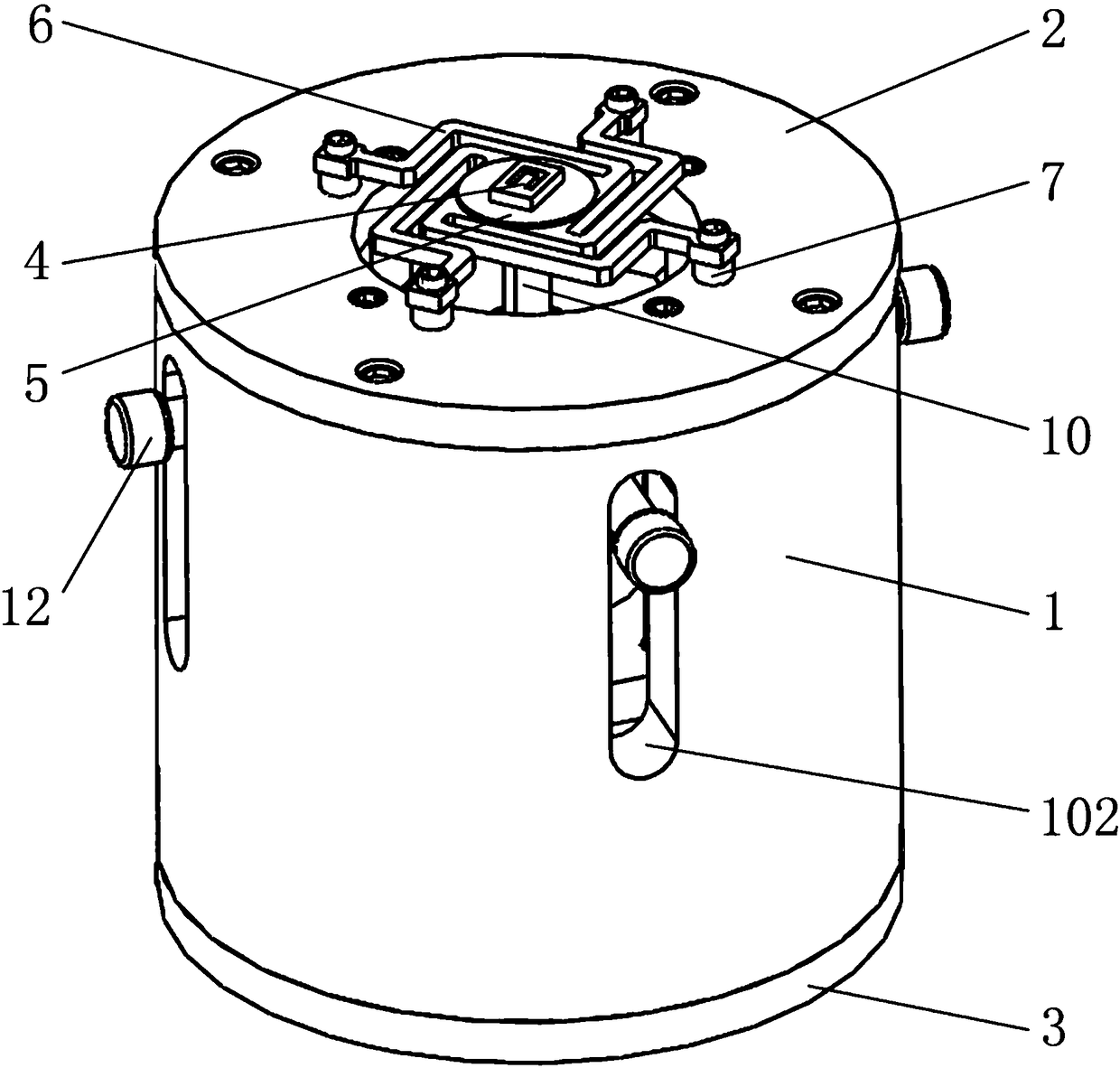

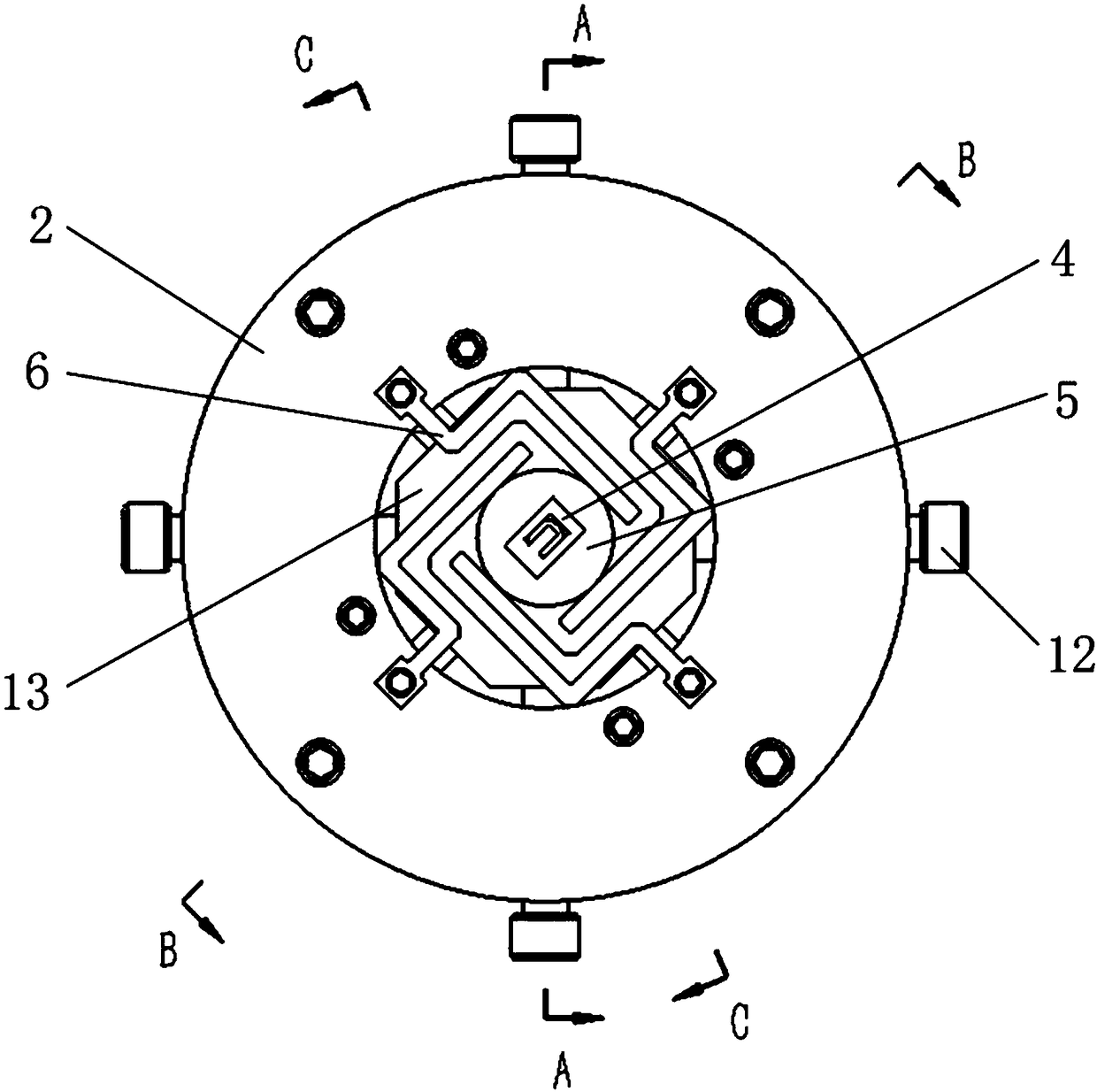

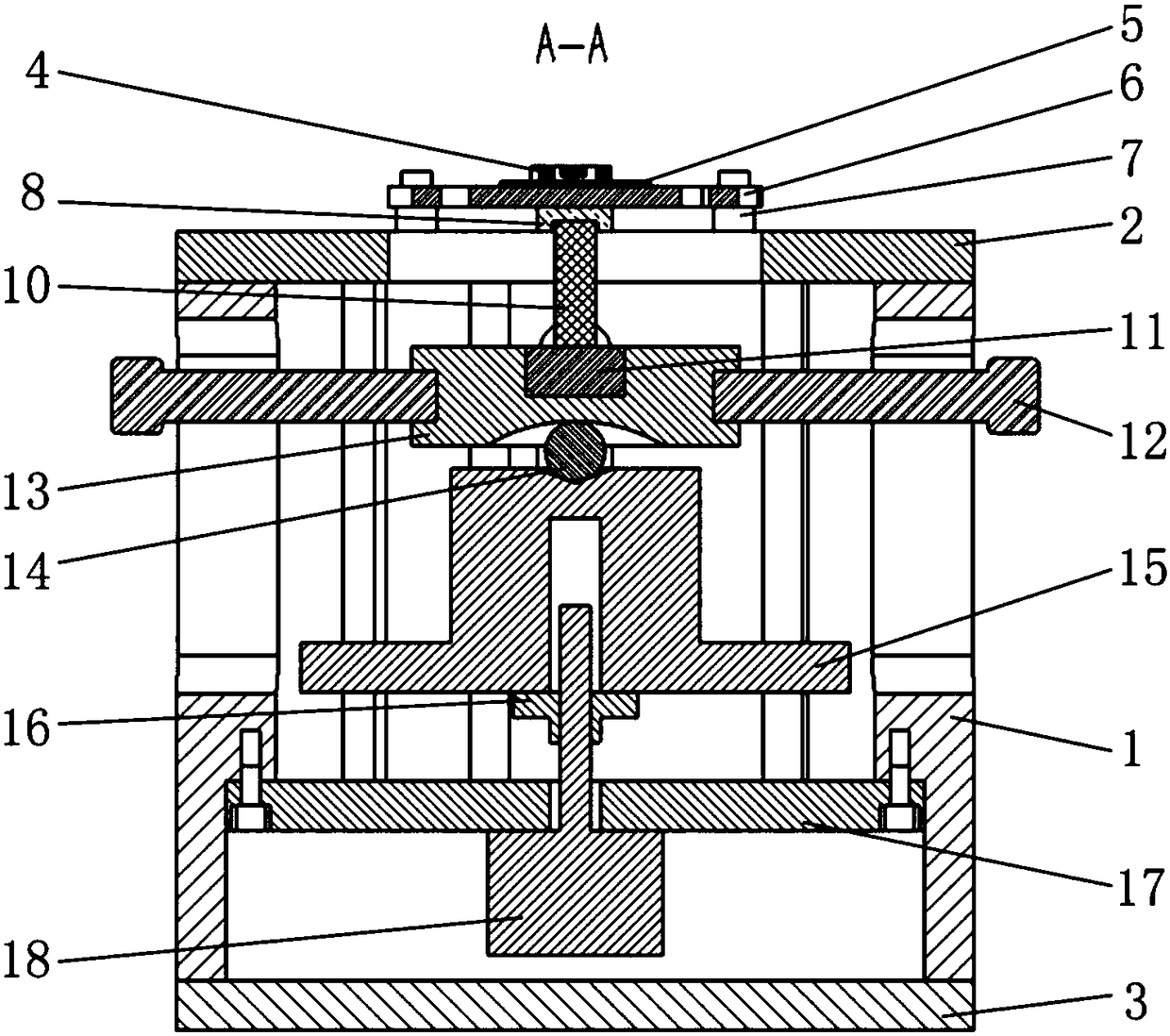

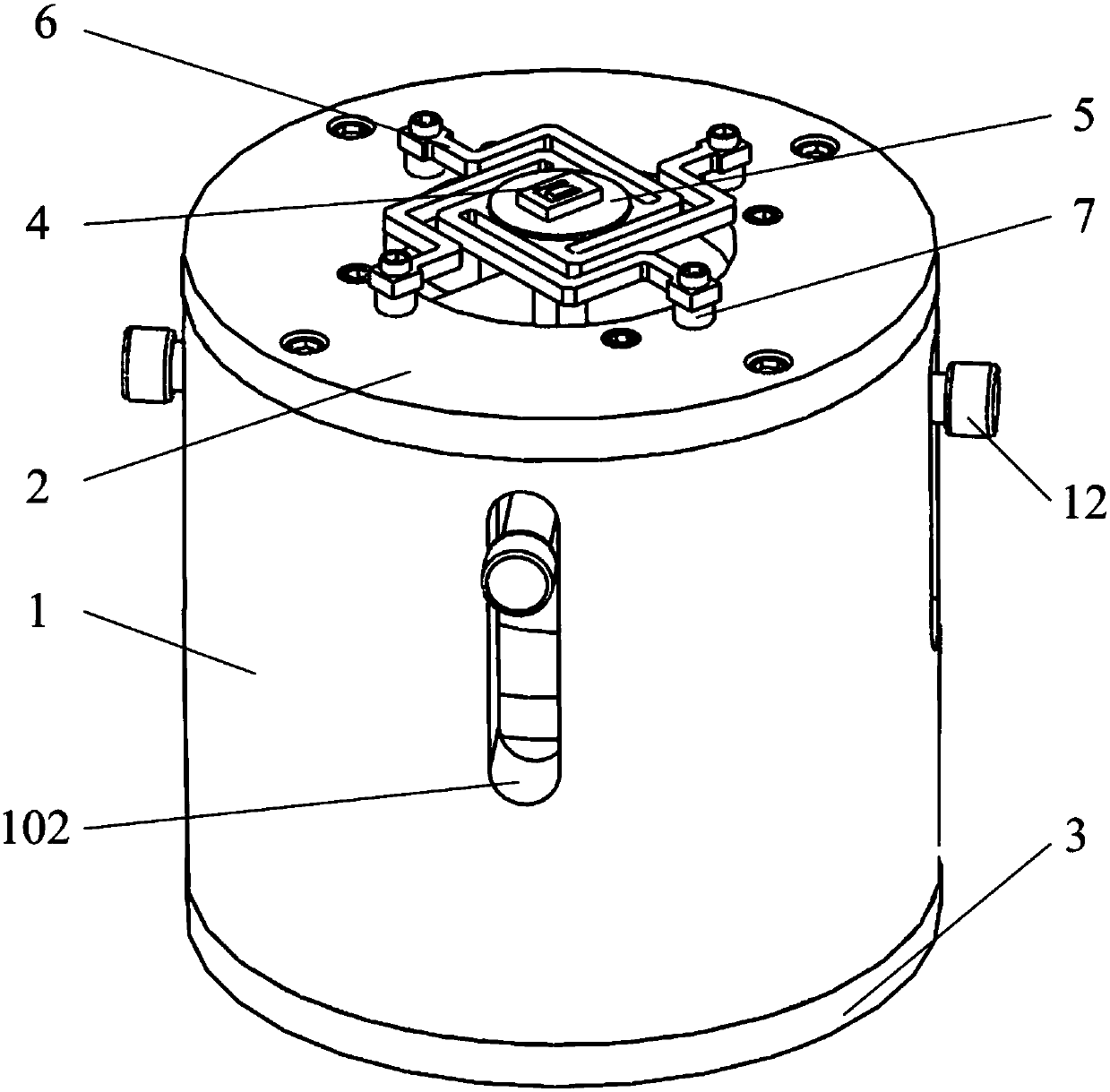

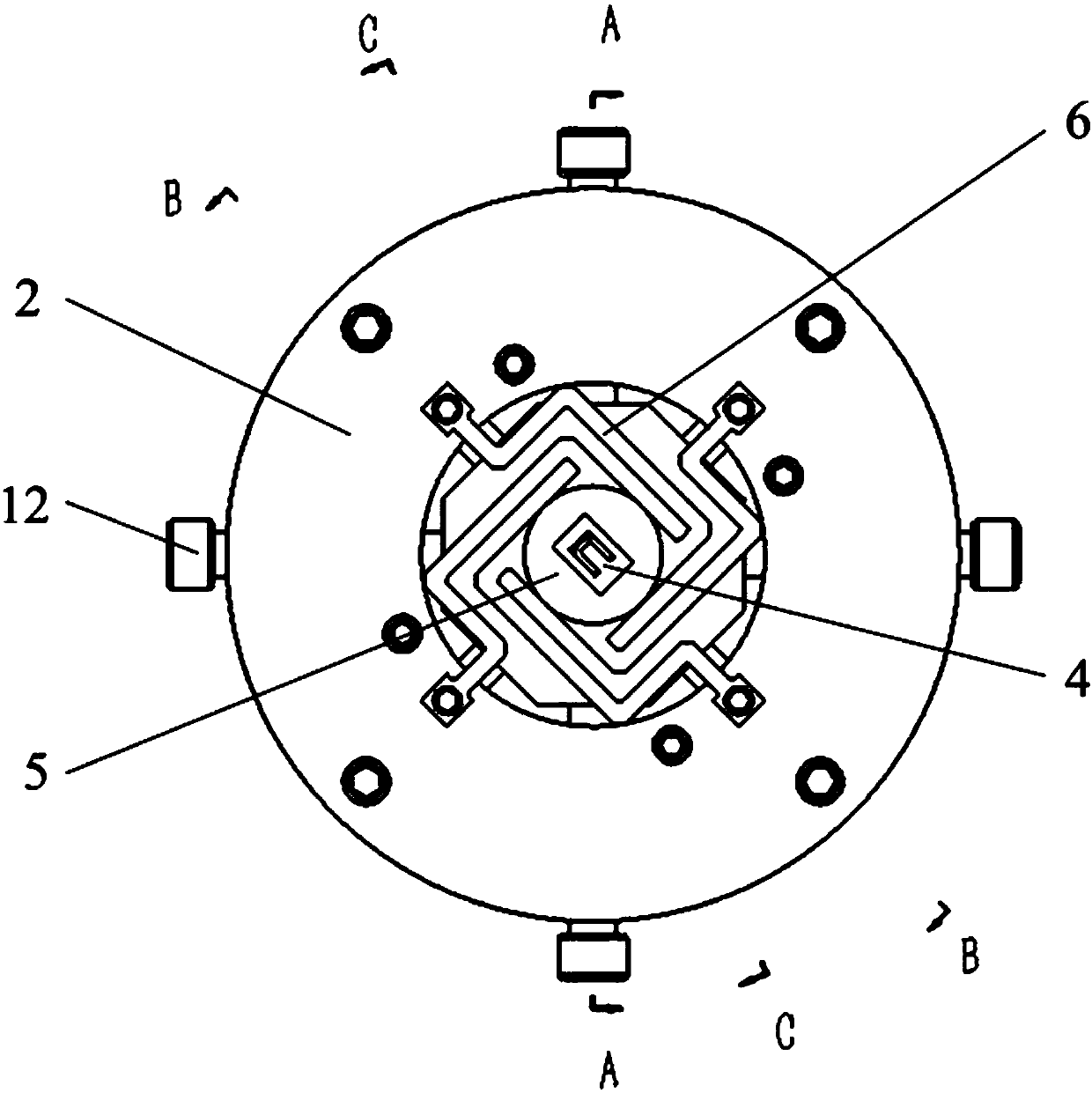

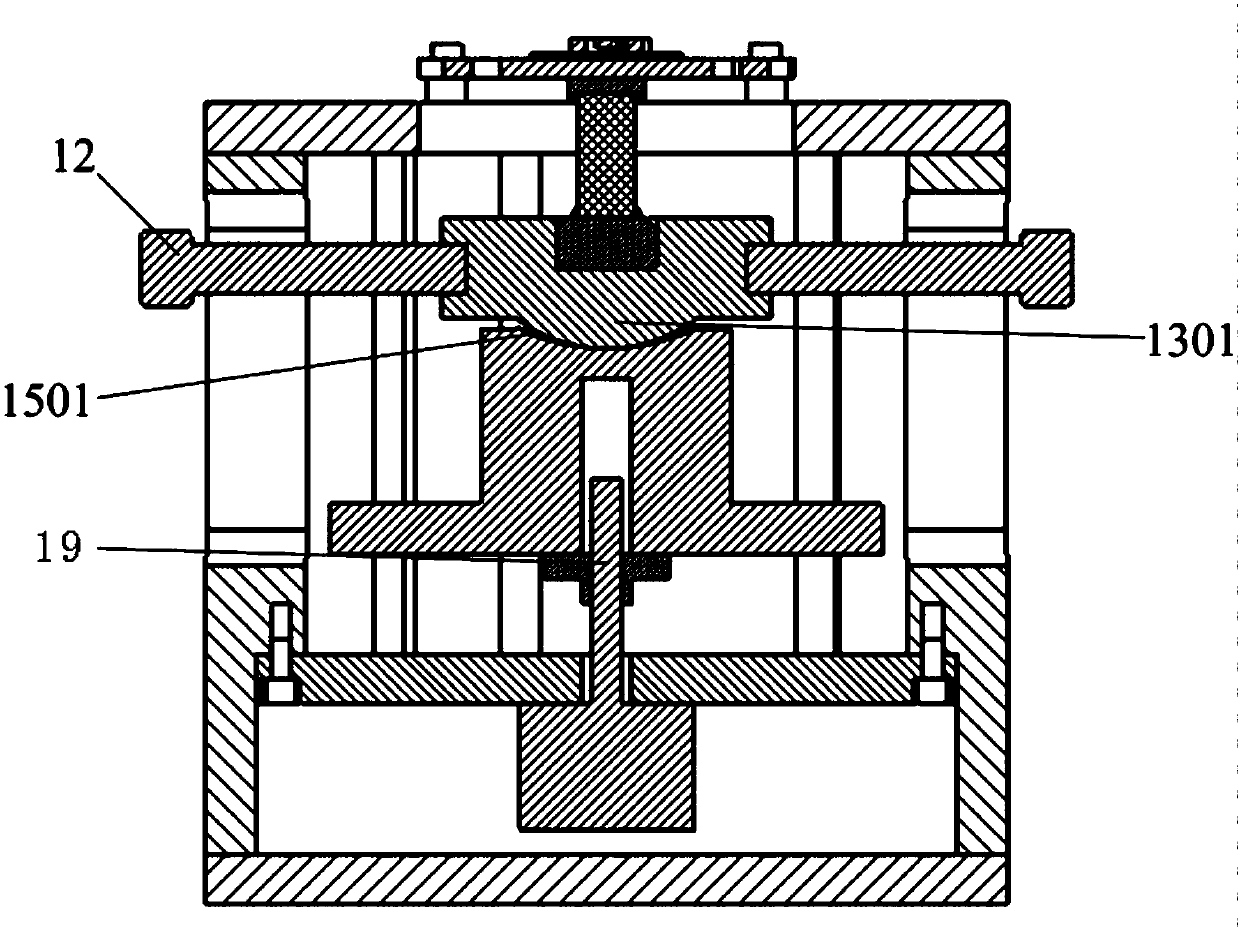

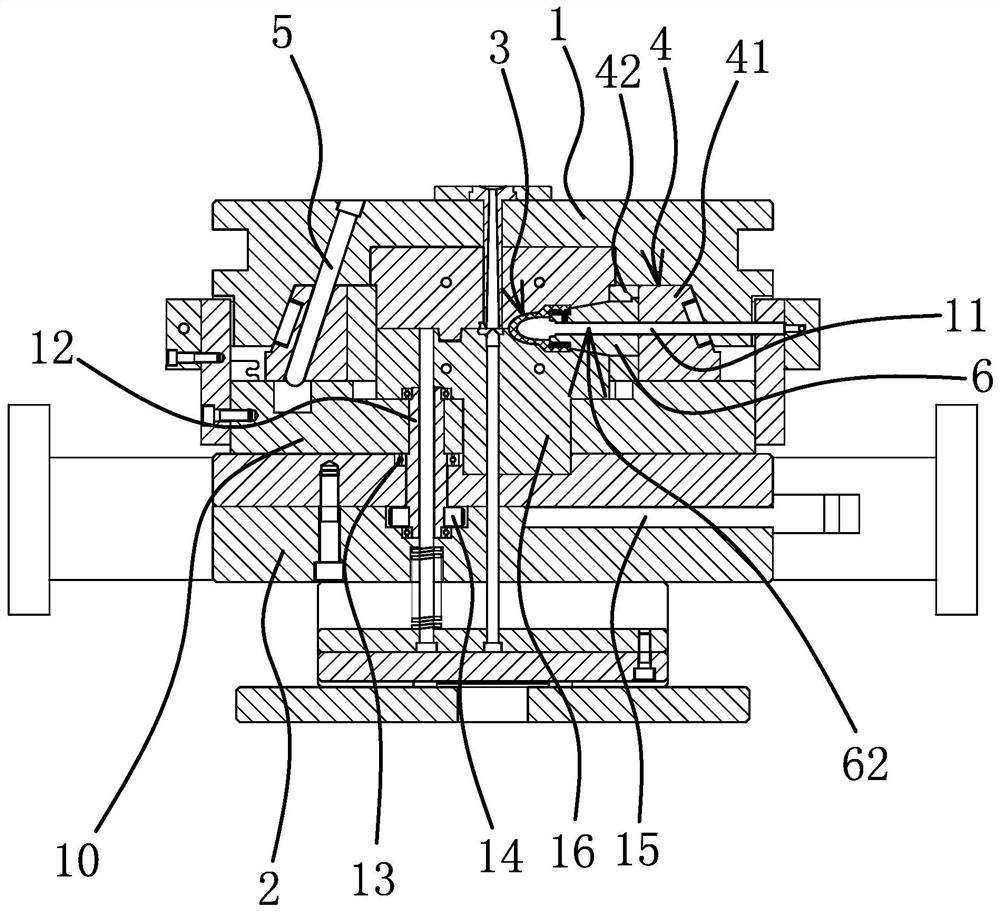

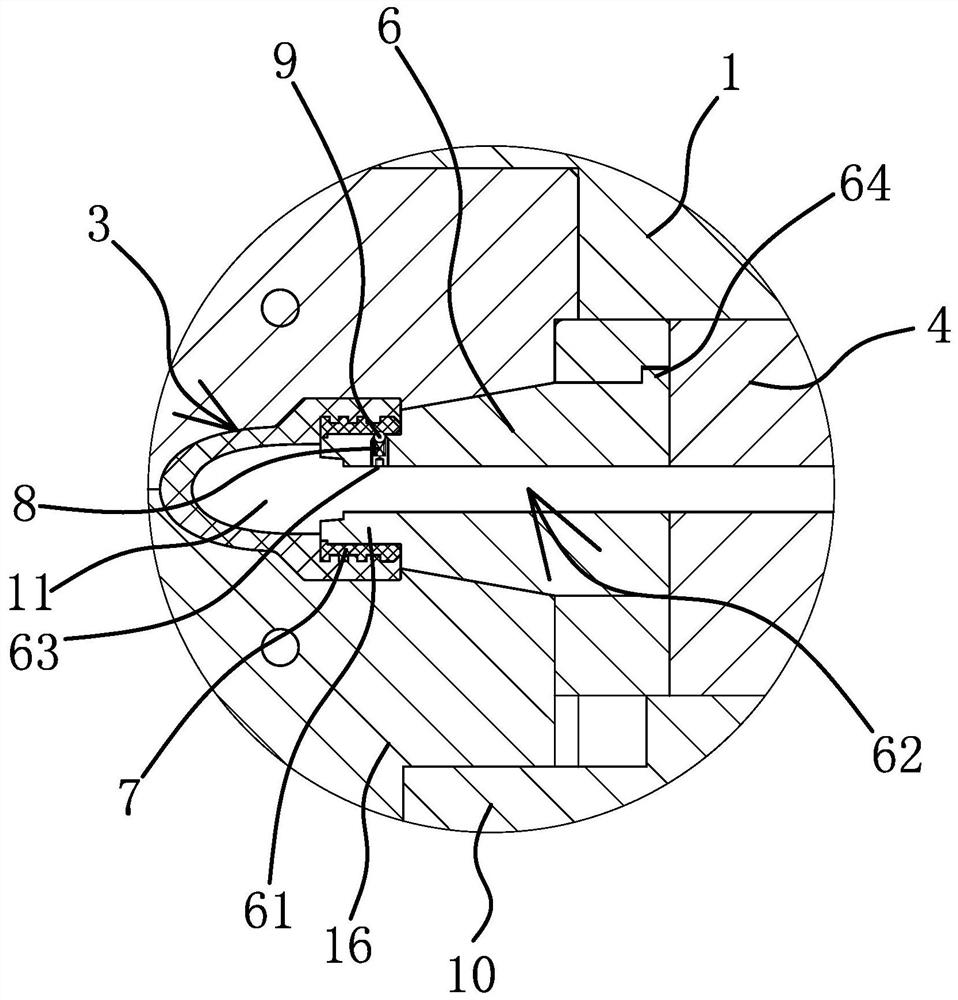

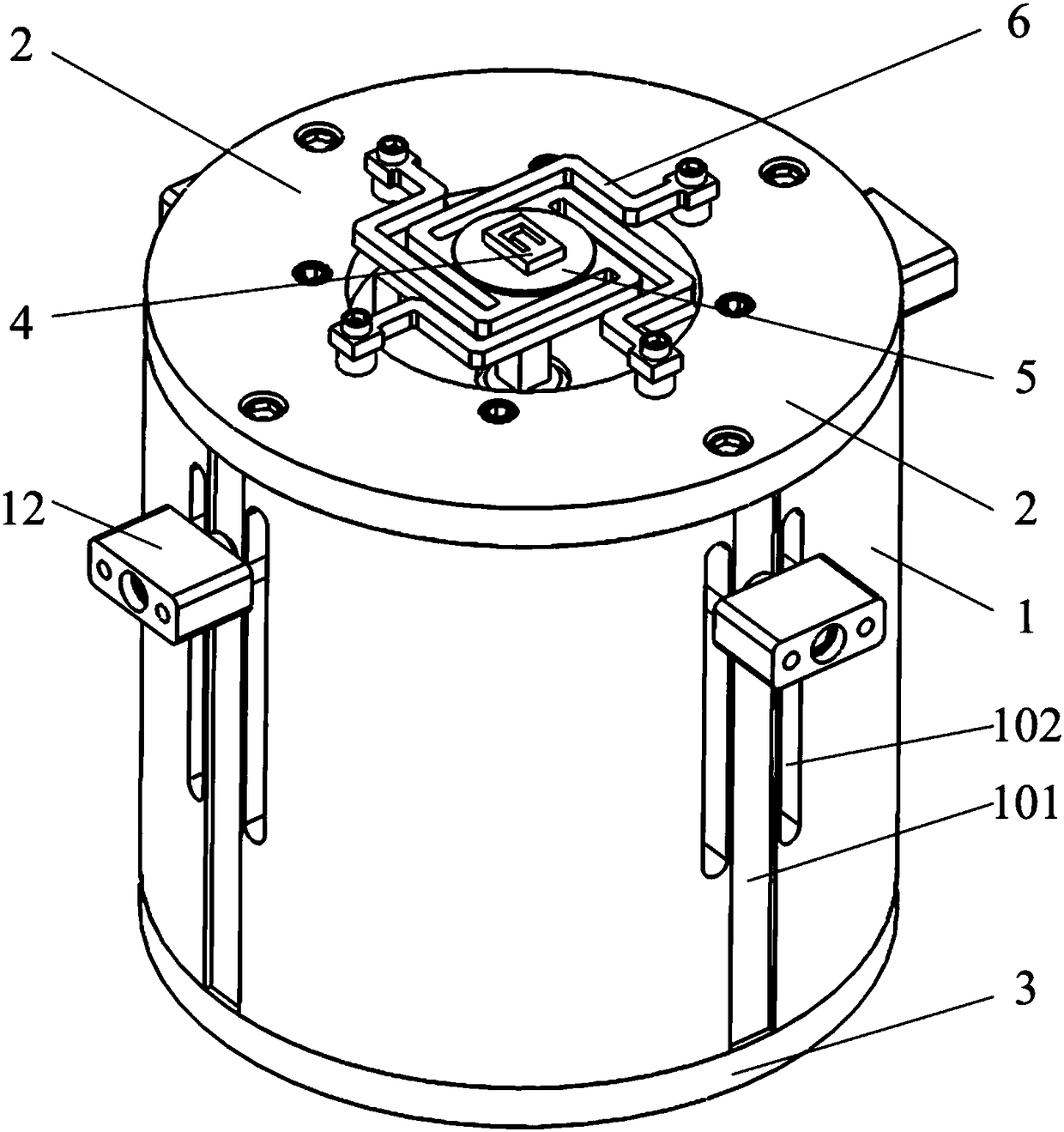

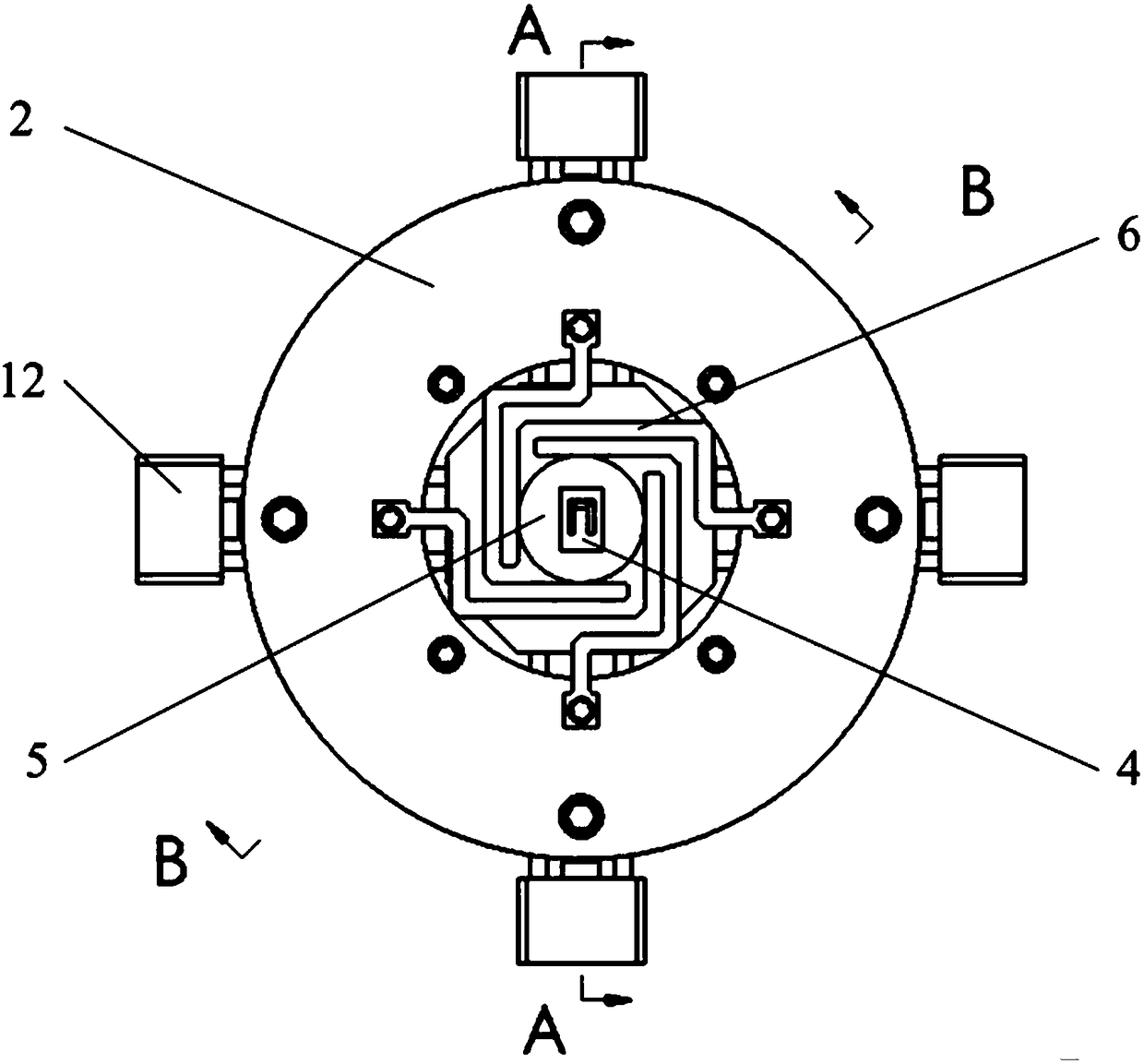

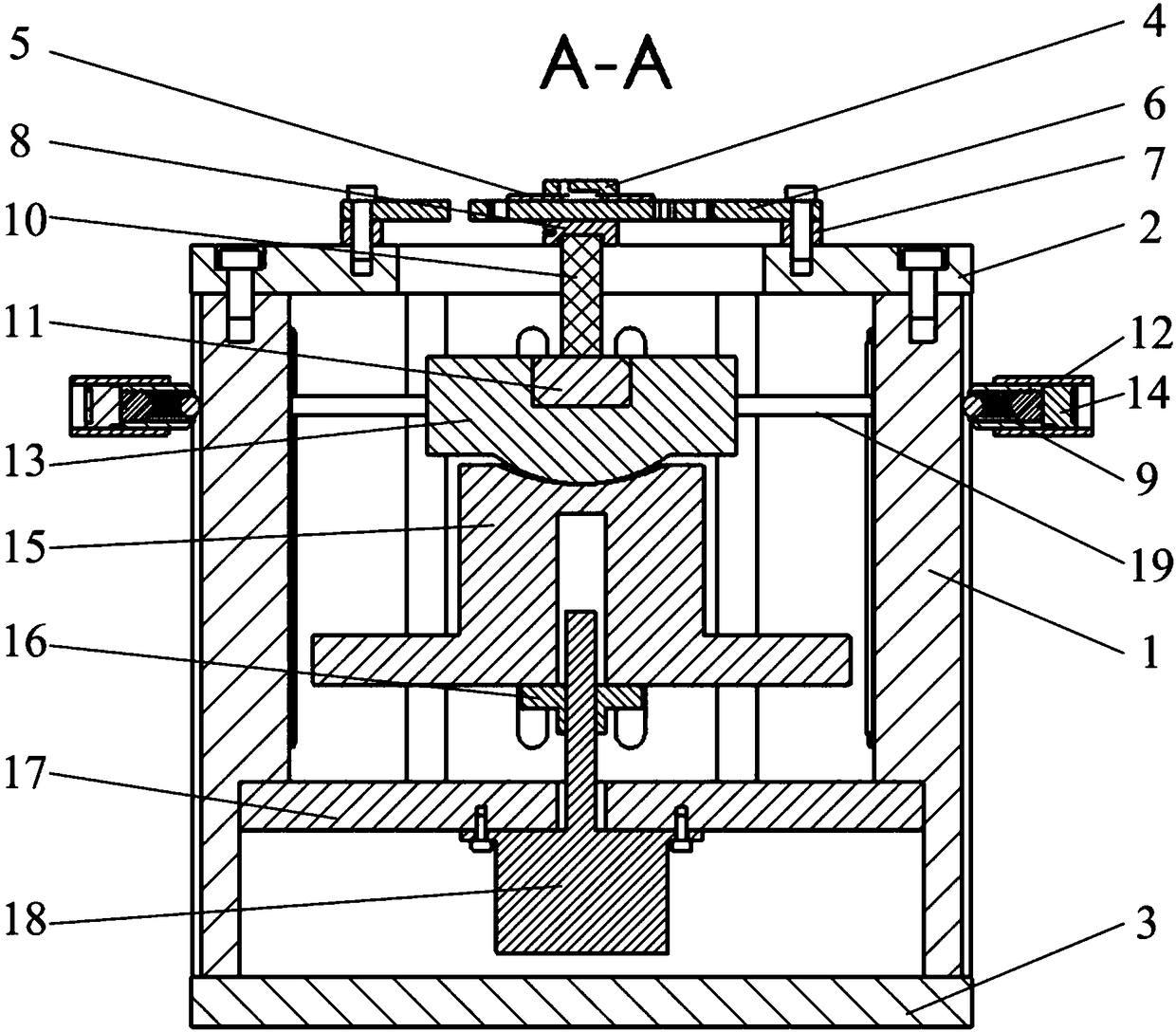

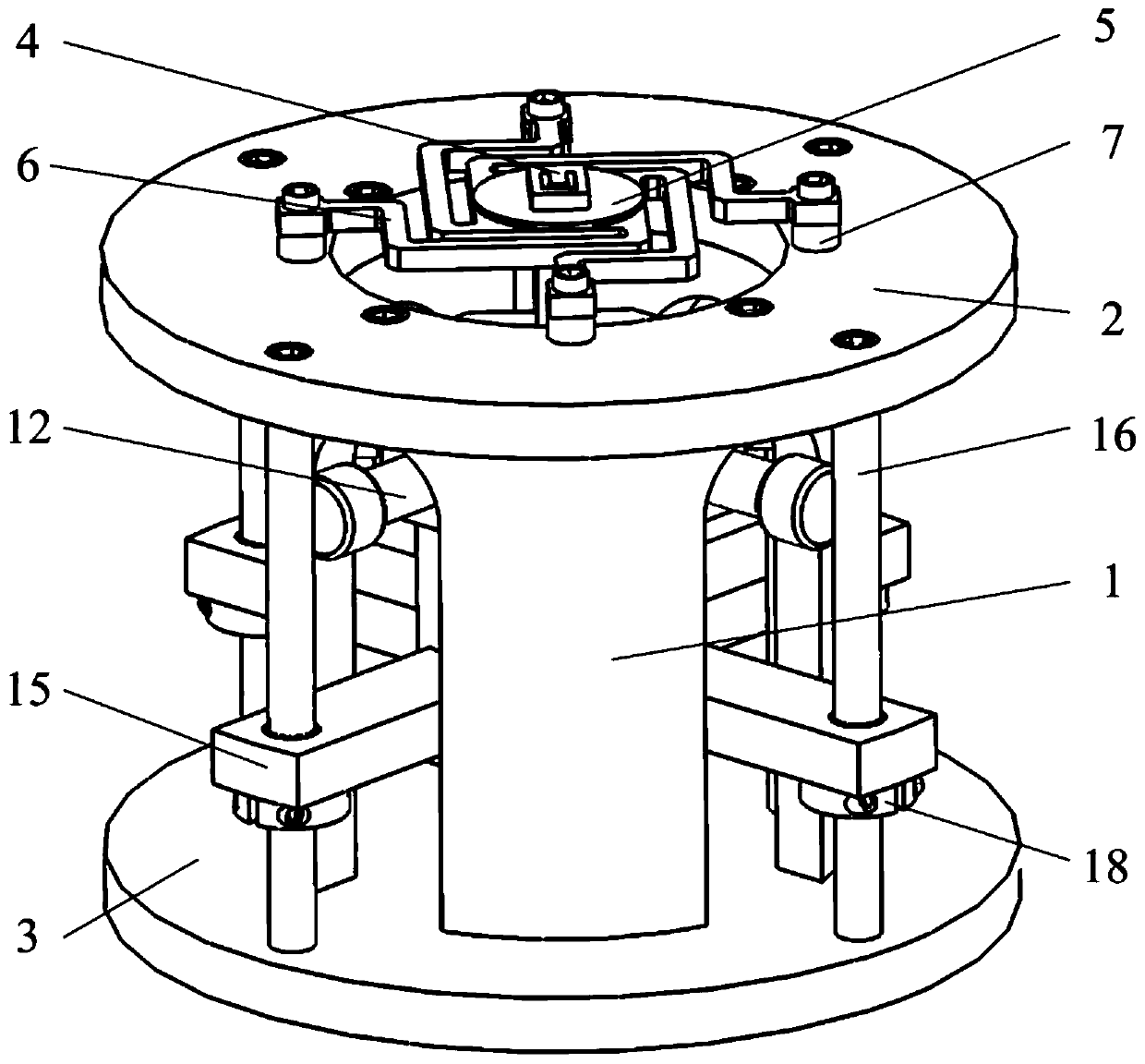

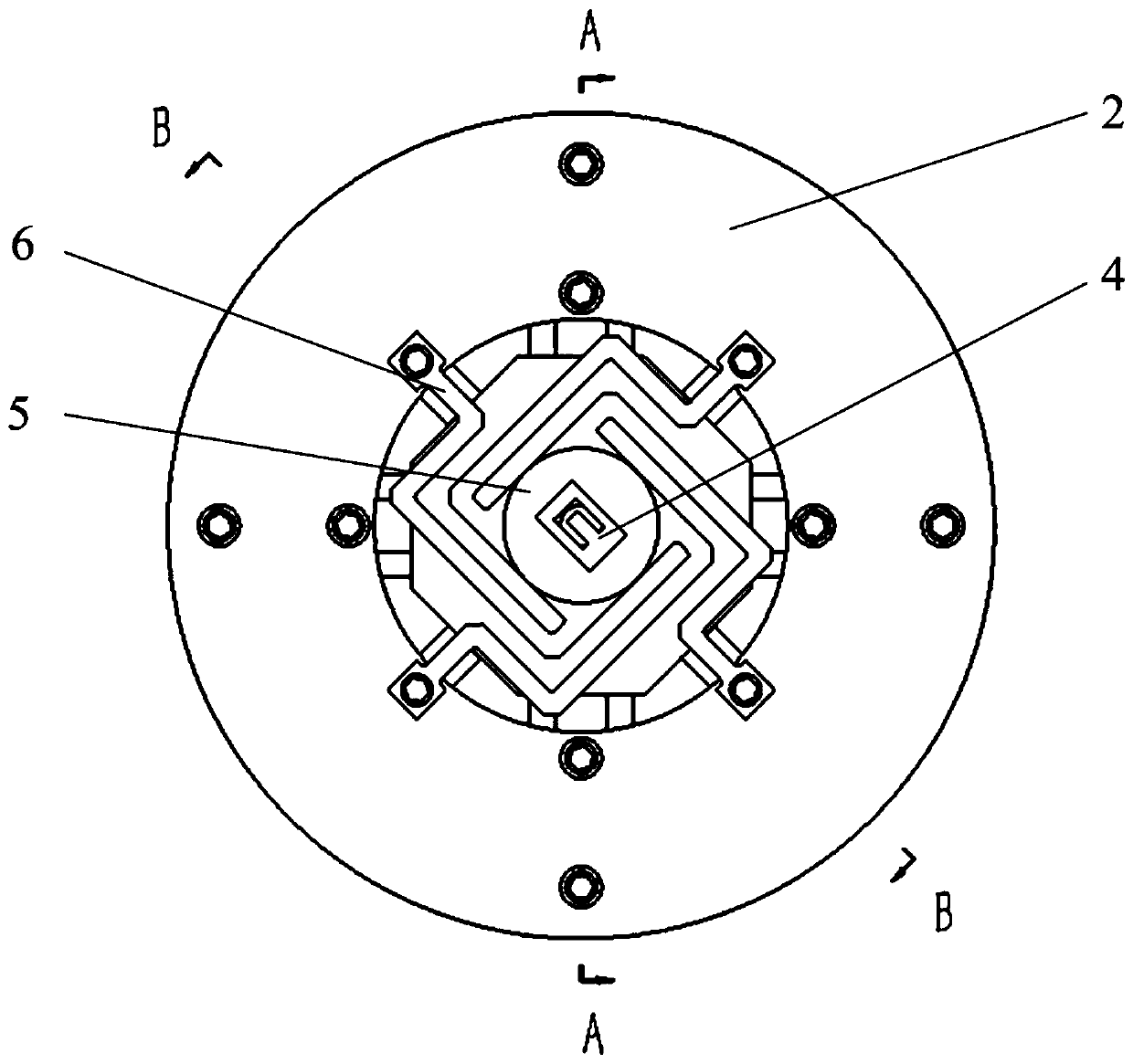

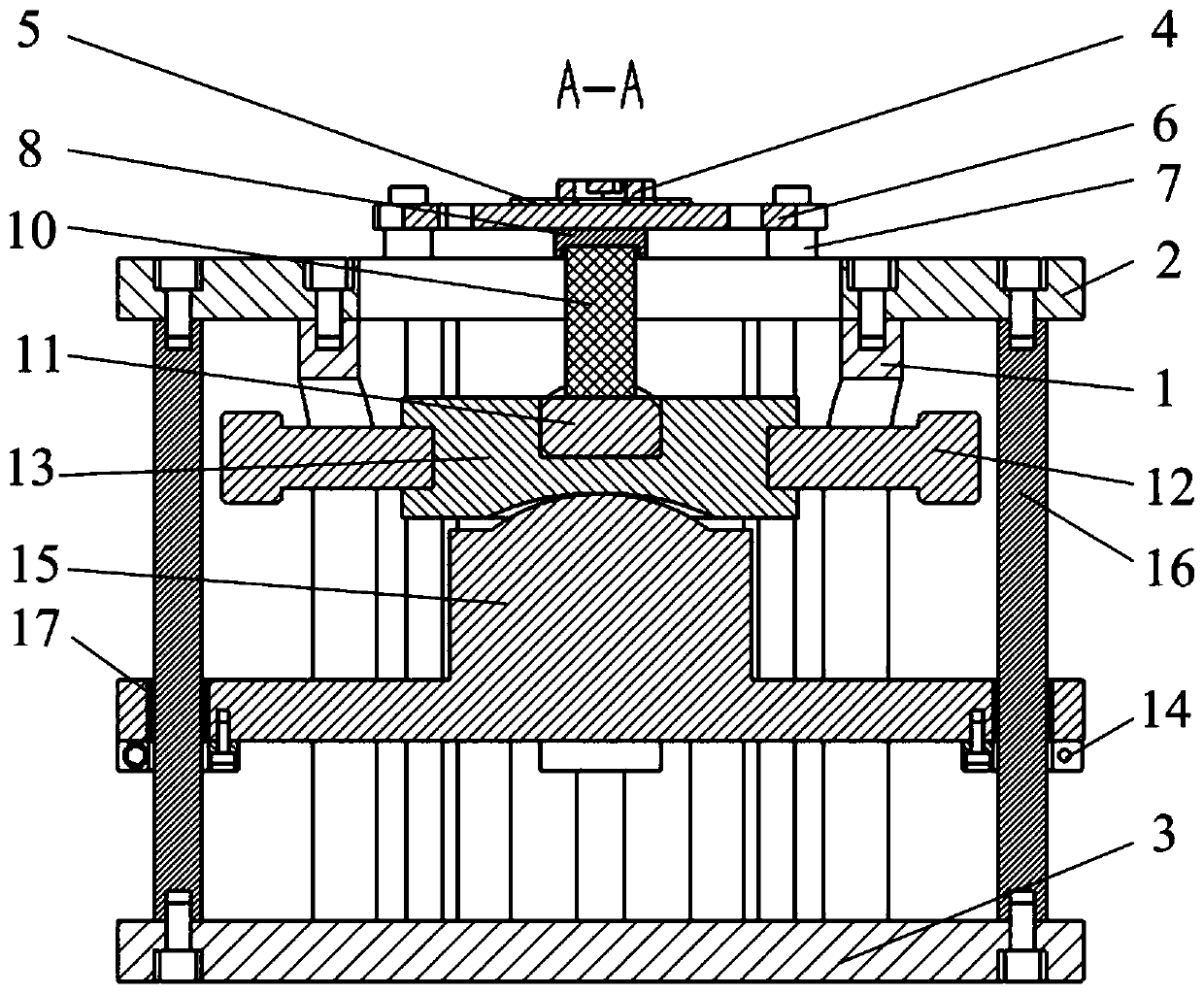

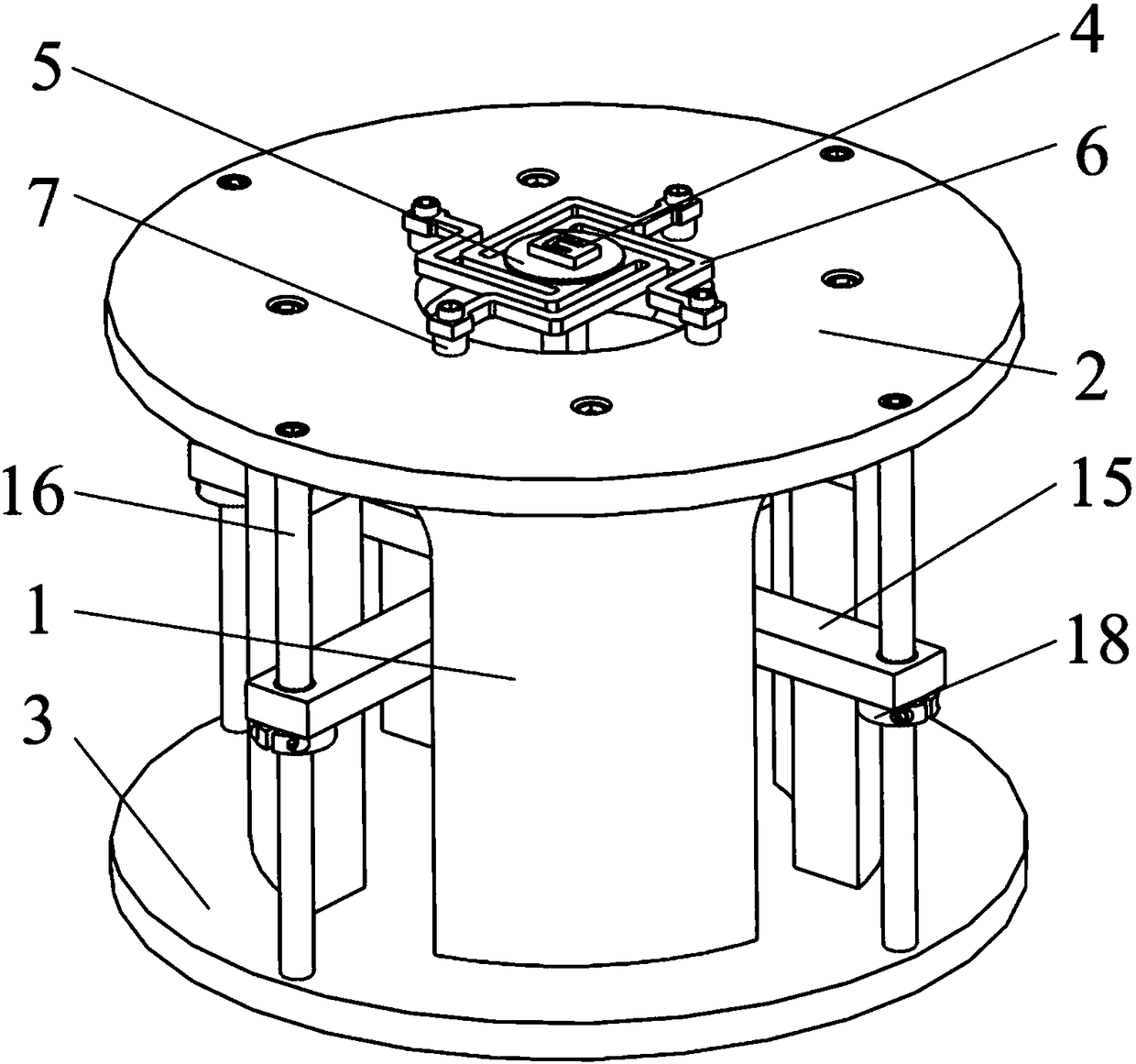

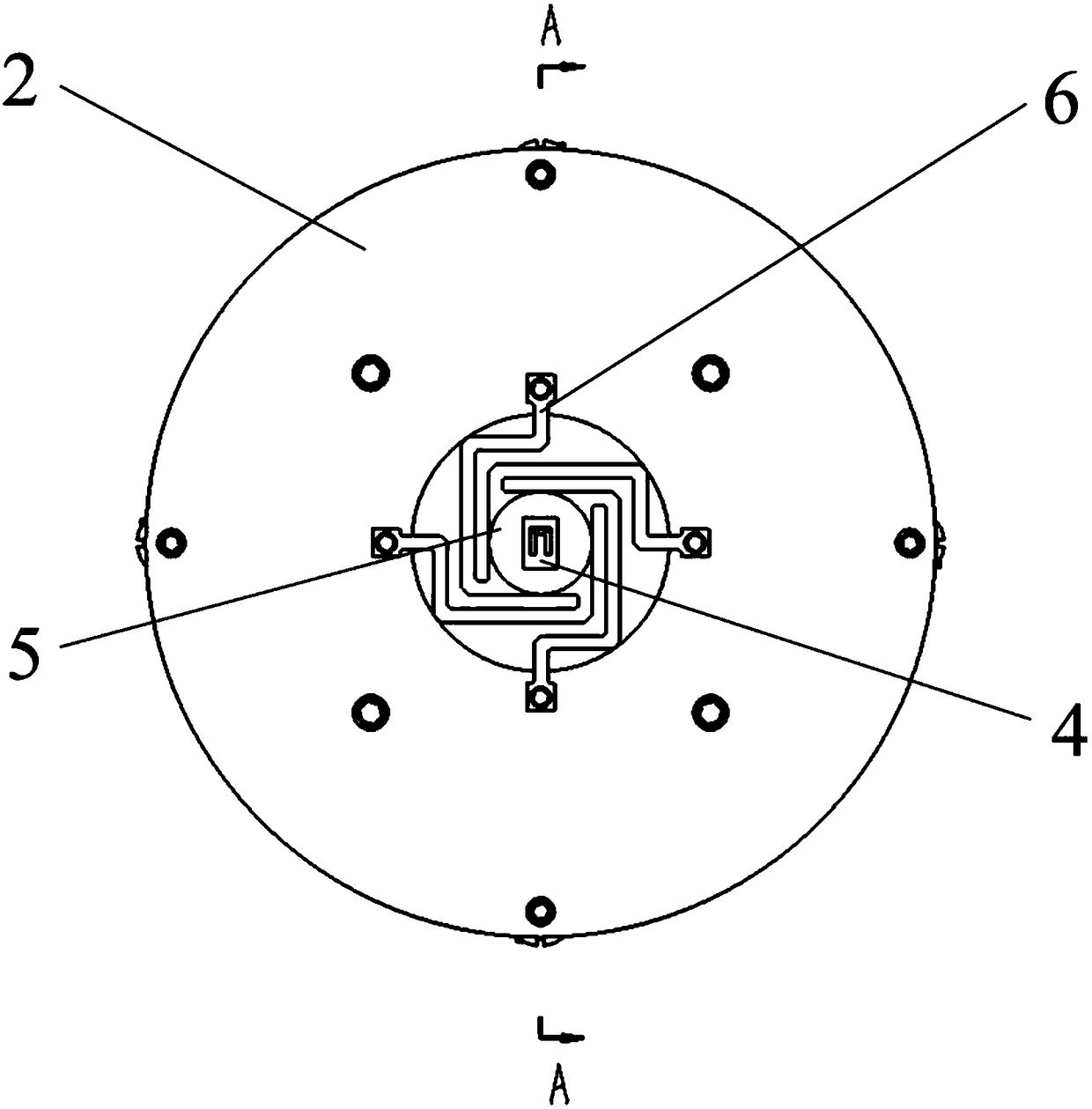

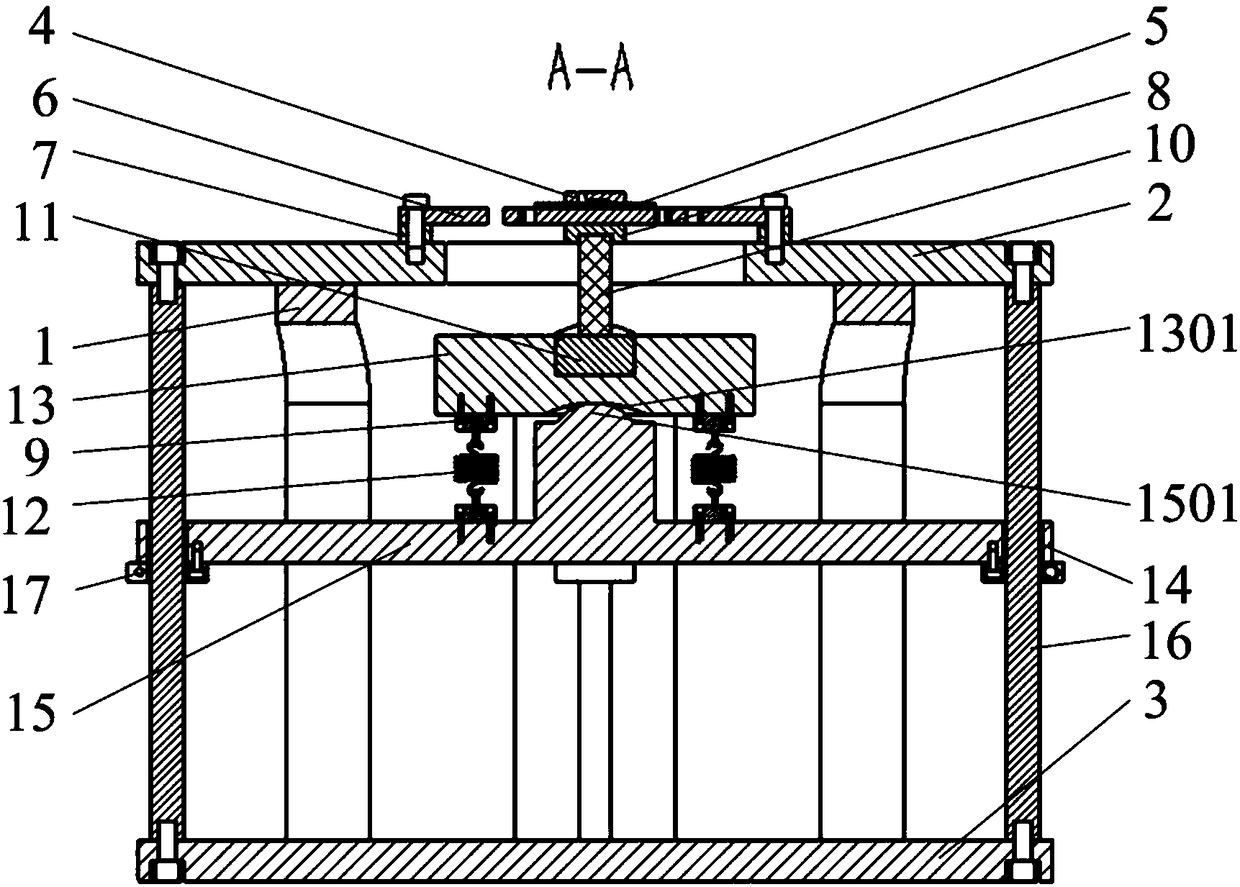

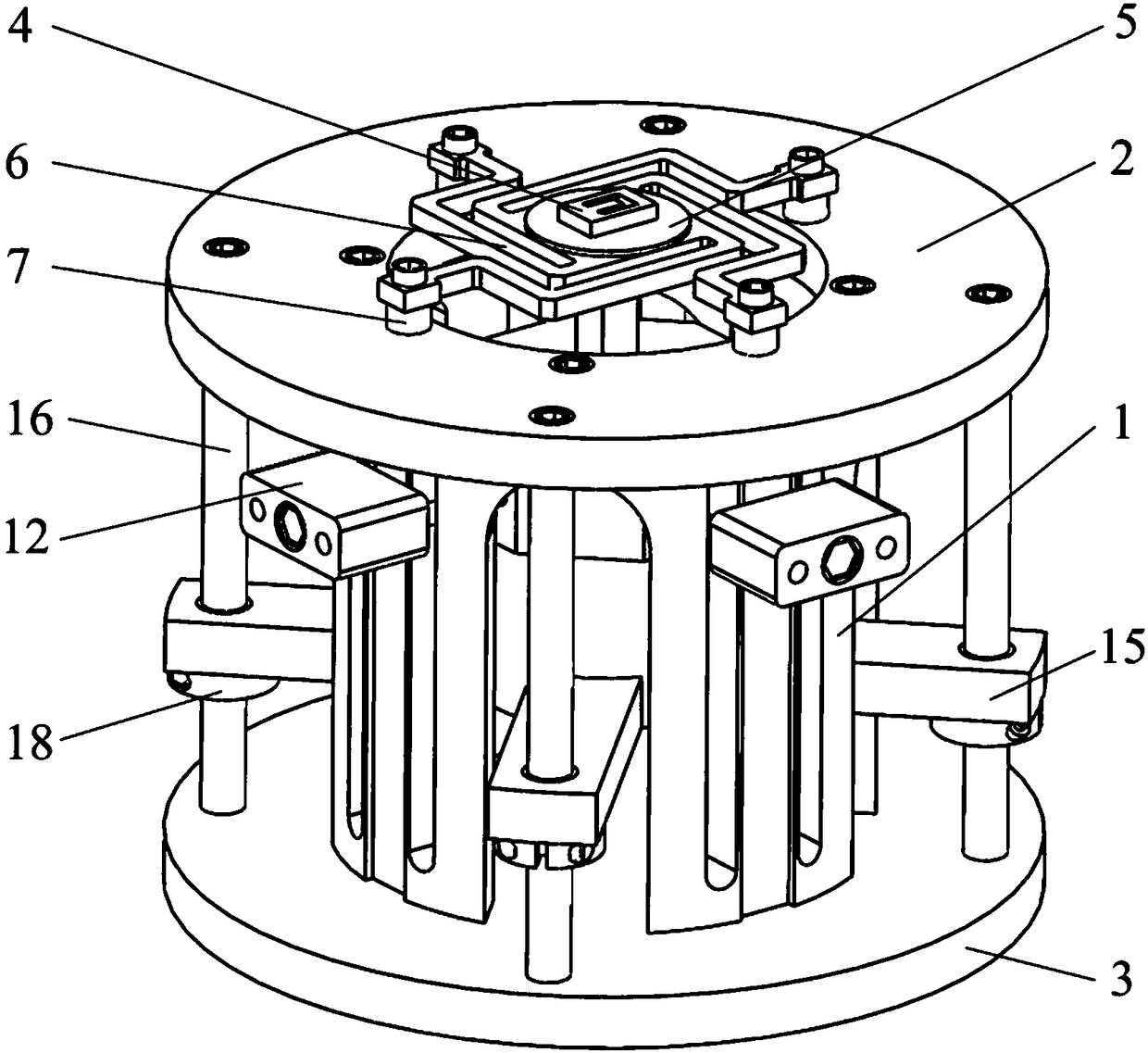

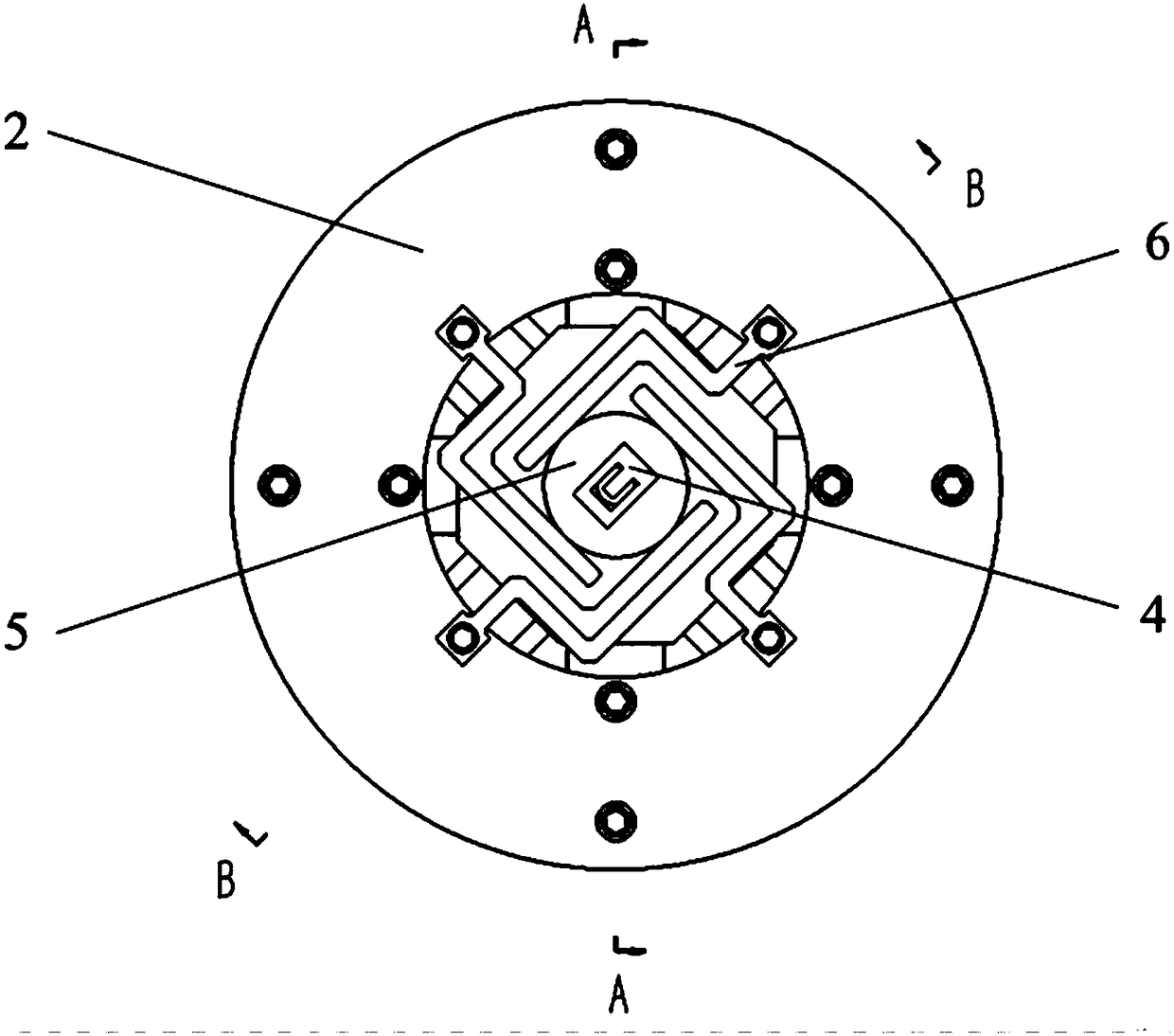

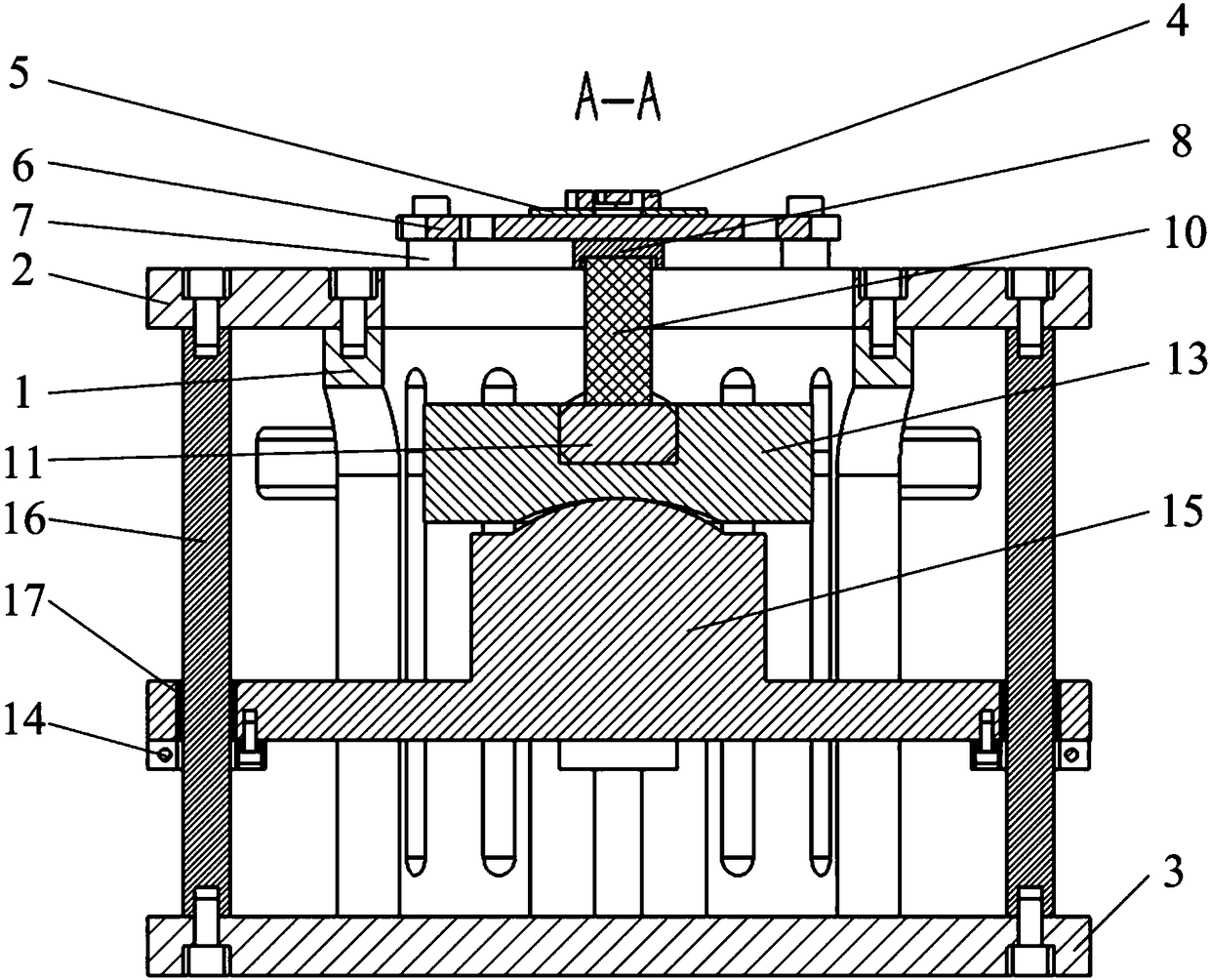

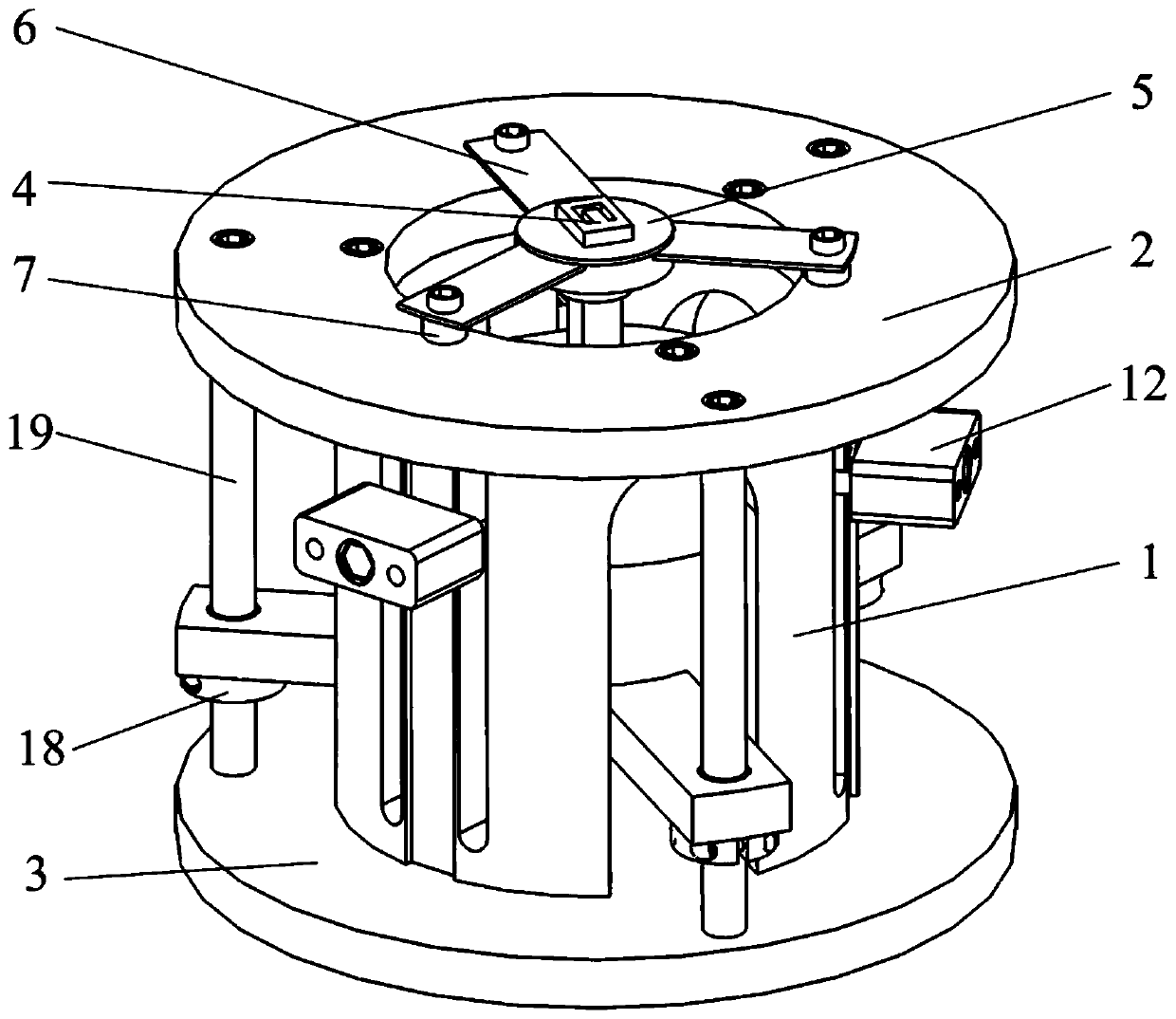

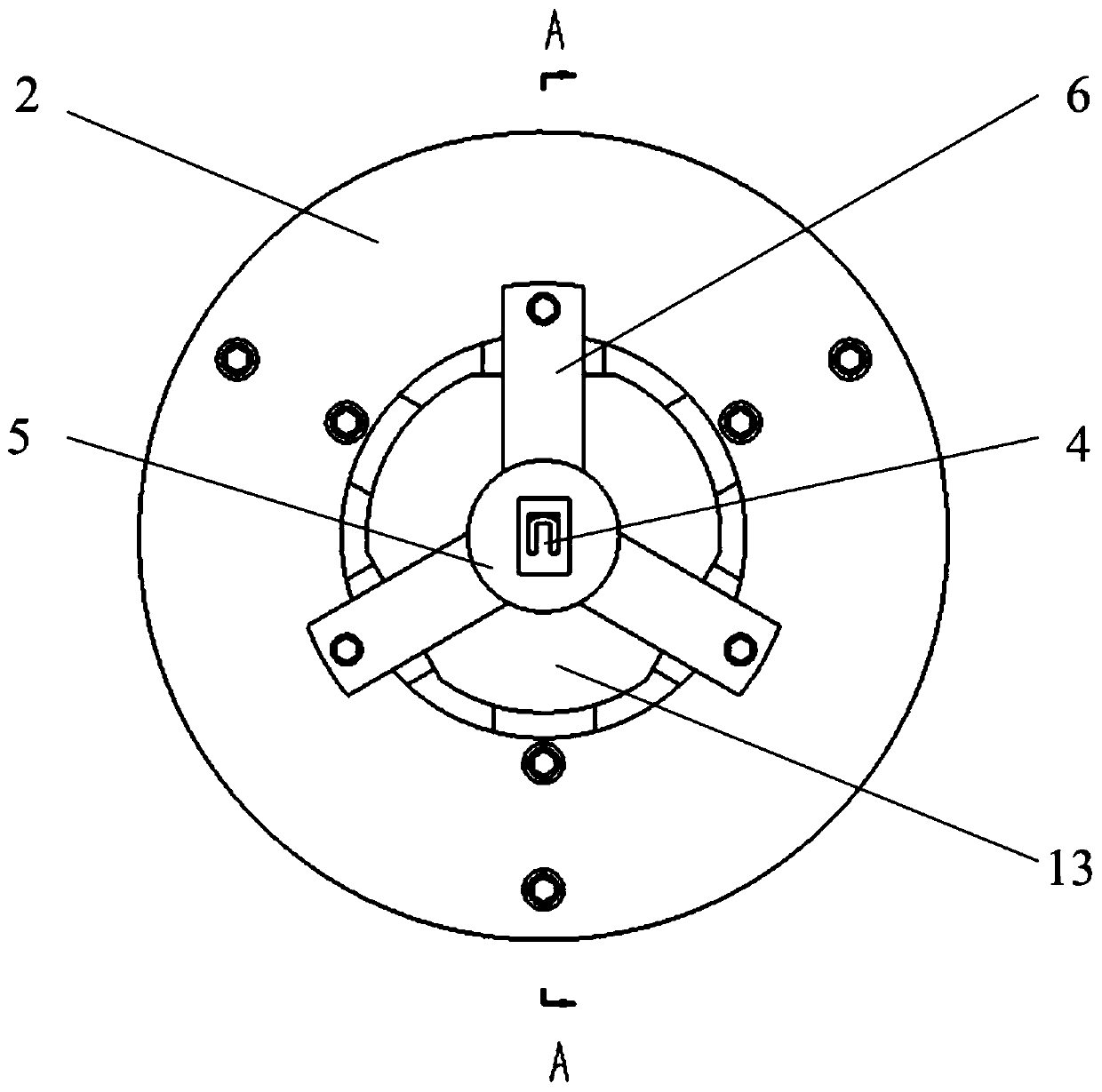

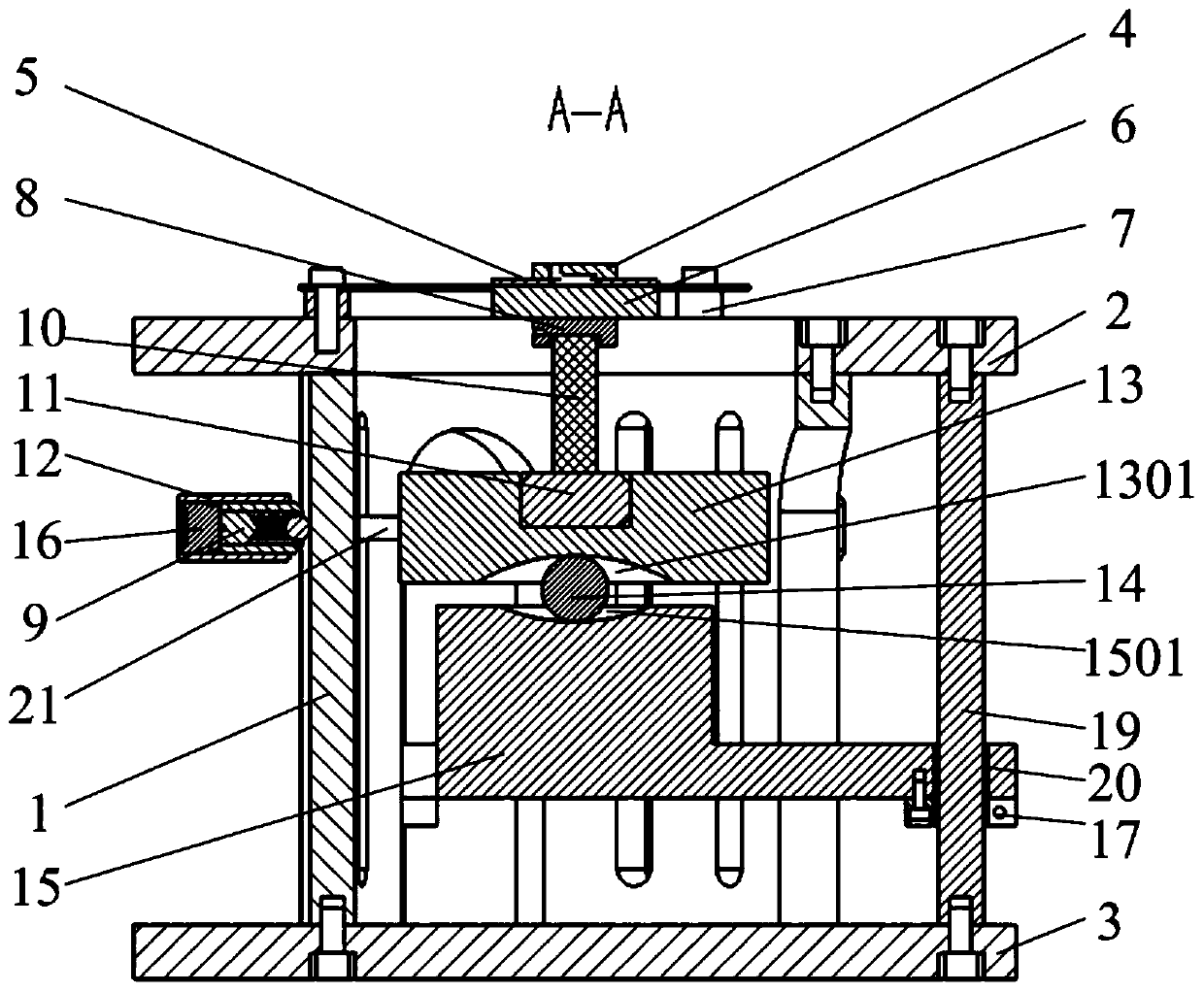

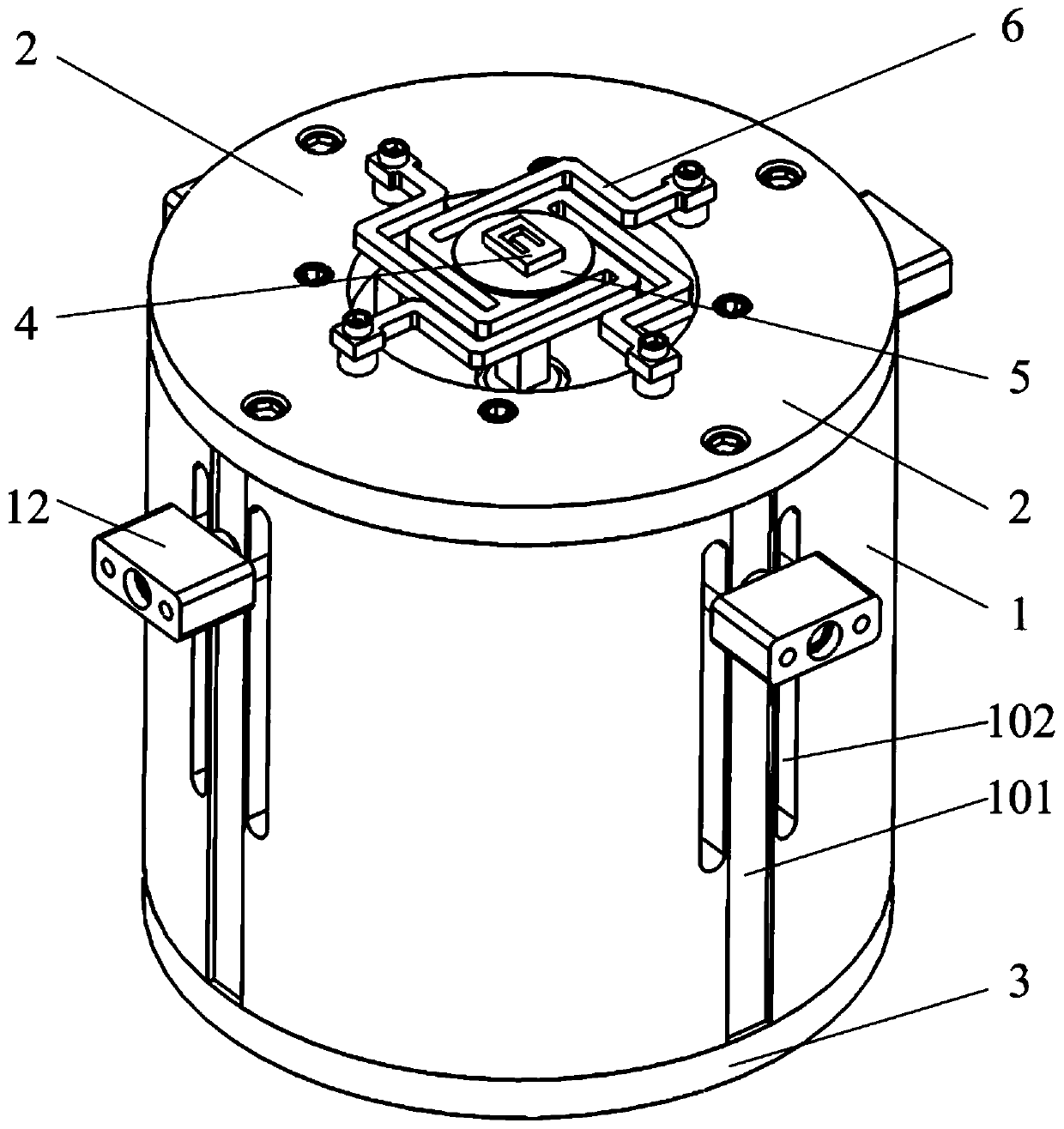

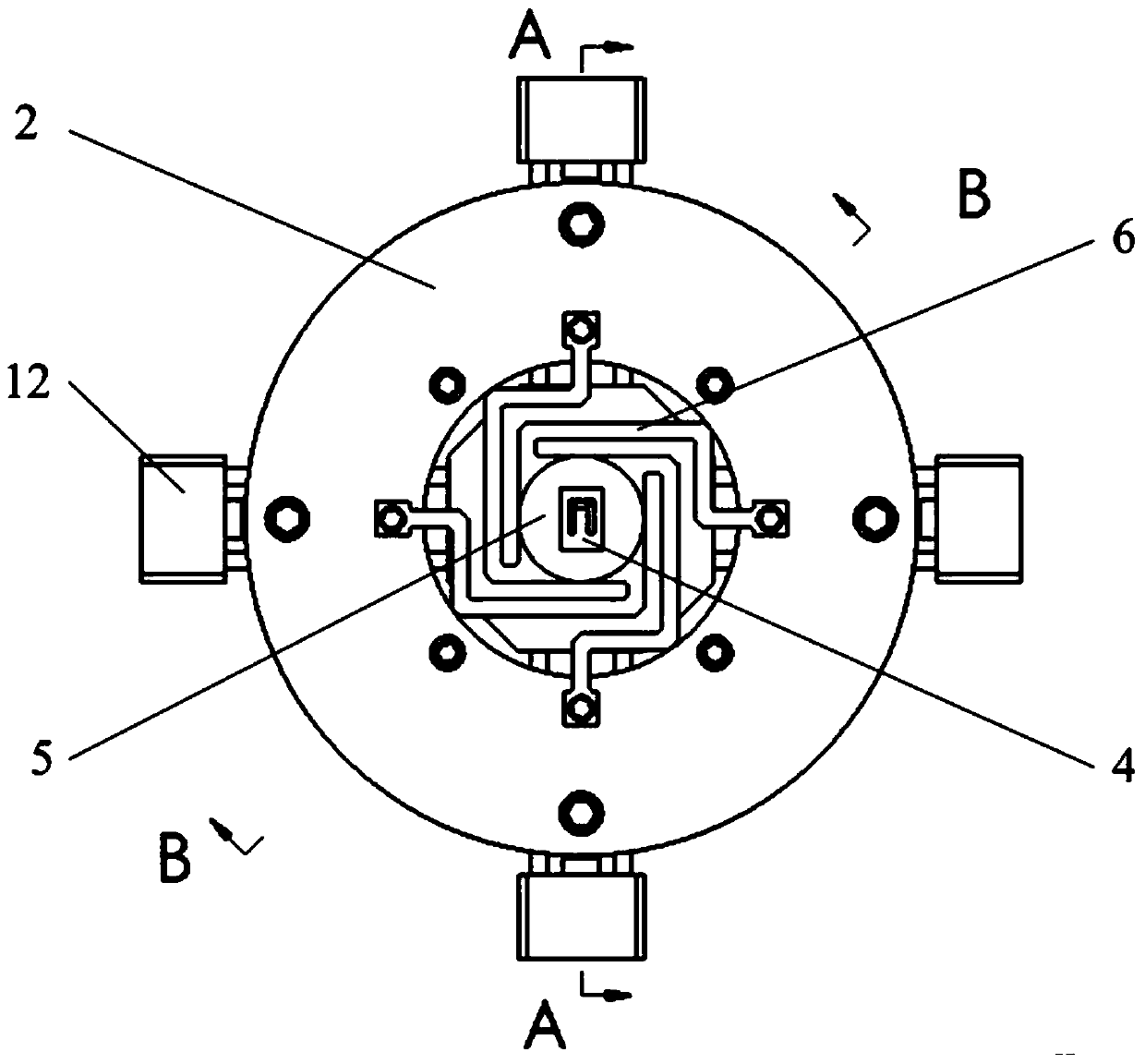

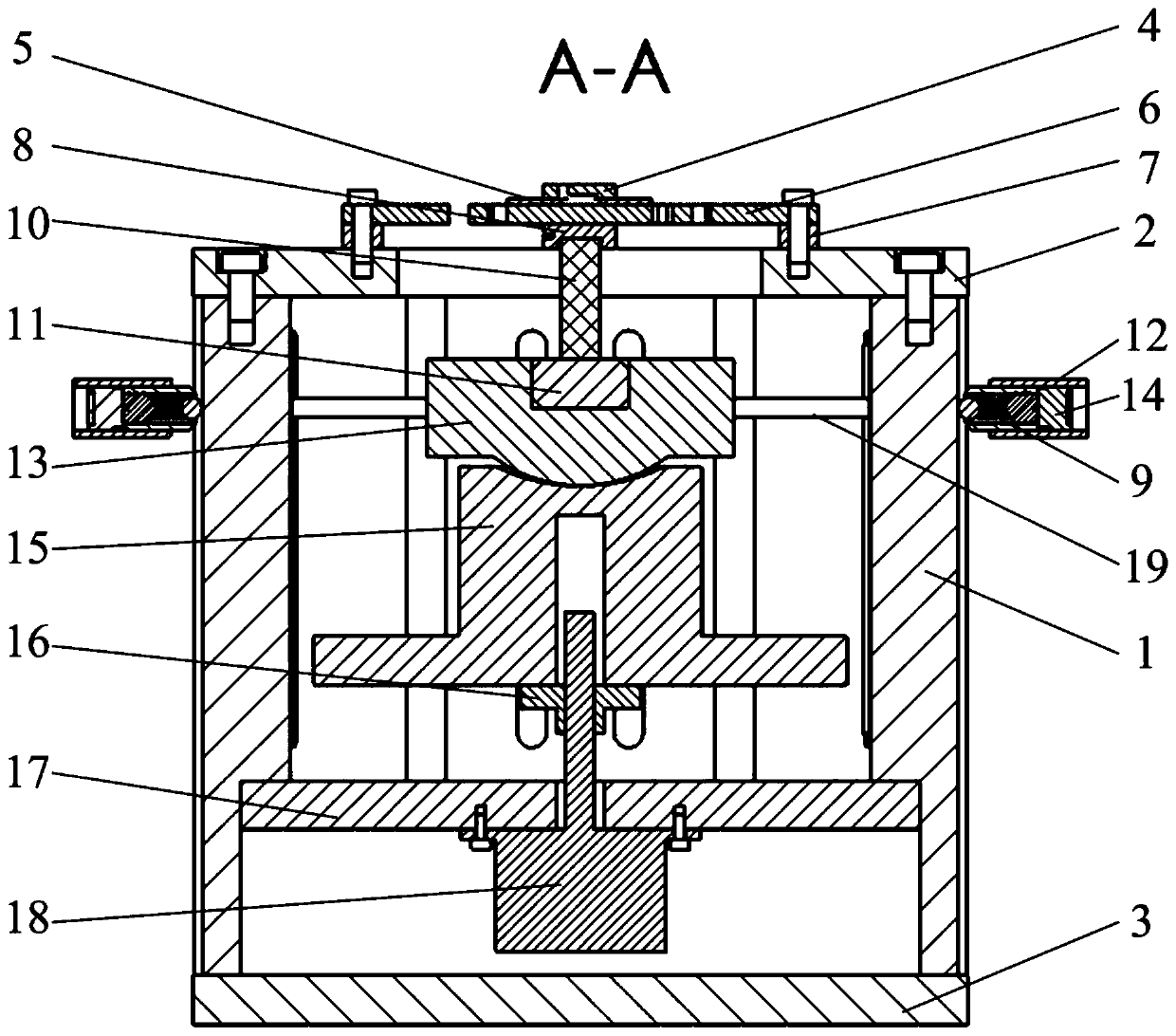

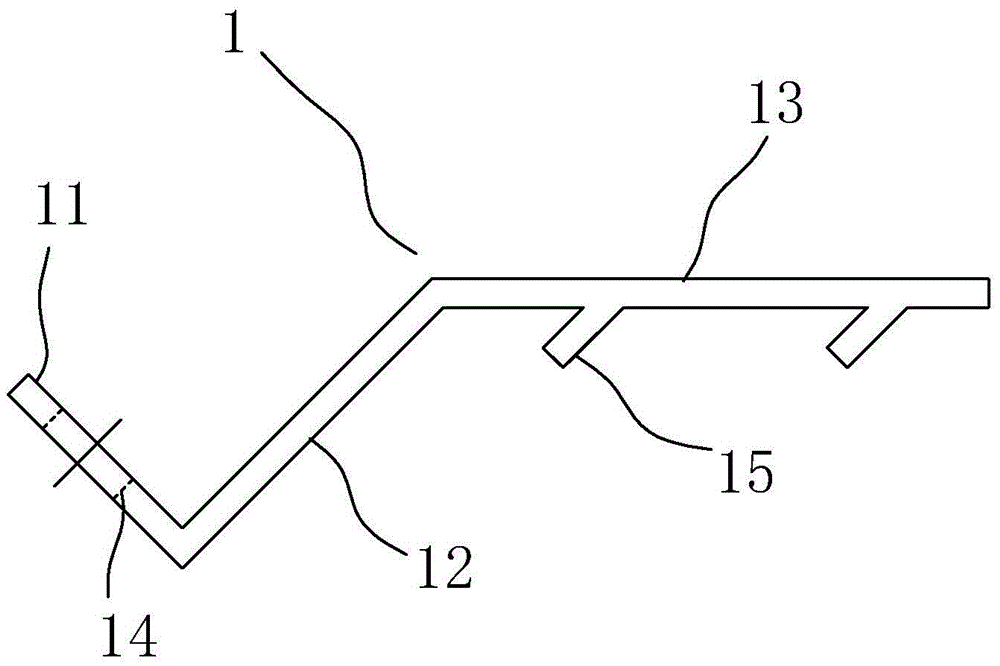

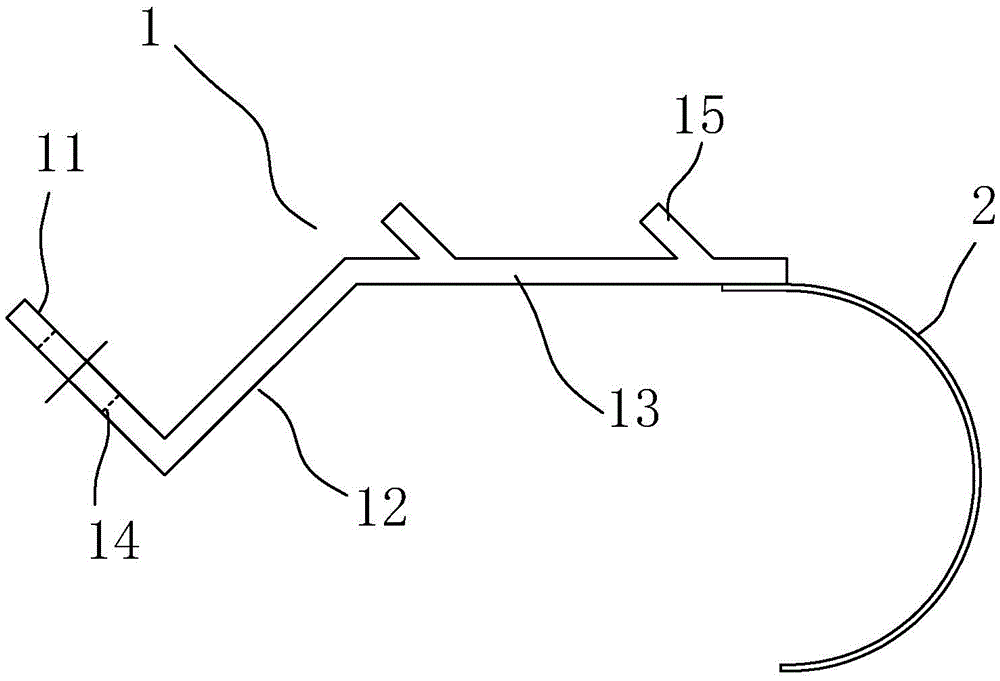

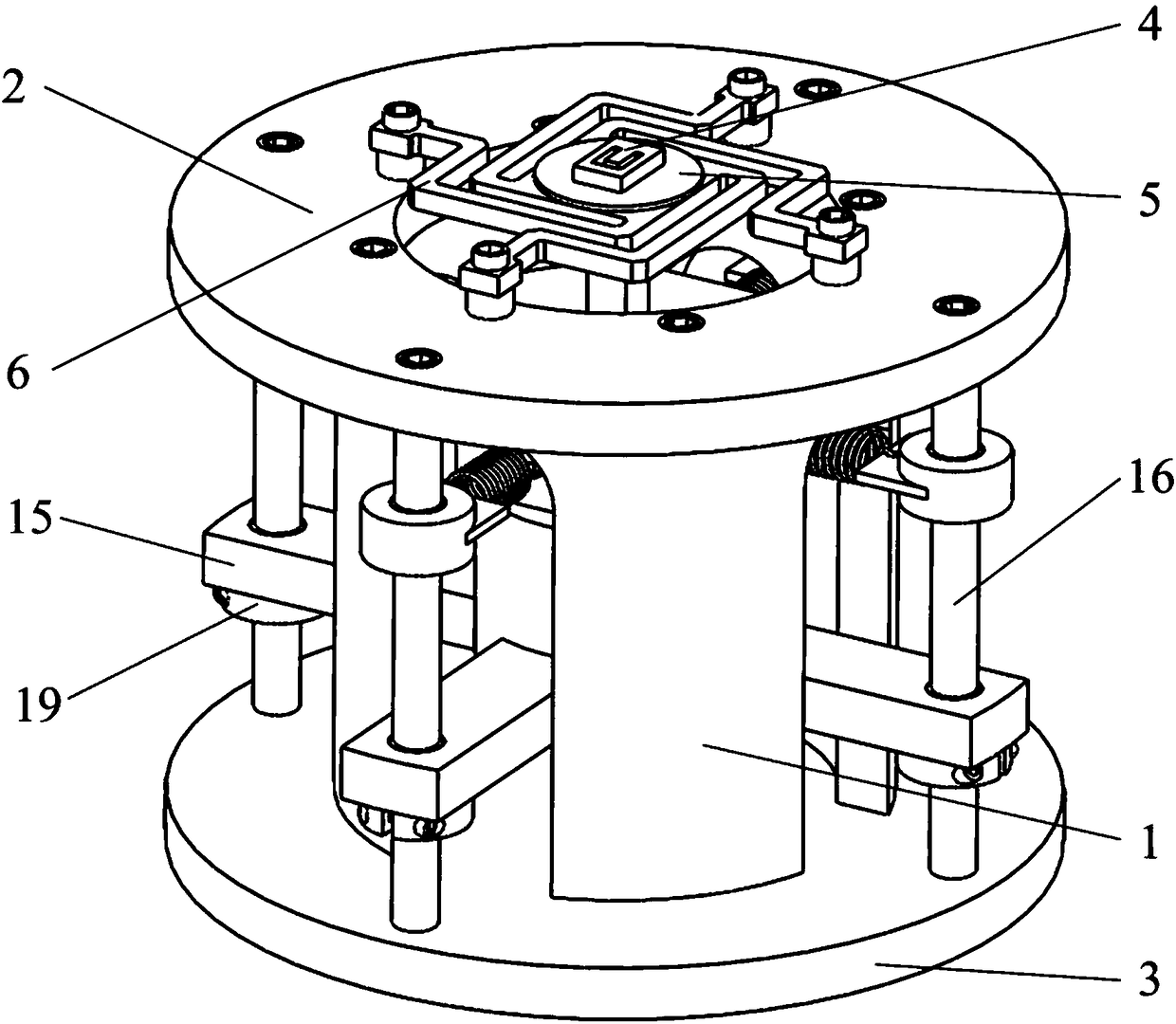

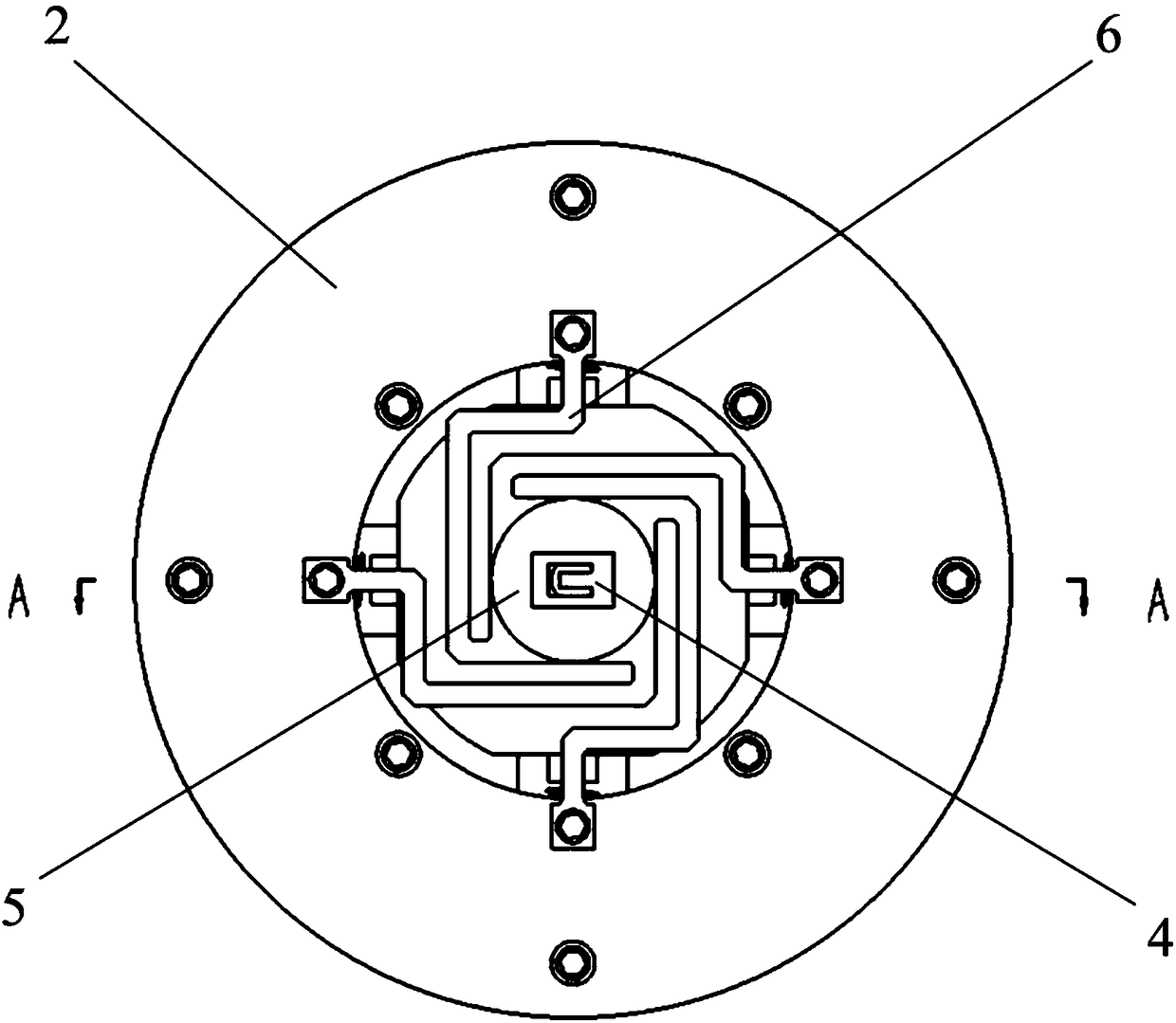

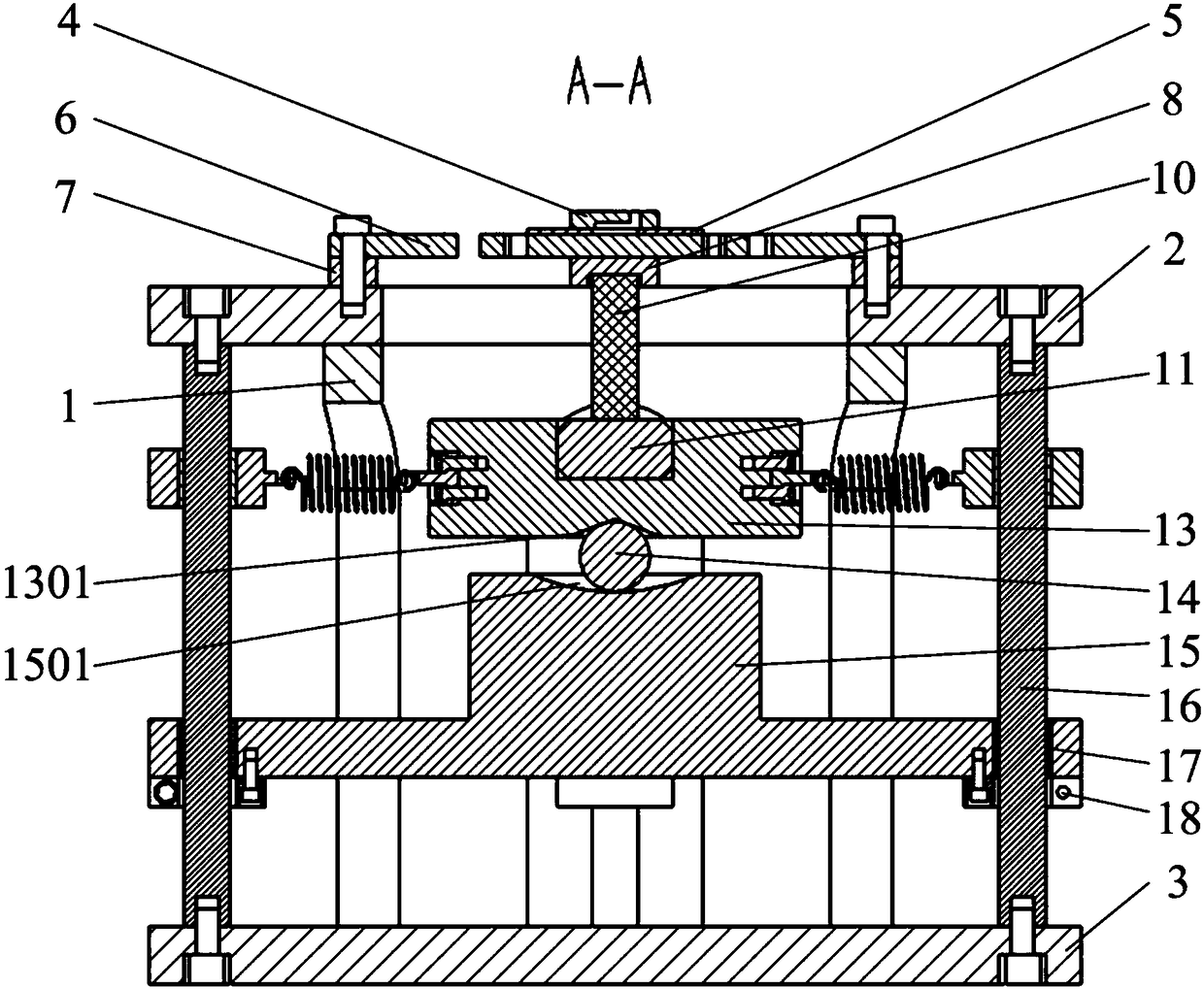

Four-axis type piezoelectric ceramic excitation device for testing dynamic characteristics of MEMS microstructure

The invention discloses a four-axis piezoelectric ceramic excitation device for testing the dynamic characteristics of an MEMS microstructure. The device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, a steel ball, an elastic supporting part and an MEMS microstructure. An annular top plate is arranged at the upper end of the sleeve. The microstructure is arranged on the annular top plate through the elastic supporting piece. Guide shafts are uniformly distributed between the annular top plate and the bottom plate. The lower connecting block is provided with guide supporting arms. The guide supporting arms penetrate through the wall of the sleeve to be sleeved on the guide shafts. Locking devices are arranged on the guide supporting arms respectively. Spherical grooves are formed in the upper connecting block and the lower connecting block respectively. The piezoelectric ceramic is clamped between thepressure sensor and the elastic supporting part. The outer edge of the upper connecting block is jacked into the inner wall of the sleeve through a ball head plunger. According to the device, pre-tightening forces of different sizes can be applied to the piezoelectric ceramic, and the obtained measurement values of pre-tightening forces are more accurate. As a result, the adjustment process for compensating the parallelism error between two working surfaces of the piezoelectric ceramic becomes more smooth and smoother. As a result, dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

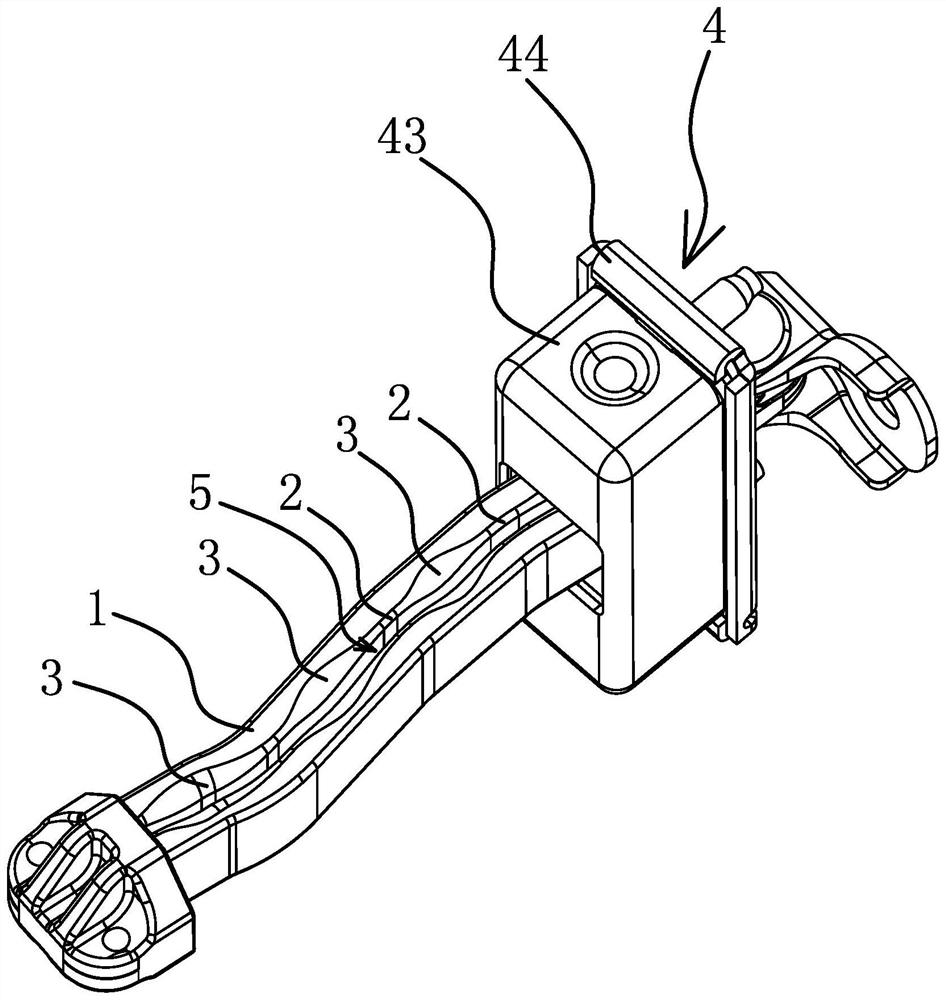

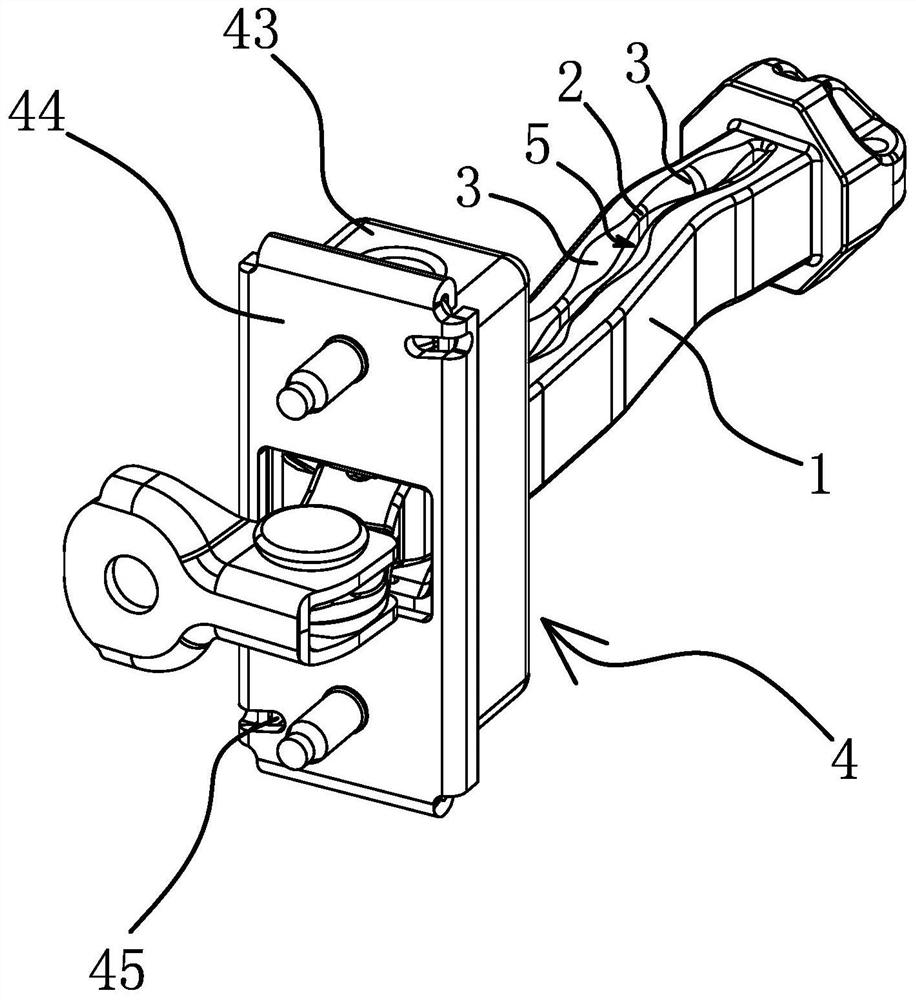

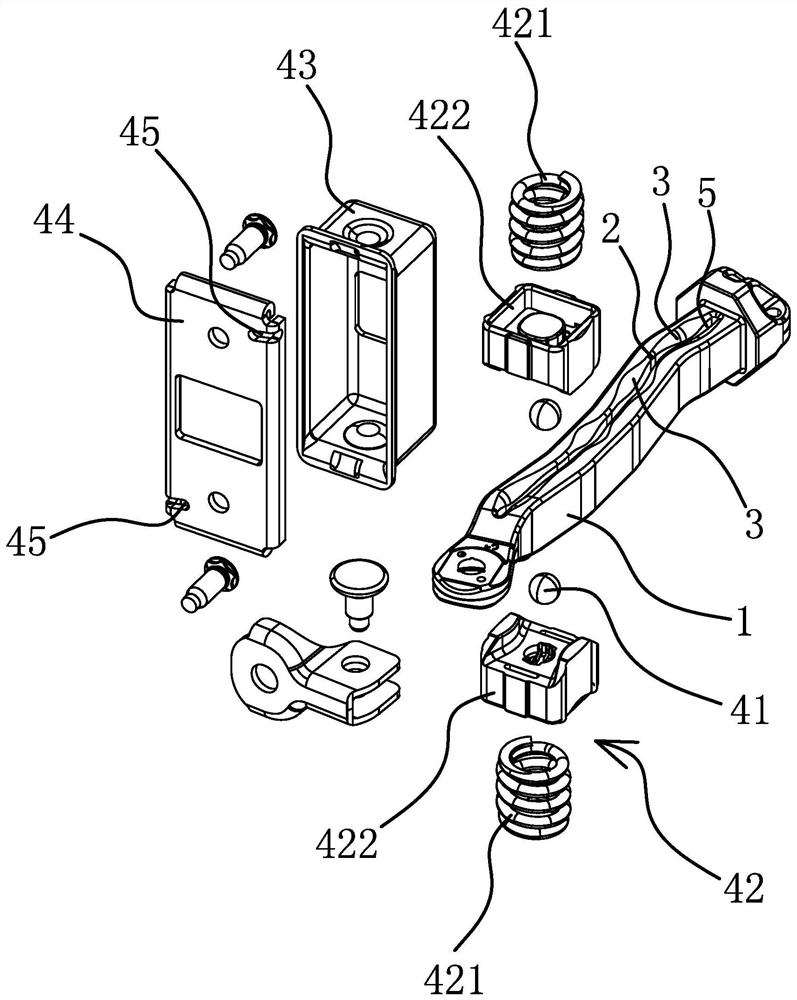

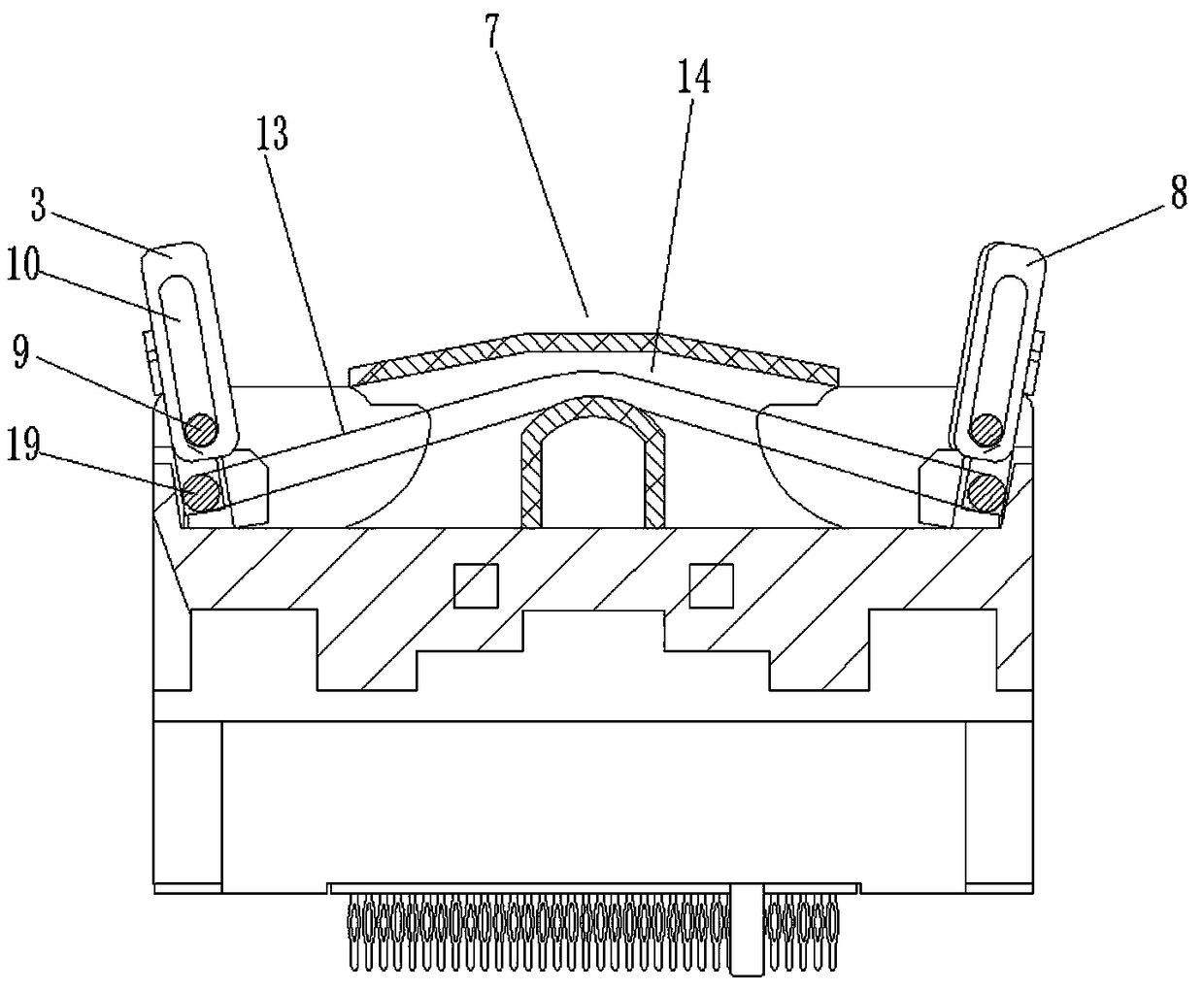

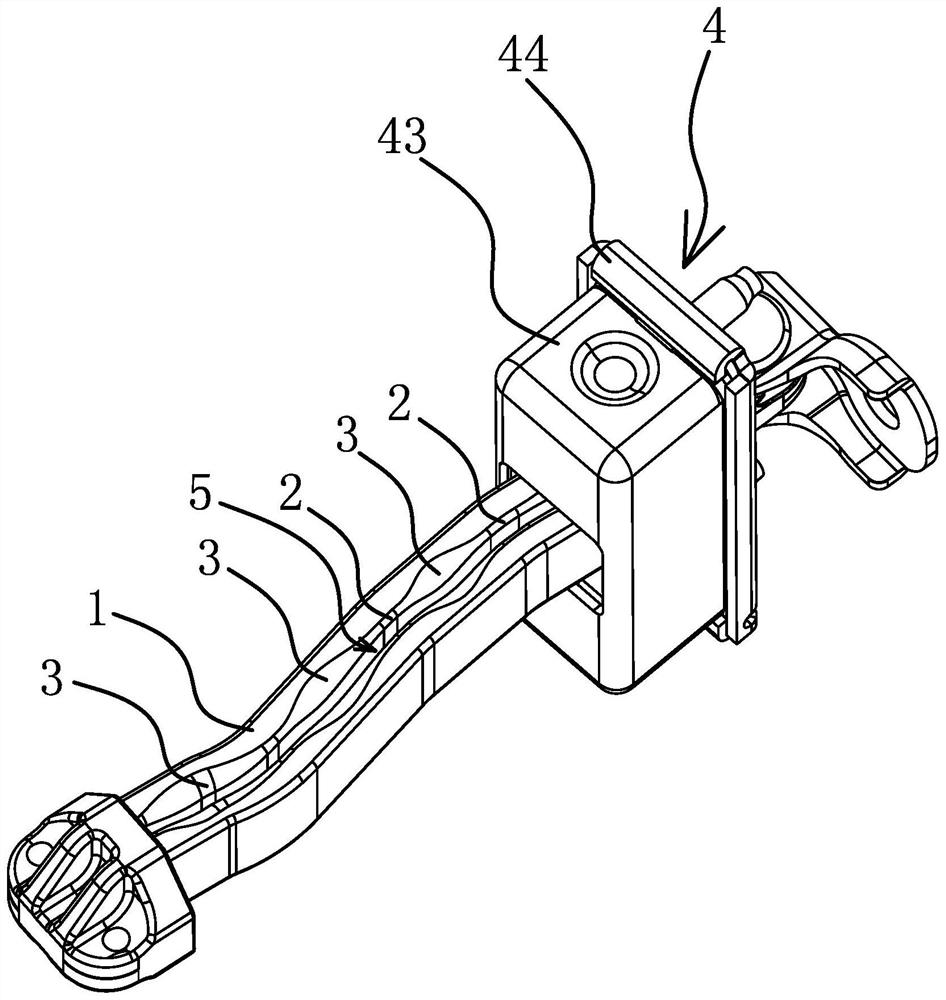

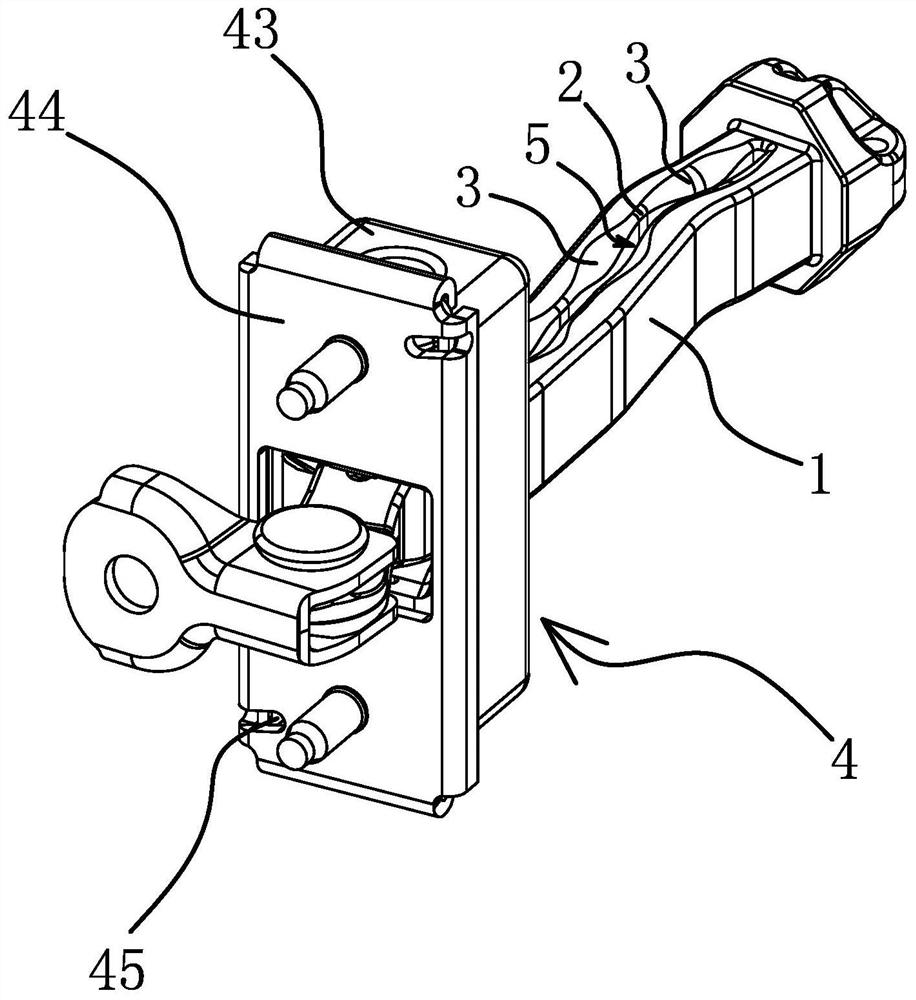

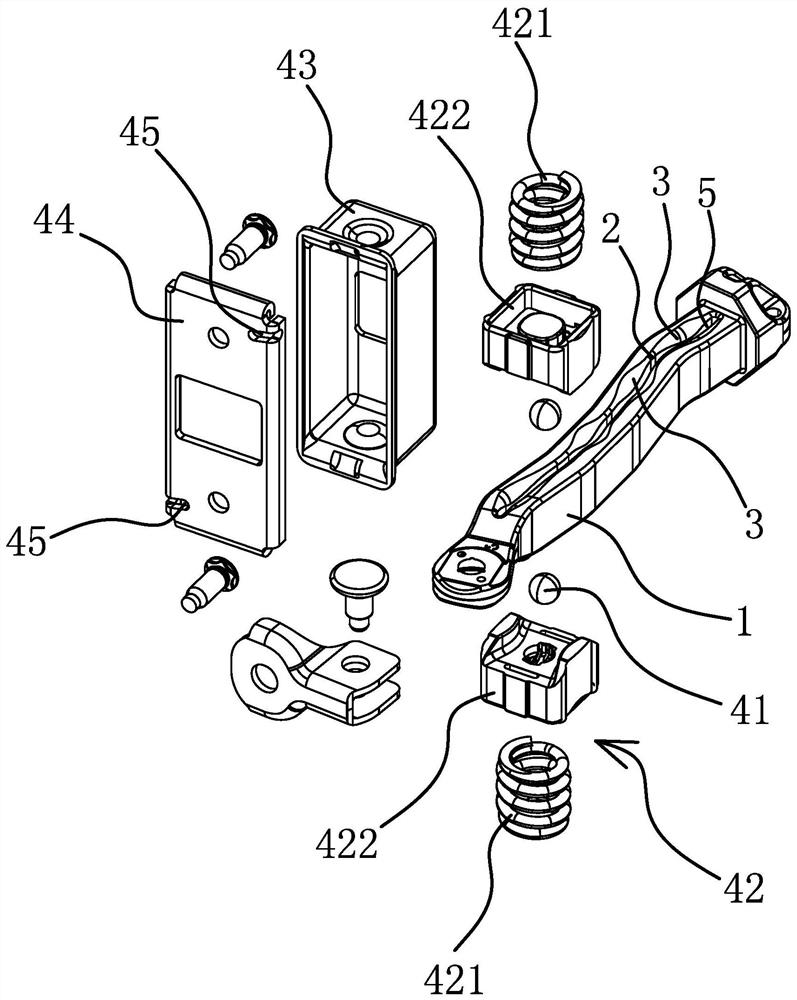

High-energy-storage limiter structure

ActiveCN112252870AReduce the risk of abnormal dust accumulationImprove the quality of car door opening and closingWing fastenersPhysicsEngineering

The invention provides a high-energy-storage limiter structure, and belongs to the technical field of automobile limiters. The high-energy-storage limiter structure solves the problem that an existinglimiter structure is large in dust accumulation and abnormal sound risk. The high-energy-storage limiter structure comprises a guide arm; guide grooves are formed in the upper side and the lower sideof the guide arm; a plurality of limiting grooves are formed in each guide groove; the guide arm is slidably sleeved with a limiting part; the limiting part comprises rolling balls capable of rollingalong the guide grooves; the rolling balls can be embedded and positioned in the limiting grooves; dust discharging grooves are formed in the guide arm along the guide grooves; and the dust discharging grooves penetrate through the upper side and the lower side of the guide arm, so that the guide grooves and the limiting grooves which are located in the upper side and the lower side of the guidearm are communicates with each other. The high-energy-storage limiter structure has the advantages of being not prone to dust accumulation and small in abnormal sound risk.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Inverse piezoelectric effect-based MEMS microstructure four-shaft type off-chip vibration excitation device

InactiveCN108020392ASmooth adjustment processReduce shear forceShock testingMicrostructureEngineering

An inverse piezoelectric effect-based MEMS microstructure four-shaft type off-chip vibration excitation device disclosed by the present invention comprises a sleeve, the stacked piezoelectric ceramics, a pressure sensor, the upper and lower connecting blocks and an MEMS microstructure, and is characterized in that a supporting plate and an electric lead screw transmission mechanism connected withthe lower connecting block are arranged in the sleeve, the lower end of the upper connecting block is equipped with a hemispherical round head and presses on the lower connecting block, and the piezoelectric ceramics are clamped between the pressure sensor and an elastic supporting member; the ball head plungers are uniformly distributed on the circumference between the upper connecting block andthe sleeve, the steel balls at the inner ends of the ball head plungers push into a chute at the outer edge of the upper connecting block, and the guiding shafts penetrating the lower connecting blockare uniformly distributed in the sleeve. The device can apply different pre-tightening forces on the stacked piezoelectric ceramics flexibly, so that the pre-tightening force measurement values are more accurate, an adjustment process for compensating a parallelism error of the two working surfaces of the stacked piezoelectric ceramics becomes more smooth, the shear forces between the stacked piezoelectric ceramics are reduced, and the dynamitic characteristic parameters of the MEMS microstructure are convenient to test.

Owner:BOHAI UNIV

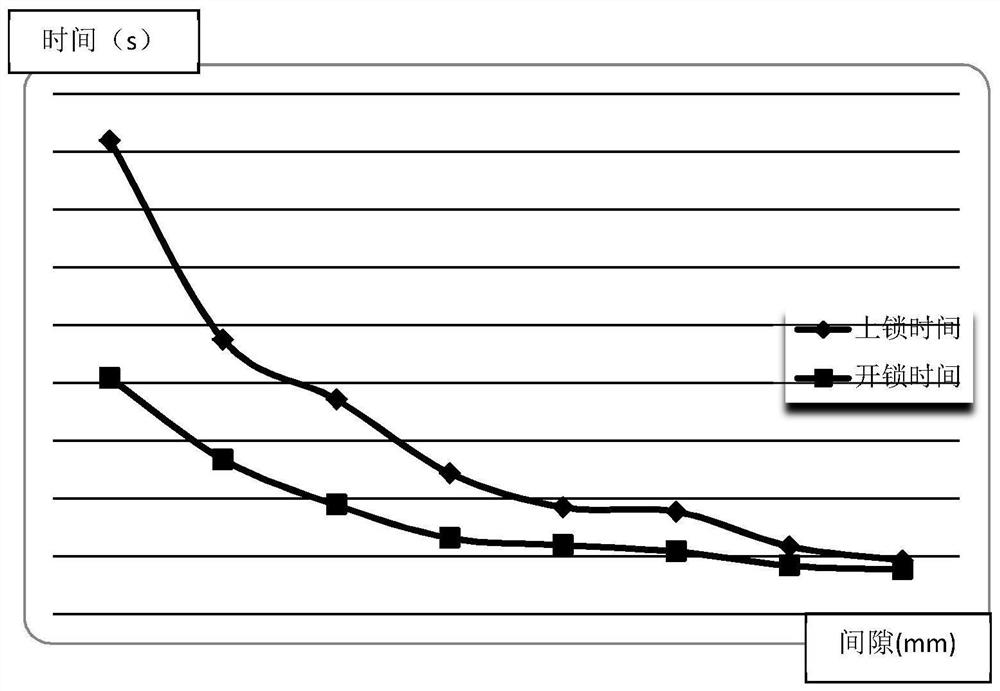

Buffering device used for controlling movement speed of actuator cylinder

PendingCN112431817AImprove reliabilityReduce severityFluid-pressure actuatorsUndercarriagesEngineeringActuator

The invention discloses a buffering device for controlling the movement speed of an actuator cylinder. The reliability of a locking device mechanism can be improved. The buffering device is achieved through the following technical scheme that an upper locking cavity is communicated with a damping pipe, and an intercepting ring groove is formed in the circumference of a sliding section of the damping pipe; when a piston rod extends downwards, hydraulic oil enters a blind hole cavity of the piston rod along the damping pipe, after the blind hole cavity is filled with the hydraulic oil, the hydraulic oil slowly flows upwards into the upper locking cavity along the intercepting ring groove in the damping pipe, the hydraulic pressure of the upper locking cavity is slowly increased, and the piston rod is pushed to move under the action of the hydraulic pressure; when the piston rod retracts, pressure of the unlocking cavity extrudes the piston rod, the piston rod extrudes the hydraulic oil in the upper locking cavity, the pressure of the upper locking cavity is increased, the hydraulic oil slowly flows into the blind hole cavity of the piston rod from the upper locking cavity along an intercepting annular groove of the damping pipe, the hydraulic oil in the unlocking cavity is reduced, and the piston rod slowly slides along the damping pipe; and liquid flow generates damping force through a gap between the inner wall of a blind hole and the damping pipe, the damping force controls the movement speed of the piston rod, and buffering of the actuator cylinder is achieved.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

Four-axis excitation device for performing out-of-chip excitation on MEMS microstructure

InactiveCN108168814AReduce shear forceRegulation stabilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElectricitySteel ball

The invention discloses a four-axis excitation device capable of dynamically driving an MEMS microstructure. The excitation device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, a steel ball, an elastic supporting part and the MEMS microstructure; an annular top plate is arranged at the upper end of the sleeve, the microstructure is arranged on the annular top plate through the elastic supporting part; guide shafts are uniformly distributed between the top plate and the bottom plate, the lower connecting block is uniformly provided with guide support arms which penetrate through the sleeve wall and sleeve the guide shafts; the upper connecting block and the lower connecting block are respectively providedwith a conical groove and a spherical groove which are matched with each other, tension springs are uniformly distributed between the upper connecting block and the lower connecting block to make thesteel ball be clamped between the conical groove and the spherical groove; and the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting part. According to the device, pre-tightening force of different sizes can be applied to the piezoelectric ceramics, meanwhile, the obtained pre-tightening force measurement value is more accurate, so that the adjustment processof the parallelism error of the two working surfaces of the compensation piezoelectric ceramic can be smoother, and dynamic characteristic parameters can be tested conveniently.

Owner:BOHAI UNIV

Four-axis type excitation device capable of dynamically driving MEMS microstructure

InactiveCN108163804ASmooth adjustment processReduce shear forceMicrostructural devicesCeramicElectricity

The invention discloses a four-axis type excitation device capable of dynamically driving a MEMS microstructure, which comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, an elastic supporting part and an MEMS microstructure, wherein an annular top plate is arranged at the upper end of the sleeve; the microstructure is arranged on the annular top plate through the elastic supporting part; guide shafts are uniformly distributed between the annular top plate and the bottom plate; the lower connecting block is uniformly provided with a guide support arm, penetrates through the sleeve wall and sleeves the guide shafts; a spherical bulge is arranged at the center of the bottom surface of the upper connecting block;tension springs are uniformly distributed between the bottom surface of the upper connecting block and the guide support arm of the lower connecting block; the spherical bulge is elastically pressedon the lower connecting block through the tension springs; and the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting part. According to the device, pre-tighteningforce of different sizes can be applied to the piezoelectric ceramic, so that the obtained pre-tightening force measurement value is more accurate, the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramic becomes smoother and smoother, and dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

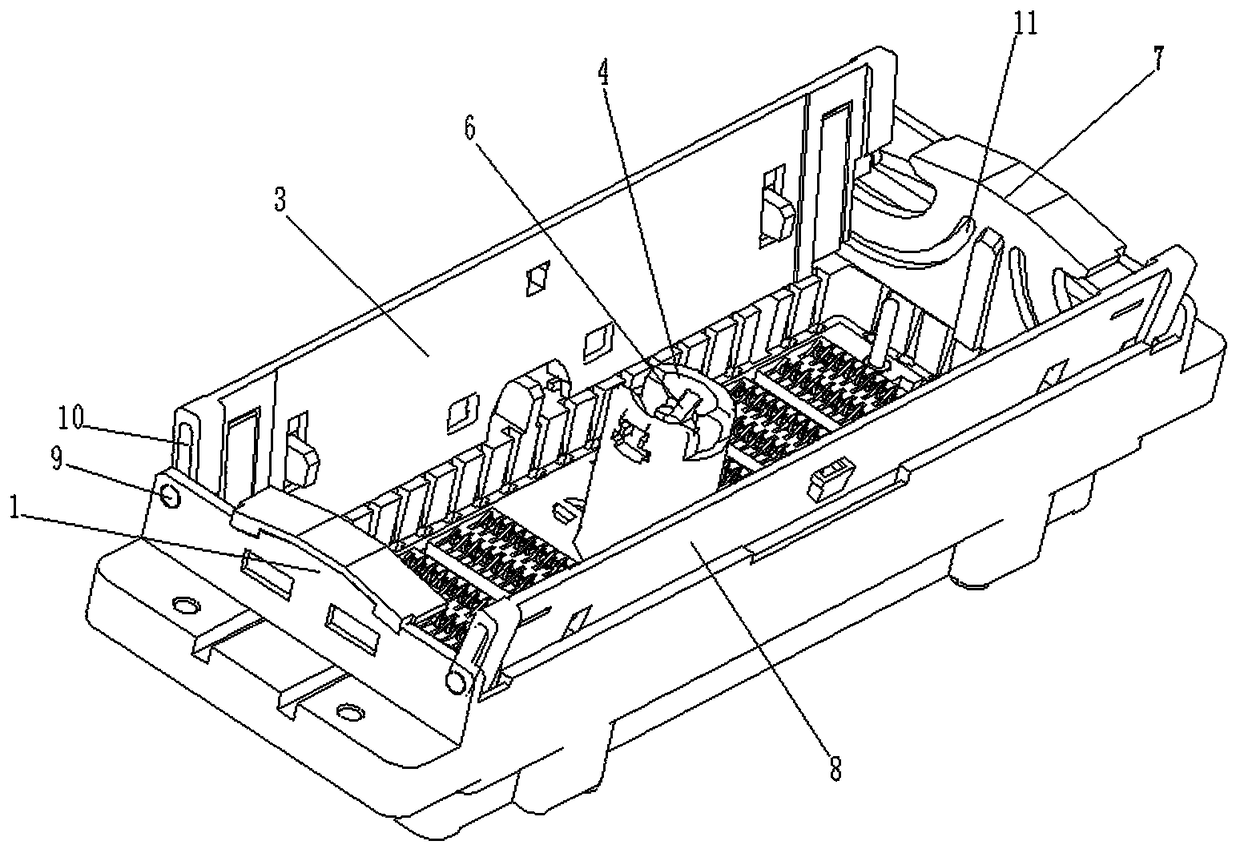

Connectors and Connector Assemblies Using the Connectors

ActiveCN106981760BMiniaturizationSmooth movementCouplings bases/casesEngineeringMechanical engineering

The invention relates to a connector and a connector assembly adopting the same. The connector comprises a shutter and a connector shell with an inserting-connecting end at the front end, wherein the shutter comprises at least one protection door; a shell assembling structure comprises a front moving hinged structure and a back moving hinged structure; a back moving guiding structure comprises a curve track formed in one of the protection door and the socket shell, and a first hinged pin which is arranged on the other one of the protection door and the socket shell and matched with the curve track in a guiding and moving manner; the front moving hinged structure comprises a guiding long groove which is formed in one of the protection door and the socket shell, and a second hinged pin which is arranged on the other one of the protection door and the socket shell and matched with the guiding long groove in a guiding and moving manner; and when each protection door is pushed by the adaptive connector, the first hinged pin moves backwardly relative to the curve track while the second hinged pin moves backwardly relative to the guiding long groove. The problem of a relatively large occupied space in an inserting direction of a protection door which can be only turned over backwardly in the prior art can be solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

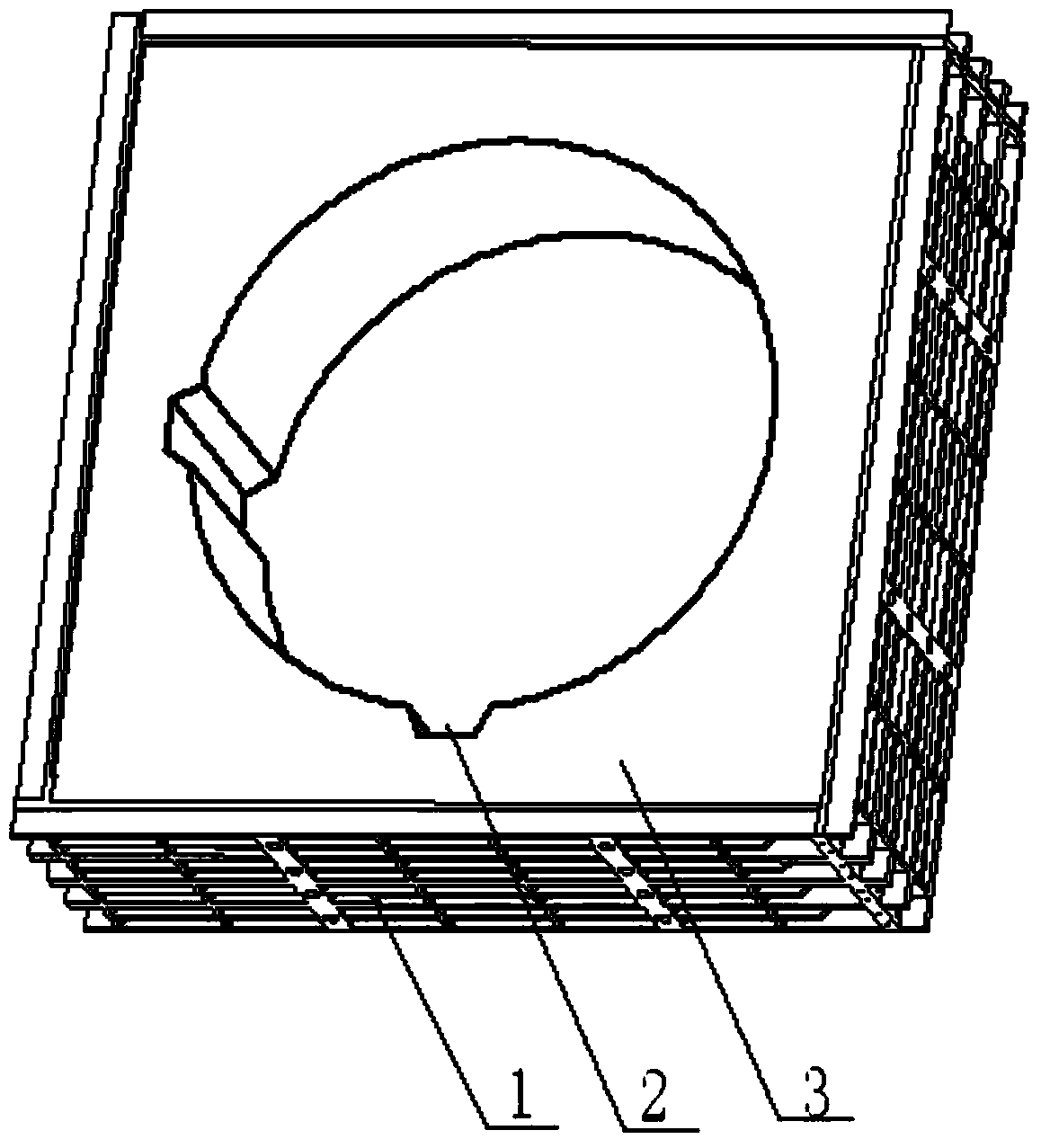

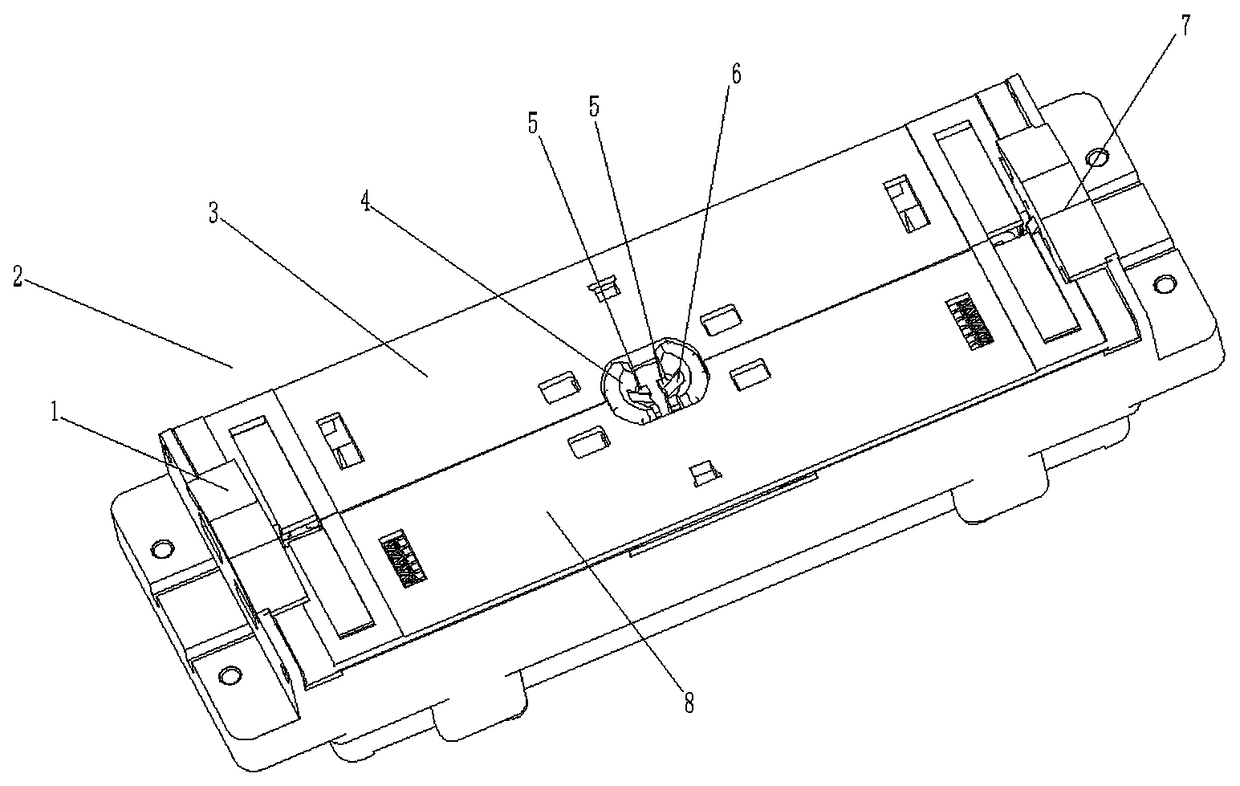

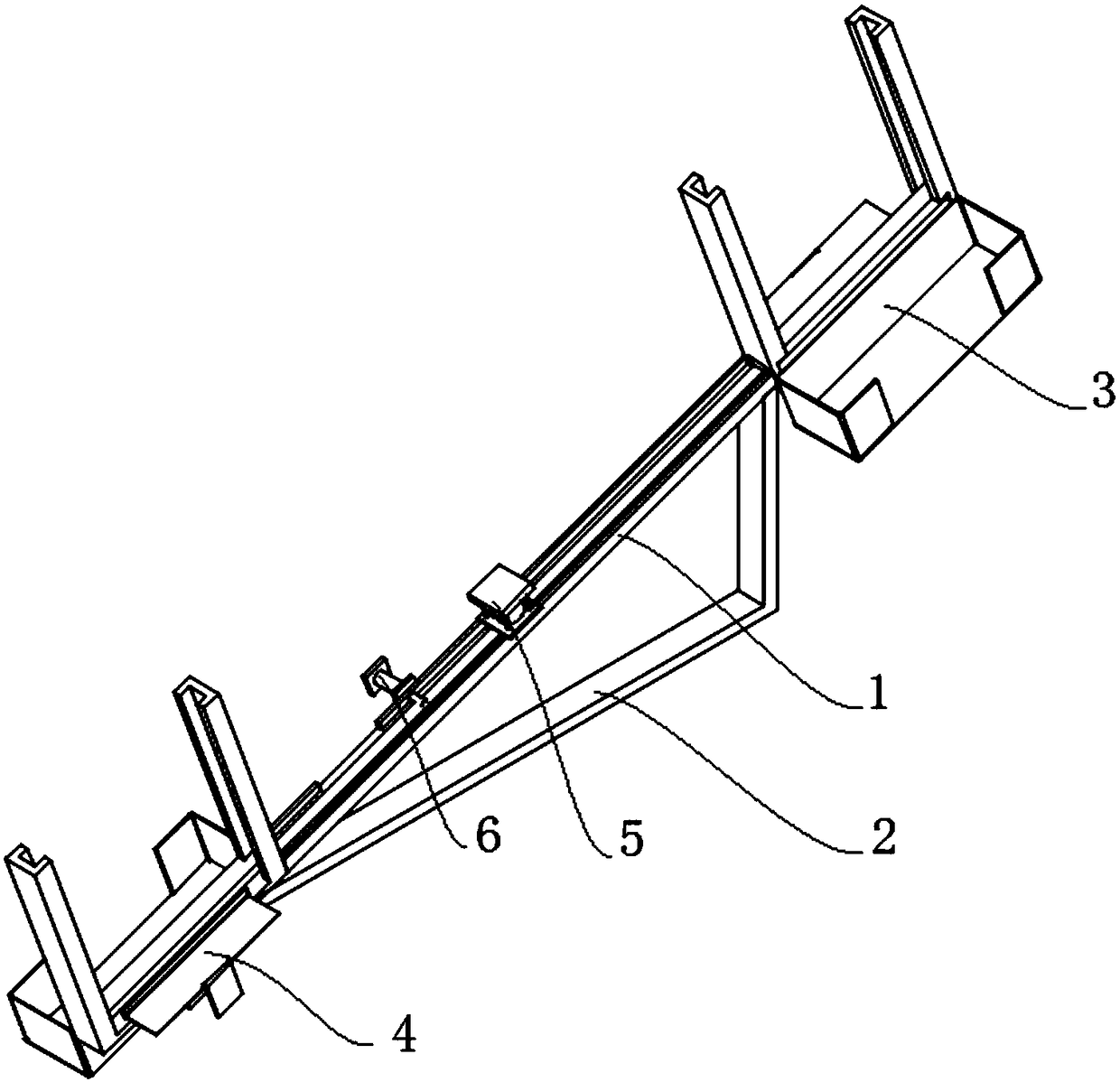

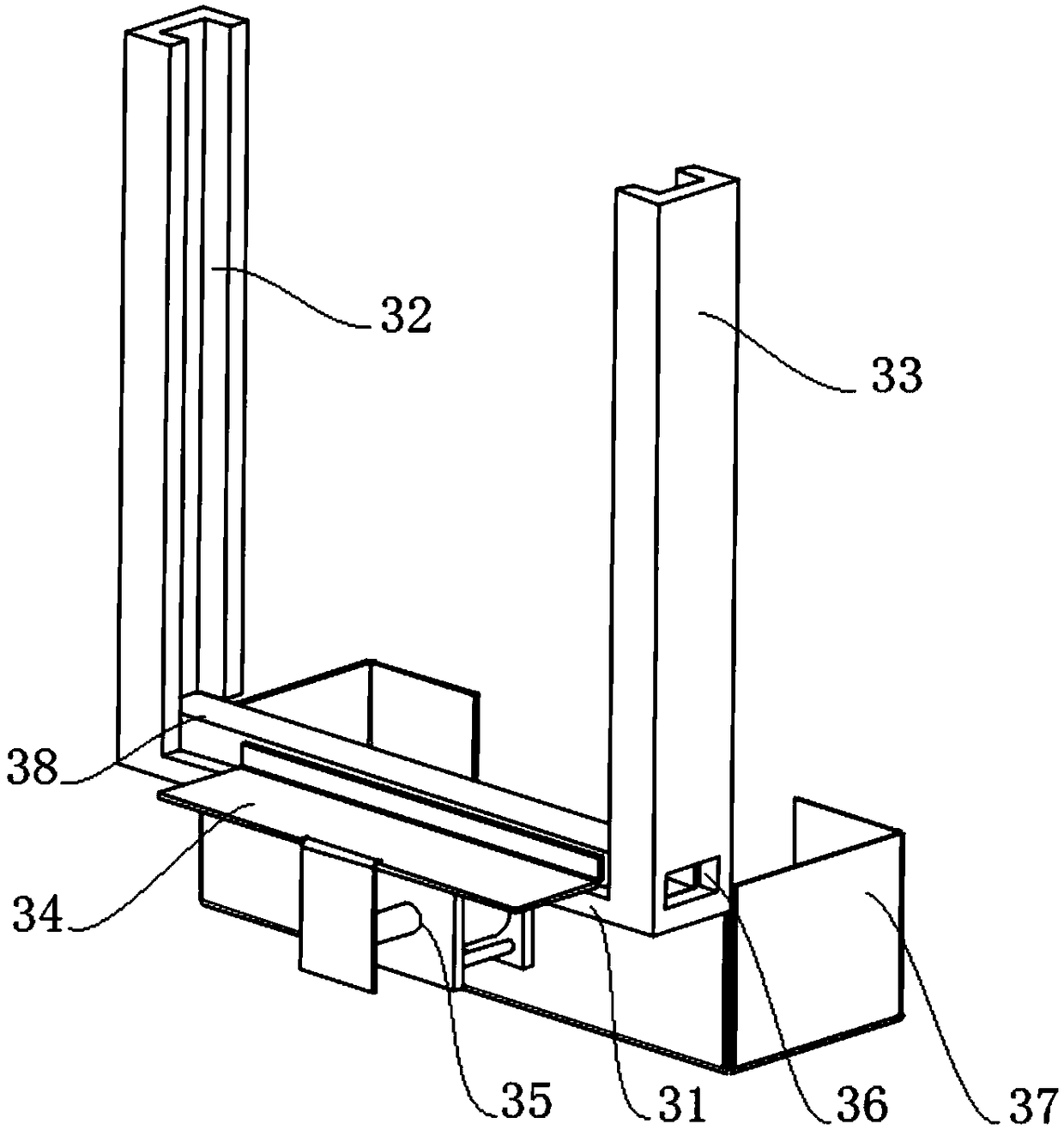

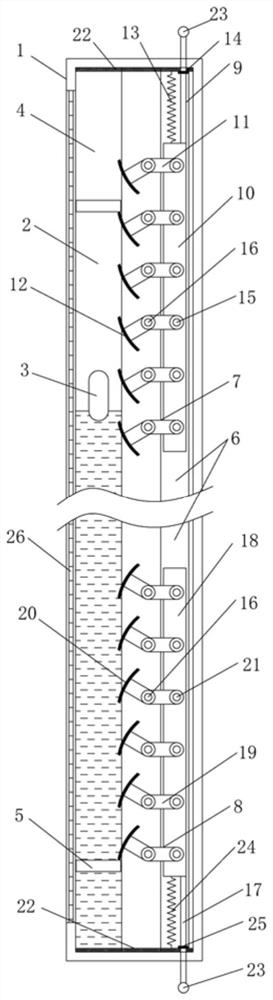

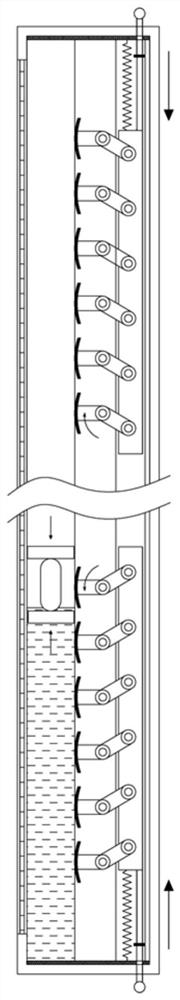

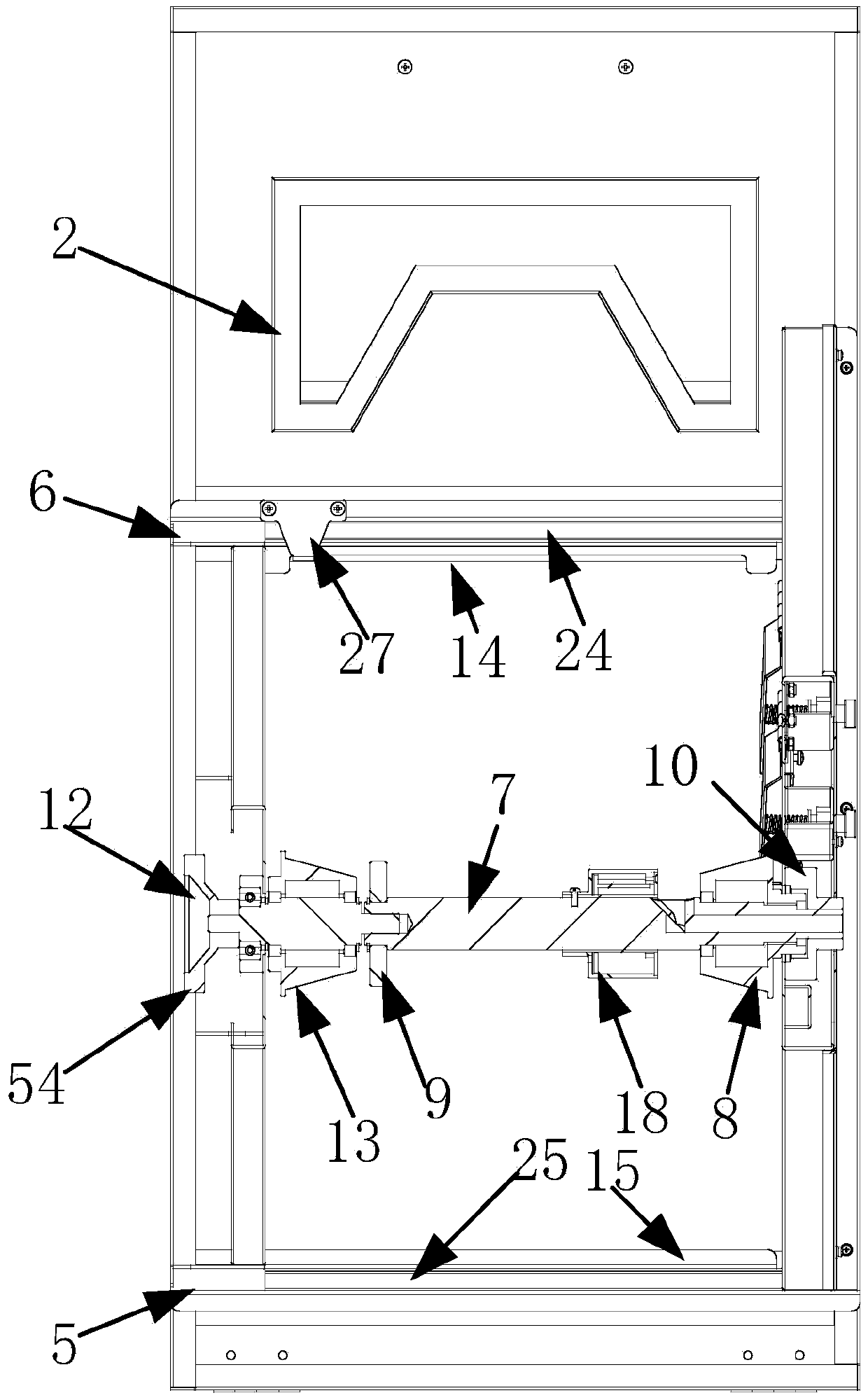

Feeding and collecting device suitable for detection of network transformer

InactiveCN108438349ASimple and fast operationReduce manual operationsIndividual articlesTransformerEngineering

The invention discloses a feeding and collecting device suitable for detection of a network transformer. The feeding and collecting device comprises a feeding mechanism and a collecting mechanism between which a conveying chute for conveying the network transformer is connected, wherein a support frame is arranged at the lower part of the conveying chute; the conveying chute and the ground form aset angle through the support frame; the feeding mechanism is positioned at the top end of the conveying chute and comprises a baseplate, a first clamp plate and a second clamp plate; the first clampplate and the second clamp plate are respectively fixedly arranged at two ends of the baseplate; a notch is formed in the length direction of each of the first clamp plate and the second clamp; the notch of the first clamp plate is opposite to that of the second clamp plate; and the notches allow a plurality of material pipes equipped with the network transformers to be stacked therein. The feeding and collecting device is simple and convenient to operate, can reduce manual operation steps, saves the production time, and avoids clamping stagnation when working because of the path, the conveying chute and a channel of which the sizes are specifically designed in accordance with the size of the network transformer, through which the network transformer passes.

Owner:ZHONGJIANG KAIXUN ELECTRONICS

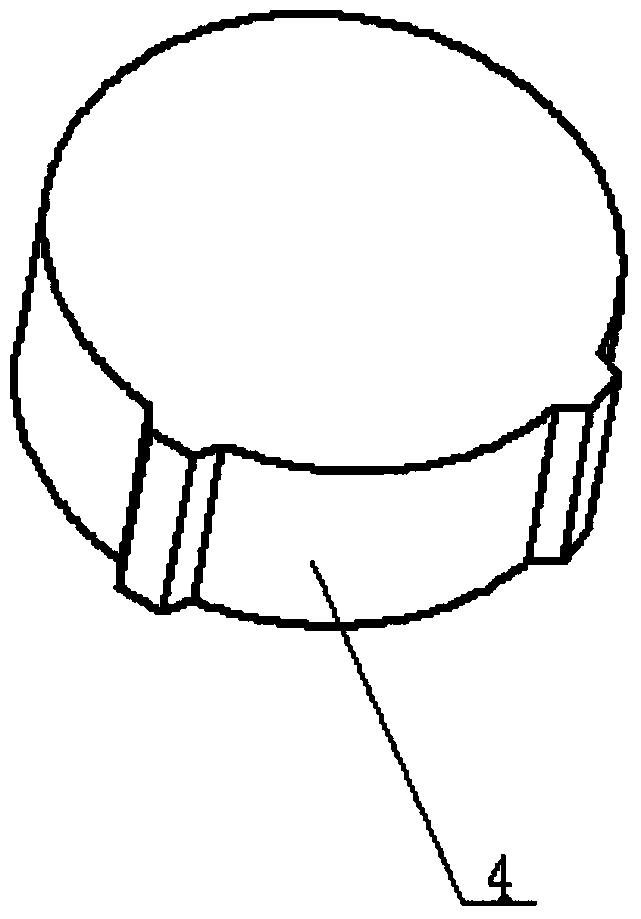

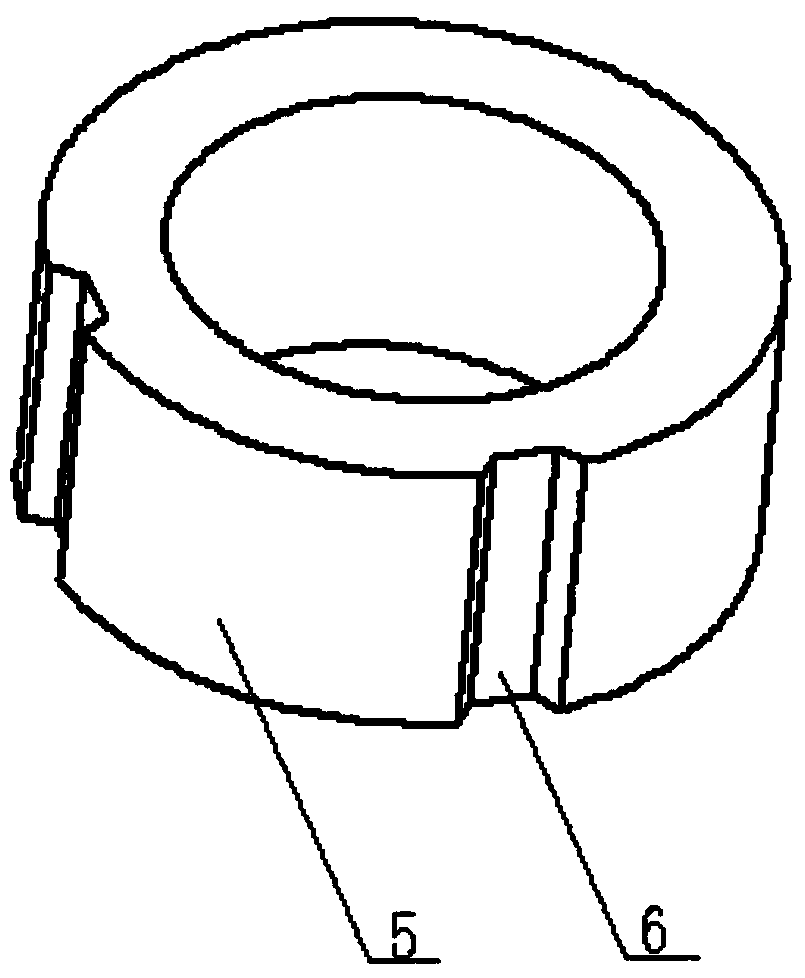

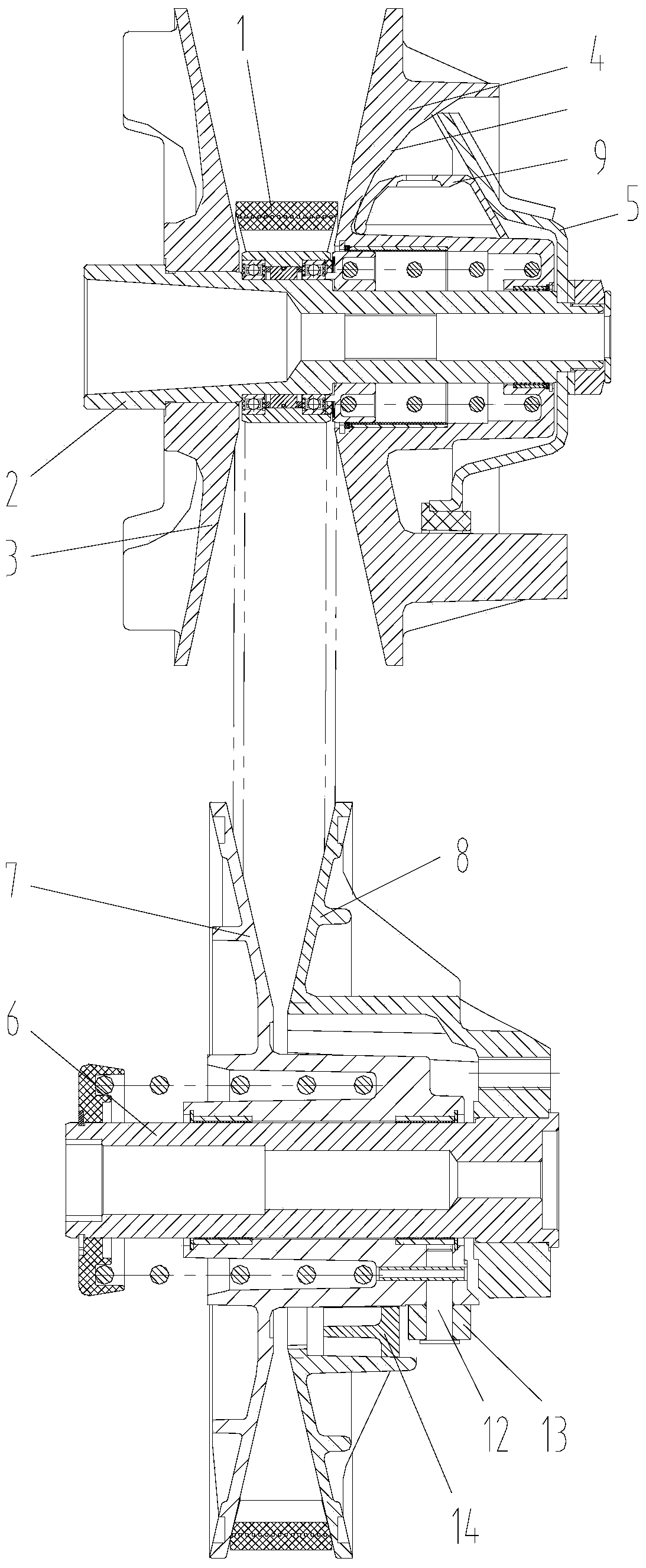

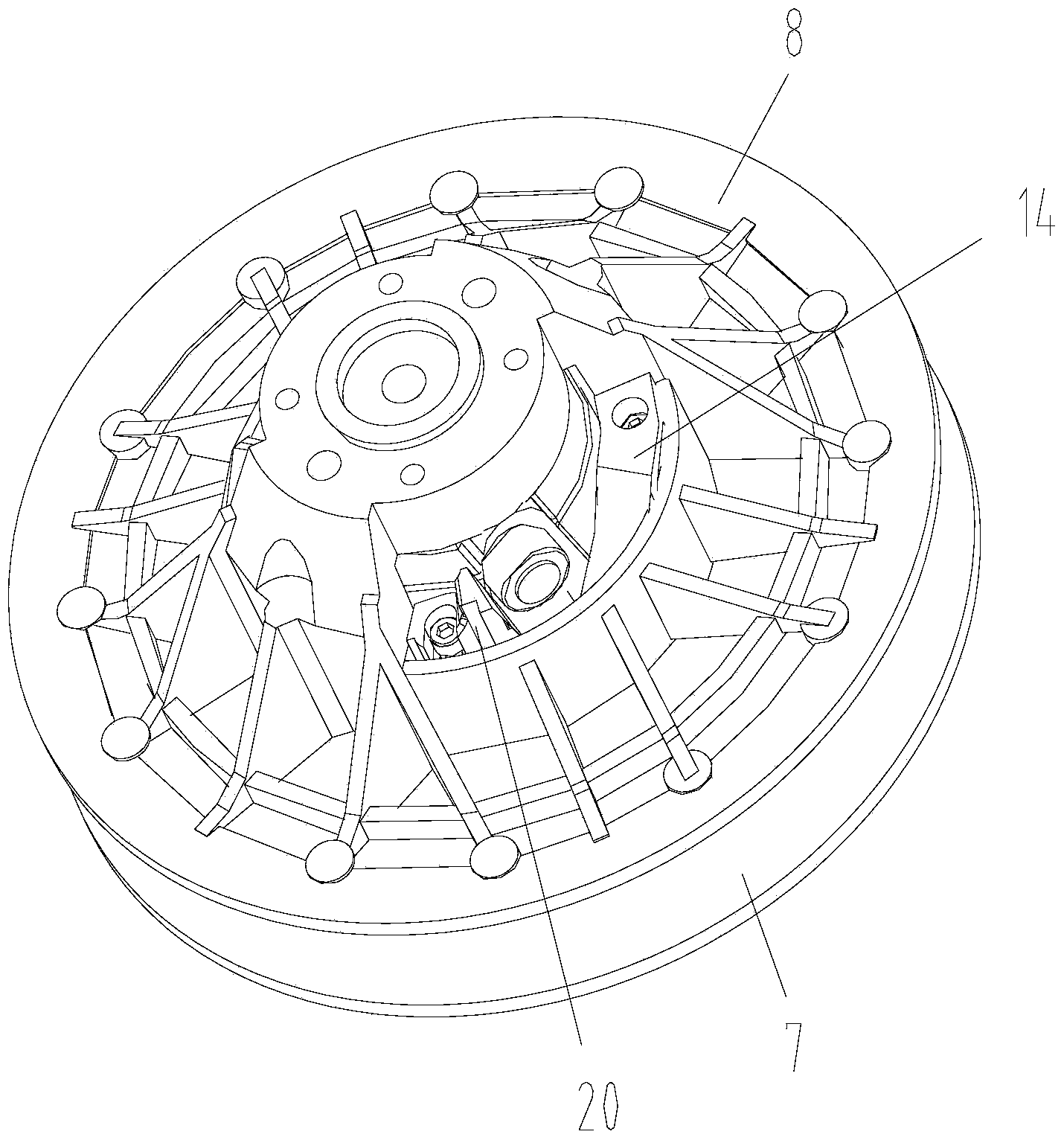

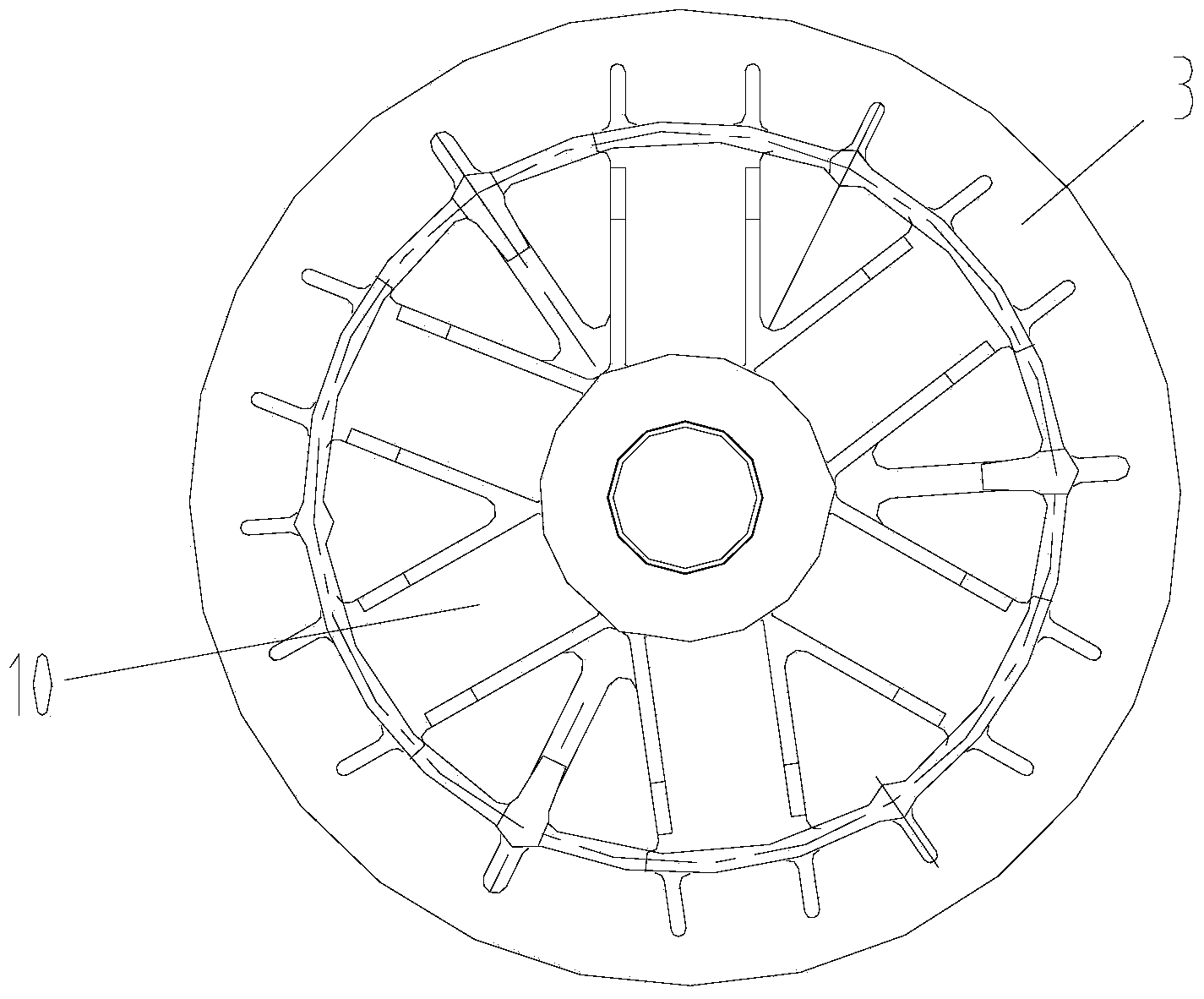

Stepless speed change clutch for dune buggy

InactiveCN104343911AContact friction resistance is smallLow calorific valueGearingPortable liftingClutchEngineering

The invention discloses a stepless speed change clutch for a dune buggy. The stepless speed change clutch comprises a driving wheel assembly, a driving belt and a driven wheel assembly, wherein a sliding block is arranged between a moving wheel and a slope plate, and in contact with and matched with a tapered plane of the slope plate through a semi-cylindrical bulge; a guiding device comprises a radial pin fixedly arranged at the end part of a moving disc, a roller arranged on the radial pin and a guide block arranged on a fixed disc; a spiral guide slope matched with a cylindrical surface of the roller is arranged on the guide block. During the speed change process, the contact part between each semi-cylindrical surface and the tapered plane of the slope plate bears smaller pressure, and the contact frictional resistance is also smaller, so that the sliding block cannot be blocked, and the speed change is stable and smooth; the spiral guide slope can meet the motion trail requirement on the moving disc, so that the pressing force between the moving wheel and the driving belt is smaller, and during the speed change speed, the clutch can ensure that the driving belt is low in abrasion and long in service life.

Owner:CHONGQING CHANGXING IND

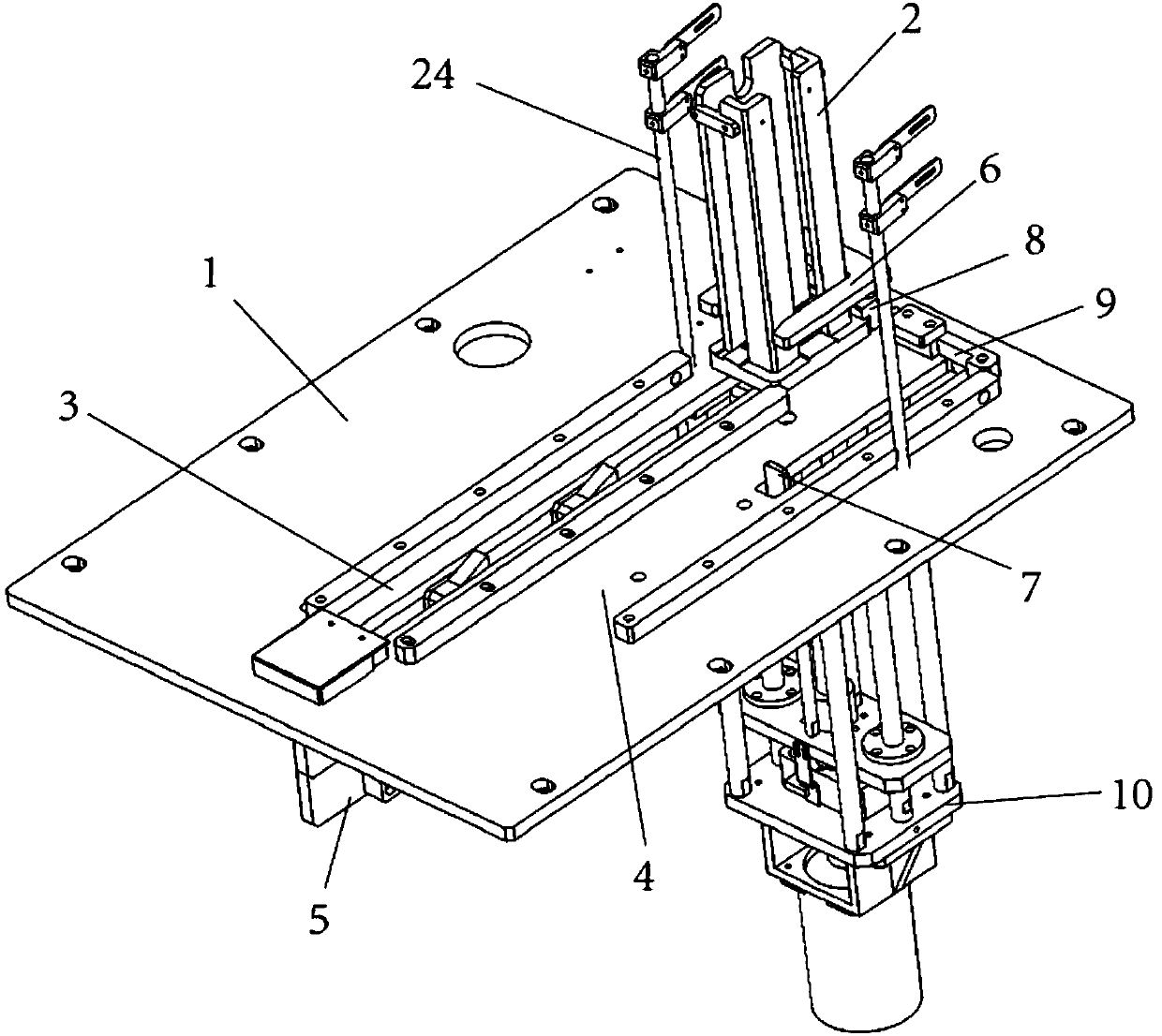

Stable feeding table

PendingCN107777369ASmooth feedingEasy to moveConveyorsDe-stacking articlesControl theoryMechanical engineering

The invention discloses a stable feeding table. The stable feeding table comprises an operation platform and a material rack and is characterized in that a feeding channel and a discharge channel arearranged on the surface of the operation platform, a material rack pusher is arranged in the feeding channel, one end of the feeding channel is a feeding part, one end of the discharge channel is in through connection with the feeding part, an inverted-n-shaped positioning conveying plate is arranged between the feeding channel and the discharge channel, the material rack is arranged in the feeding channel and is pushed towards the feeding part through the material rack pusher, the inverted-n-shaped positioning conveying plate conveys the material rack in the feeding part into the discharge channel, a discharge push plate is further arranged in the discharge channel, and four universal spherical wheels are arranged at the bottom of the material rack. The stable feeding table is capable ofstably supplying substrates, smooth in operation and less prone to jamming.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

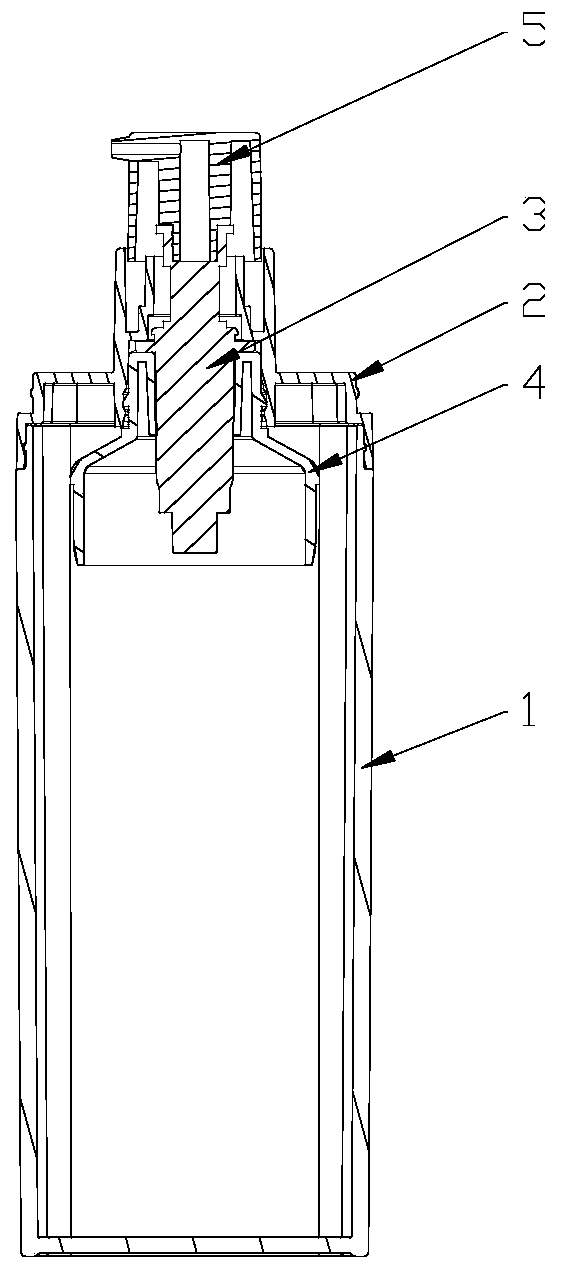

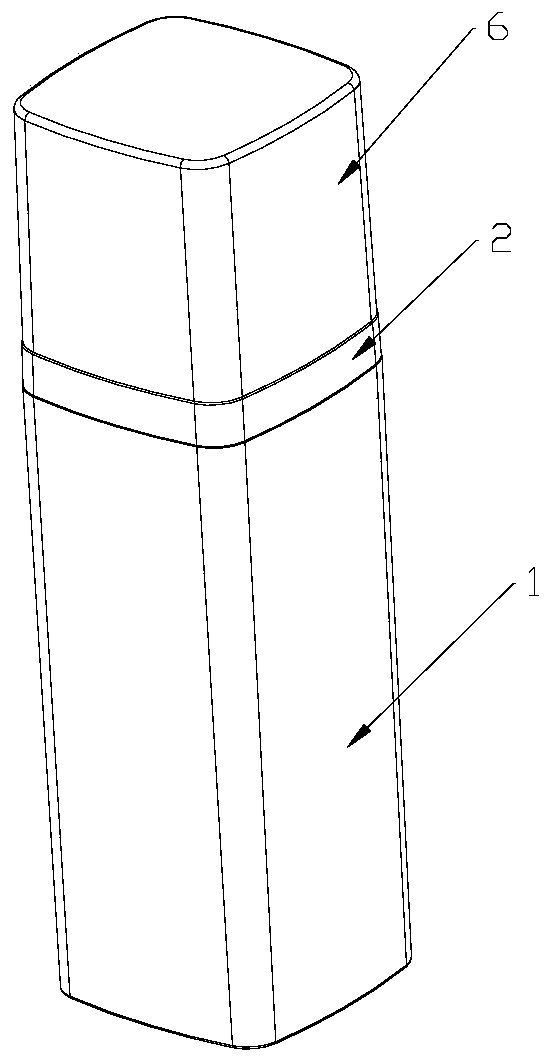

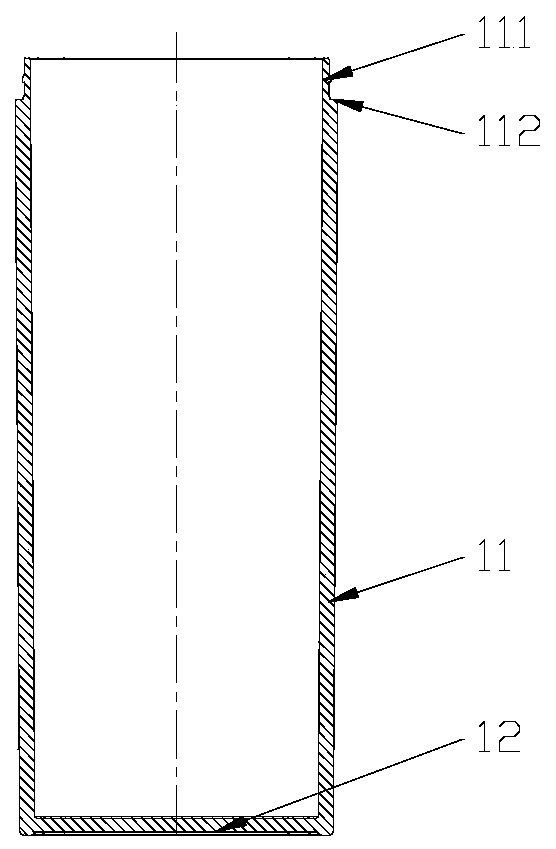

Vacuum pumping-out bottle

PendingCN110844314ANo stuck issuesSimple structureClosuresSingle-unit apparatusVacuum pumpingEngineering

The invention provides a vacuum pumping-out bottle. The bottle comprises a barrel body, a soft containing structure, a pump core, a shoulder sleeve, a press cap and an outer cover, wherein the shoulder sleeve is connected with the open end of the barrel body; the soft containing structure is connected with the shoulder sleeve; the pump core is installed inside the shoulder sleeve; the press cap isconnected with the pump core; and the shoulder sleeve is connected with the outer cover. According to the structure, movement of a piston is not needed, and when the pump core is pressed to pump outcontent liquid, the soft containing structure contracts, so that the content liquid can be stably pumped out, and the problem that the piston is stuck is solved. The bottle has simple structure and reliable technology. A smearing structure is installed on the press cap, and is convenient and practical. A plurality of pump core joints can also be arranged on the shoulder sleeve, and connected withdifferent pump cores and soft containing structures respectively, different content liquids are put into different soft containing structures, so that various use requirements of users can be met, thecost is low, and the bottle is portable.

Owner:SHENZHEN BEAUTYSTAR CO LTD

An opening and closing intelligent weeding device based on binocular vision to obtain seedling grass information

ActiveCN109005693BMultiple depth of field effectsImprove accuracyTelevision system detailsSoil-working equipmentsHydraulic cylinderImaging processing

The invention belongs to the technical field of agricultural equipment, and relates to an opening and closing intelligent weeding device for obtaining seedling grass information based on binocular vision. Servo control system, inter-plant weeding end effector and parallel four-bar profiling unit; the binocular visual servo control system includes a binocular camera fixed on the front end of the crossbeam for collecting grass information in a large field, with Single chip microcomputer and servo controller with image processing function. The parallel four-bar profiling unit includes a parallel four-bar mechanism, a ground wheel rod and a ground wheel; the parallel four-bar mechanism includes an upper pull rod, a lower pull rod, a front mounting plate, a rear mounting plate, a hanging rod and a hook. The inter-row weeding end effector includes a top plate, a bottom plate, a hydraulic cylinder, a hoe bar and a hoe knife. The invention has the advantages of compact structure, high weeding efficiency, high accuracy, strong portability and wide applicability, and can be applied to various field working conditions.

Owner:CHINA AGRI UNIV

MEMS (Micro-electromechanical System) microstructure tetra-axial base exciting device driven by stack piezoelectric ceramic

The invention discloses an MEMS (Micro-electromechanical System) microstructure tetra-axial base exciting device driven by stack piezoelectric ceramic. The MEMS microstructure tetra-axial base exciting device comprises a sleeve, the stack piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block and an MEMS microstructure, wherein a hemispherical head is arranged at the lower end of the upper connecting block and presses the lower connecting block; the piezoelectric ceramic is clamped between the pressure sensor and elastic supporting members; ball head plungers are uniformly distributed in the circumference between the upper connecting block and the sleeve; steel balls at the inner ends of the ball head plungers jack into a sliding chute in the outer edge of the upper connecting block; guiding shafts are uniformly distributed in the circumference between an annular top plate and a base plate; and guiding support arms which are uniformly distributedon the edge of the lower connecting block respectively penetrate through the sleeve and sleeve the corresponding guiding shafts. The device has the advantages that pretightening forces with differentstrengths can be applied to the stack piezoelectric ceramic, a pretightening force measurement value is more accurate, the adjusting process of compensating parallelism error between two working facesof the stack piezoelectric ceramic is enabled to smoother, and dynamic characteristic parameters are favorably tested.

Owner:BOHAI UNIV

Four-shaft pedestal excitation device used for dynamic characteristics test of MEMS microstructure

The invention discloses a four-shaft pedestal excitation device used for dynamic characteristics test of a MEMS microstructure. The four-shaft pedestal excitation device comprises a sleeve, a stackedpiezoelectric ceramic, a pressure sensor, an upper linkage block, a lower linkage block, a steel ball and the MEMS microstructure; a support plate and an electric lead screw transmission mechanism arearranged in the sleeve; the upper linkage block and the lower linkage block are respectively provided with a spherical groove and a conical groove for clamping the steel ball; the stacked piezoelectric ceramic is clamped between the pressure sensor and an elastic support; spring plungers are evenly distributed and connected on the upper linkage block, and an external end steel bead of the springplunger is respectively supported into a rectangular groove of an internal wall of the sleeve. The device can flexibly apply a pretightening force of different size on the stacked piezoelectric ceramic, and simultaneously makes an obtained pretightening force measurement value more accurately, makes an adjusting process for compensating parallelism error of two work surfaces of the stacked piezoelectric ceramic more unhindered and smooth, greatly reduces a shear force among each layer of the stacked piezoelectric ceramic, can avoid falling off of micro devices for test and is convenient for testing dynamic characteristics parameters of the MEMS microstructure.

Owner:BOHAI UNIV

Four-axis excitation device capable of loading impact load on MEMS microstructure

The invention discloses a four-axis excitation device capable of loading impact load on an MEMS microstructure. The four-axis excitation device comprises a sleeve, a stacked piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block and an MEMS micro structure; wherein a supporting plate and an electric lead screw transmission mechanism connected with the lower connecting block are arranged in the sleeve; the upper connecting block and the lower connecting block are respectively provided with spherical protrusions and spherical grooves which are matched witheach other; the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting piece; and ball head plungers are uniformly distributed on the upper connecting block, and the outer ends of the ball head plungers are jacked into rectangular grooves in the inner wall of the sleeve. According to the device, pre-tightening force of different magnitudes can be flexibly applied to the stacked piezoelectric ceramics. Meanwhile, the obtained pre-tightening force measurement value is more accurate, so that the adjustment process for compensating the parallelism error of the twoworking surfaces of the stacked piezoelectric ceramic can be smoother, the shearing force between the layers of the stacked piezoelectric ceramics is greatly reduced, falling of micro-devices for testing can be avoided, and dynamic characteristic parameters of the MEMS micro-structures can be tested conveniently.

Owner:BOHAI UNIV

Fixing mechanism of mold

PendingCN111645269AImprove processing efficiencyFlexible positioning is goodTubular articlesEngineeringSteel ball

The invention provides a fixing mechanism of a mold, belongs to the technical field of injection molds, and solves the problem that existing pipes and rotary copper pieces are processed in two steps.The mold comprises an upper mold and a lower mold, wherein a forming cavity can be formed after the upper mold and the lower mold are combined, a sliding block capable of sliding is arranged on the lower mold, the sliding block is matched with the upper mold through an inclined guide column structure, the mold is characterized in that the fixing mechanism comprises a first core fixedly connected to the sliding block, the inner end, capable of extending into the forming cavity, of the first core is a positioning part for sleeving a rotary copper piece, and an elastic piece and a steel ball arearranged in the positioning part. The steel ball can be partially positioned outside the positioning part and embedded into an internal thread of the rotary copper piece under the action of elastic force of the elastic piece. According to the mold, the rotary copper piece is embedded and fixed in a pipe while the pipe is formed, and the processing efficiency is high.

Owner:YONGGAO CO LTD

MEMS microstructure four-axis type dynamic loading apparatus based on piezoelectric ceramics

The invention discloses an MEMS microstructure four-axis type dynamic loading apparatus based on piezoelectric ceramics. The apparatus comprises a sleeve, the piezoelectric ceramics, a pressure sensor, upper and lower connection blocks, and an MEMS microstructure, a support plate and an electric leading screw transmission mechanism are arranged in the sleeve, the upper connection block and the lower connection block are respectively provided with a spherical projection and a spherical groove matched with each other, the piezoelectric ceramics are clamped between the pressure sensor and an elastic support member, an outer rim of the upper connection block is connected with installation blocks through connecting rods uniformly distributed in a circumferential manner, the installation blocksare respectively provided with bulb plungers, and steel balls at the outer ends of the bulb plungers are respectively ejected into rectangular grooves of an outer wall of the sleeve. According to theapparatus, different pre-tightening forces can be flexibly applied to the piezoelectric ceramics, obtained measuring values of the pre-tightening forces are more accurate, the adjusting process for compensating parallelism errors of two operating surfaces of the piezoelectric ceramics becomes more smooth, the falling of micro-devices for the test can be avoided, and the test of dynamic characteristic parameters of the MEMS microstructure is facilitated.

Owner:BOHAI UNIV

A four-axis vibration excitation device of mems microstructure based on the base excitation method

InactiveCN108217582BReduce shear forceRegulation stabilityVibration testingMicrostructural devicesElectricityBaseboard

The invention discloses a MEMS microstructure four-axis vibration device based on a base excitation method, which includes a sleeve and a bottom plate, piezoelectric ceramics, a pressure sensor, upper and lower coupling blocks, elastic supports and MEMS microstructures; The upper end is provided with an annular top plate, and the microstructure is set on the annular top plate through an elastic support; guide shafts are uniformly distributed between the annular top plate and the bottom plate, and the lower connecting block is evenly distributed with guide arms that are passed through the sleeve wall and set in the On the guide shaft, a locking device is provided on the guide arm; matching spherical grooves and spherical protrusions are respectively provided on the upper and lower connecting blocks; piezoelectric ceramics are sandwiched between the pressure sensor and the elastic support; the upper The outer edge of the coupling block is pushed into the inner wall of the sleeve through the ball plunger. The device can apply different sizes of pre-tightening force to the piezoelectric ceramics, so that the obtained pre-tightening force measurement value is more accurate, and the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics becomes smoother and smoother, which is convenient Test dynamic characteristic parameters.

Owner:BOHAI UNIV

MEMS micro-structure four-axis excitation device

InactiveCN108168813AReduce shear forceRegulation stabilityVibration testingMicro structureEngineering

The invention discloses a MEMS micro-structure four-axis excitation device. The four-axis excitation device comprises a sleeve, a bottom plate, a piezoelectric ceramic, a pressure sensor, an upper connecting block, a lower connecting block, an elastic supporting part and an MEMS micro-structure; an annular top plate is arranged at the upper end of the sleeve, the micro-structure is arranged on theannular top plate through the elastic supporting part; guide shafts are uniformly distributed between the annular top plate and the bottom plate, and guide support arms are uniformly distributed on the lower connecting block and penetrate through the sleeve wall and sleeve the guide shafts, and a locking device is arranged on each guide support arm; the upper connecting block and the lower connecting block are provided with a spherical groove and a spherical bulge that are matched; the piezoelectric ceramic is clamped between the pressure sensor and the elastic supporting piece; and tension springs are uniformly and circumferentially connected between the bottom surface of the upper connecting block and the guide support arms of the lower connecting block. According to the device, pre-tightening force of different sizes can be applied to the piezoelectric ceramic, and the obtained pre-tightening force measurement value is more accurate, so that the adjustment process of the parallelism error of the two working surfaces of the compensation piezoelectric ceramic becomes smoother, and the dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

MEMS microstructural four-axis shock excitation device using piezoelectric ceramics as excitation source

The invention discloses an MEMS microstructural four-axis shock excitation device using piezoelectric ceramics as an excitation source. The device comprises a sleeve, a baseboard, the piezoelectric ceramics, a pressure sensor, upper and lower linking blocks, an elastic support piece and an MEMS microstructure, wherein an annual top board is arranged at the upper end of the sleeve, and the microstructure is arranged on the annular top board via the elastic support piece; guiding shafts are uniformly distributed between the annular top board and the baseboard, guiding support arms are distributed on the lower linking block and pass through the sleeve wall to sleeve the guiding shafts, and a locking device is arranged on the guiding support arms; the upper and lower linking blocks are separately provided with a spherical groove and a spherical bump; the piezoelectric ceramics is clamped between the pressure sensor and the elastic support piece; and the outer edge of the upper linking block is ejected into the inner wall of the sleeve via ball plungers uniformly distributed and connected. The device can apply different sizes of pretightening force to the piezoelectric ceramics, so thatthe acquired measured value of the pretightening force is more accurate, and thus an adjustment process for compensating a parallelism error of two working surfaces of the piezoelectric ceramics canbecome smoother, and the tests of dynamic characteristic parameters are facilitated.

Owner:BOHAI UNIV

A four-axis dynamic loading device for mems microstructure based on piezoelectric ceramics

The invention discloses a MEMS microstructure four-axis dynamic loading device based on piezoelectric ceramics, which includes a sleeve, piezoelectric ceramics, a pressure sensor, upper and lower connecting blocks and MEMS microstructures; a support plate is arranged in the sleeve and the electric screw drive mechanism; the upper and lower connecting blocks are respectively provided with mutually matching spherical protrusions and spherical grooves; piezoelectric ceramics are clamped between the pressure sensor and the elastic support; the outer edge of the upper connecting block passes through The connecting rods evenly distributed on the circumference are connected with installation blocks, on which ball plungers are installed respectively, and the steel balls at the outer ends of the ball plungers are pushed into the rectangular grooves on the outer wall of the sleeve respectively. The device can flexibly apply different sizes of pre-tightening force to the piezoelectric ceramics, and at the same time make the measured value of the pre-tightening force more accurate, and can make the adjustment process of compensating the parallelism error of the two working surfaces of the piezoelectric ceramics smoother and smoother , can avoid the falling off of the micro-device used for testing, and is convenient for testing the dynamic characteristic parameters of the MEMS microstructure.

Owner:BOHAI UNIV

Profile corner system

The invention discloses a profiled corner tension fitting unit, a profiled corner tension plate and a profiled corner system employing the profiled corner tension fitting unit and the profiled corner tension plate. The profiled corner tension plate comprises a plate body which is elongated and which is bent from front to tail to provide a connecting segment and a hooking segment; the connecting segment is provided with a connecting hole; the hooking segment is provided with more than one pull hook; each pull hook is straightly extended or bent towards the front of the plate body. The profiled corner tension fitting unit comprises a transverse tension plate and a vertical tension plate which are connected together through connecting screws. The profiled corner system comprises the profiled corner tension fitting unit, a transverse frame and a vertical frame; the profiled corner tension fitting unit allows the transverse frame and the vertical frame to be connected together through the pull hooks. The profiled corner tension plate, the profiled corner tension fitting unit and the profiled corner system have the advantages that parts are few, the structure is simple, the cost is low, connection is reliable, and the profiled corner tension plate, the profiled corner tension fitting unit and the profiled corner system are widely applicable to assembly of profiled corners of doors and windows.

Owner:佛山市三水和美斯金铝业有限公司

A generator rotor insulation monitoring brush device

ActiveCN110571983BGood running current waveformStrong dust resistanceStructural associationSuction forceBrush device

A generator rotor insulation monitoring brush device, including a lever device, the lever device is fixed on the casing of the unit through the lever shaft and bearings on both sides, one end of the lever device is slotted into a carbon brush, and the lead wire of the carbon brush passes through the lever device and comes out from the Its lower part is drawn out and finally connected to the aviation plug; the other end of the lever device is connected with an iron core, and the iron core and the lever device are connected flexibly. The iron core passes through the spring and is inserted into the electromagnetic coil. The spring is located between the electromagnetic coil lever device During this period, when the electromagnetic coil is energized, the iron core is subjected to downward electromagnetic attraction, at this time the spring is compressed, the iron core drives the lever device to move downward, and the carbon brush end is lifted.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

MEMS microstructure four-axis base excitation device driven by stacked piezoelectric ceramics

The invention discloses an MEMS microstructure four-axis base excitation device driven by stacked piezoelectric ceramics, comprising a sleeve, piezoelectric ceramic, a pressure sensor, upper and lowerconnecting blocks, a steel ball, an elastic supporting member and an MEMS microstructure, wherein an annular top plate and a bottom plate are arranged at both ends of the sleeve, and the microstructure is arranged on the annular top plate through the elastic supporting member; guiding shafts are uniformly arranged between the annular top plate and the bottom plate, guide supporting arms are uniformly distributed on the lower edge of the lower connecting block, are penetrated by the sleeve wall and are sheathed on the guiding shafts, and locking devices are respectively arranged on the guide supporting arms; conical grooves and spherical grooves are respectively formed in the upper and lower connecting blocks; and the piezoelectric ceramic is sandwiched between the pressure sensor and theelastic supporting member. The device can apply different pre-tightening forces to the piezoelectric ceramic, and meanwhile, the obtained pre-tightening force measurement value is more accurate, the adjustment process for compensating the parallelism error of two working surfaces of the piezoelectric ceramic can be smoother, and dynamic characteristic parameters can be conveniently tested.

Owner:BOHAI UNIV

Real-time liquid level meter capable of automatically recording highest position and lowest position of past floating

The invention discloses a real-time liquid level meter capable of automatically recording the highest position and the lowest position of past floating. The real-time liquid level meter comprises an outer shell and a floater arranged in a floating groove in the outer shell; and the real-time liquid level meter further comprises a liquid level recording part, a limiting mechanism and a sliding groove; the liquid level recording part is arranged in the floating groove; the limiting mechanism is arranged behind the liquid level recording part; the limiting mechanism is matched with the liquid level recording part in a sliding and clamping mode; and the liquid level recording part comprises a high-position recording part and a low-position recording part; the limiting mechanism comprises a high-position limiting mechanism and a low-position limiting mechanism; and sealing gaskets are arranged in the lower surface of the upper end of the outer shell and the upper surface of the lower end of the outer shell. The real-time liquid level meter has the advantages of being more complete in function, rapid in connection, convenient to reset, high in liquid level display precision, accurate in liquid level recording and capable of recording and displaying historical highest liquid level and lowest liquid level data achieved in the operation process of equipment at any time. and With the real-time liquid level meter adopted, the past operation condition of the equipment can be more intuitively known, and the problem of abnormity generated in the operation process of the equipment can be more quickly traced.

Owner:HUANENG SHANTOU HAIMEN POWER GENERATION CO LTD

A High Energy Storage Limiter Structure

ActiveCN112252870BReduce the risk of abnormal dust accumulationNot easy to accumulate dustWing fastenersHigh energyEngineering

The invention provides a high-energy-storage limiter structure, which belongs to the technical field of automobile limiters. It solves the problem of high risk of dust accumulation and abnormal noise in the existing limiter structure. The structure of the high-energy storage limiter includes a guide arm. Guide grooves are provided on the upper and lower sides of the guide arm. Each guide groove is provided with several limit grooves. The slidable sleeve on the guide arm is provided with a limit piece. The limiter includes balls that can roll along the guide groove, the balls can be embedded and positioned in the limit groove, the guide arm has a dust discharge groove arranged along the guide groove, and the dust discharge groove runs through the upper and lower sides of the guide arm so that it is located on the guide arm The guide grooves on the upper and lower sides and the limit grooves are all connected. The structure of the high-energy storage limiter has the advantages of not easy to accumulate dust and less risk of abnormal noise.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

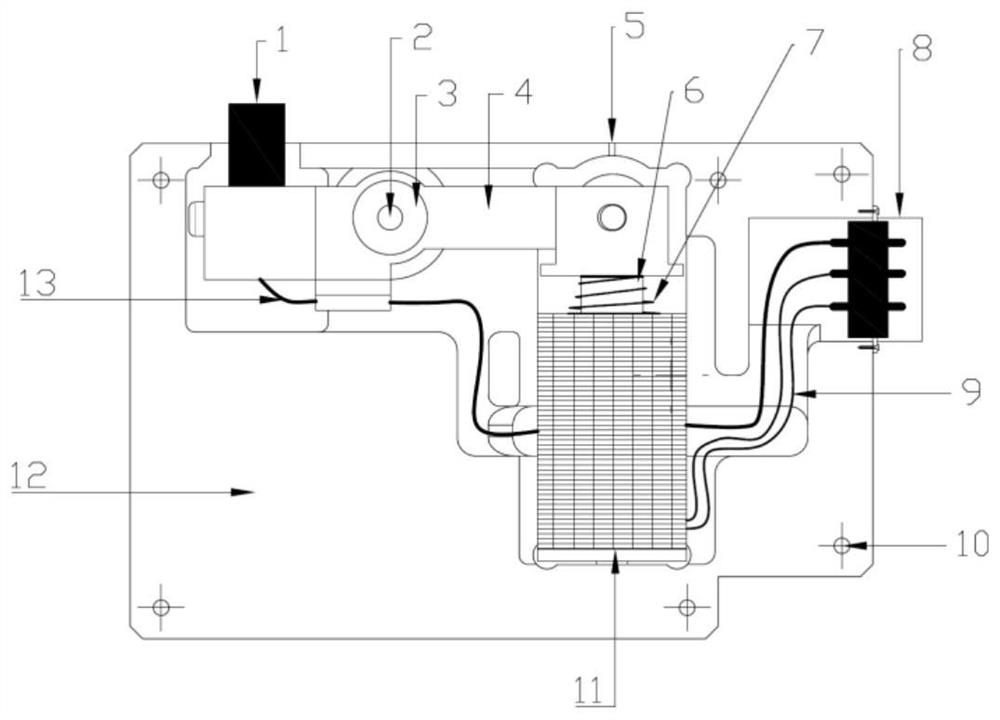

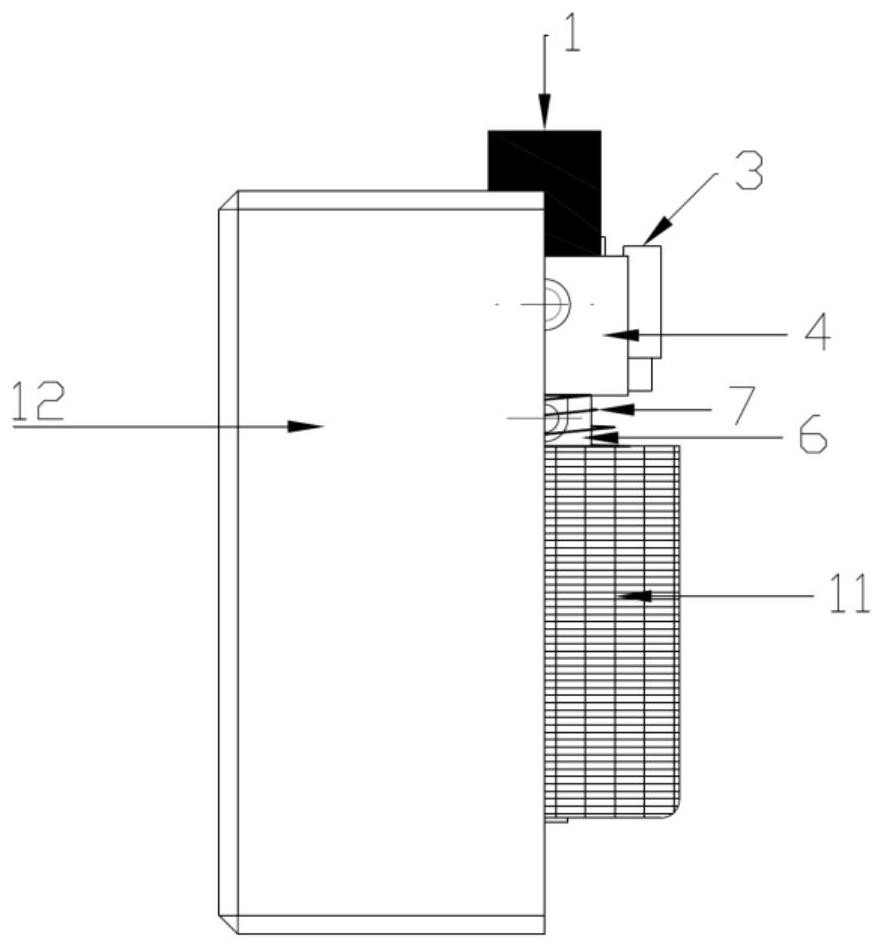

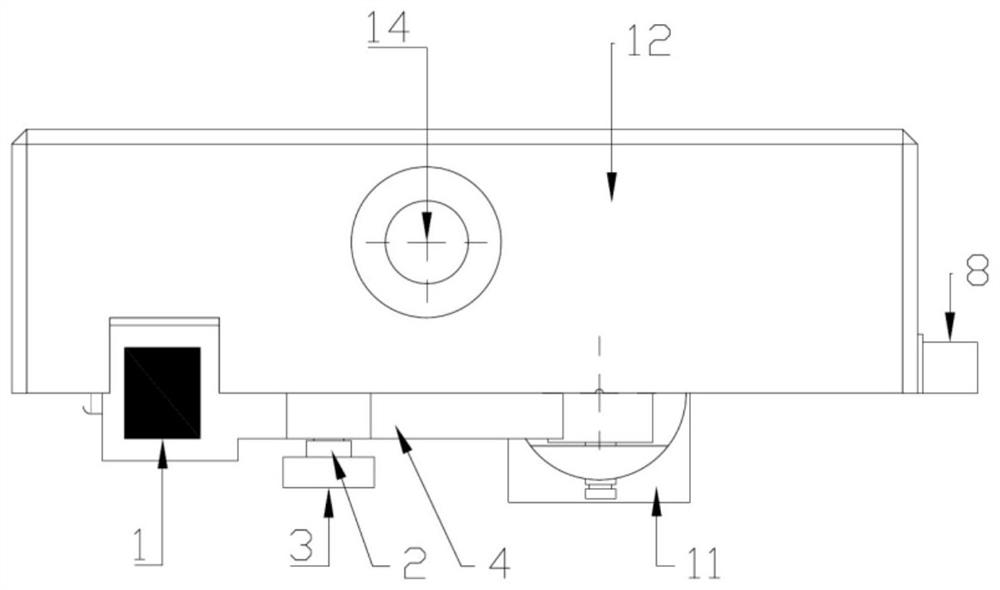

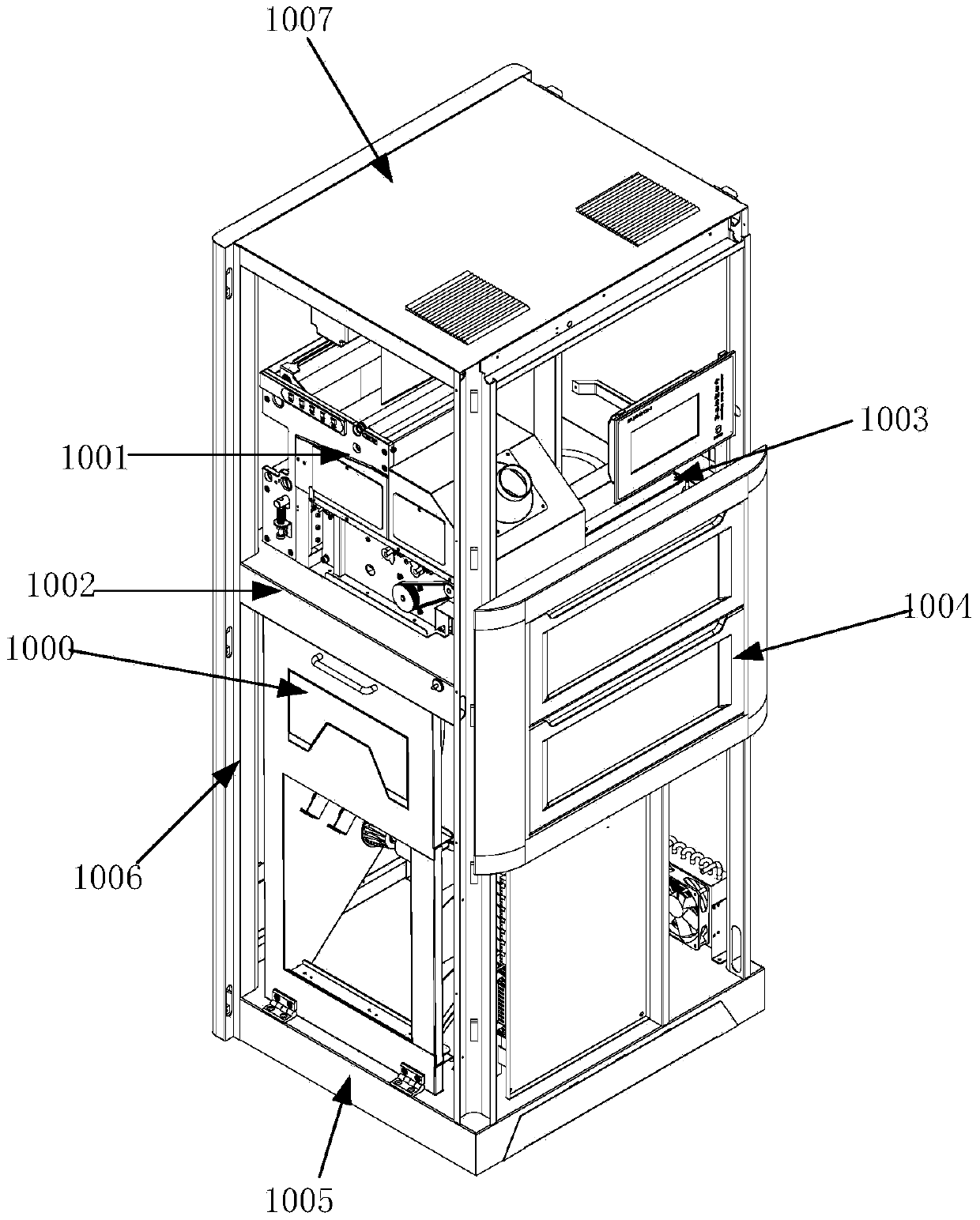

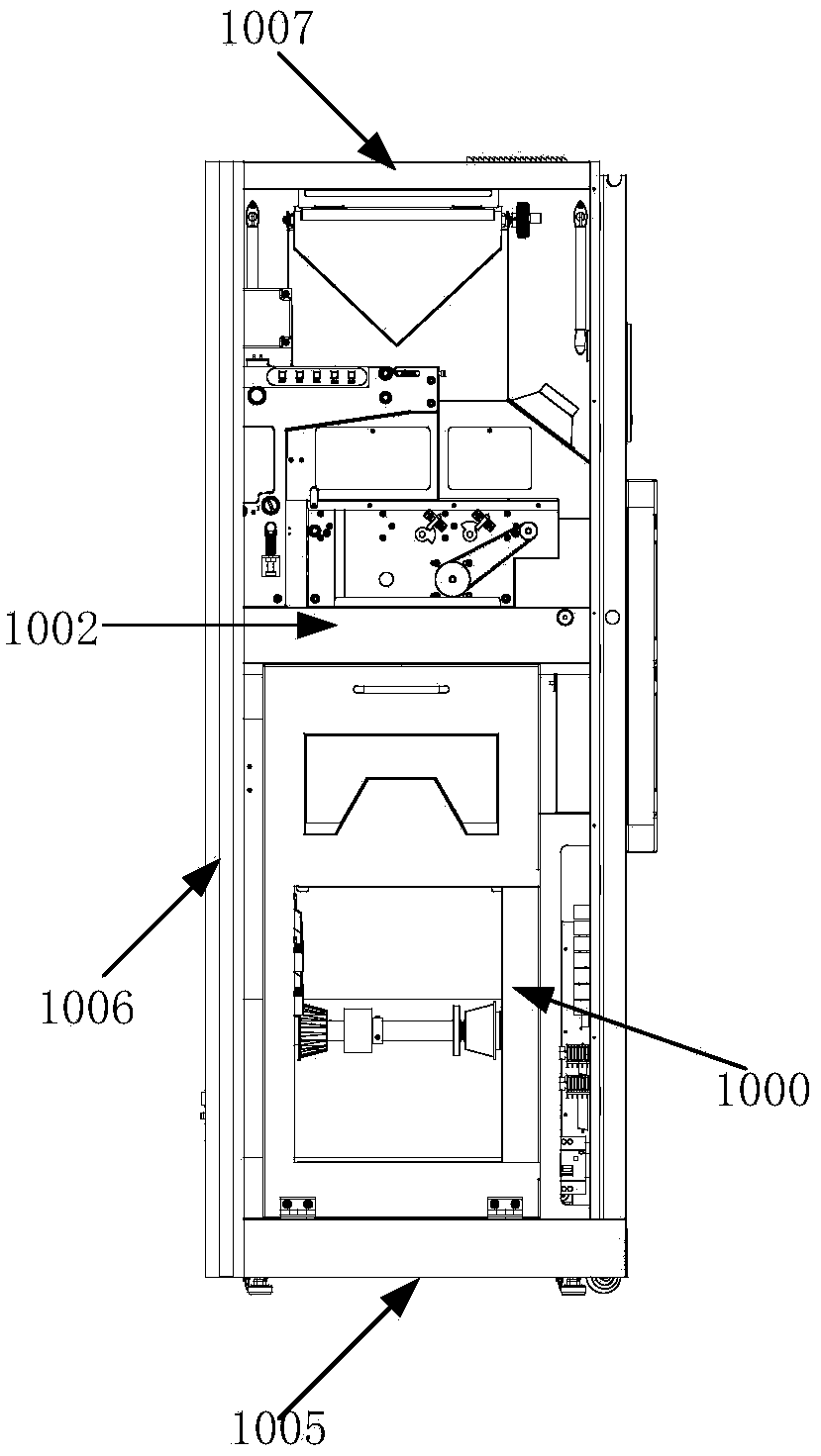

Commercial Soft Towel Machine

ActiveCN104013344BSimple structureSave spacePaper/cardboard articlesDomestic applicationsBiomedical engineeringSoft tissue

The invention provides a commercial soft tissue machine which comprises a tissue packaging mechanism of the commercial soft tissue machine, a tissue folding mechanism of the commercial soft tissue machine, a tissue cutting mechanism of the commercial soft tissue machine, a tissue manufacturing mechanism of the commercial soft tissue machine, a tissue storage bin of the commercial soft tissue machine, bases, supporting frames and a top cover. The bases are fixed to the bottoms of the supporting frames, the top cover is fixed to the tops of the supporting frames, the bases, the four supporting frames and the top cover form an assembly space, the tissue packaging mechanism of the commercial soft tissue machine is located in the assembly space, the bottom end of the tissue packaging mechanism is rotatably connected with one base, the tissue cutting mechanism of the commercial soft tissue machine is located between the tissue packaging mechanism of the commercial soft tissue machine and the tissue folding mechanism of the commercial soft tissue machine, the tissue manufacturing mechanism of the commercial soft tissue machine is located on the right side of the tissue cutting mechanism of the commercial soft tissue machine, and the tissue storage bin of the commercial soft tissue machine is located in front of the tissue manufacturing mechanism of the commercial soft tissue machine. The commercial soft tissue machine can achieve automated operation, is convenient to operate and saves space.

Owner:XINLONG HLDG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com