Connectors and Connector Assemblies Using the Connectors

A connector assembly and connector technology, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve problems such as large space, achieve smooth movement, and facilitate miniaturized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

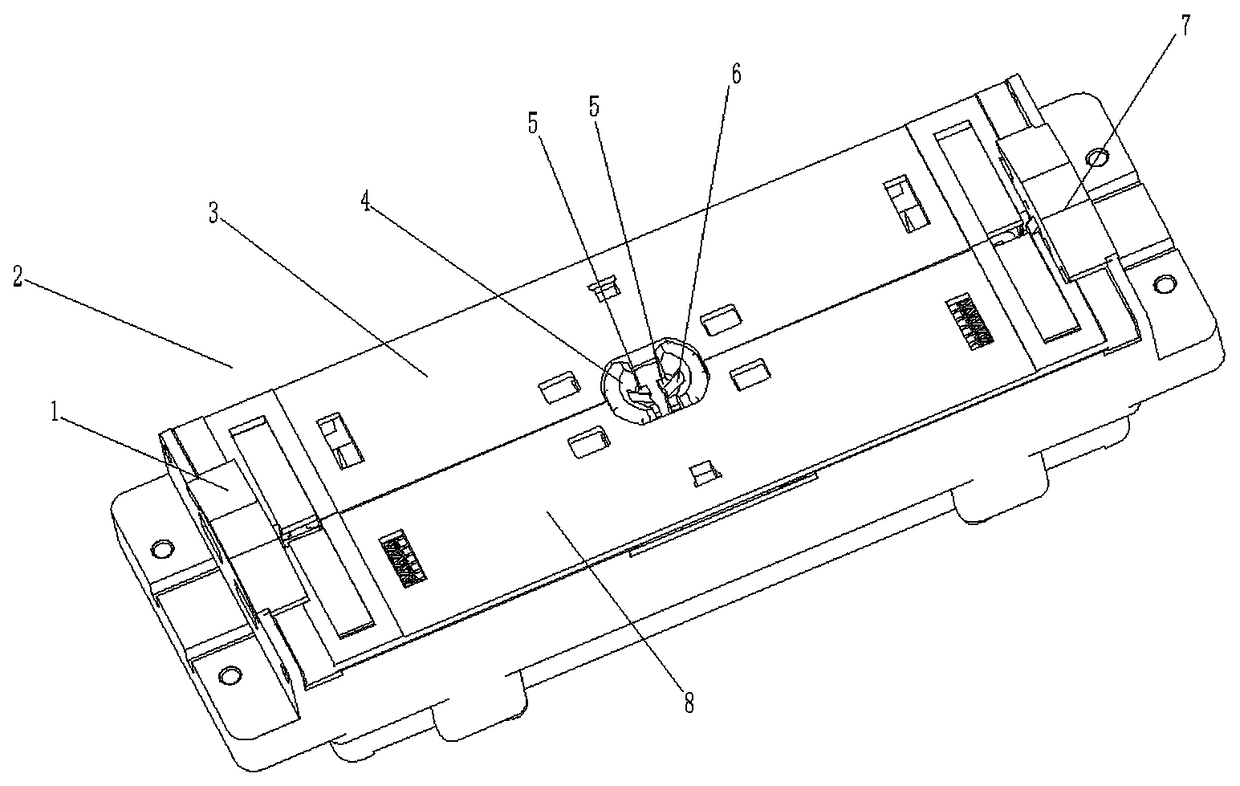

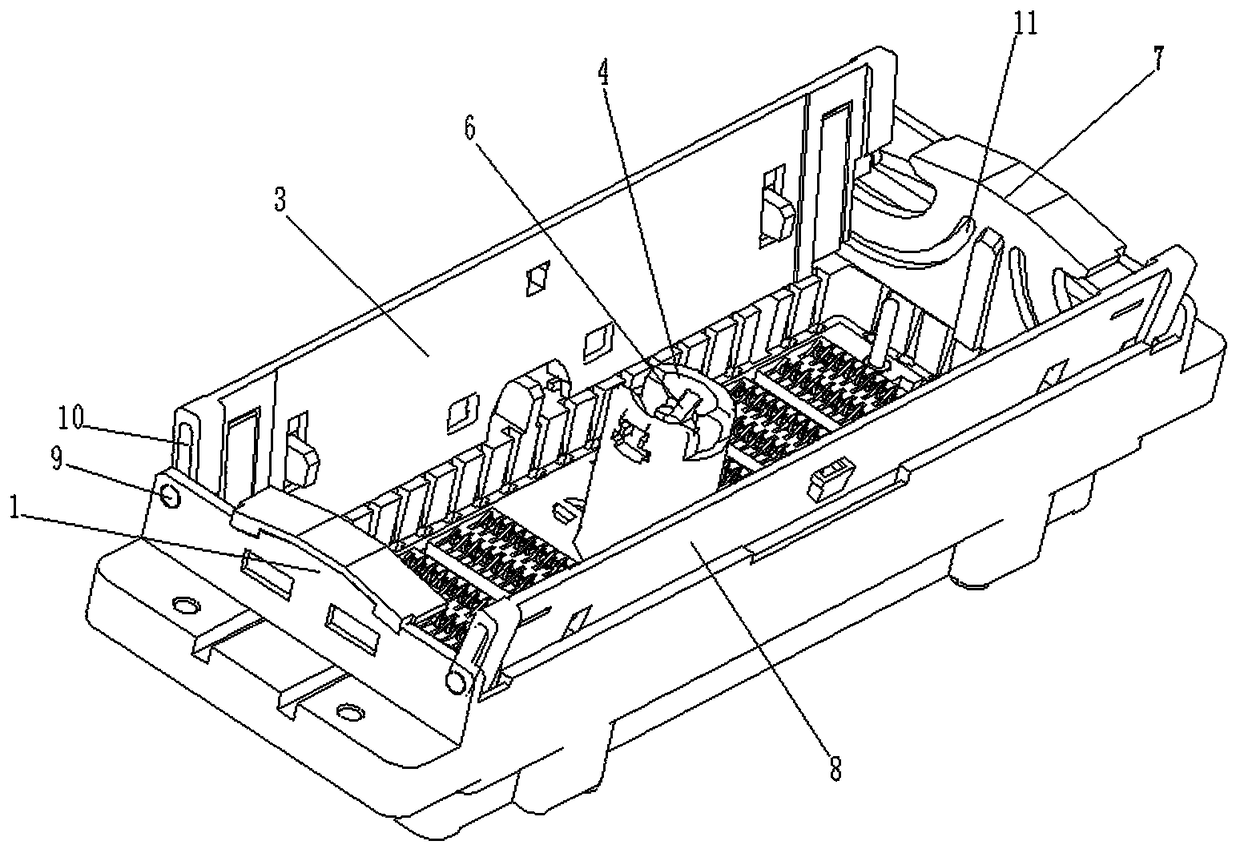

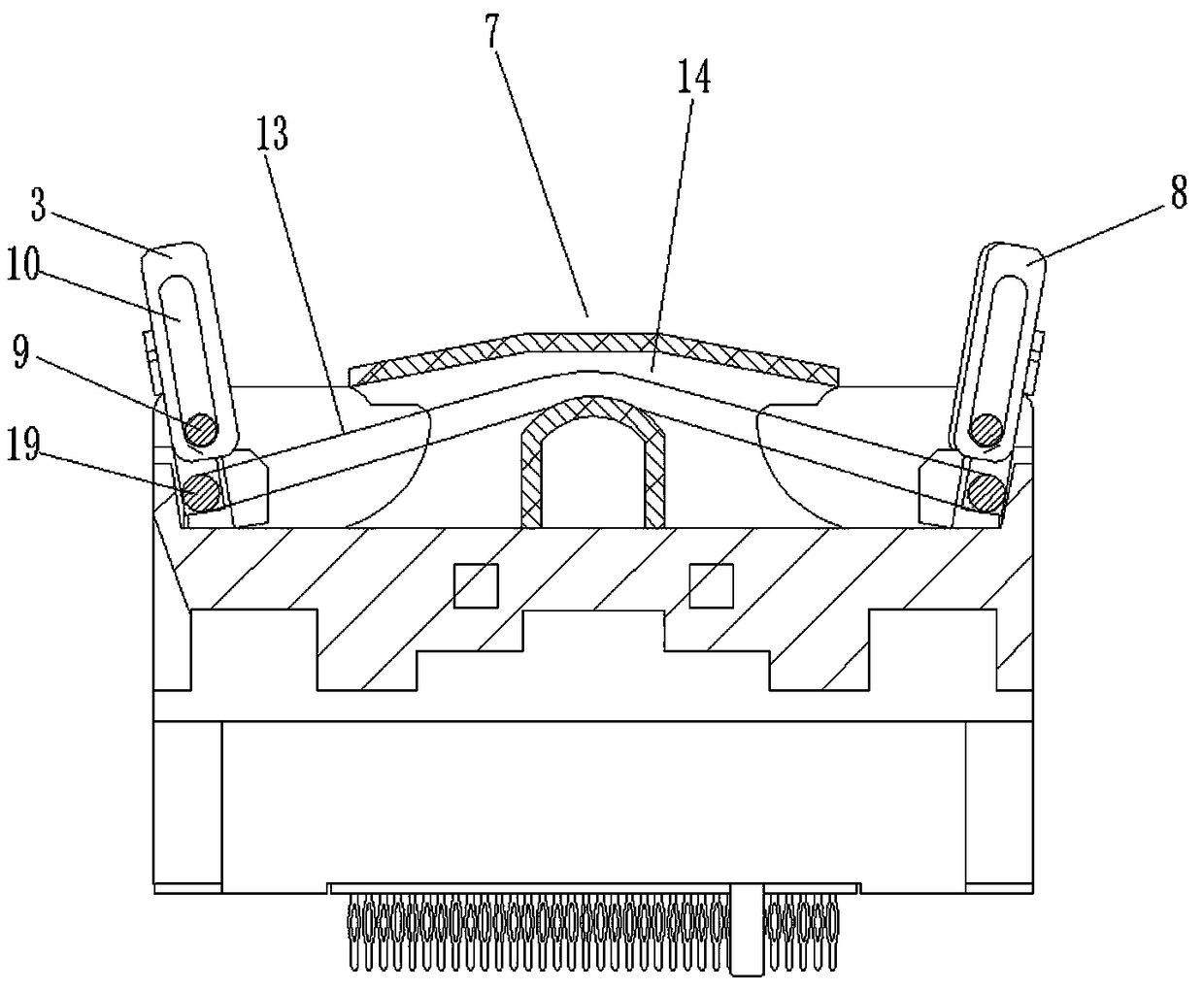

[0026] Example of connector assembly Figure 1~7 Shown: Including an adaptor connector and a connector. In this embodiment, the adaptor connector is a plug 21, and the connector is a socket 2. Both the plug 21 and the socket 2 are ZIF (no insertion force) connectors, and the plug includes a plug The housing and the plug contact piece arranged in the plug housing, the middle part of the plug housing is rotatably provided with a lock shaft 23 whose axis extends in the front-to-rear direction, and both sides of the plug housing have push protrusions 22, wherein the lock shaft is provided There is a lock shaft cam used to drive the plug contact to move in the direction perpendicular to the insertion direction. When the lock shaft is rotated, the lock shaft cam can drive the plug contact to move in the direction perpendicular to the insertion direction, thereby realizing the contact between the plug contact and the socket The reliable contact of the parts and the cooperation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com