Profile corner system

A technology of corners and profiles, applied in the direction of corner joints/side joints, etc., can solve problems such as increased production costs, differences, and installation obstacles, and achieve the effects of reducing the number of parts, light overall structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment S1

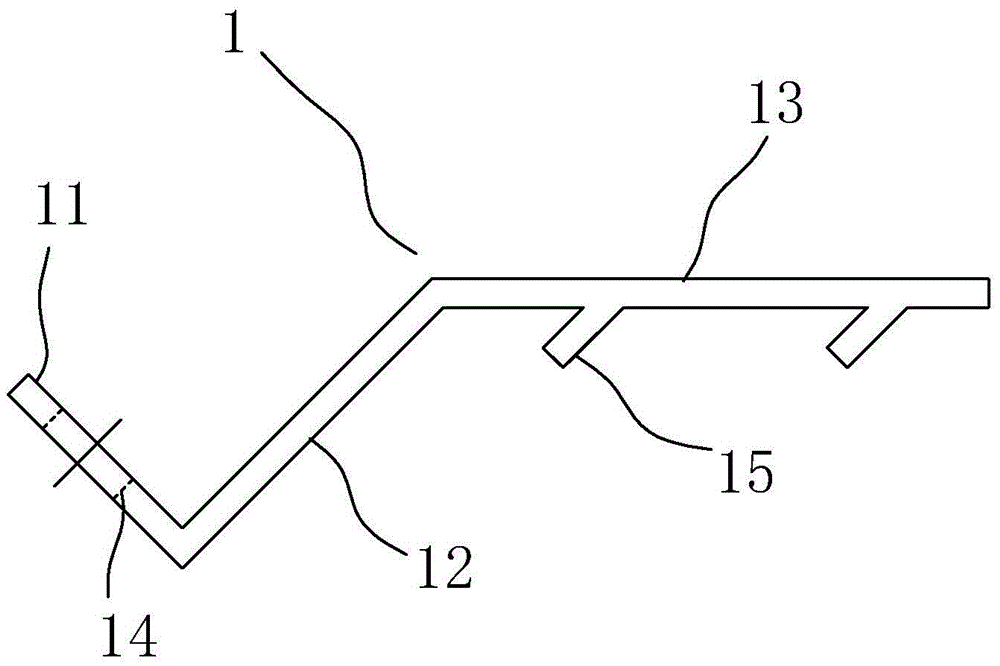

[0033] refer to figure 1 , a profile corner pull piece, comprising a pull piece main body 1, the pull piece main body 1 is in the shape of a narrow strip as a whole, and is sequentially bent from the head end to the tail end to form a connecting section 11 and a hook pull section 13, The connection section 11 has a connection hole 14 , and the hook section 13 punches out more than one pull hook 15 , and the pull hook 15 as a whole is straight or curved toward the head end of the pull piece main body 1 . In order to reduce the length of the corner cavity of the profile, sometimes a transition section 12 is provided between the connection section 11 and the hook section 13, and the connection section 11, the transition section 12, and the hook section 13 are integrated. Of course, if the position is suitable, for example, the external setting of the pull code group at the corner of the profile is required in the future, then the transition section 12 can be made very short, even...

Embodiment S2

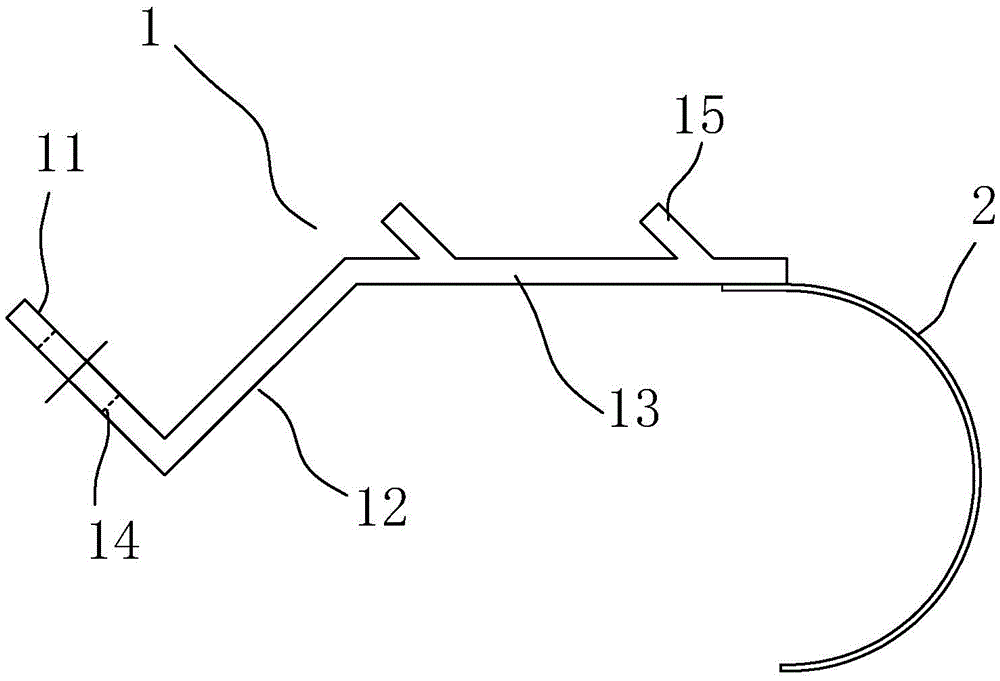

[0035] refer to figure 2 , the profile corner of embodiment S2 is basically the same as that of embodiment S1, but the rear section or tail end of hook pull section 13 is also connected with elastic abutting body 2, and the stretching direction of elastic abutting body 2 is the hook The opposite direction of the side where the drag hook 15 on the pull section 13 is located. In practice, the elastic supporting body 2 can be a shrapnel or an elastic steel wire, etc., which is mainly used to lean against the inner cavity when the pull code group is installed in the corner of the profile, so as to ensure that the connecting section is tightly attached to the inner cavity wall of the profile and is not easy to loosen. take off.

Embodiment S3

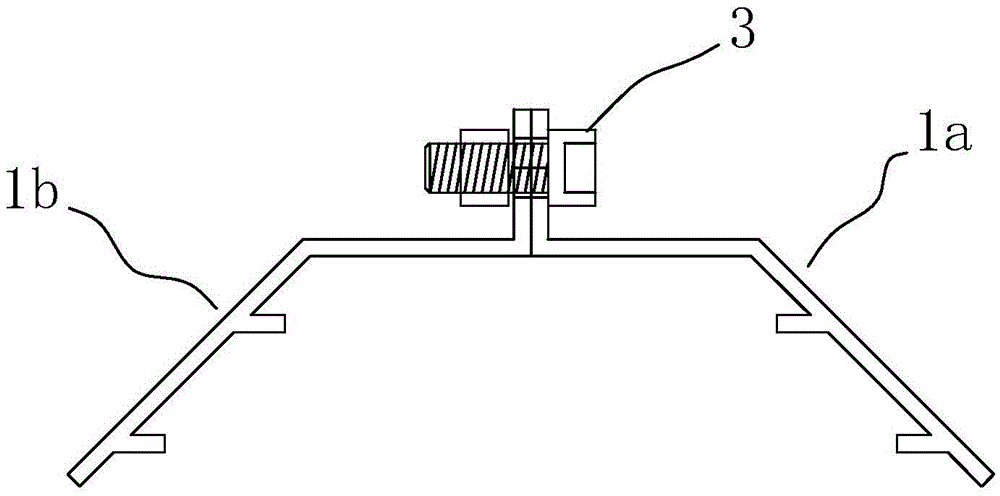

[0038] refer to image 3 , the profile corner position pull code group of embodiment S3 comprises horizontal pull code sheet 1a and vertical pull code sheet 1b, and described horizontal pull code sheet 1a is the profile corner position pull code sheet described above, is connected with horizontal pull code sheet 1a The bottom surface of the section is a mirror-image symmetrical plane, and the shape and structure of the vertical pull code sheet 1b is basically mirror-image-symmetrical to the horizontal pull code sheet 1b. A connecting screw 3 passes through the connecting hole of the horizontal pull code sheet 1a and the vertical pull code sheet 1b at the same time. The horizontal pull code sheet 1a and the vertical pull code sheet 1b are connected together.

[0039] In order to make it easier to overlap the two pull codes in practice and not easy to rotate relative to the connecting screw 3 to make installation inconvenient, further, the connecting section of the horizontal pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com