Buffering device used for controlling movement speed of actuator cylinder

A technology of movement speed and buffer device, applied in the direction of fluid pressure actuating device, chassis, etc., it can solve the problems that the rubber pad is easy to fall off or age, it is not enough to overcome the friction torque, and it is difficult to meet the structural requirements, so as to achieve the inertia impact force Small size, simple structure, and the effect of reducing mechanical impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

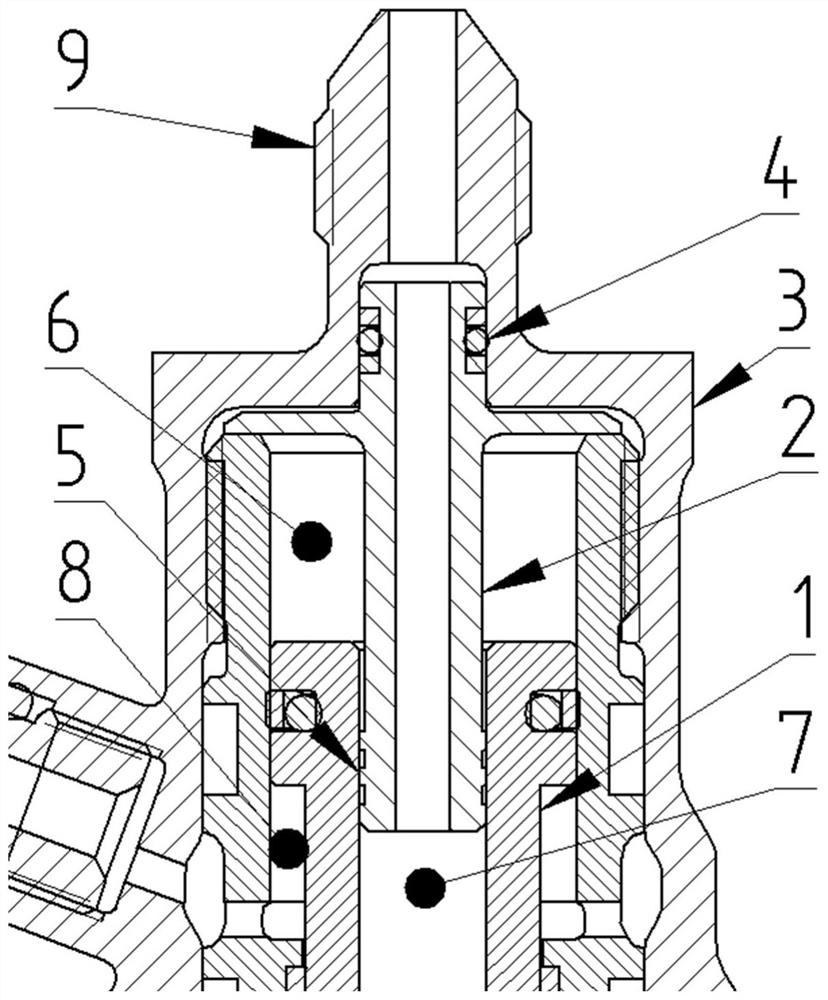

[0013] refer to figure 1. In the preferred embodiment described below, a buffer device for controlling the movement speed of the actuator includes: a piston rod 1 integrated in the outer cylinder 3 of the actuator and assembled in the locking chamber 6, and the piston rod 1 is made of The blind hole chamber 7 is characterized in that: the upper lock chamber 6 is equipped with a damper tube 2 passing through the O-shaped sealing ring 4, sealed in the lock nozzle of the actuator, and connected to the oil flow path of the lock nozzle; On the circumference of the sliding section of the damping tube 2, there is a cut-off ring groove 5 that moves in the direction of the blind hole 7 to adjust the movement distance between the damping tube 2 and the piston rod 1; when the piston rod 1 extends downward, the hydraulic pressure The oil enters the damping tube 2 from the locking nozzle 9, and enters the blind cavity 7 of the piston rod 1 along the damping tube 2. After the blind cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com