Patents

Literature

363results about How to "Simple control algorithm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

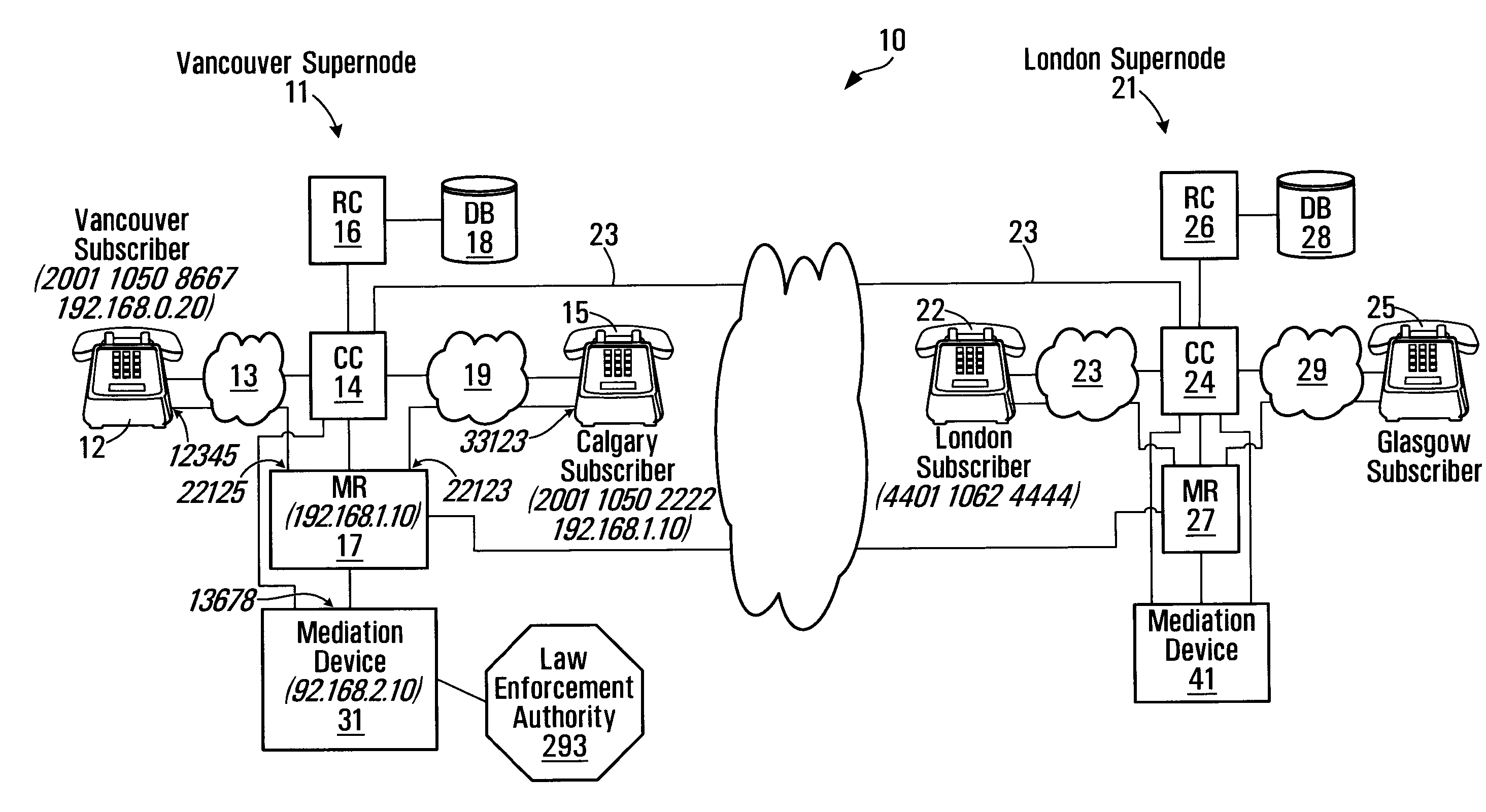

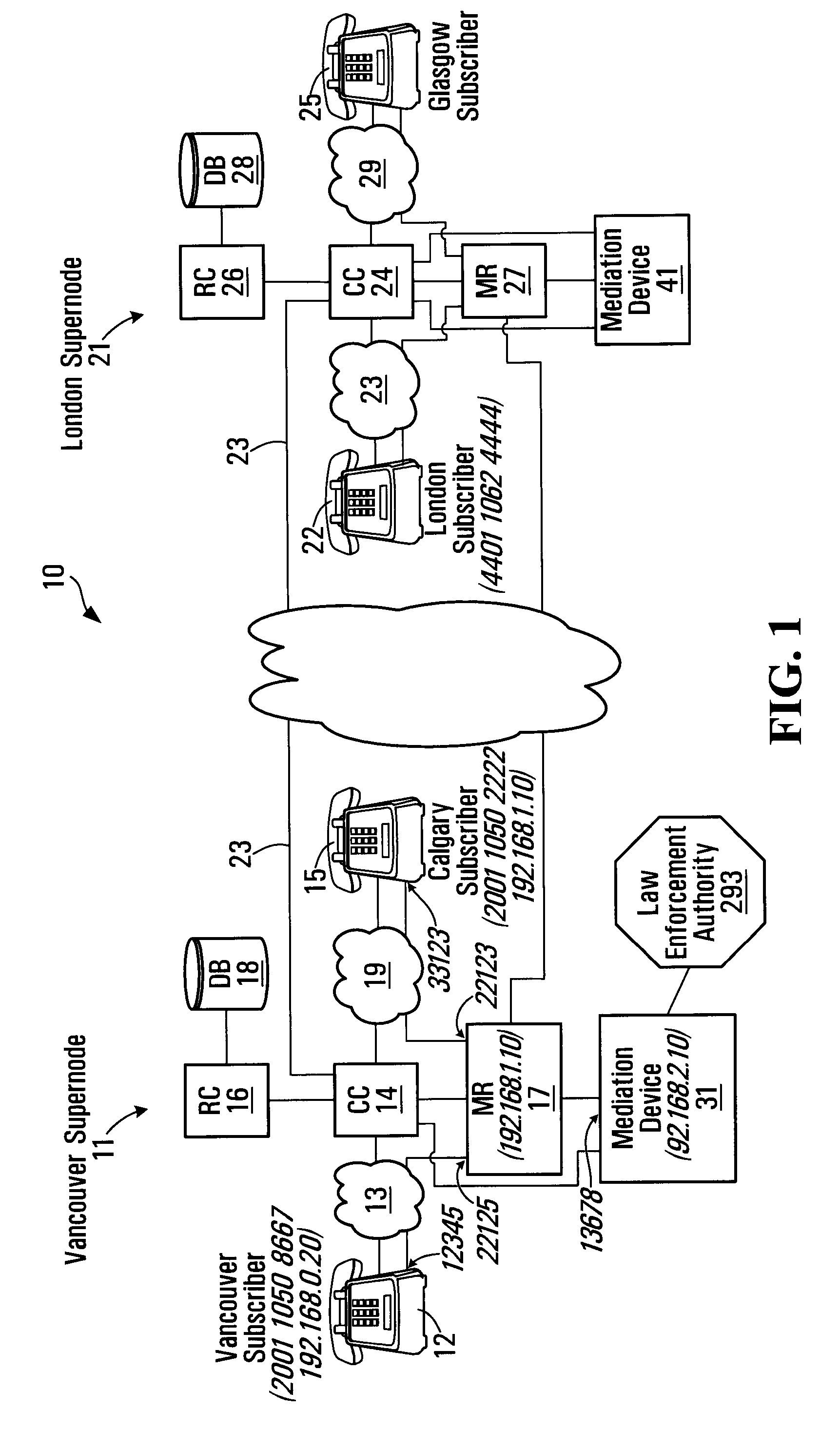

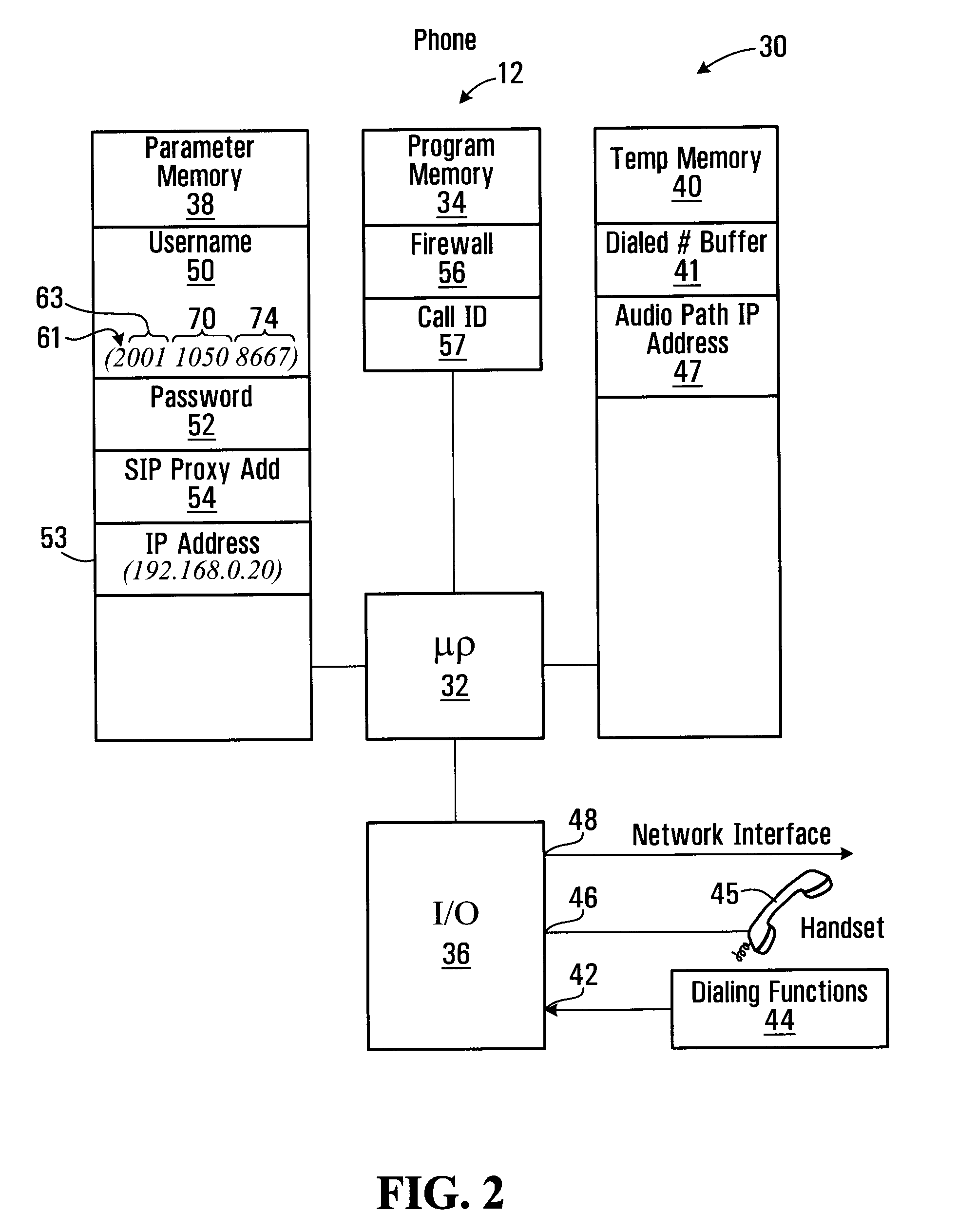

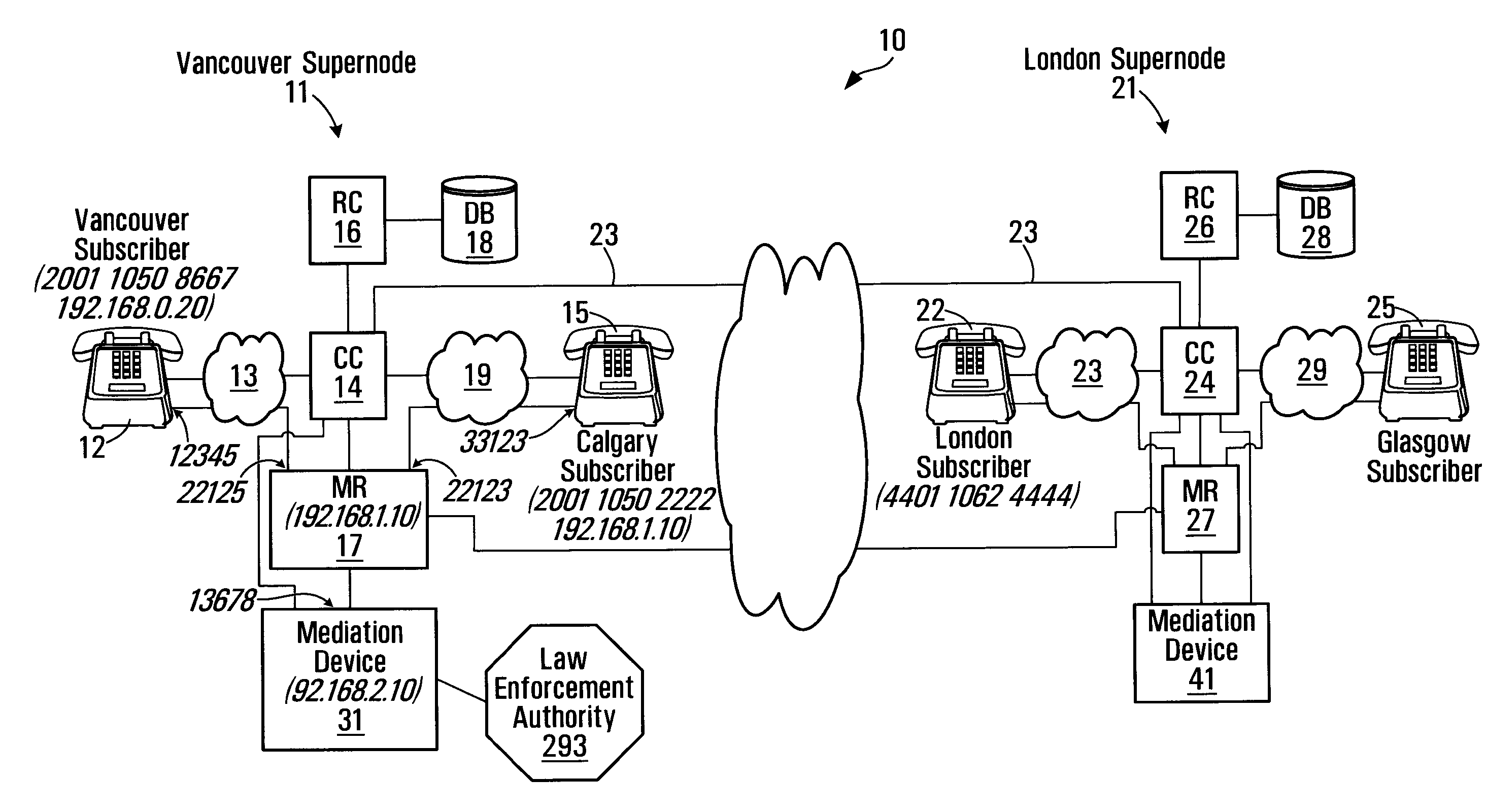

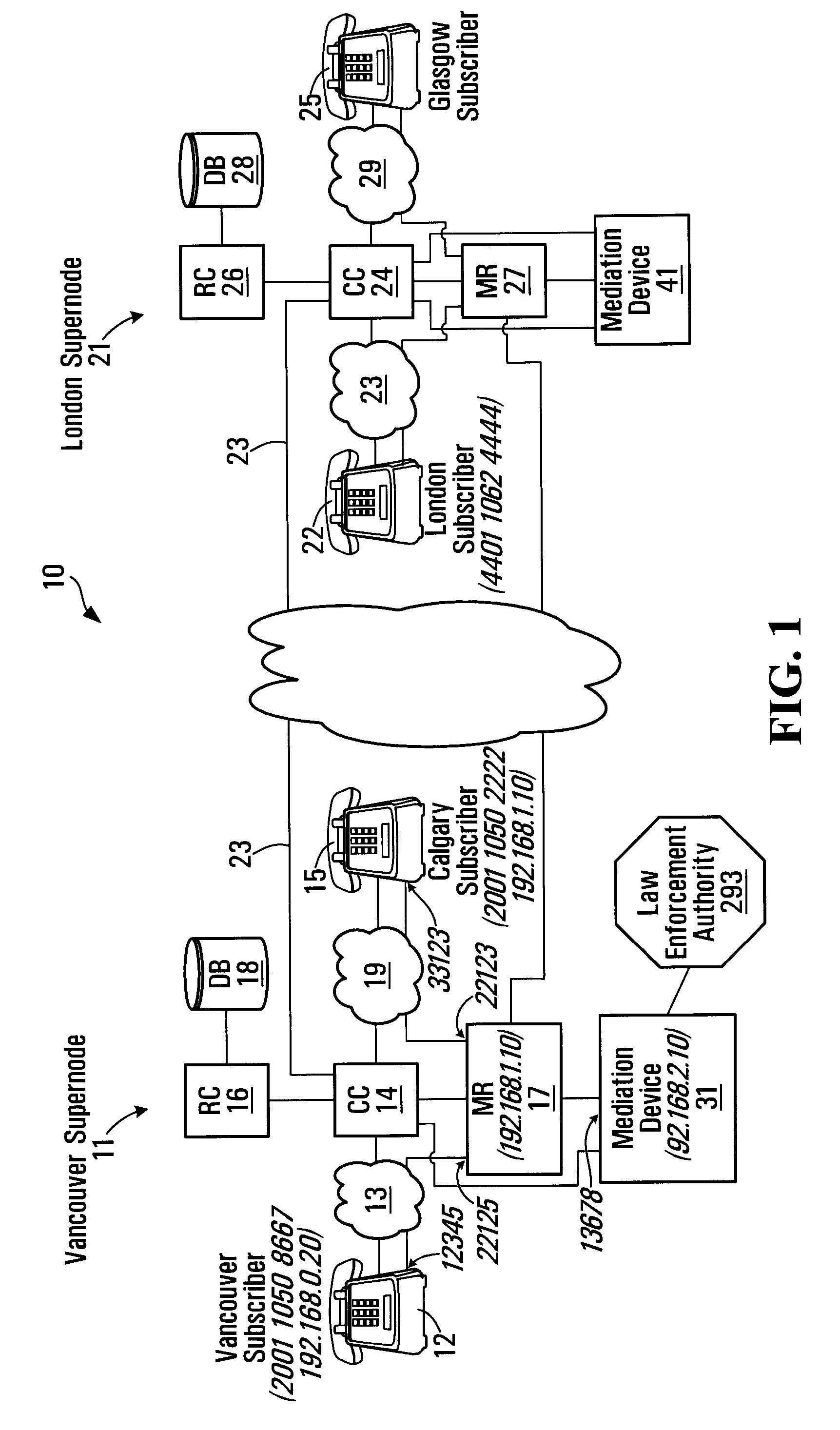

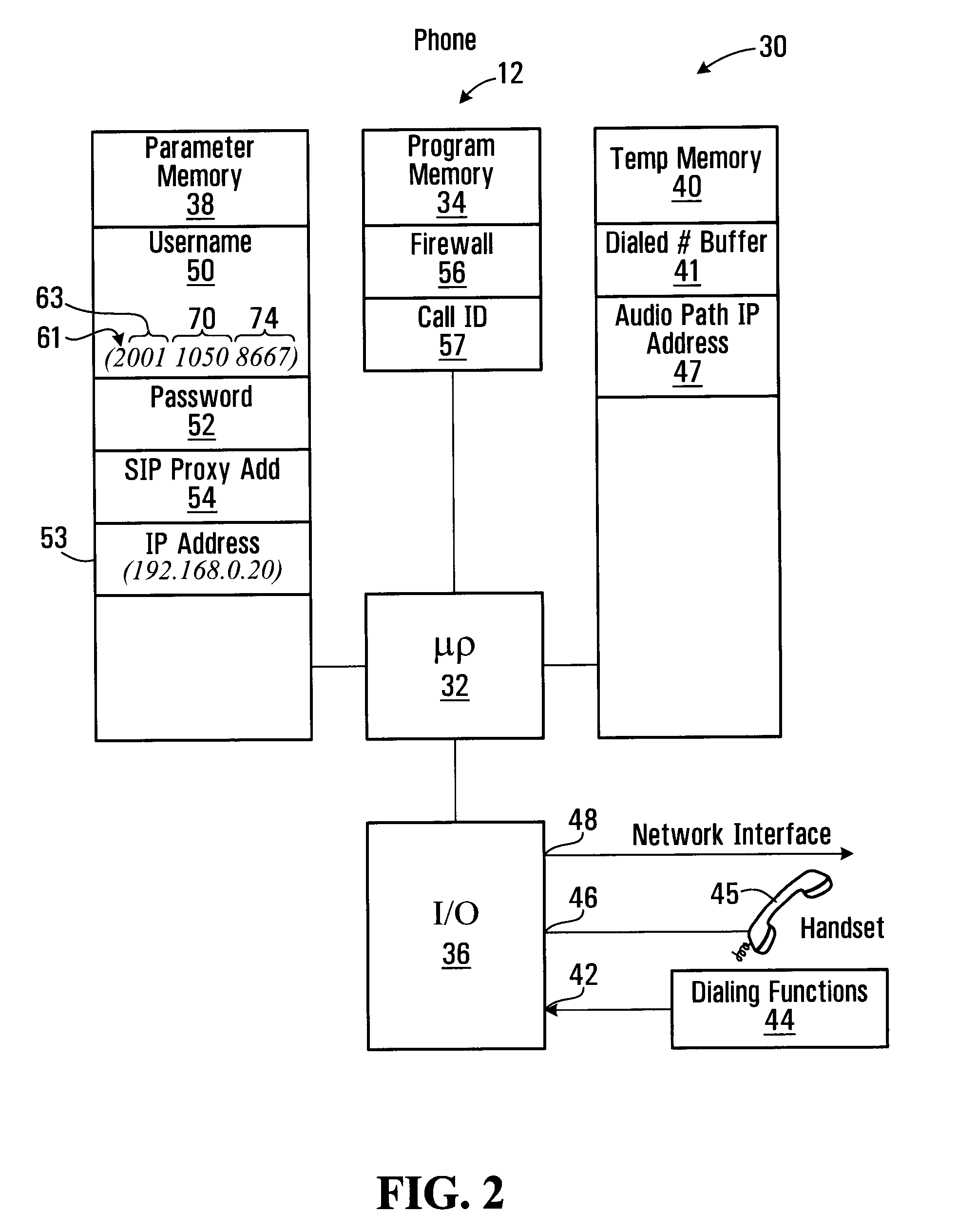

Intercepting voice over IP communications and other data communications

ActiveUS20100150138A1Simple control algorithmFacilitates profileSpecial service for subscribersSupervisory/monitoring/testing arrangementsTelecommunicationsVoice over IP

Methods and apparatus for intercepting communications in an Internet Protocol (IP) network involve maintaining dialing profiles for respective subscribers to the IP network, each dialing profile including a username associated with the corresponding subscriber, and associating intercept information with the dialing profile of a subscriber whose communications are to be monitored. Intercept information will include determination information for determining whether to intercept a communication involving the subscriber, and destination information identifying a device to which intercepted communications involving the subscriber are to be sent. When the determination information meets intercept criteria communications are established with a media relay through which communications involving the subscriber will be conducted or are being conducted to cause the media relay to send a copy of the communications involving the subscriber to a mediation device specified by the destination information.

Owner:VOIP PAL COM INC

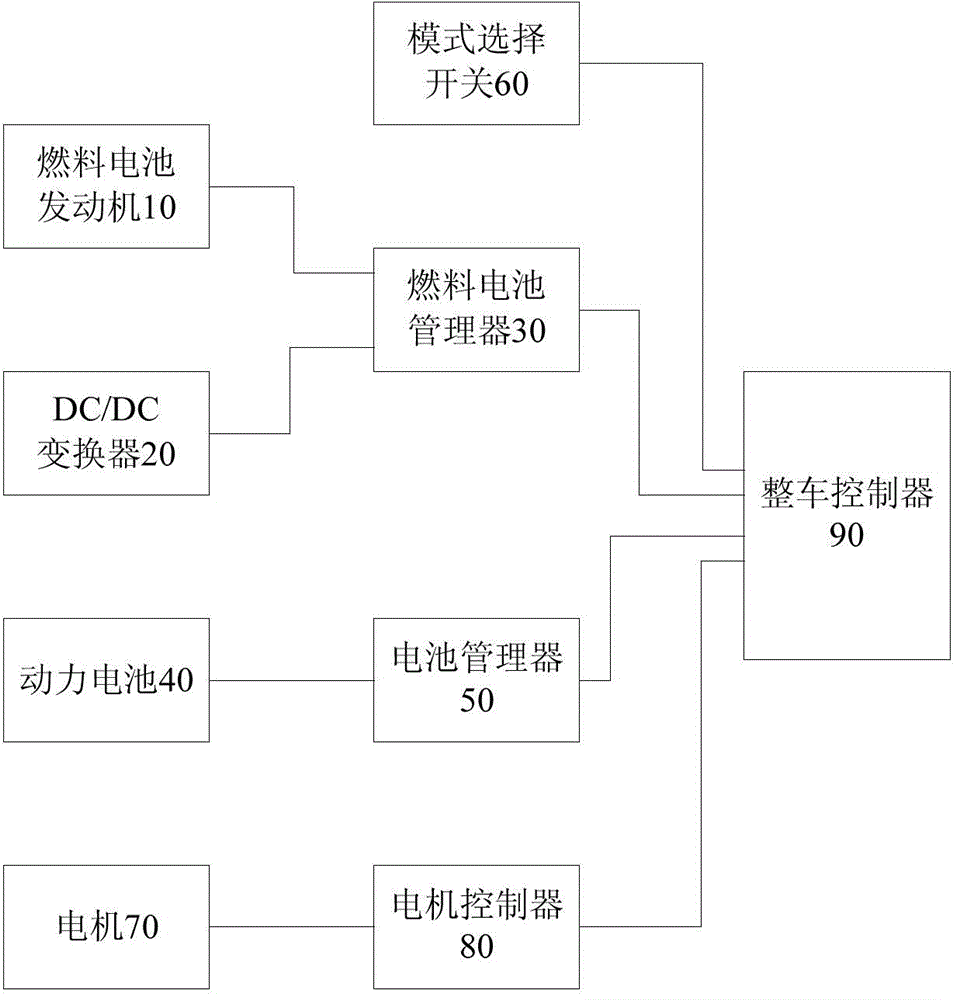

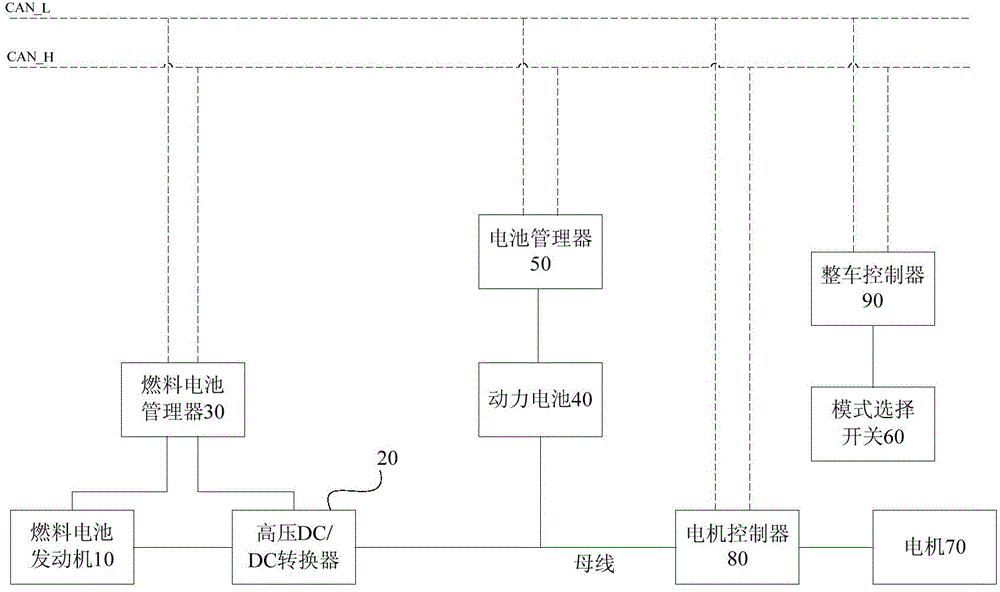

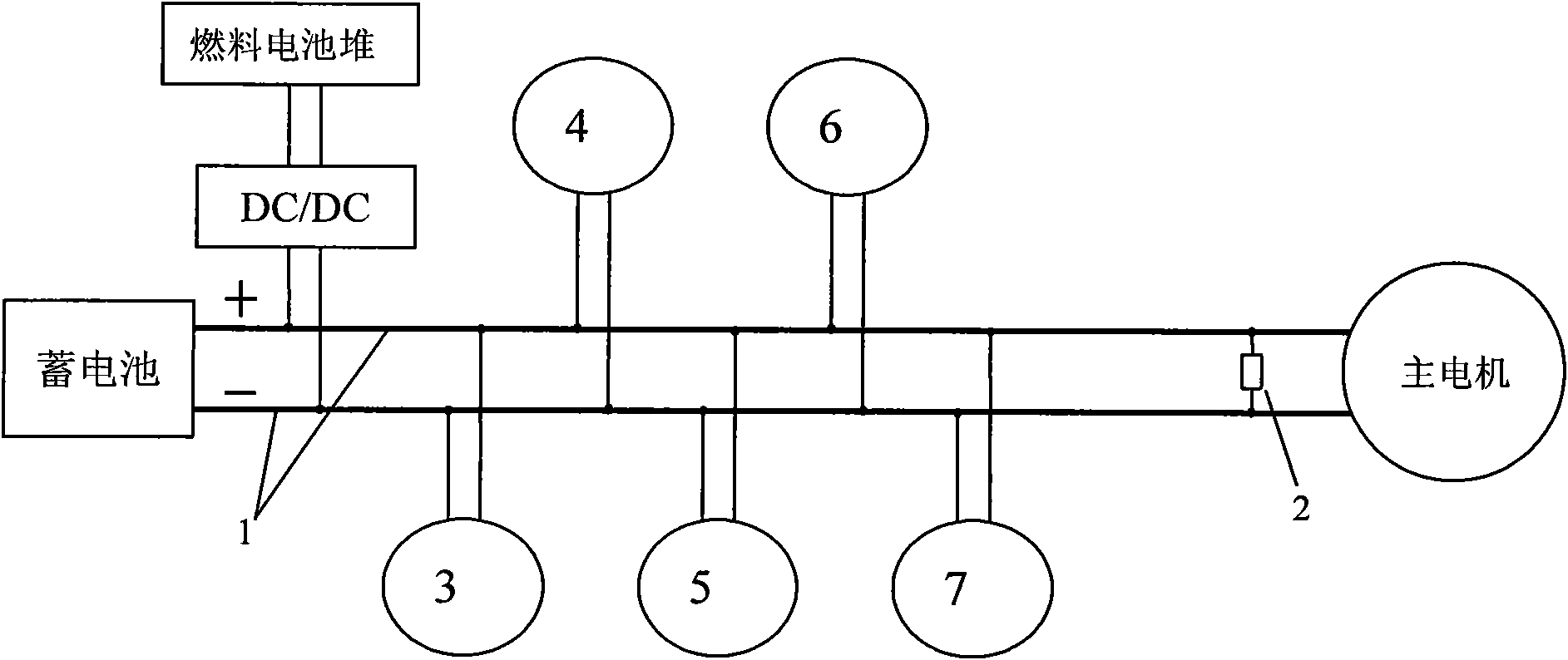

Fuel cell vehicle, control method and control system thereof

ActiveCN104827922AOptimize energy distributionSimple control algorithmSpeed controllerElectric machinesPower batteryFuel cells

The invention discloses a control system of a fuel cell vehicle. The control system includes a fuel cell engine, a DC / DC converter, a fuel cell manager for controlling the fuel cell engine and the DC / DC converter, a power battery, a battery manager for controlling the power battery, a mode selection switch, a motor and a motor controller; a vehicle controller is connected with the fuel cell manager, the battery manager and the motor controller respectively; the vehicle controller determines the working mode of the fuel cell engine according to the fault state of the fuel cell vehicle, the charge value of the power battery and the state of the mode selection switch, and controls the fuel cell manager according to the working mode. With the control system of the fuel cell vehicle of the invention adopted, vehicle energy distribution can be optimized, and the efficiency of a fuel cell system and the power battery can be improved, and the fuel cell system can be effectively protected, and a vehicle control algorithm can be simplified, and the control algorithm is reliable and effective. The invention also discloses a fuel cell vehicle and a control method of the fuel cell vehicle.

Owner:BEIQI FOTON MOTOR CO LTD

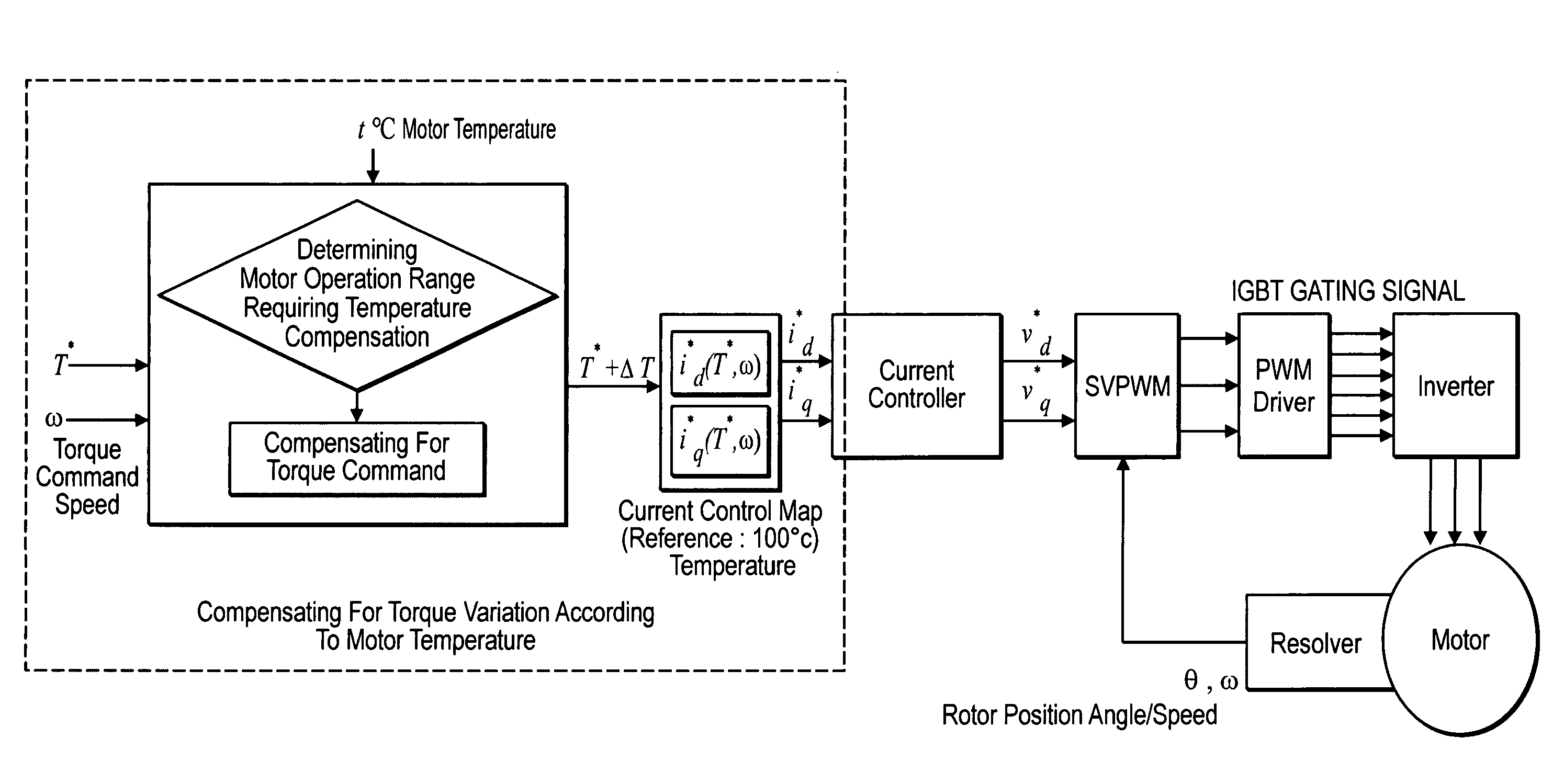

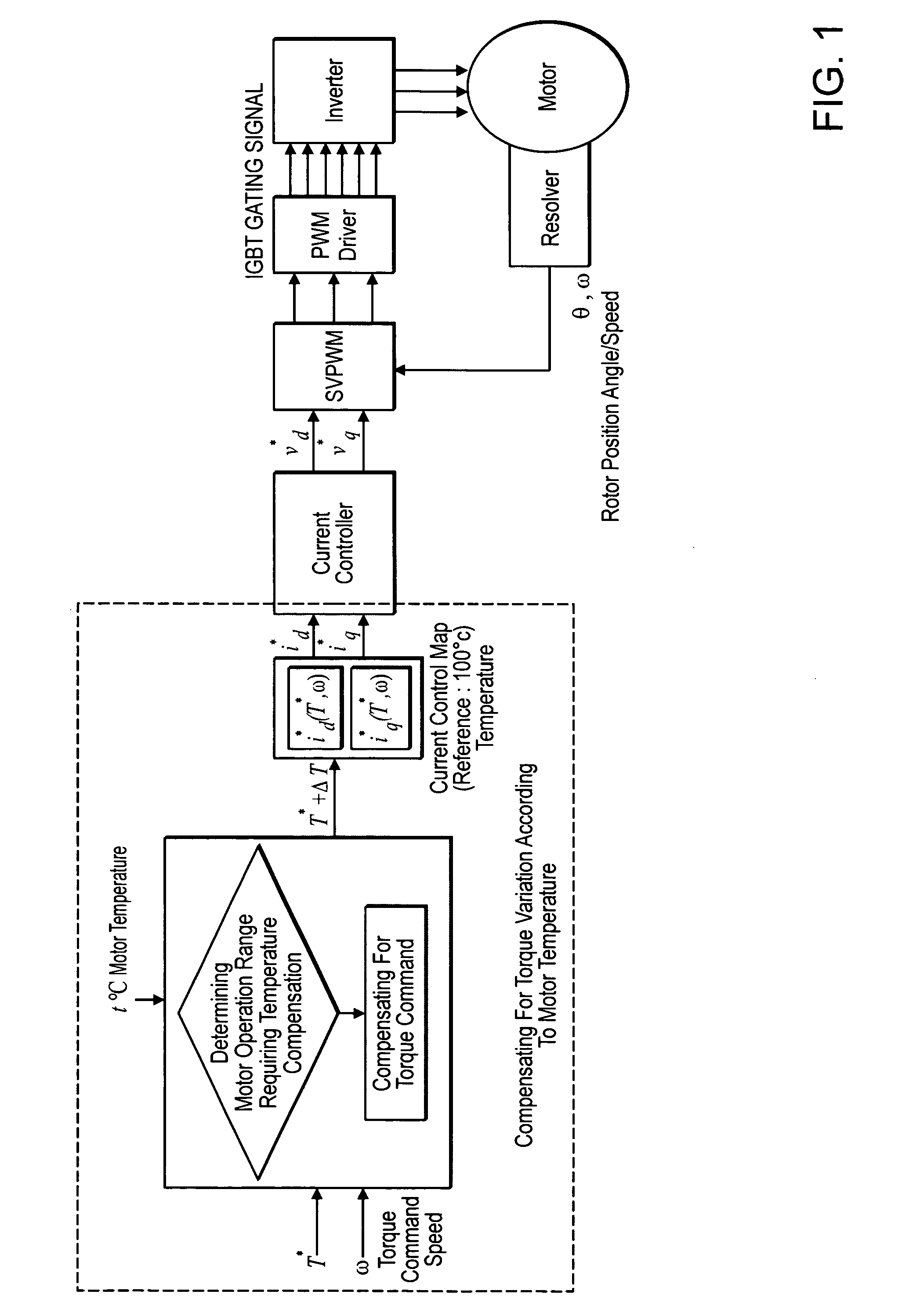

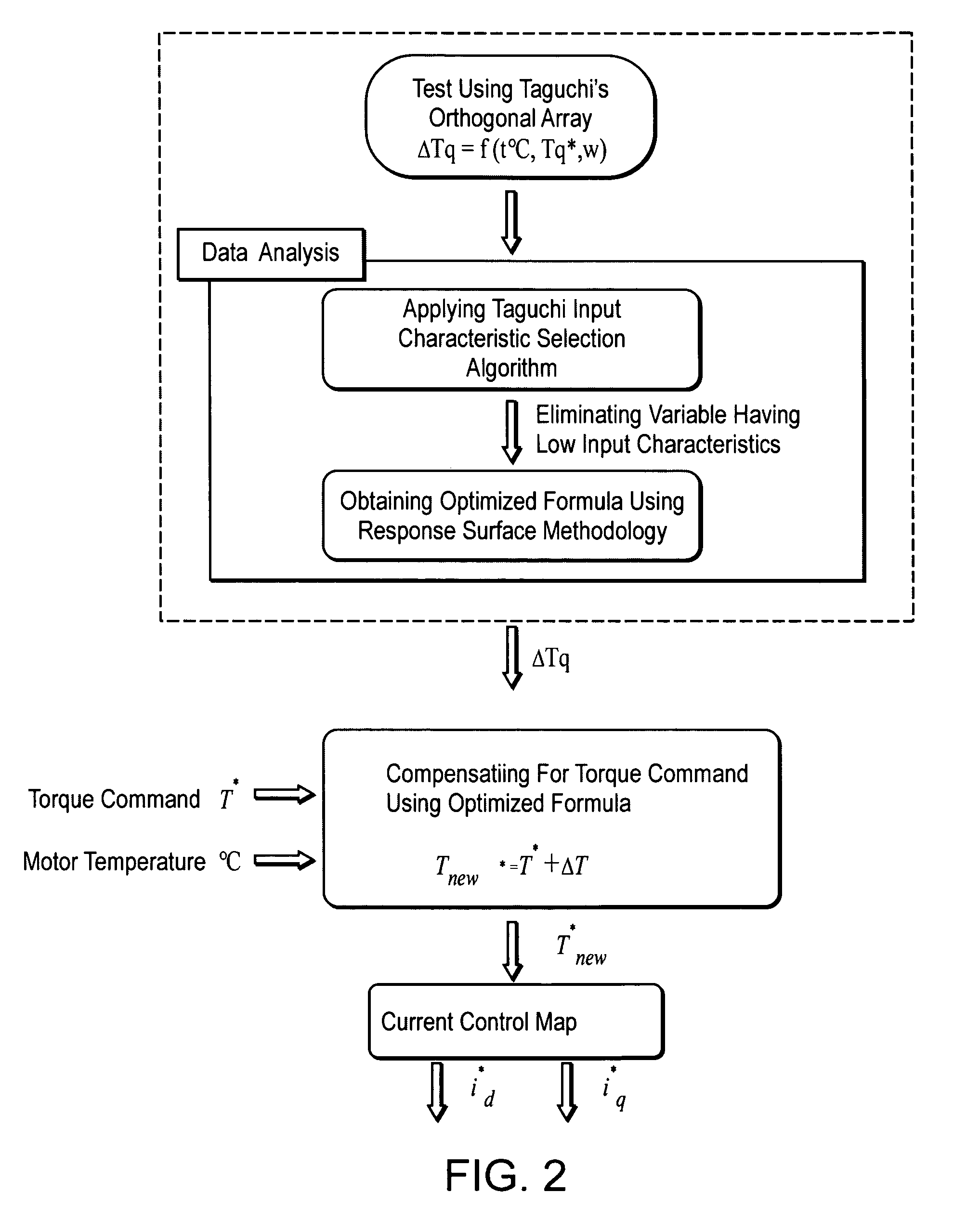

Method for controlling motor torque in hybrid electric vehicle

InactiveUS20090153087A1Require controlImprove torque control performanceHybrid vehiclesCommutation monitoringElectric vehicleEngineering

The present invention provides a method for controlling motor torque in a hybrid electric vehicle, which can reduce current control mapping time and simplify control algorithm by providing a torque control compensation logic against a change in temperature of a motor (interior permanent magnet synchronous motor) of the hybrid electric vehicle. The present method includes: forming a single current control map based on an engine room temperature; determining a motor operation range that requires temperature compensation according to motor load conditions such as speed and torque; obtaining an optimization formula for torque command compensation; determining a torque command compensation value using the optimization formula; generating a new torque command with the torque command compensation value and applying the new torque command to the single current control map; and applying to a motor a current for which a torque variation according to a temperature change is compensated.

Owner:HYUNDAI MOTOR CO LTD

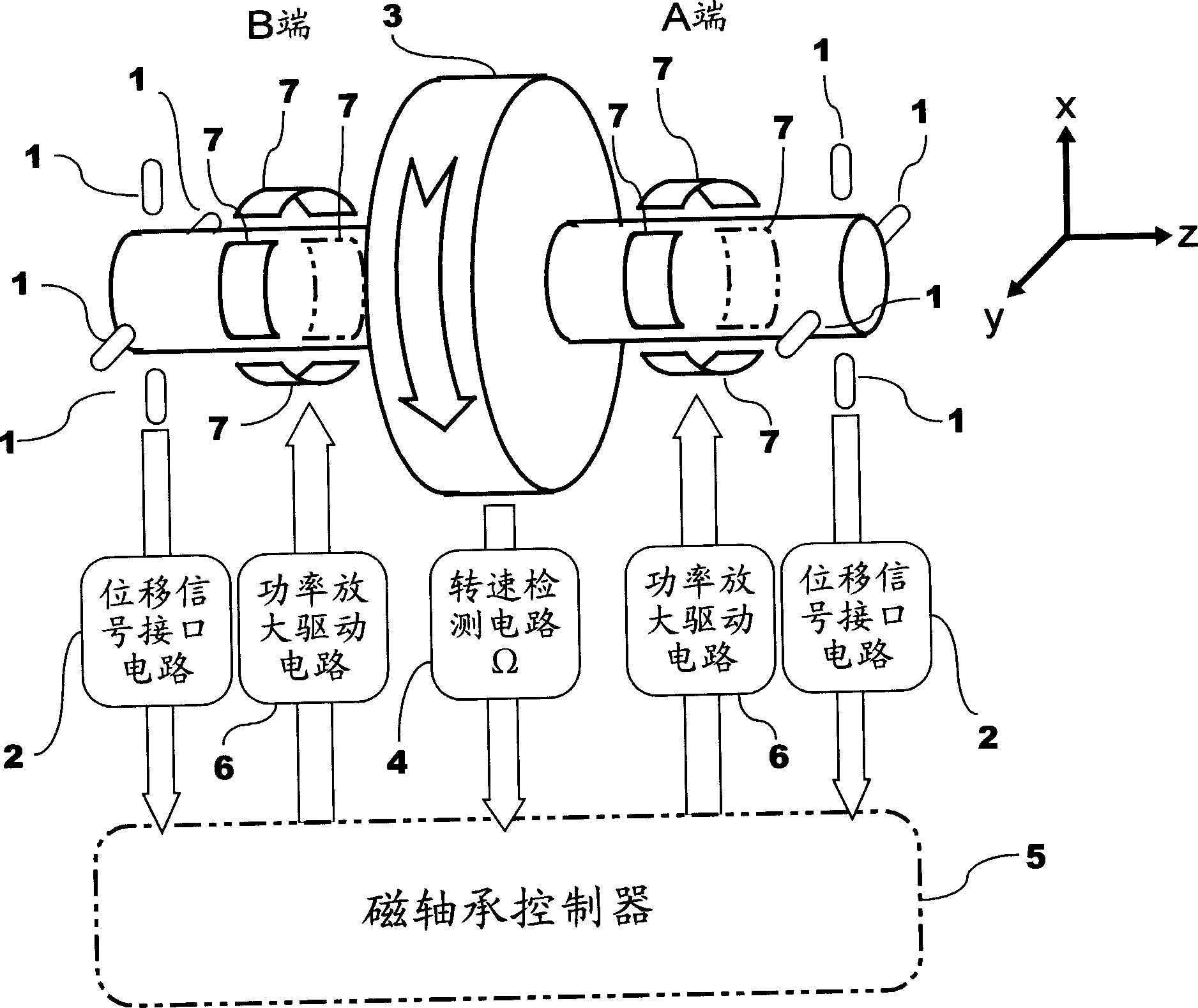

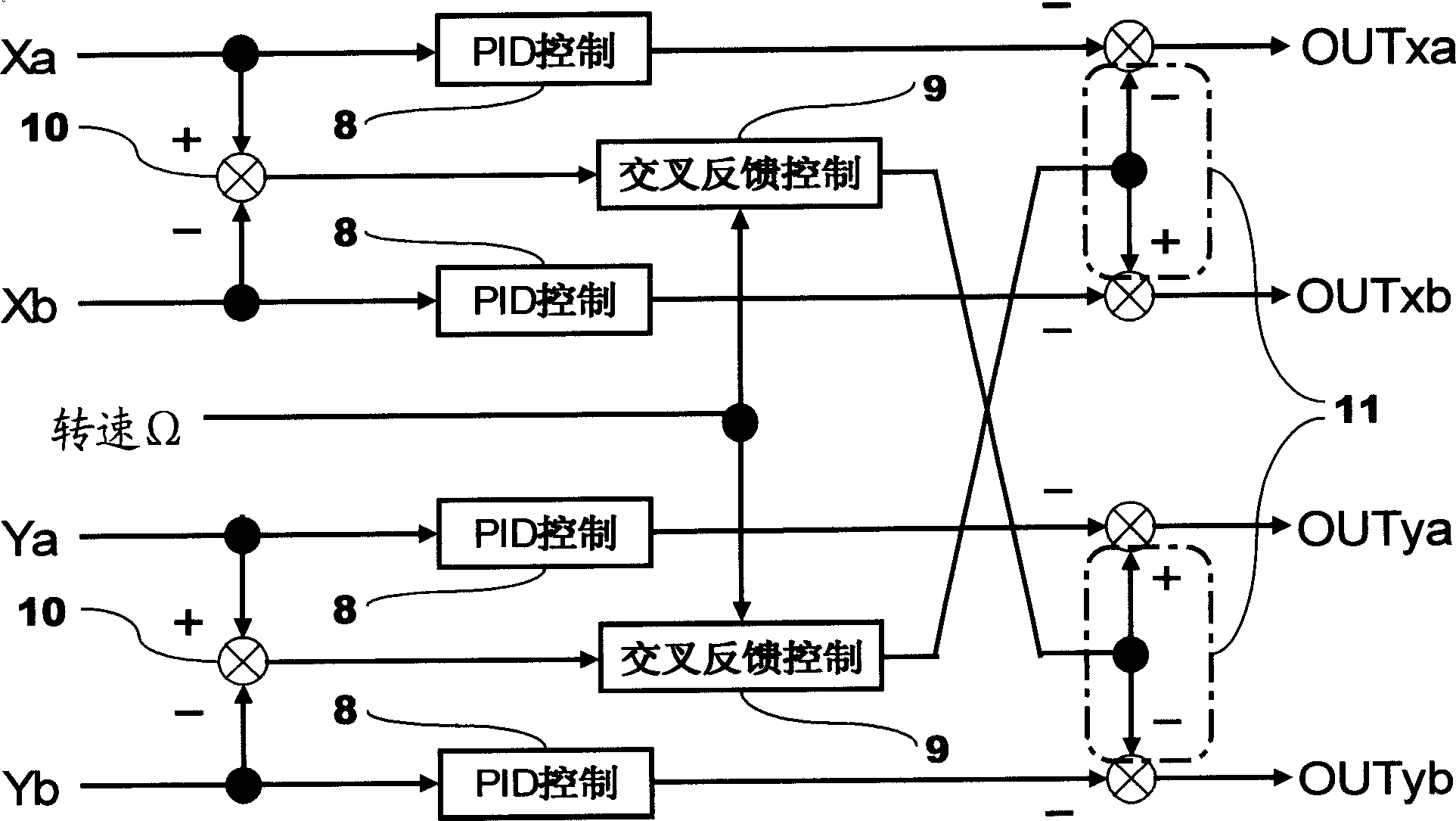

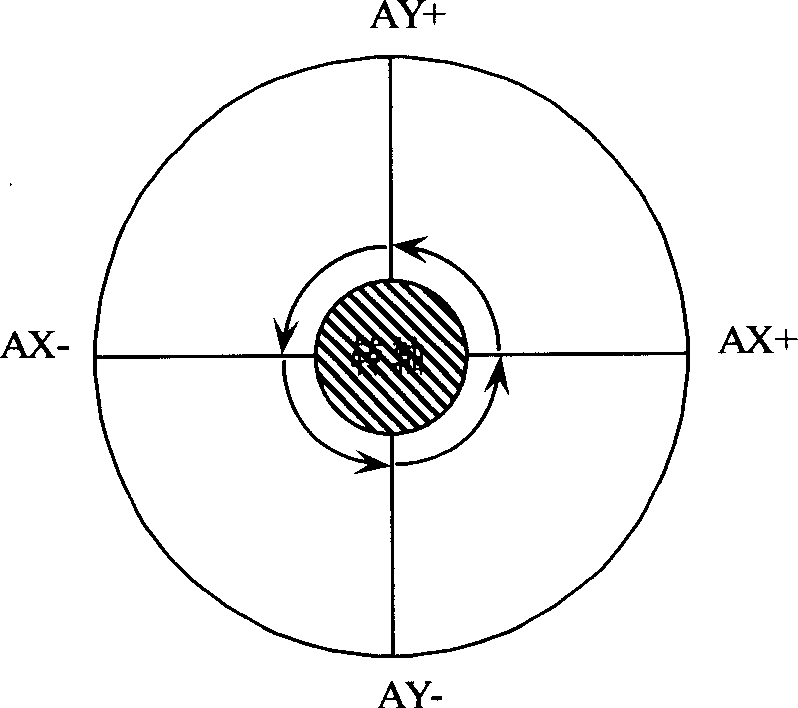

High-speed magnetic levitation flywheel stabilization control system

InactiveCN1738183ASimple designEasy to set upIgnition automatic controlBearingsMagnetic bearingStabilization control

Disclosed a high speed magnetic levitation flywheel stability control system, comprises a displacement sensor, a displacement signal interface circuit, a rotary speed detect circuit, a magnetic bearing controller, and a magnetic bearing power amplifying drive circuit. Wherein, the magnetic bearing controller comprises a axial magnetic bearing controller and a radial magnetic bearing controller, while the radial one is formed by decentralized PID control module and a cross feedback control module whose outputs are connected by the feedback method in cross and parallel. Said invention utilizes the cross feedback control formed by forward whirling motion filter and backward whirling motion filter based on the decentralized PID control; it reaches the phase lead compensation to the forward and backward whirling motion by using the difference of their frequency and whirling motion directions, their variation rule of rotary speed, and the signal of rotary speed of flywheel. So the breakdown speed of flywheel is improved while the stable operation of magnetic levitation flywheel in whole rising and falling process is confirmed too.

Owner:BEIHANG UNIV

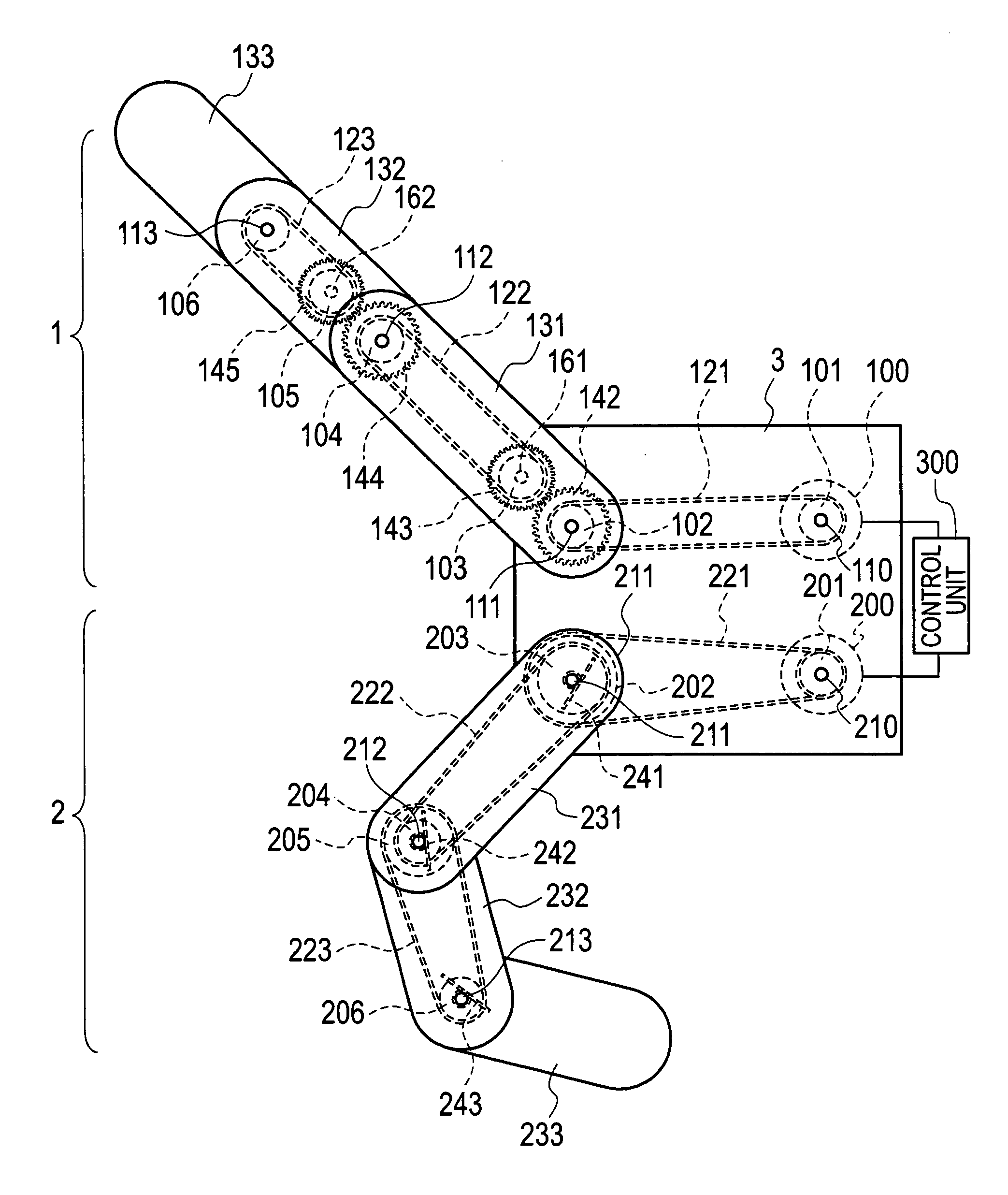

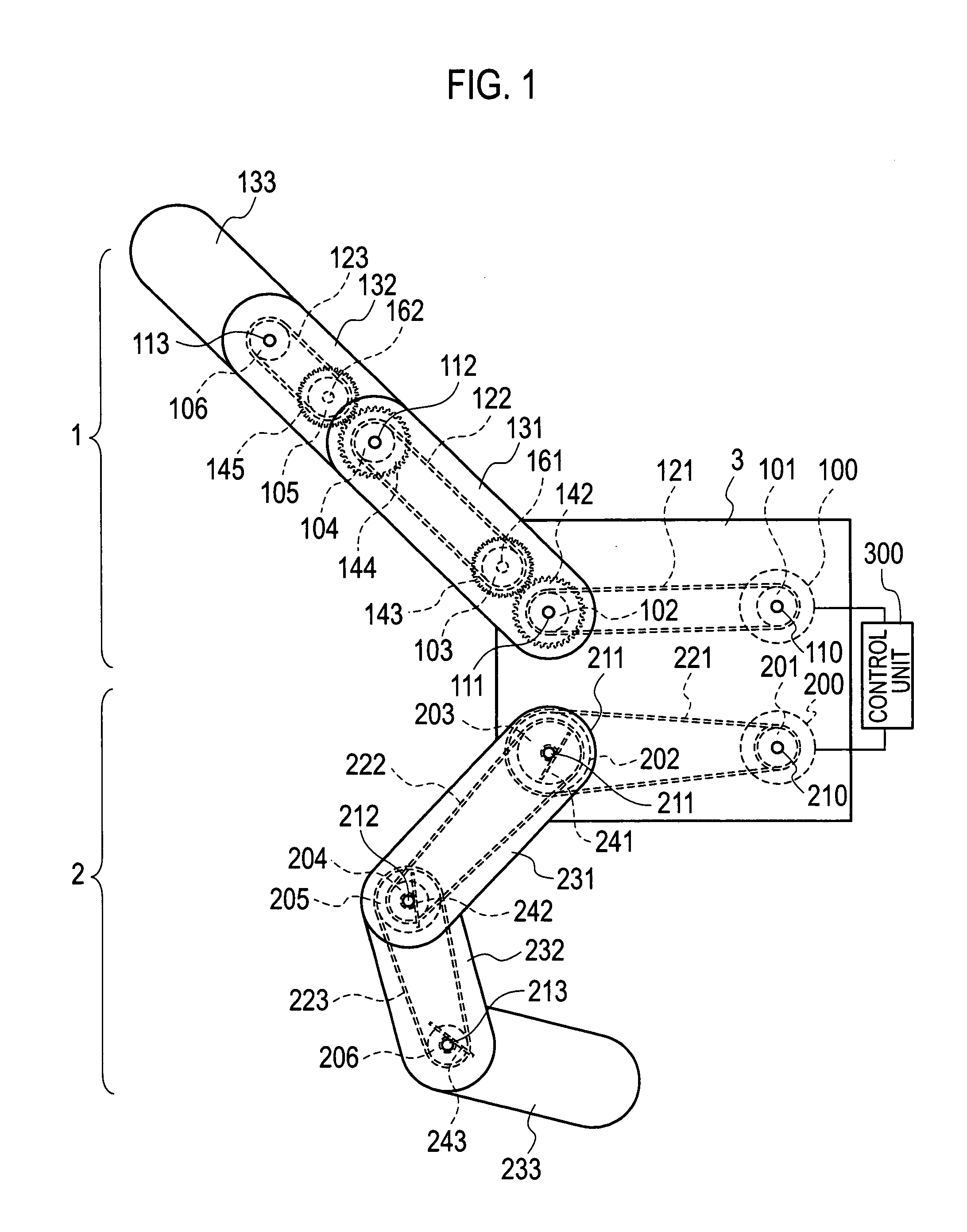

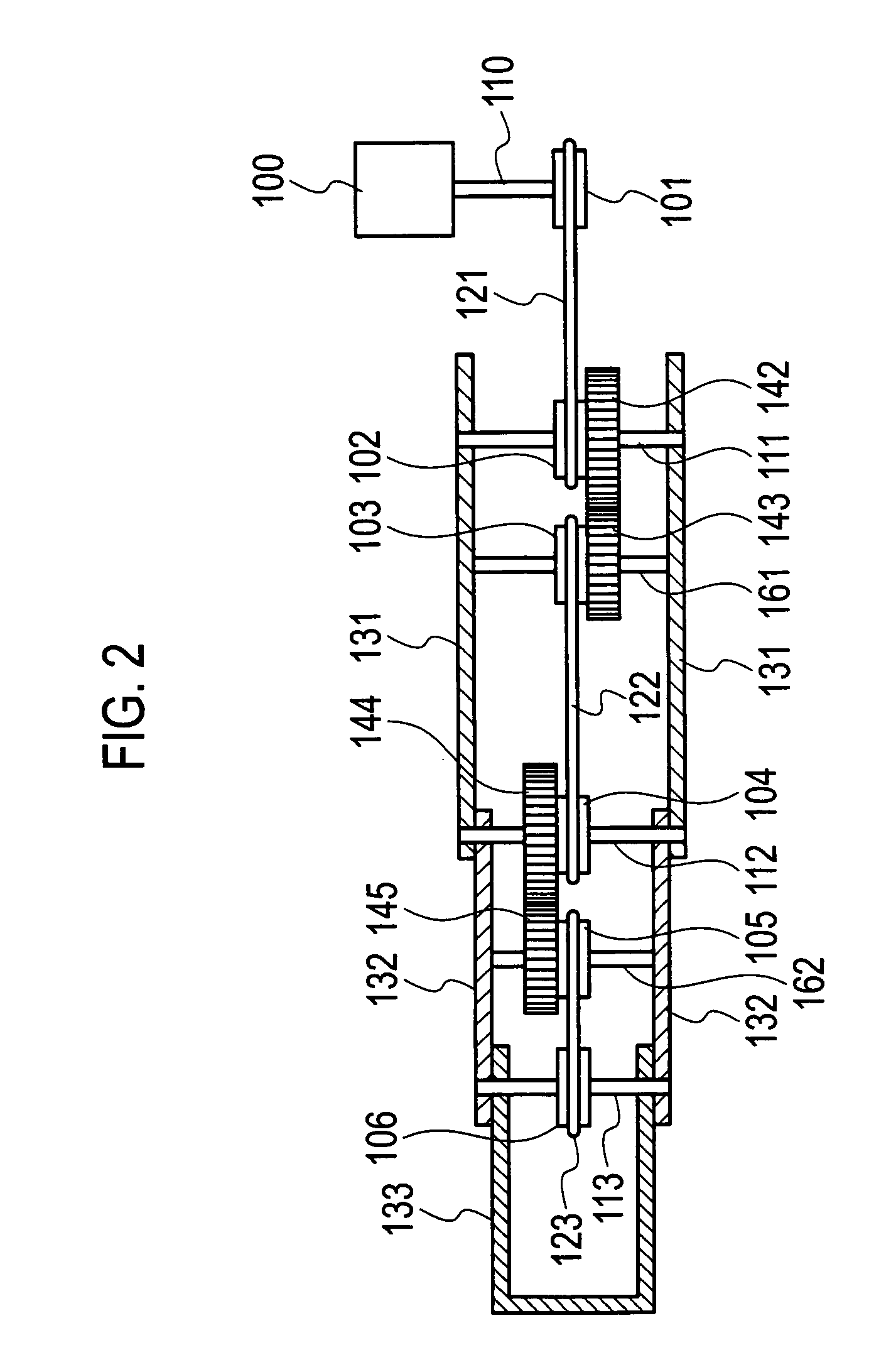

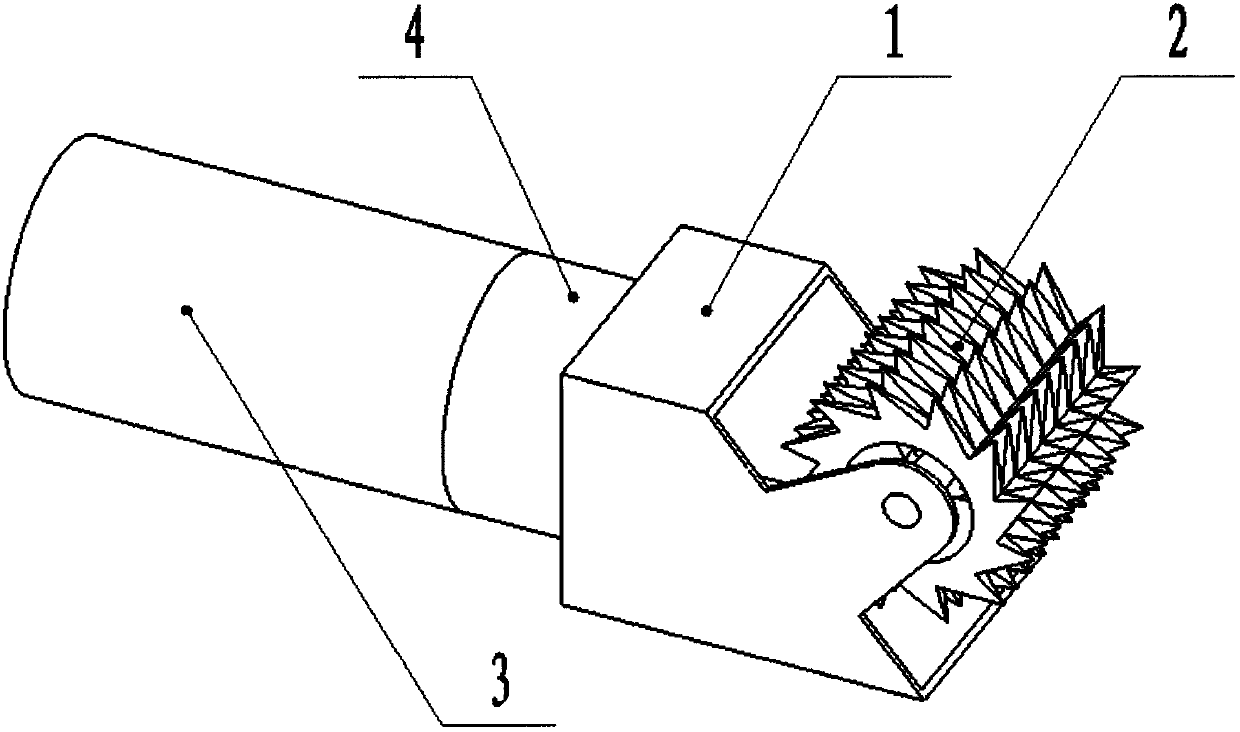

Manipulator and robot

InactiveUS20090025502A1Simple control algorithmSimple mechanismProgramme-controlled manipulatorMechanical apparatusManipulatorSecond finger

A manipulator includes: a first finger having a sequence of first links and first joint shafts, the sequence of first links bending so that rotation angles of the first joint shafts maintain a fixed relationship; a second finger having a sequence of second links bending sequentially from one of the second links assigned at a basal side of the second finger; and drive sources driving the first and second fingers, wherein an adjacent second link next to the second link assigned at the basal side moves after contacting the second link assigned at the basal side with the object.

Owner:KK TOSHIBA

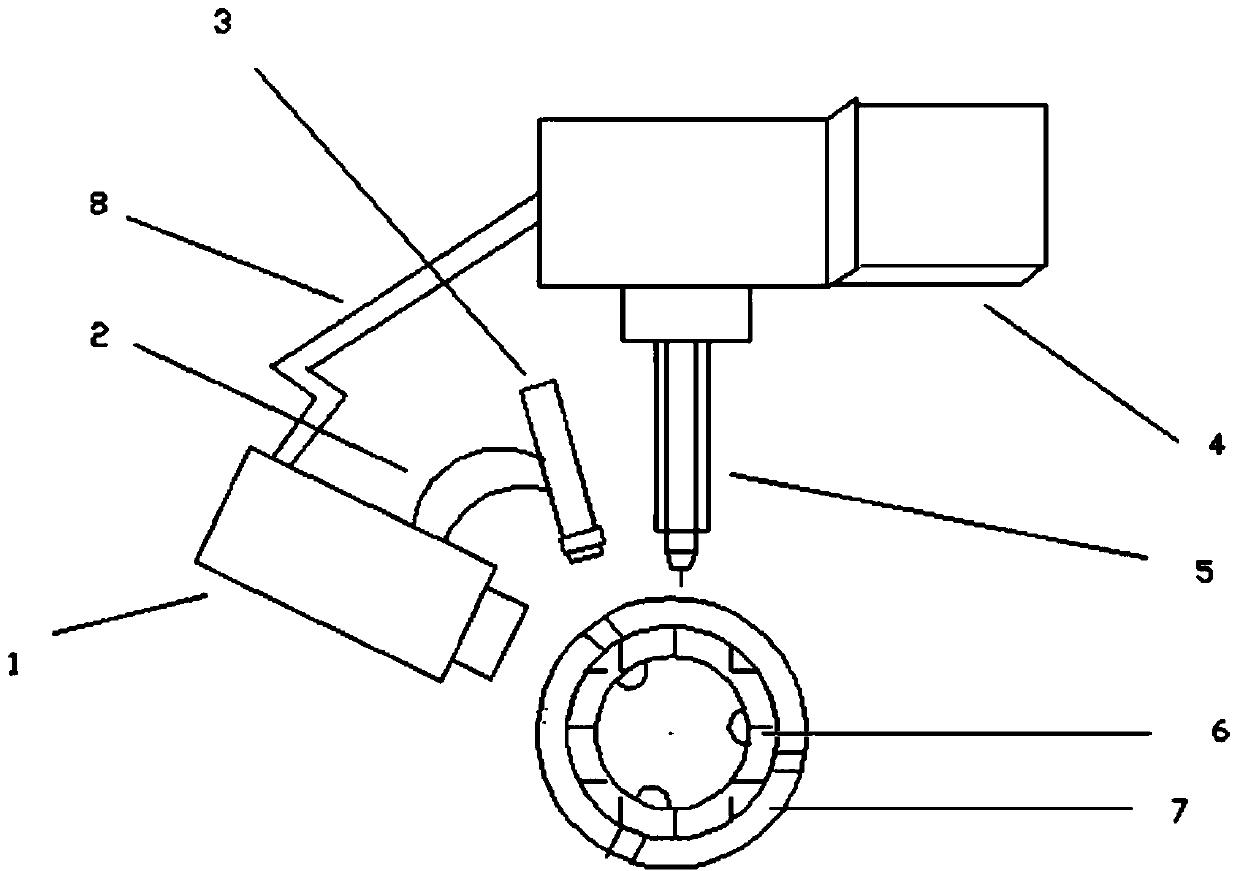

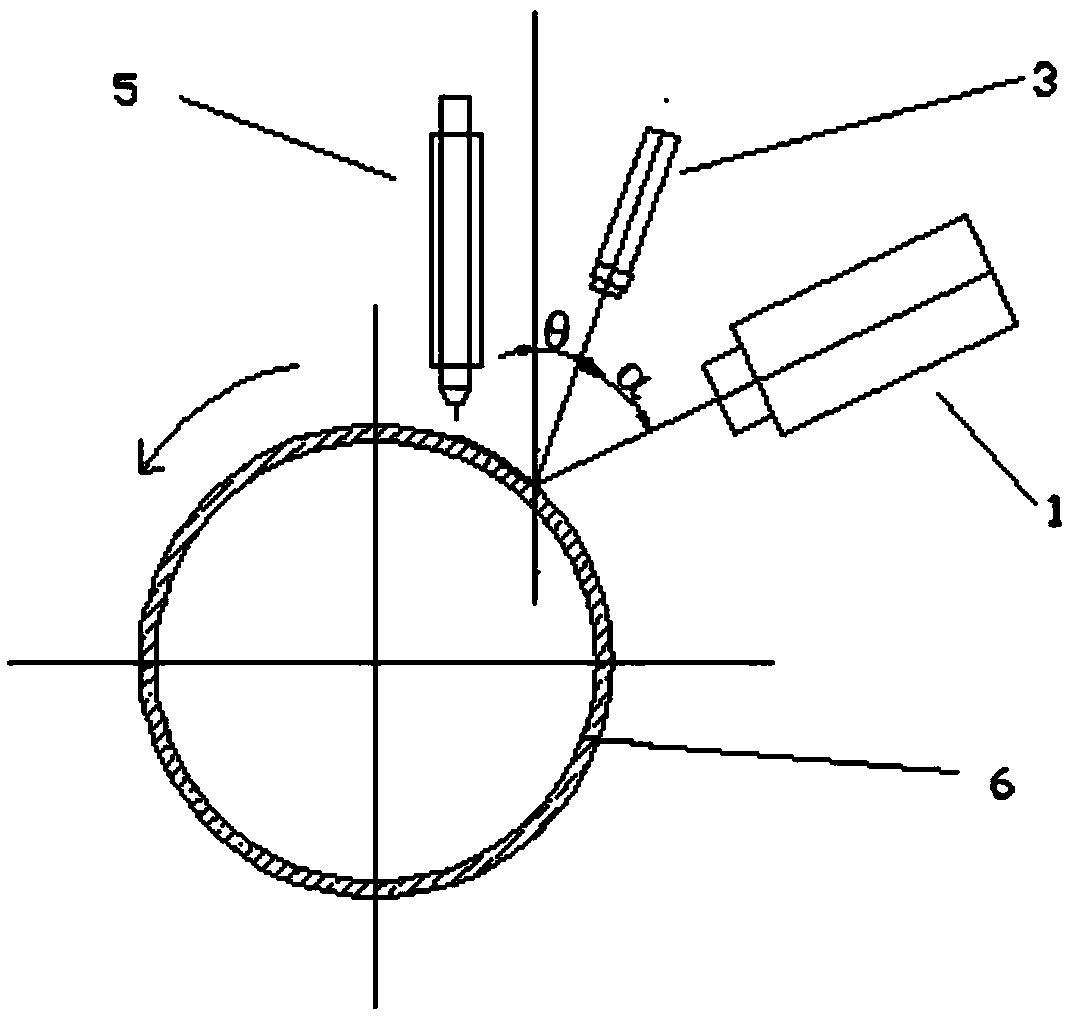

Visual detecting method and device based on decoupling detection for circular seams

ActiveCN104084669AHigh precisionImprove robustnessUsing optical meansWelding accessoriesFeature extractionThree-dimensional space

The invention relates to a visual detecting method based on decoupling detection for circular seams. The method is used for detecting, recognizing and welding the welding seams of circular welding pieces with V-shaped grooves. The method is characterized by comprising the following steps: first, processing pictures and extracting features; and second, decoupling image information. For the method, according to the three-dimensional welding seam feature information extracted by decoupling single frame images, the deviation value of a welding gun in a two-dimensional plane relative to the welding seam center can be calculated, the accurate positioning of welding spots in three-dimensional space can be realized, the decoupling algorithm is performed by monocular vision when the two-dimensional welding seam information is obtained, the tedious matrix transformation when the welding seam information is demarcated is avoided, the demarcating and calculating time is greatly saved, and the real-time performance of a system is obviously improved. On one hand, building a complex imaging model of a camera is avoided, and on the other hand, the demarcating precision, the robustness and the applicability of the camera are improved.

Owner:HEBEI UNIV OF TECH

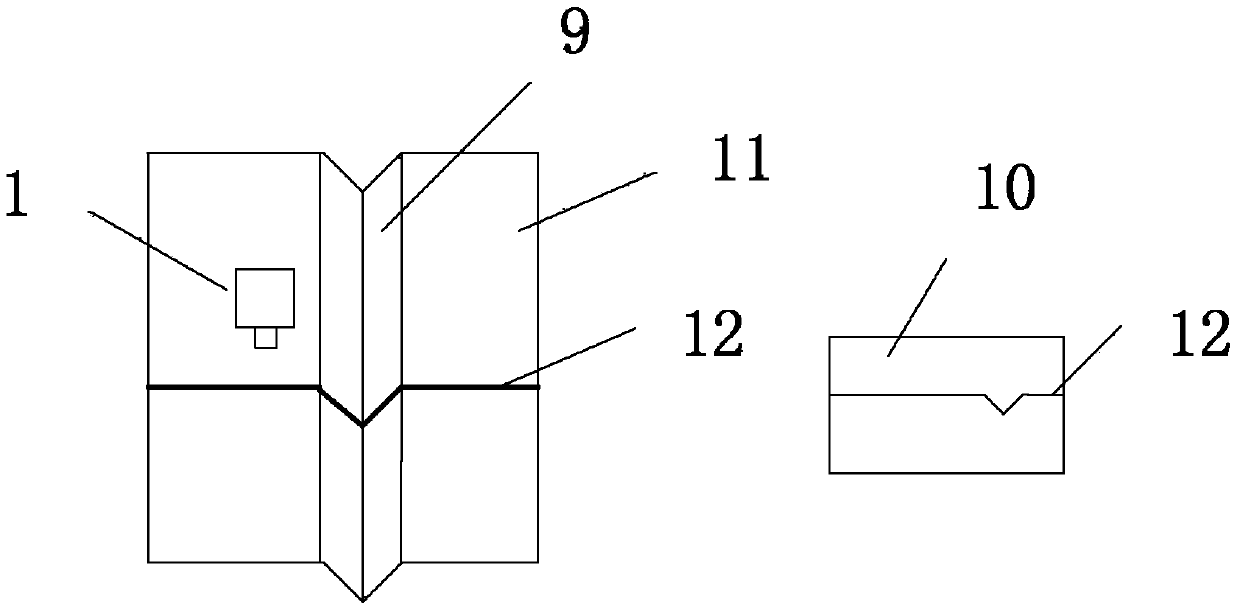

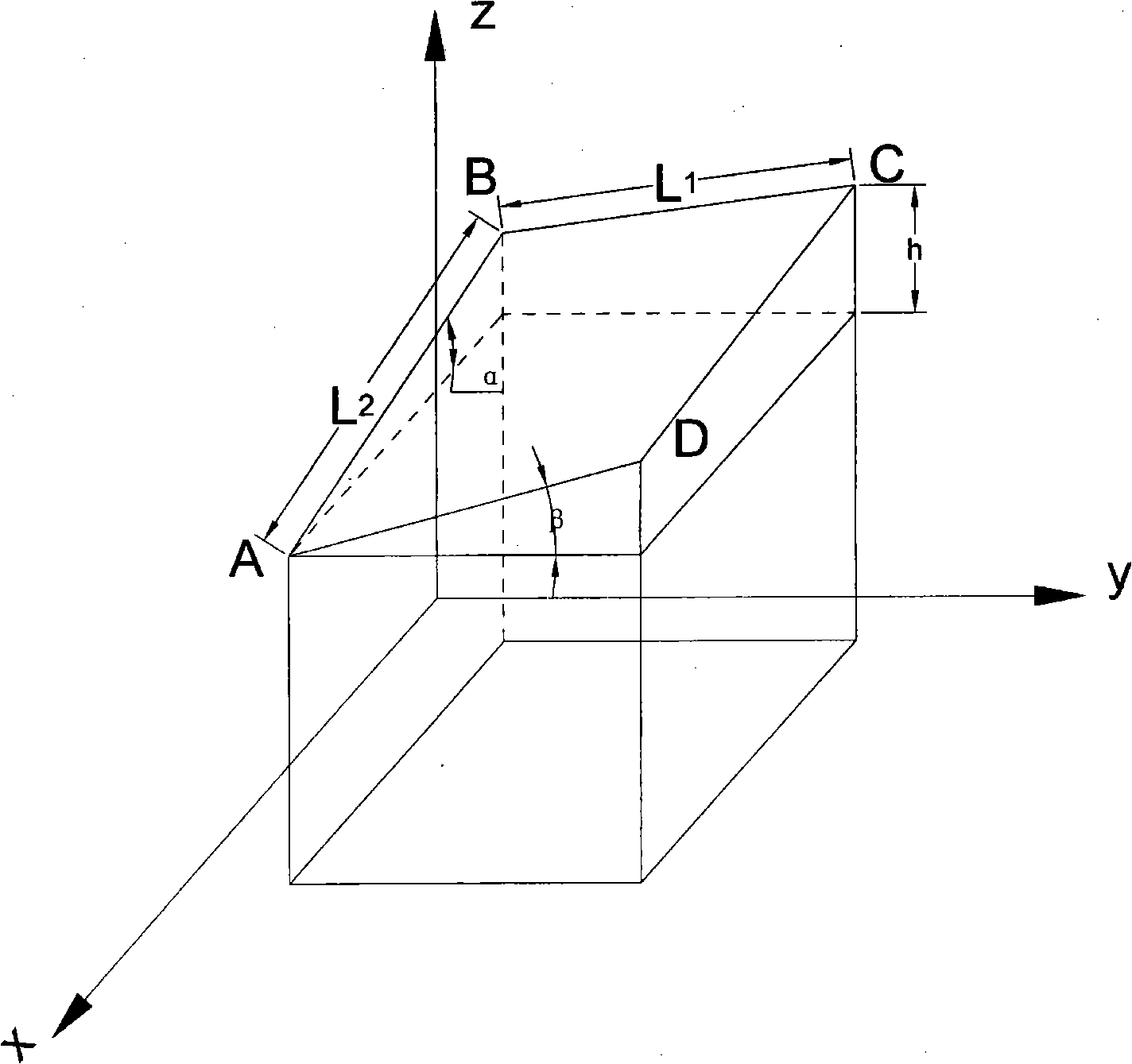

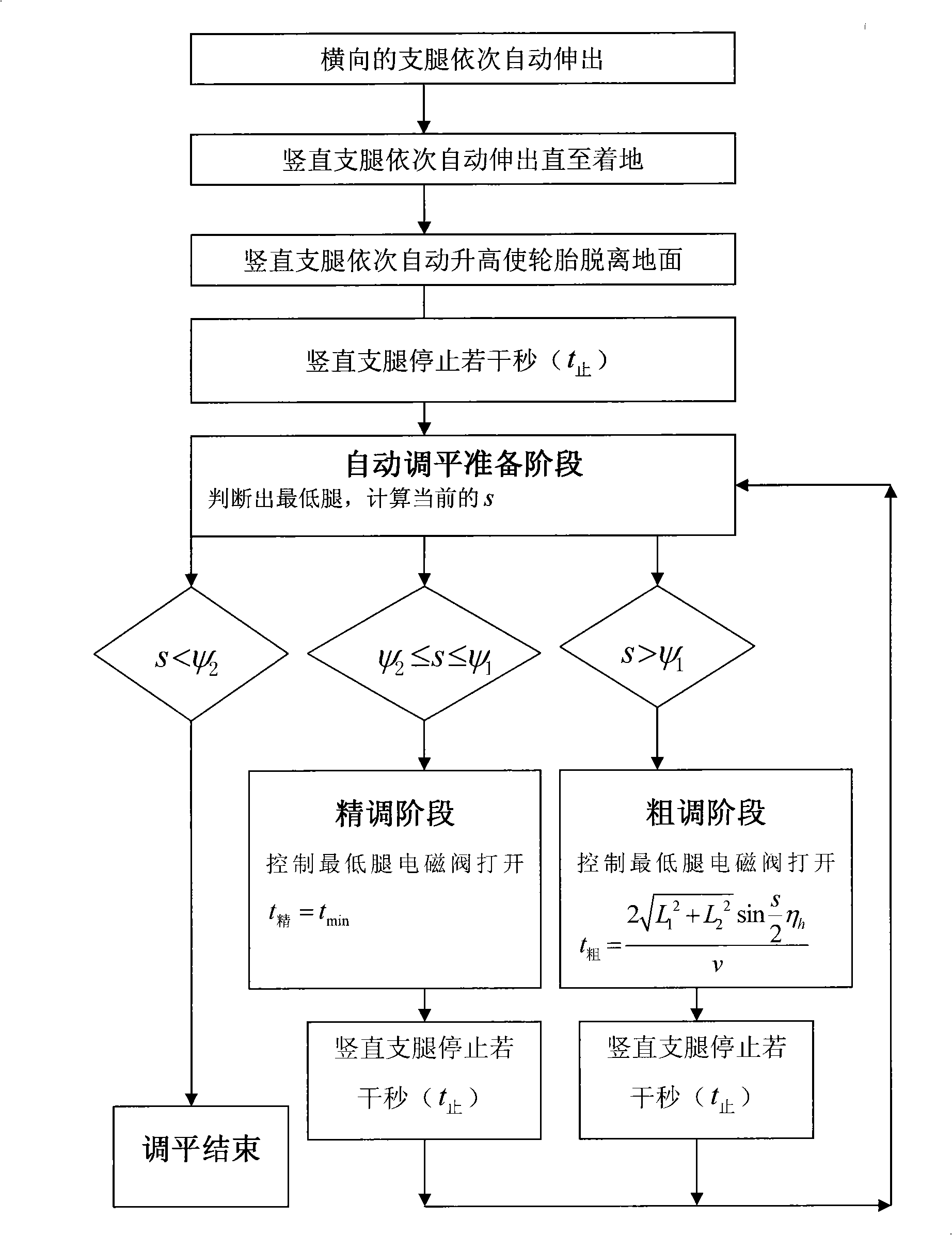

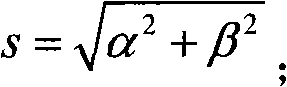

Control method of automatic leveling system

InactiveCN101280875AHigh precisionEfficient and stable performancePortable framesControl without using feedbackLeveling effectAutomatic control

A control method for automatic leveling system in automatic control technology field comprises steps of: automatically protruding transverse support legs in turn; automatically protruding vertical support legs to touchdown in turn; automatically lifting the vertical support legs to take off from ground in turn; stopping the vertical support legs; estimating a lowest leg according to alpha, beta angles in X, Y directions respectively, calculating leveling effect parameter; executing rough leveling if s>Psi1; executing accurate leveling if Psi2<=s<=Psi1; stopping the leveling if s F16M 3 / 00 G05D 3 / 10 2 7 3 2008 / 5 / 22 101280875 2008 / 10 / 8 000000000 Shanghai Jiao Tong University Shanghai 200240 Weng Xinhua Tang Junmao Kong Zuo Wu Changmao Gan Zhimei wangti lin wanggui zhong 31201 The Patent Agency of Shanghai University of Communications No.1954 Huashan Road, Shanghai 200030

Owner:SHANGHAI JIAO TONG UNIV

Composite Linearization Control Method and Realization Circuit for Hysteresis Characteristics of Piezoelectric Ceramic Actuators

ActiveCN102280572AAvoid errorsSimple control algorithmPiezoelectric/electrostrictive device detailsHysteresisSignal conditioning circuits

The invention discloses a composite linear control method of a hysteresis characteristic of a piezoelectric ceramic actuator and a realization circuit thereof. The composite linear control method comprises a feedforward linear control process and a closed-loop linear control process, wherein in the feedforward linear control process, a built mathematical model of the piezoelectric ceramic actuator is utilized to construct a hysteresis component observer which observes the hysteresis components of the piezoelectric ceramic actuator under the action of control voltages, compensating voltages required by compensating the hysteresis components are calculated, and the compensating voltages and the control voltages are overlapped to obtain actual driving voltages which are acted on the piezoelectric ceramic actuator to generate displacement output; in the closed-loop linear control process, a displacement sensor is utilized to obtain feedforward linear errors and the closed-loop control is utilized to reduce the errors to be zero; and a composite linear controller comprises a control signal generator, an analog to digital converter, a composite linear controller, a digital to analog converter, a power amplifier, the displacement sensor and a signal conditioning circuit. According to the invention, the hysteresis nonlinearity relation between the output displacement of the piezoelectric ceramic actuator and the control voltages can be linearized, thus simplifying a control algorithm of the piezoelectric ceramic actuator greatly and improving the positioning accuracy of the piezoelectric ceramic actuator.

Owner:CHONGQING UNIV

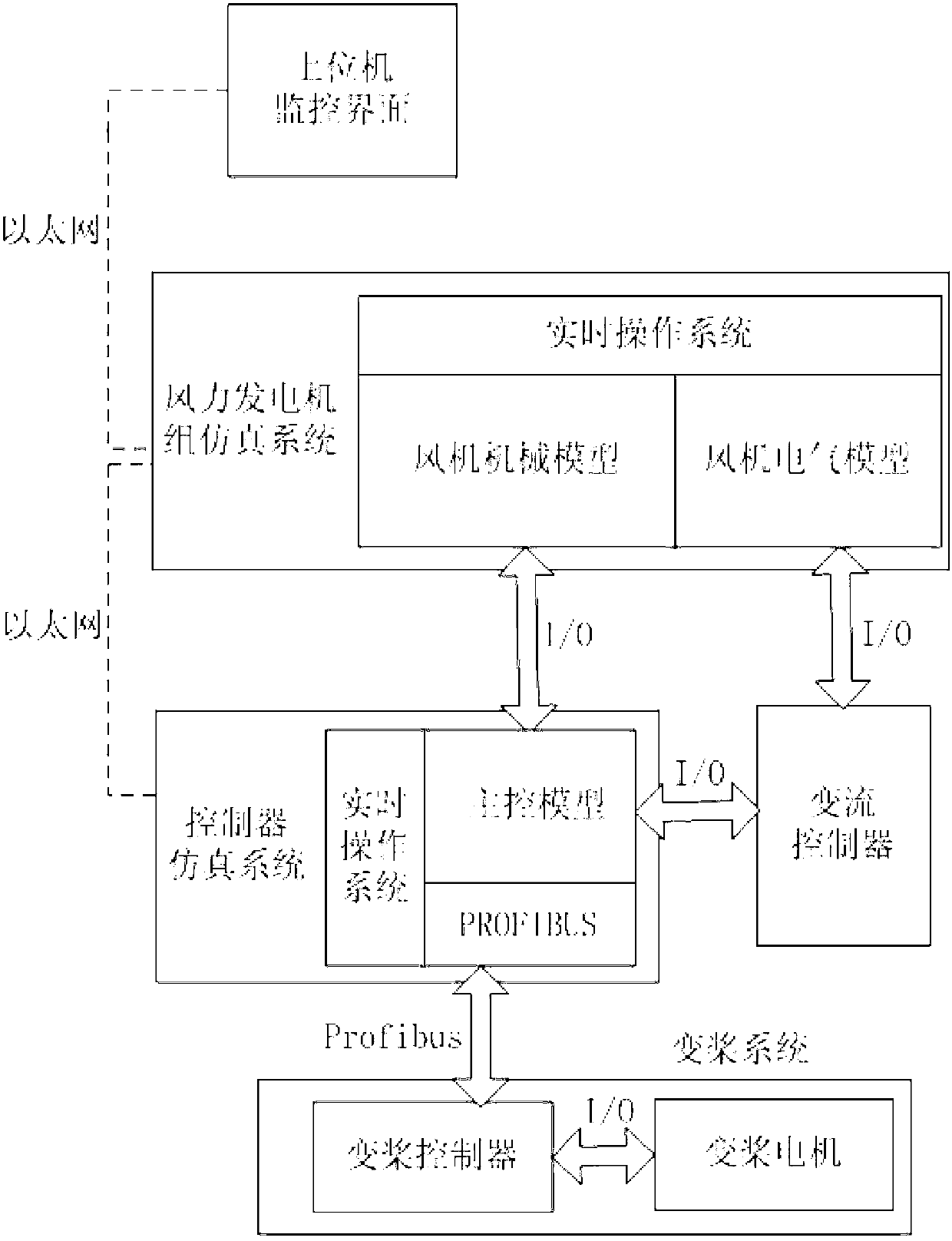

Semi-physical real-time simulation platform for wind generating set

ActiveCN103344437AFlexible adjustment functionFlexible adjustment performanceSimulator controlEngine testingComputer monitoringBasic research

The invention discloses a semi-physical real-time simulation platform for a wind generating set and belongs to the technical field of clean energy. The simulation platform is mainly composed of an upper computer monitoring interface, a wind generating set simulation system, a controller simulation system, a current transformer controller and a variable pitch system. An upper computer is respectively connected with the wind generating set simulation system and the controller simulation system through Ethernet. The simulation platform can quickly develop and verify a control algorithm, can simulate operation characteristics of a real wind generating set, enables a controller to carry out comprehensive loop test before true machine set test, saves test cost, improves operation safety, can control the output power of a fan, stabilizes power grid fluctuation and provides a basic research platform for optimal operation of a wind power plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

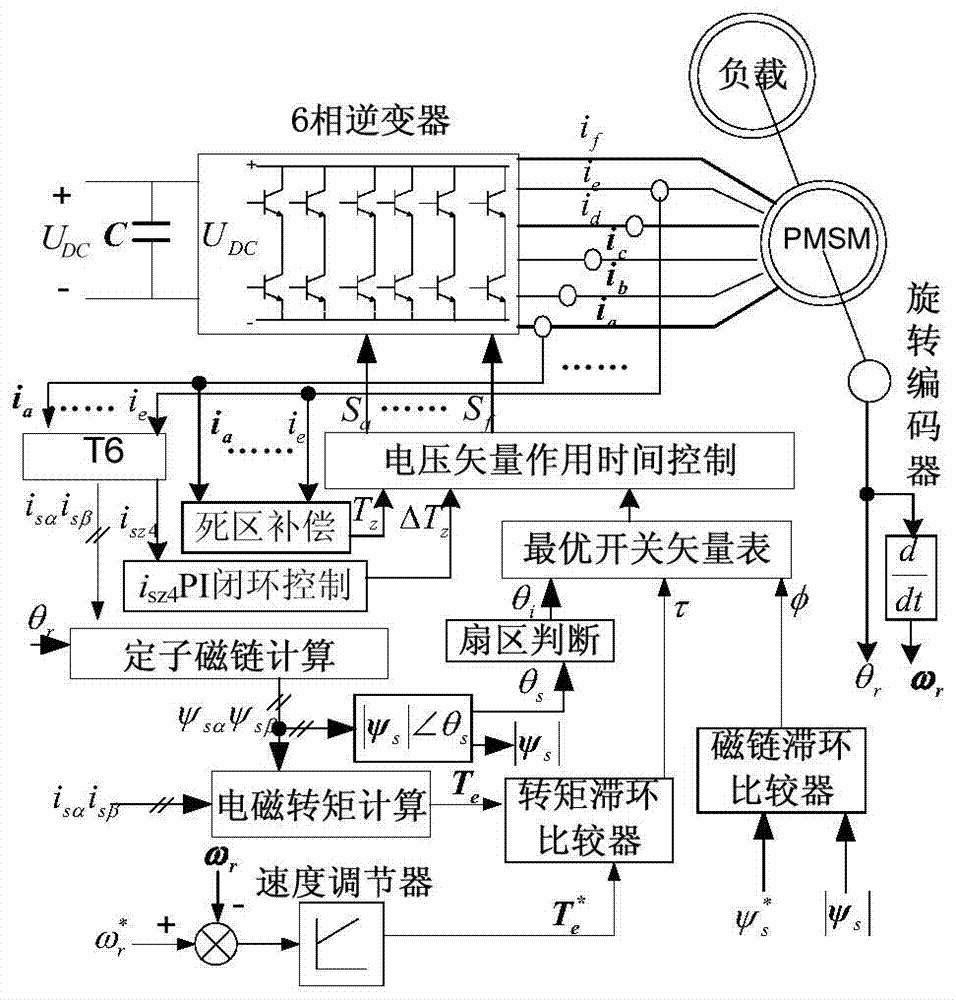

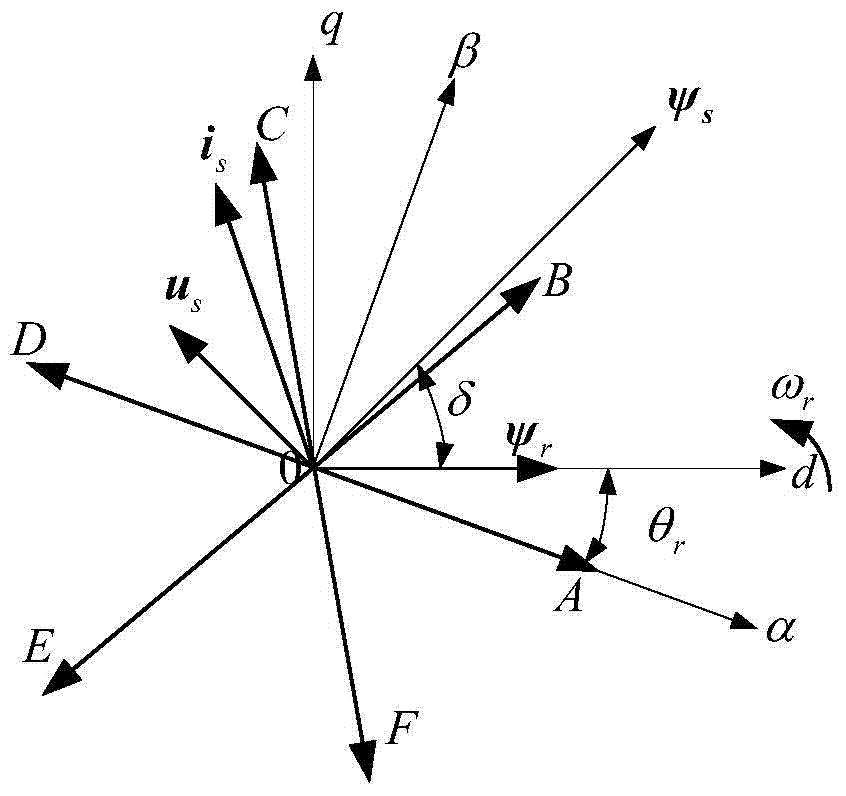

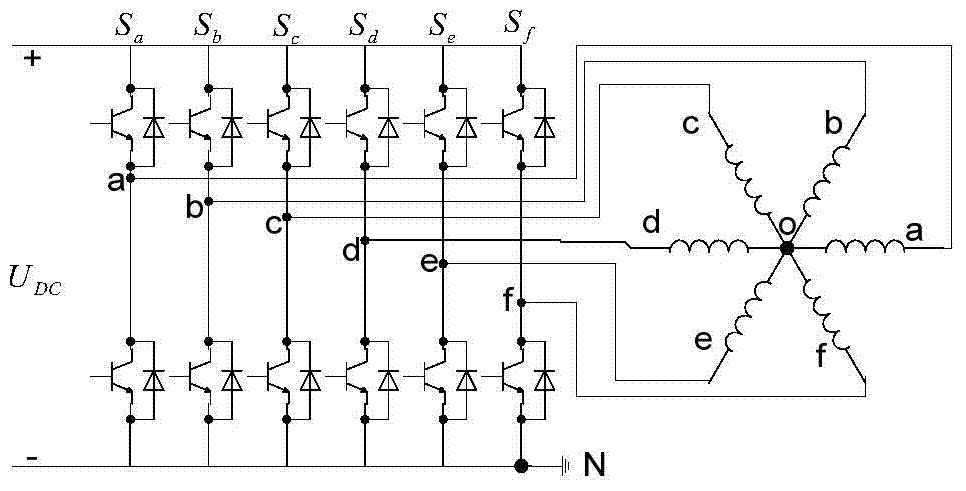

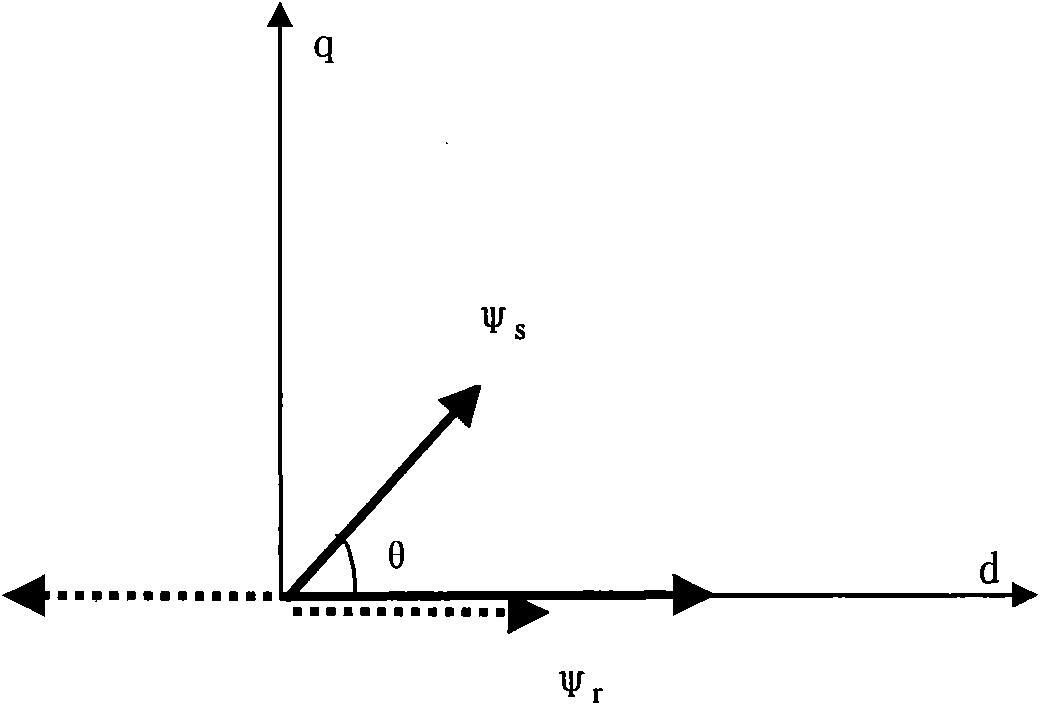

Direct torque control method for six-phase synchronous motor with zero-sequence current self-correction

ActiveCN104333284AReduce load capacityReduce high frequency ripple amplitudeElectronic commutation motor controlVector control systemsMagnetic fluxVoltage vector

The invention discloses a direct torque control method for a six-phase synchronous motor with zero-sequence current self-correction. The direct torque control method for the six-phase synchronous motor with the zero-sequence current self-correction comprises firstly, performing voltage vector reconstruction based on an idea that a zero-sequence current is equal to zero and accordingly proposing an idea DTC (Direct Torque Control); secondly, performing discrete compensation on the actual voltage vector acting time based on the dead-time compensation principle; finally, continuously compensating the voltage vector acting time through a PI adjuster and achieving a purpose that the zero-sequence current is equal to zero. The direct torque control method for the six-phase synchronous motor with the zero-sequence current self-correction solves the problem of eliminating low-order harmonic currents in a six-phase symmetrical winding permanent magnet motor DTC system of a torque and magnetic flux linkage double-hysteresis-loop structure.

Owner:SOUTHEAST UNIV

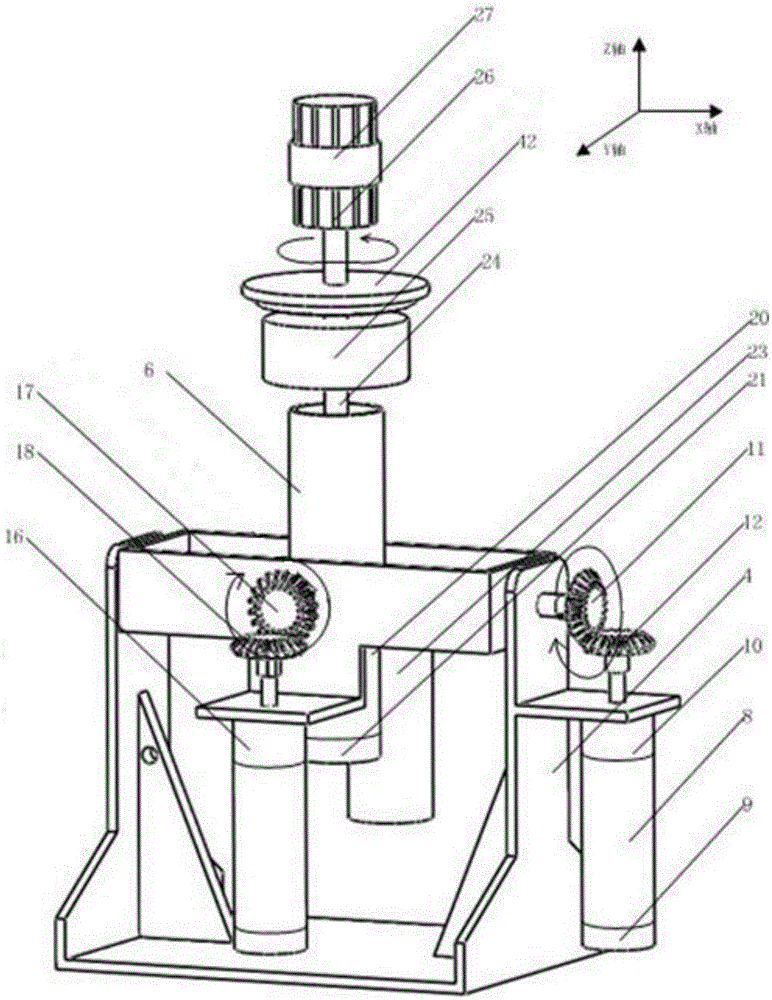

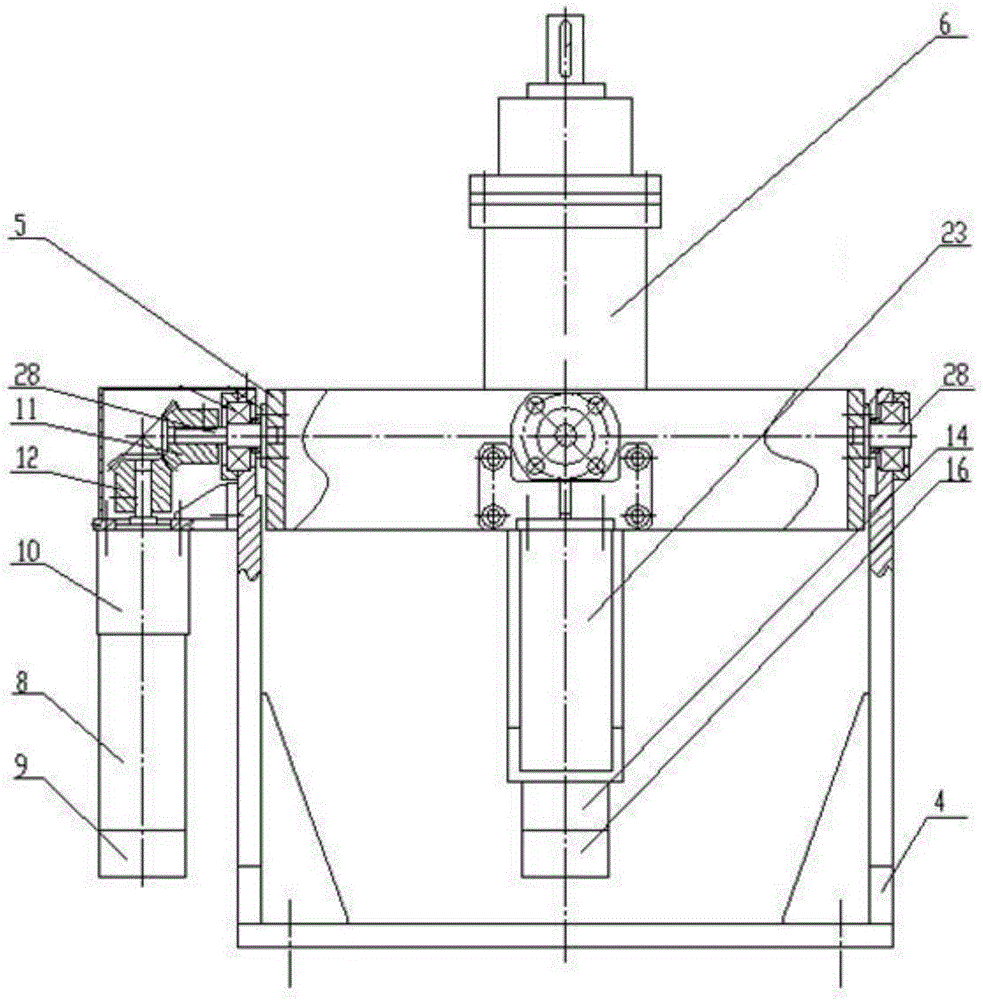

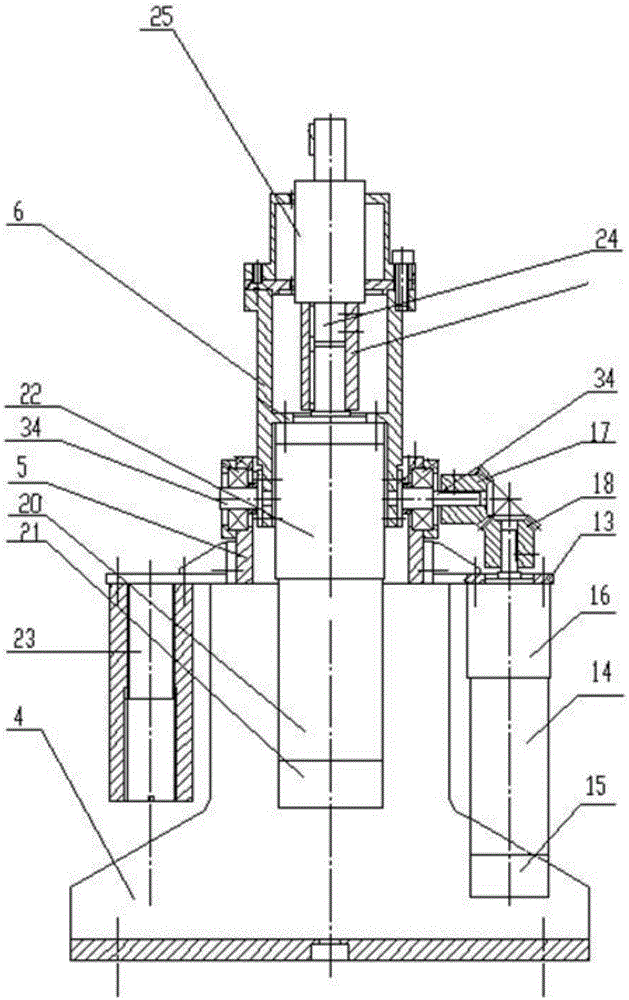

Intelligent force feedback handle and control method thereof

The invention discloses an intelligent force feedback handle and a control method thereof. The handle comprises an X-axis rotation part, a Y-axis rotation part, and a Z-axis rotation part. The X-axis rotation part comprises an inner frame and an X-axis driving device for driving the inner frame to rotate about the X axis. The Y-axis rotation part comprises a center cylinder and a Y-axis driving device for driving the center cylinder to rotate about the Y axis. The Z-axis rotation part comprises a handle operation lever and a Z-axis driving device for driving the handle operation lever to rotate about the Z axis. The center cylinder is rotationally arranged in a hollow frame body of the inner frame, and the rotation direction of the center cylinder and the rotation direction of the inner frame are perpendicular to each other. The handle operation lever is rotationally arranged inside the center cylinder around the axis, and the handle operation lever and the center cylinder are coaxial. The size of the handle is optimized, and the method achieves an intelligent damping control effect and an automatic reset effect.

Owner:SOUTHEAST UNIV

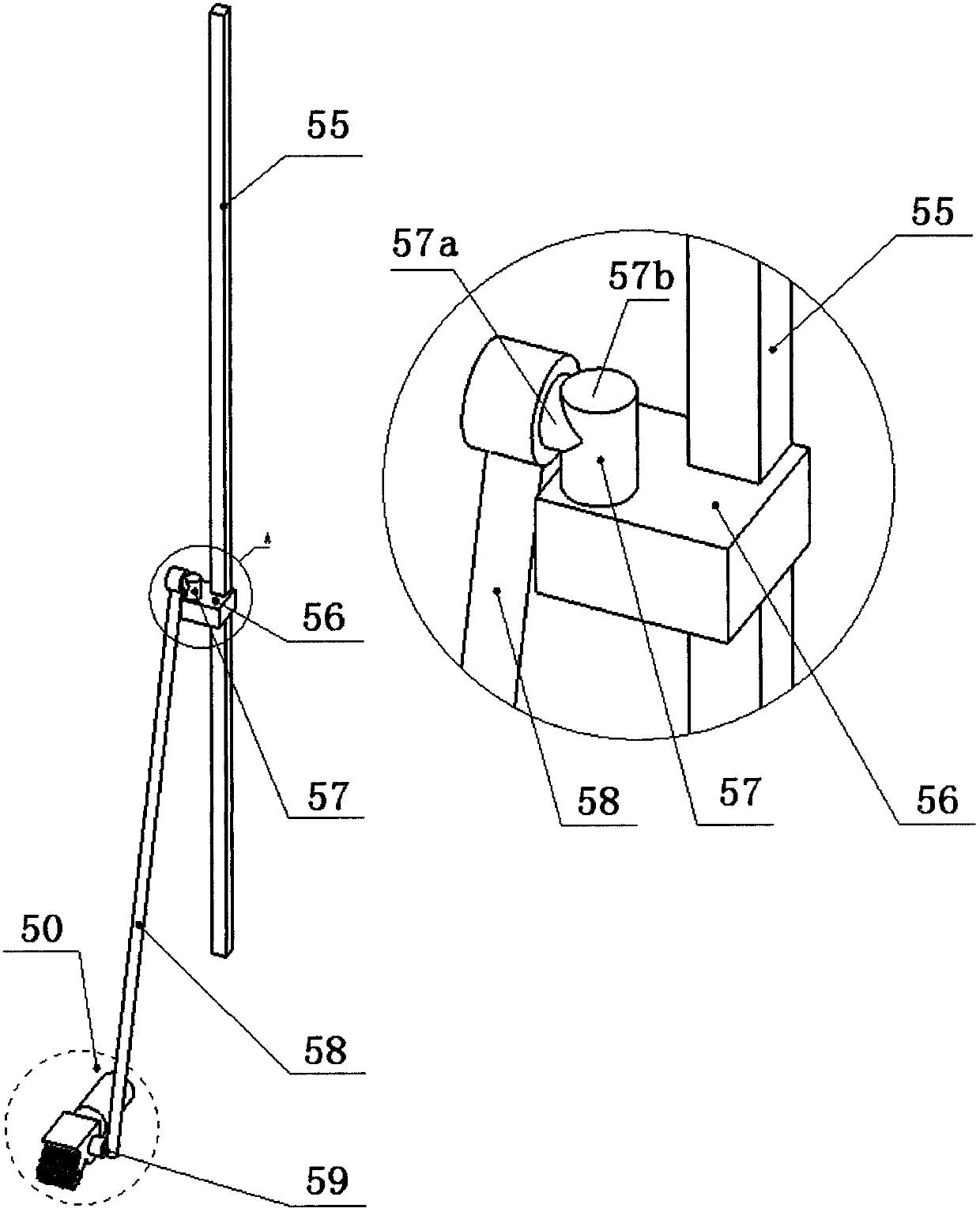

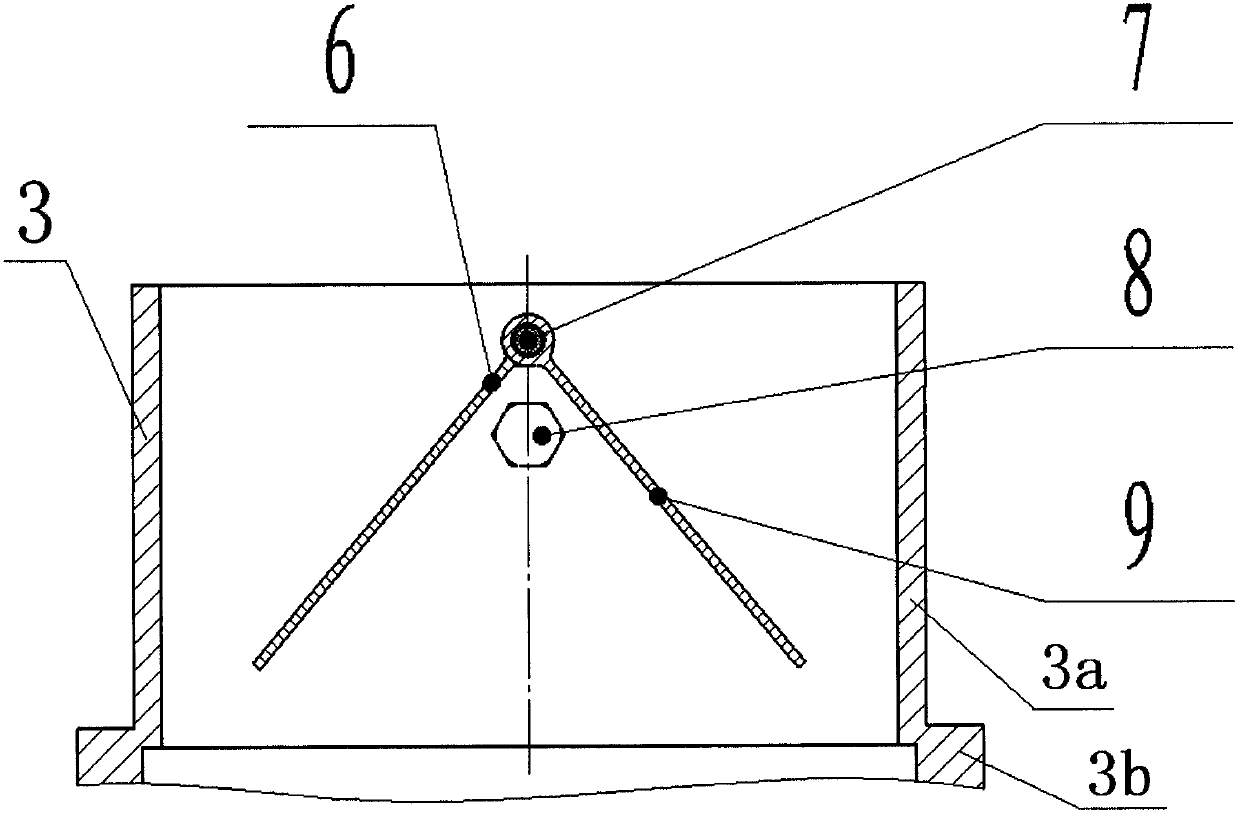

Device for sampling shallow soil of extraterrestrial star

InactiveCN102680275AReduce couplingSimple control algorithmWithdrawing sample devicesEngineeringShovel

The invention relates to a device for sampling shallow soil of an extraterrestrial star. The device comprises two parts, namely a guide rail swing-arm type position mechanism and a terminal executing mechanism, wherein the guide rail swing-arm type position mechanism comprises a guide rail, a moving unit, a swing arm joint, a swing arm and a terminal joint; the terminal executing mechanism comprises a shovel, a ratchet wheel, a sample box and a connecting and separating mechanism; a position mechanism has the advantages of high rigidity, good flexibility and simplicity in the control method and can be used for completing tasks of currently frequently-used four-freedom-degree two-stage space mechanical arms besides sampling the shallow soil of the extraterrestrial star; the terminal executing mechanism mainly relies on a shoveling task method while a ratchet wheel rotary-digging task method as a subsidiary; soil samples can be obtained effectively; the device has functions of temporary storage and primary package for samples; in addition, the samples are transferred into an airtight packaging device on an ascender; and thedevice for sampling soil has a wide application range.

Owner:BEIJING SATELLITE MFG FACTORY

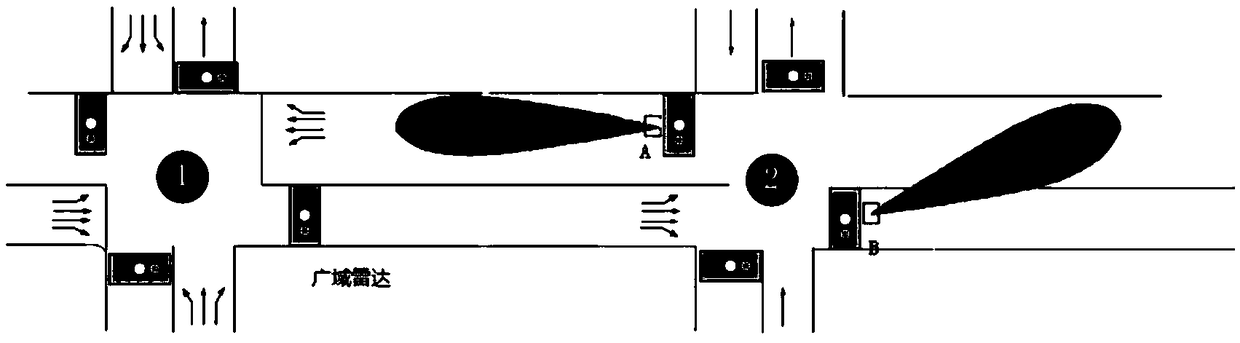

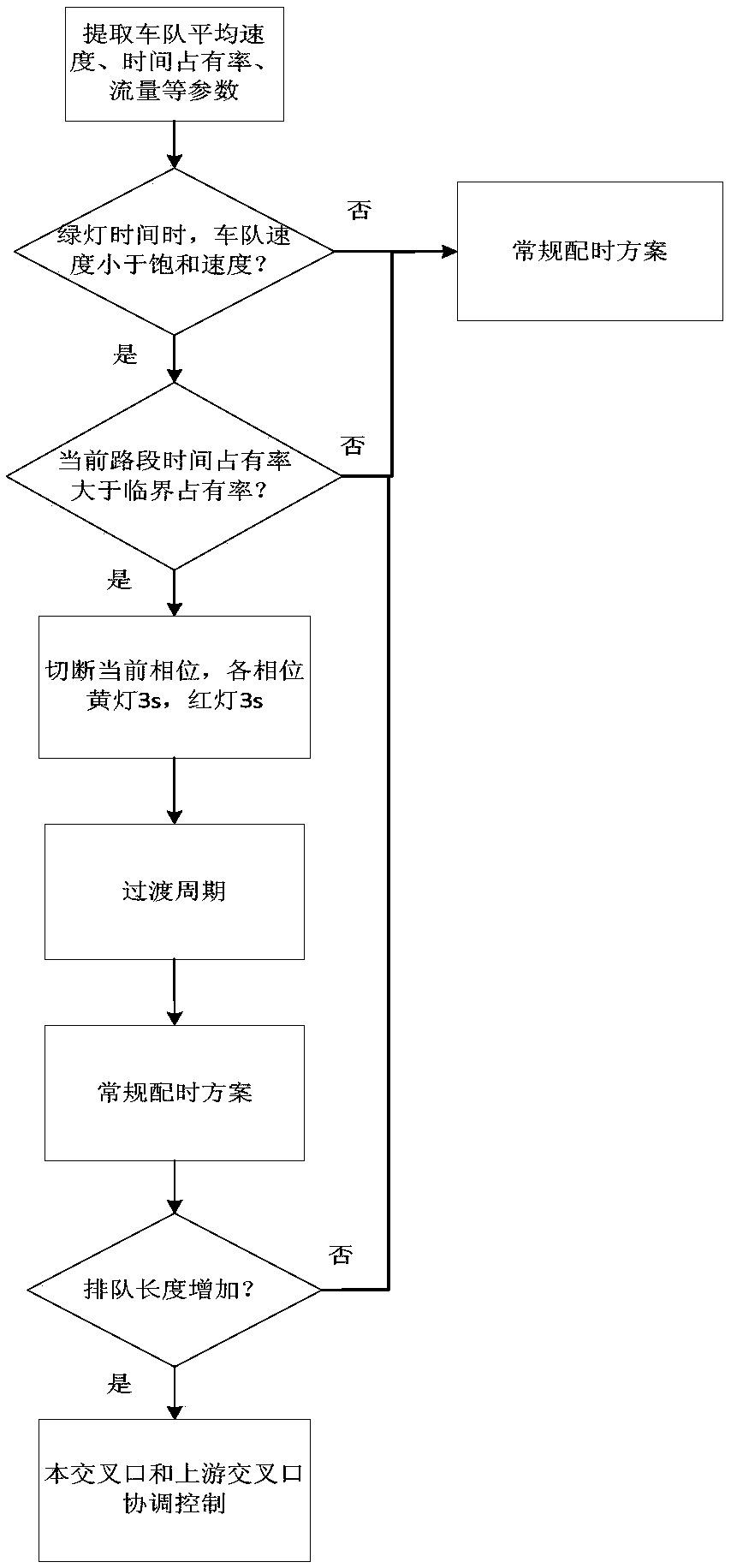

Overflow control method for city intersection based on wide area radar microwave detector

ActiveCN109003444AImprove real-time performanceImprove reliabilityControlling traffic signalsDetection of traffic movementRadarTraffic congestion

The invention provides an overflow control method for a city intersection based on a wide area radar microwave detector. The overflow control method gives the concept of overflow of the intersection from the aspect of signal control ability, the wide area radar microwave detector is installed, and the current operating condition of the intersection is judged according to the regional vehicle number collected by the detector, overflow coefficient built by space occupancy and average speed of road condition information. After the condition that the intersection is in overflowed state is judged by the overflow coefficient, traffic congestion is eased by using the method of changing the timing scheme, and the signal control resource method is provided.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

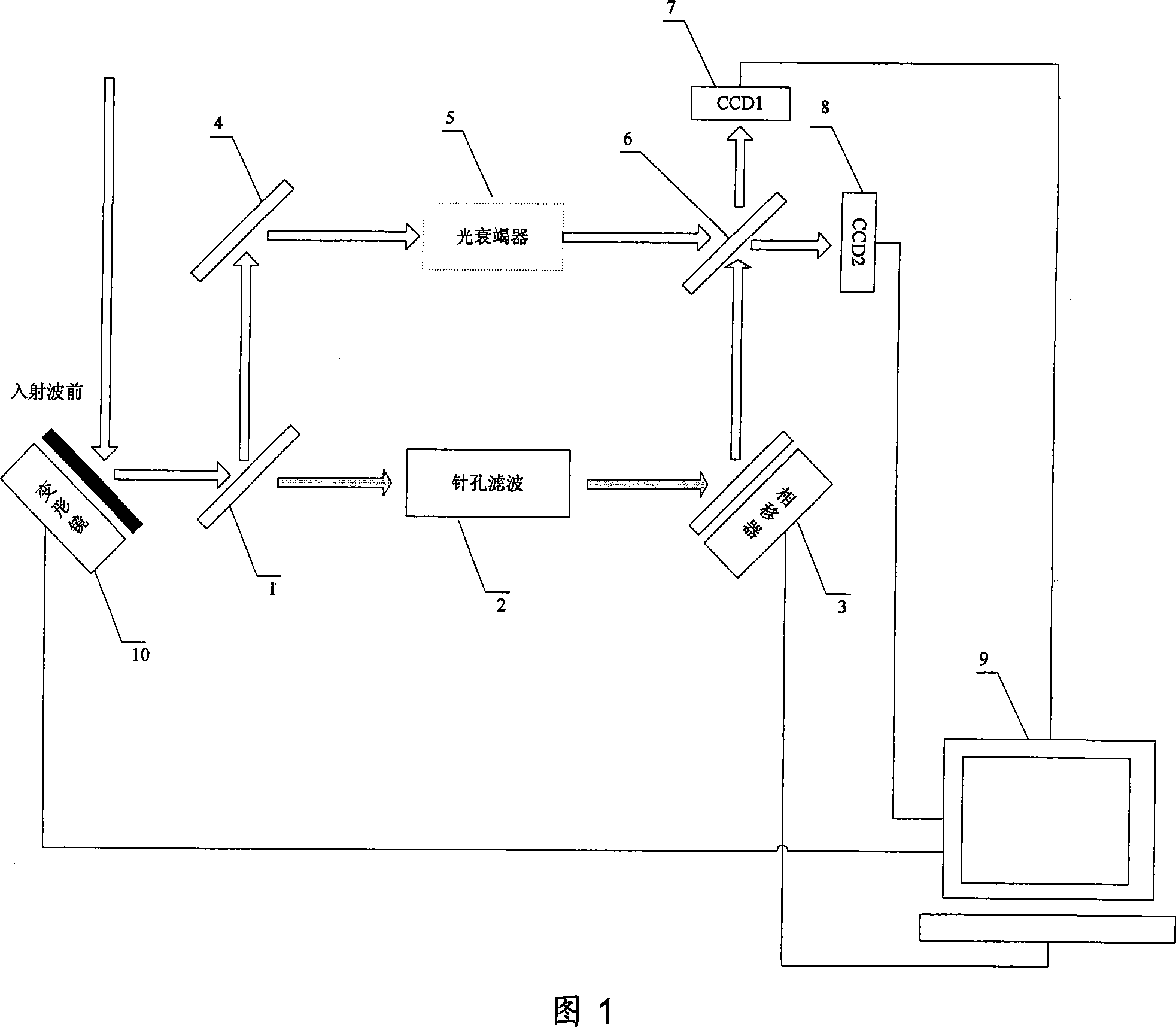

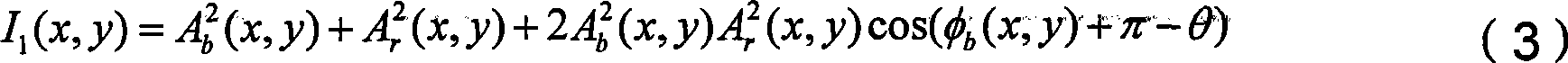

Self-adaptive optical system based on self-reference wavefront sensor and continuous surface deformable mirror

InactiveCN101055348AHigh precisionImprove spatial resolutionOptical elementsWavefront sensorClosed loop

An self adaptive optics system for based self-reference wave front sensor and continuous surface deformation lens is consisted of a wave front corrector, a Mach-Zehnder interference method-based self-reference wave front sensor and an industrial control computer. After through the wave front corrector, the beam is reflected into the Mach-Zehnder interference method-based self-reference wave front sensor. The wave front information detected by the Mach-Zehnder interference method-based self-reference wave front sensor passes the once matrix operation of the industrial control computer, then directly output the controlling voltage to the wave front corrector for closed loop. The wave front corrector using the independent unit continuous interference deformation lens has a quicker respond speed. The wave front detector using the interference principle has upper spatial resolution and detecting precision. Thereby, the wave front correction performance of the interference wave front detector-based self adaptive optics system is largely improved, the application domain of the self adaptive optics system is enlarged, and the advantages are obviously.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

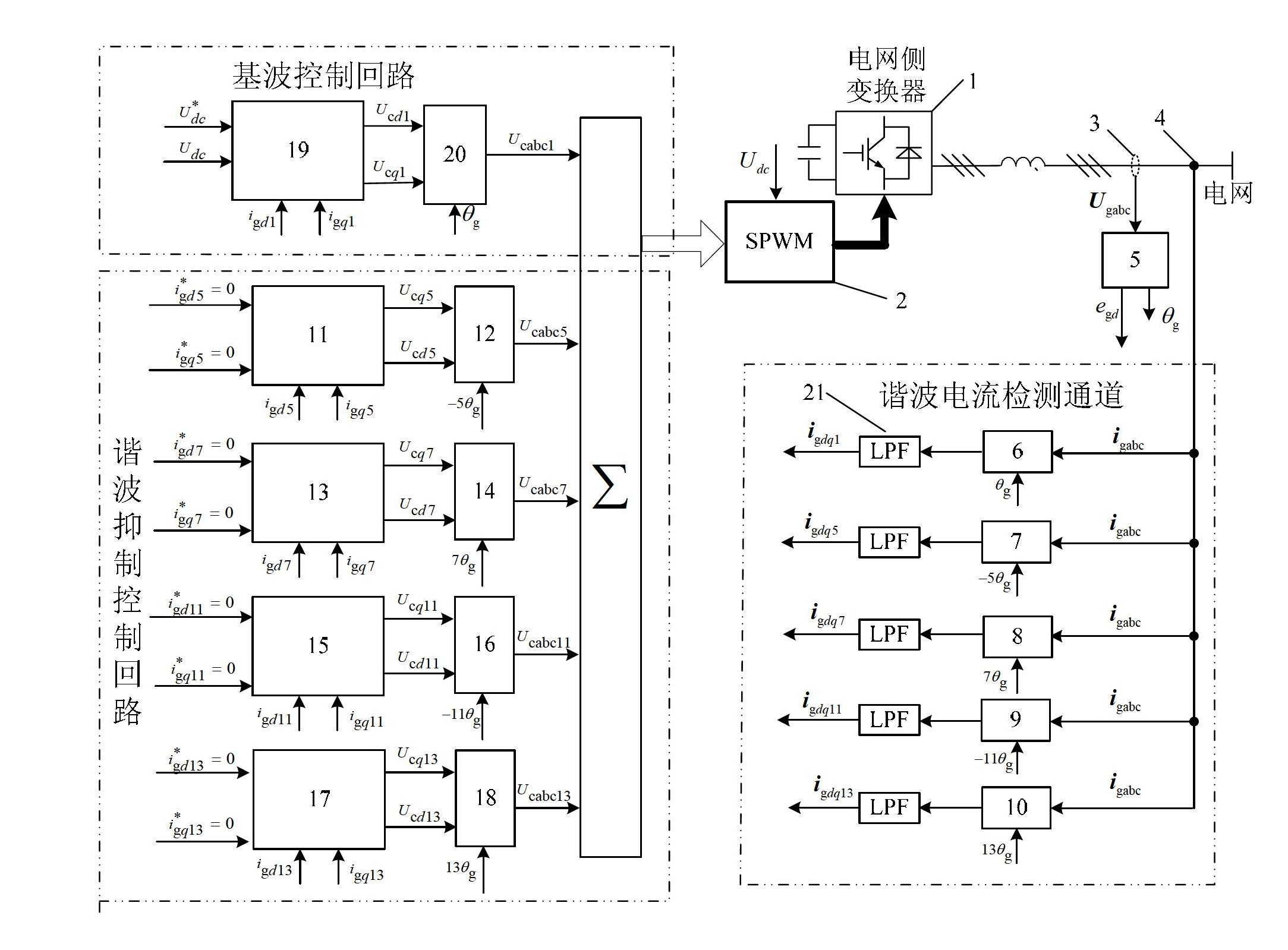

Method for controlling harmonic current of full-power converter for suppressing wind power grid integration and controller

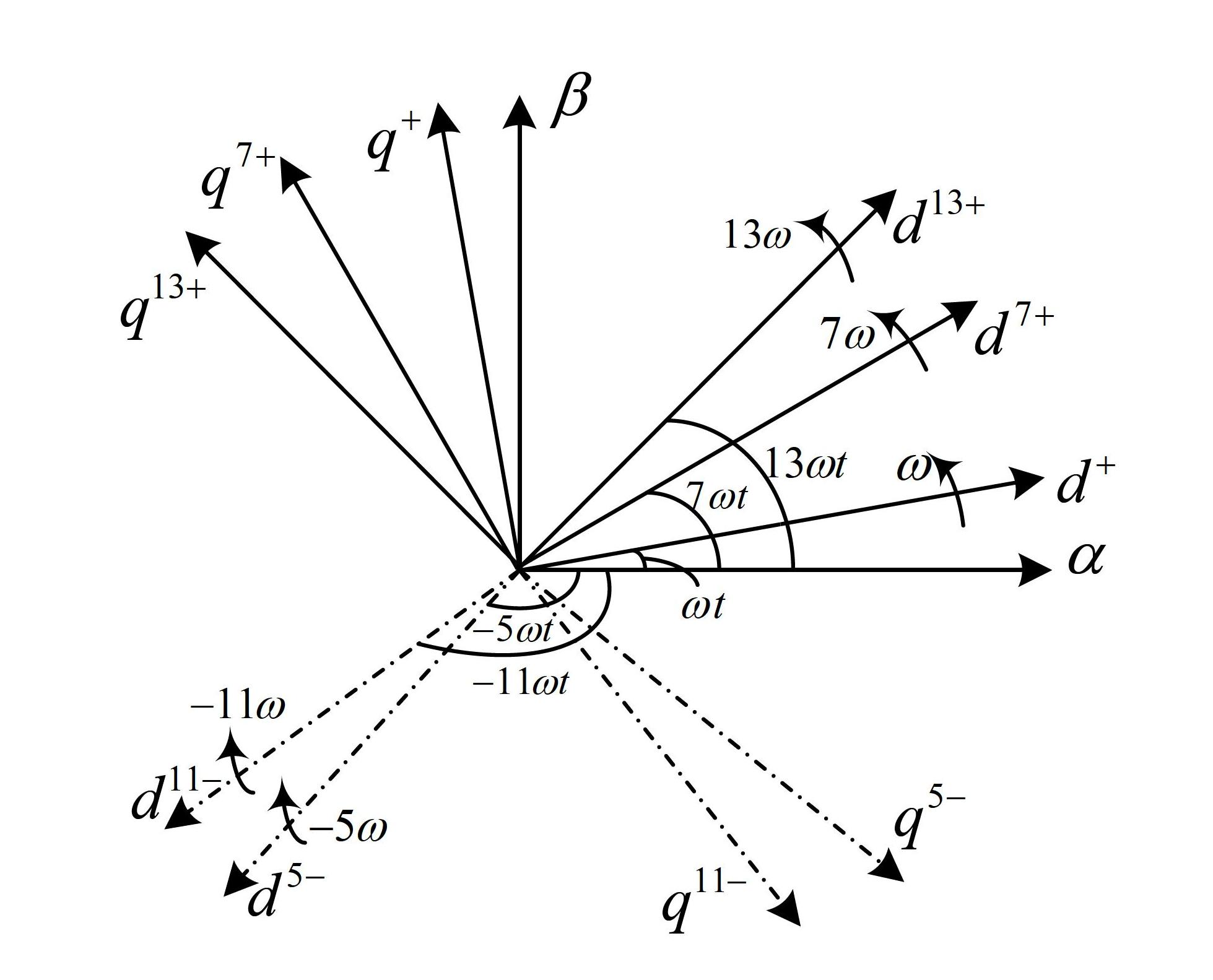

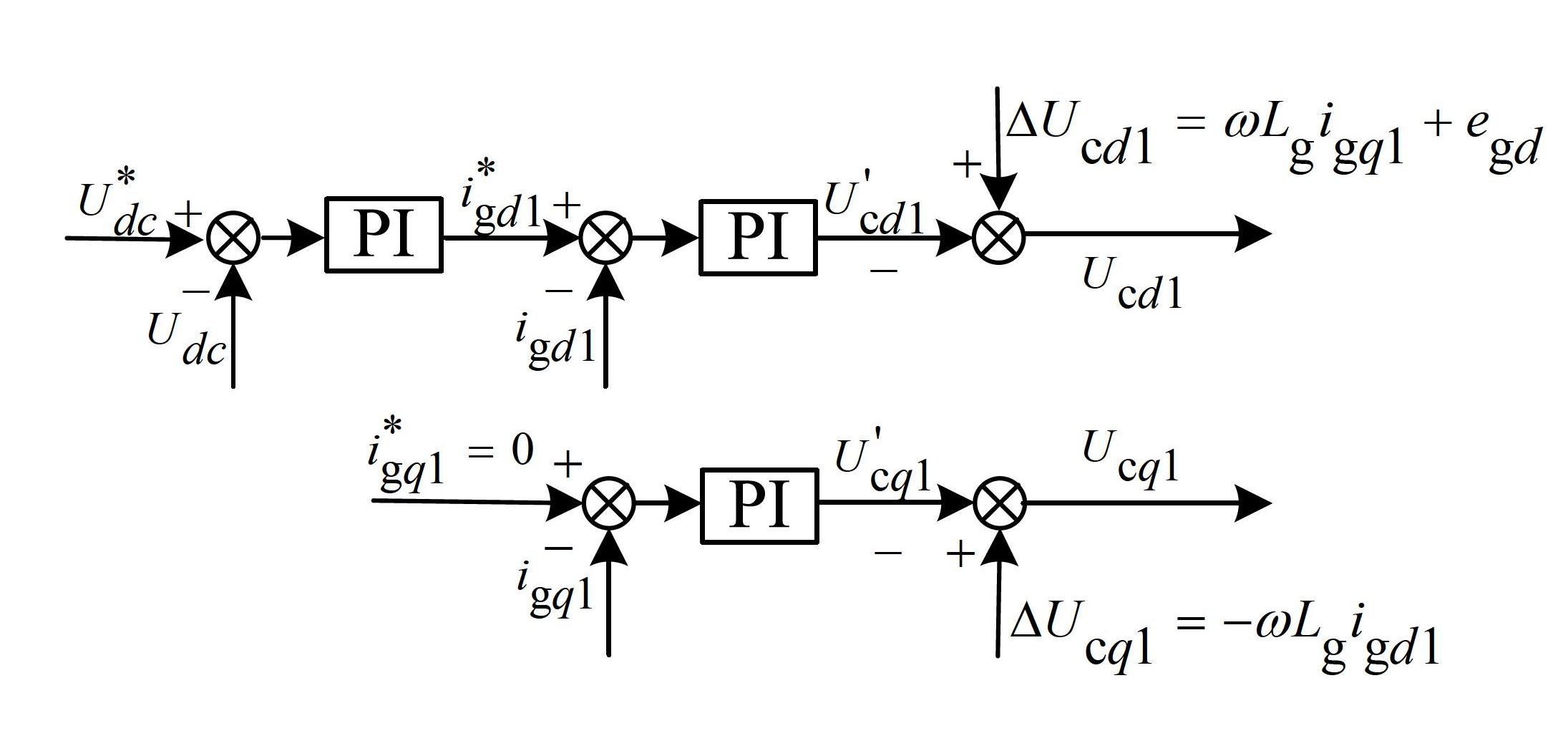

InactiveCN102664413AImprove power qualityImprove stabilitySingle network parallel feeding arrangementsHarmonic reduction arrangementControl modePower grid

The invention discloses a method for controlling the harmonic current of a full-power converter for suppressing wind power grid integration and a controller. The method comprises the following steps of: acquiring three-phase current and three-phase voltage of a grid-integrated converter, performing constant power conversion on an acquired network side three-phase current signal from a static three-phase coordinate system to synchronous, five-time, seven-time, eleven-time and thirteen-time rotary coordinate systems, and performing low pass filtering to obtain a dq axis component; and obtaining a dq axis control voltage by adopting a network voltage directional vector control way, performing constant power conversion on the control voltage from synchronous, five-time, seven-time, eleven-time and thirteen-time rotary coordinate systems to the static three-phase coordinate system to obtain a fundamental wave control voltage and five-time, seven-time, eleven-time and thirteen-time harmonic wave three-phase control voltages, adding the fundamental wave control voltage and the five-time, seven-time, eleven-time and thirteen-time harmonic wave three-phase control voltages to obtain a final control voltage, and modulating the final control voltage to obtain a control switch signal, so that accurate control of five-time, seven-time, eleven-time and thirteen-time harmonic current is realized.

Owner:CHONGQING UNIV

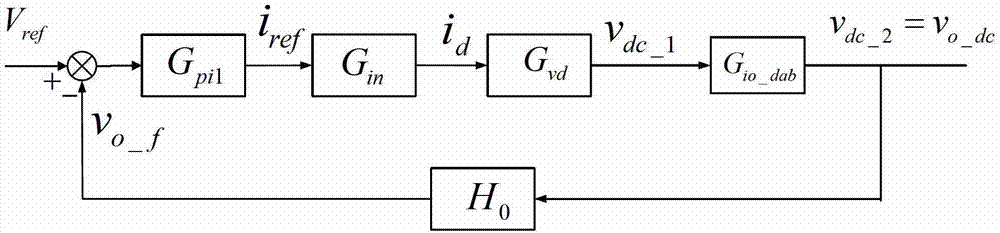

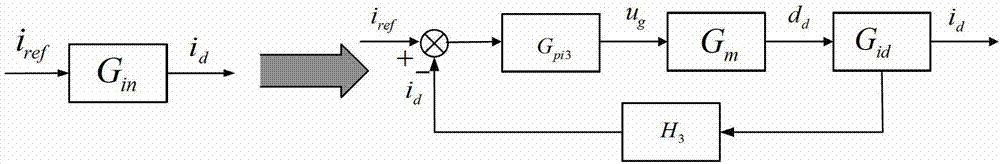

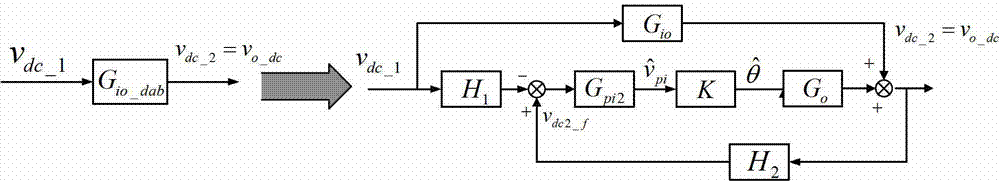

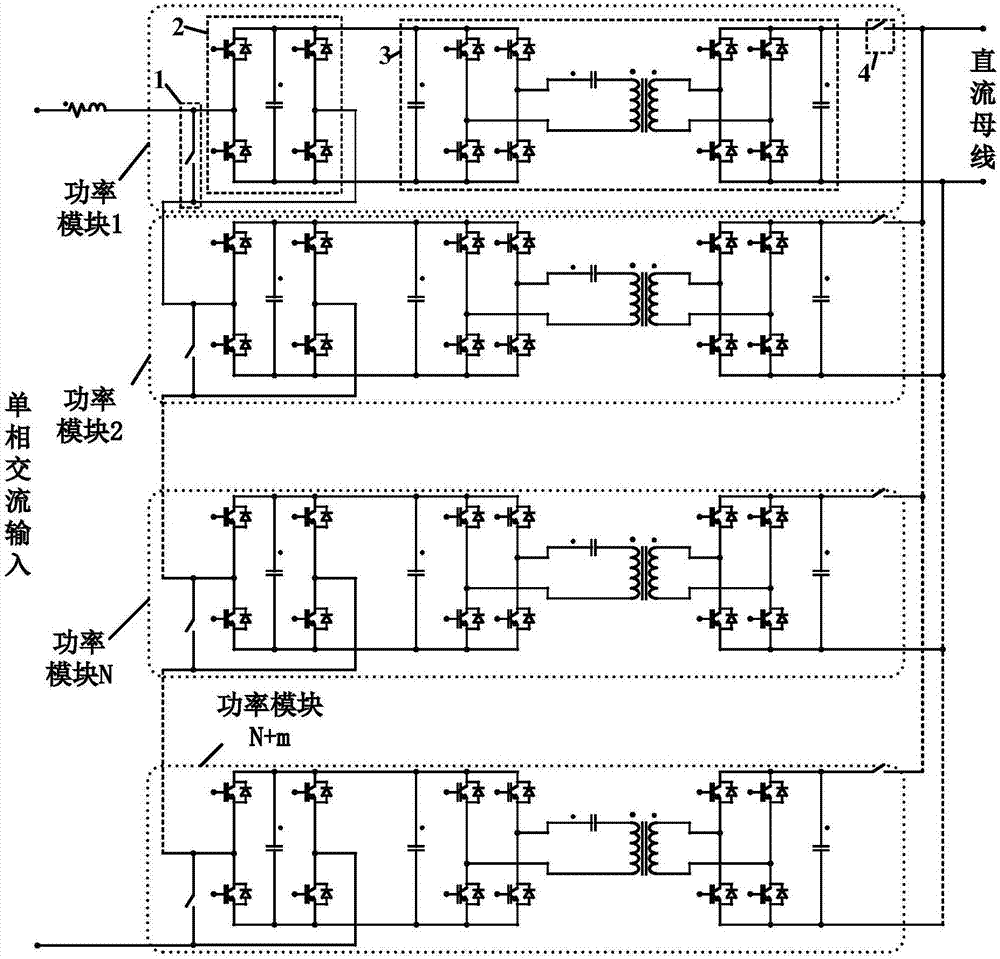

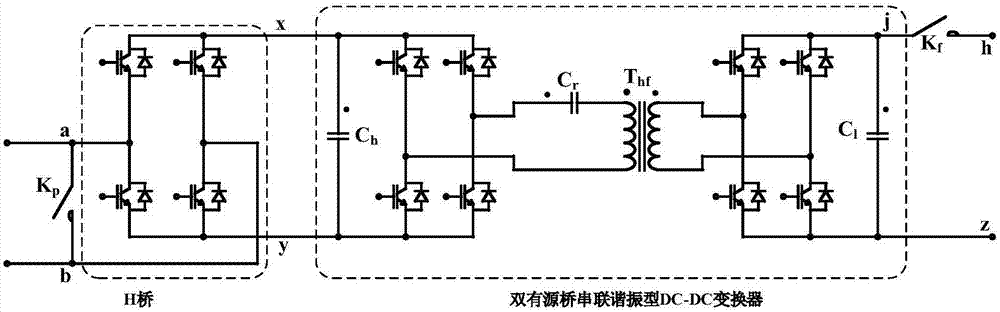

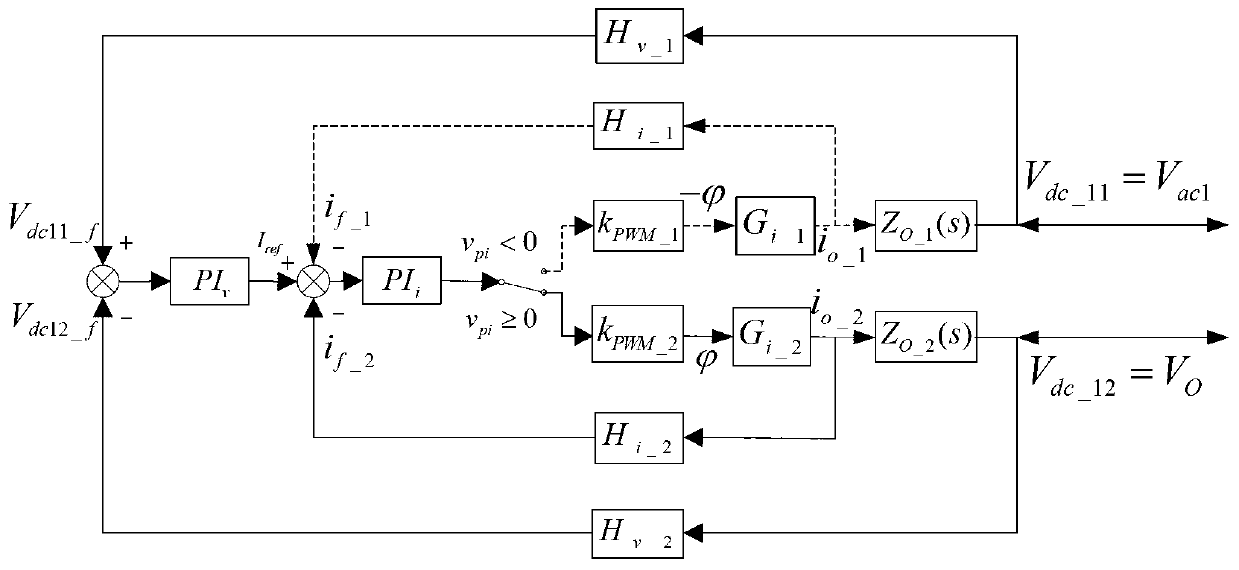

Voltage-sharing and power-sharing control method of single-phase multi-module cascading solid-state transformer

ActiveCN103490638AThe output regulator capacitor is reducedHigh current sineAc-dc conversionDc-dc conversionPower factorEngineering

The invention discloses a voltage-sharing and power-sharing control method of a single-phase multi-module cascading solid-state transformer. A power main circuit part of the single-phase solid-state transformer is composed of an AC / DC rectifying input stage, a DC / DC middle stage and a DC / AC output stage. The rectifying stage and the middle stage serve as a system for controlling and designing, a common duty ratio control strategy based on single-phase d-q vector control is adopted in the input stage, the output direct voltage of the middle stage serves as feedback quantity of an outer voltage loop, the stability of the output direct voltage of the middle stage is achieved, and a unity power factor of an input end of a power grid is achieved; a control strategy based on voltage feed-forward and voltage feed-backward is introduced into all modules in the middle stage at the same time, the voltage feed-forward serves the benchmark of the voltage feed-backward, and errors of the voltage feed-forward and voltage feed-backward serve as the benchmark of a module current inner loop after being output by a voltage PI regulator. The front stage control strategy is interacted with the middle stage control strategy, and therefore the purposes that voltage and the power of modules of an SST are balanced, the power grid side unity power factor is achieved, the power grid current sine degree is high, the voltage stress of a switch tube is low, and the ripple of the output direct voltage of the middle stage is low.

Owner:ZHEJIANG UNIV

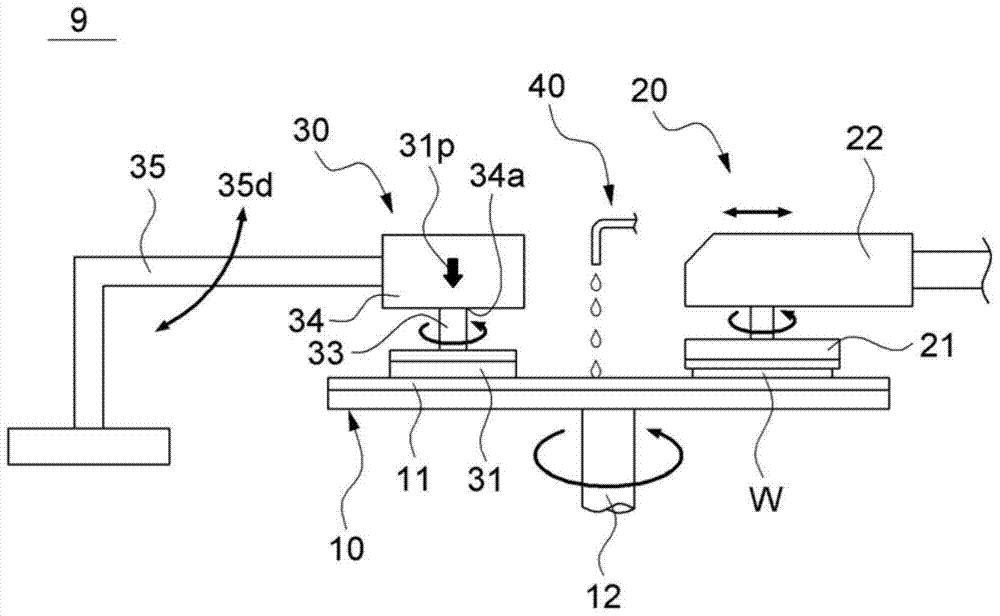

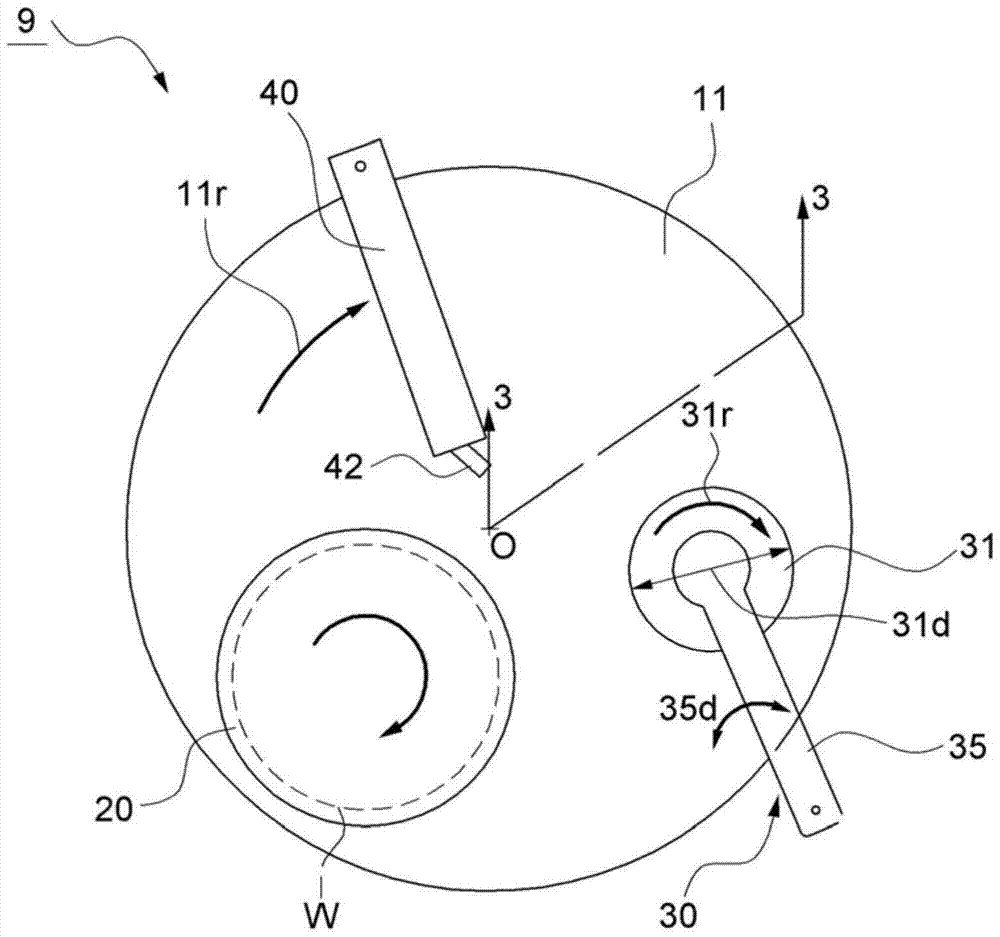

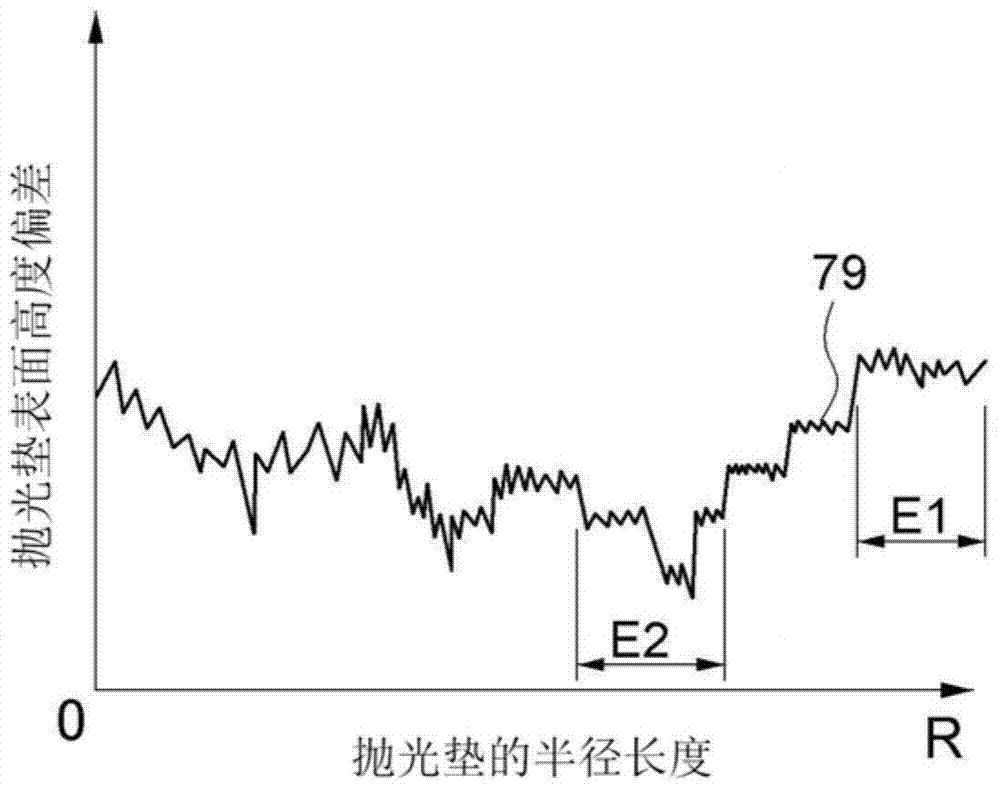

Chemical mechanical polishing apparatus and method thereof

The invention relates to a chemical mechanical polishing apparatus and a method thereof. The apparatus comprises a polishing head for pressing and rotating a wafer in a state where the wafer is on a lower side; a height measuring portion for obtaining a height deviation in the radial direction of a polishing pad during the chemical mechanical polishing; a regulating device having an arm portion and an adjusting disc, the arm being rotated about a hinge axis to rotate at a predetermined angle, and the adjusting disc pressing the polishing pad against the lower side of the arm portion and rotating; and a control portion for adjusting the rotational speed of the arm portion with a second rotation speed at a second position, the height of the polishing pad at the second position being higher than the height at the first position, and the second rotational speed being smaller than the first rotational speed, such that, by adjusting the rotational speed of the adjusting disc, it is possible to alleviate the height deviation of the polishing pad at different positions. Therefore, even if the same pressure is applied to the wafer, the friction amount is different depending on the height deviation of the polishing pad, so that the polishing amount per hour of the wafer can be adjusted in each region.

Owner:K C TECH

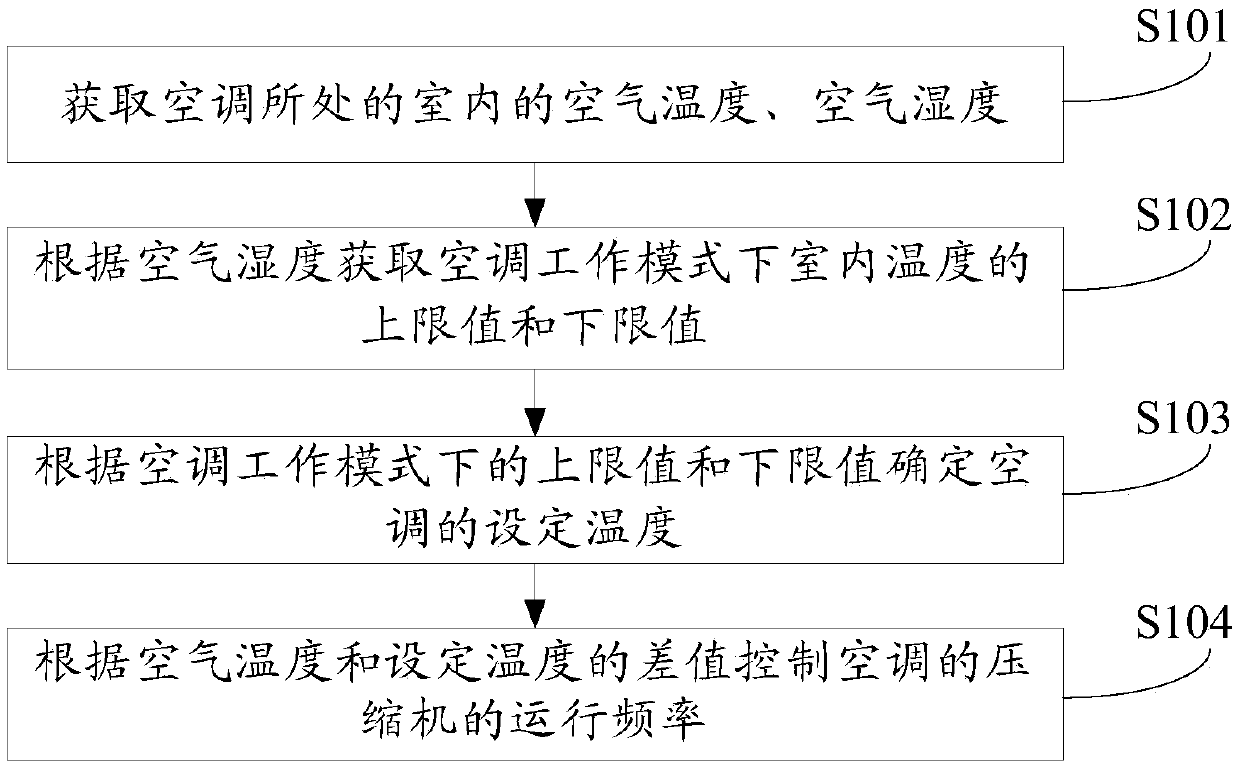

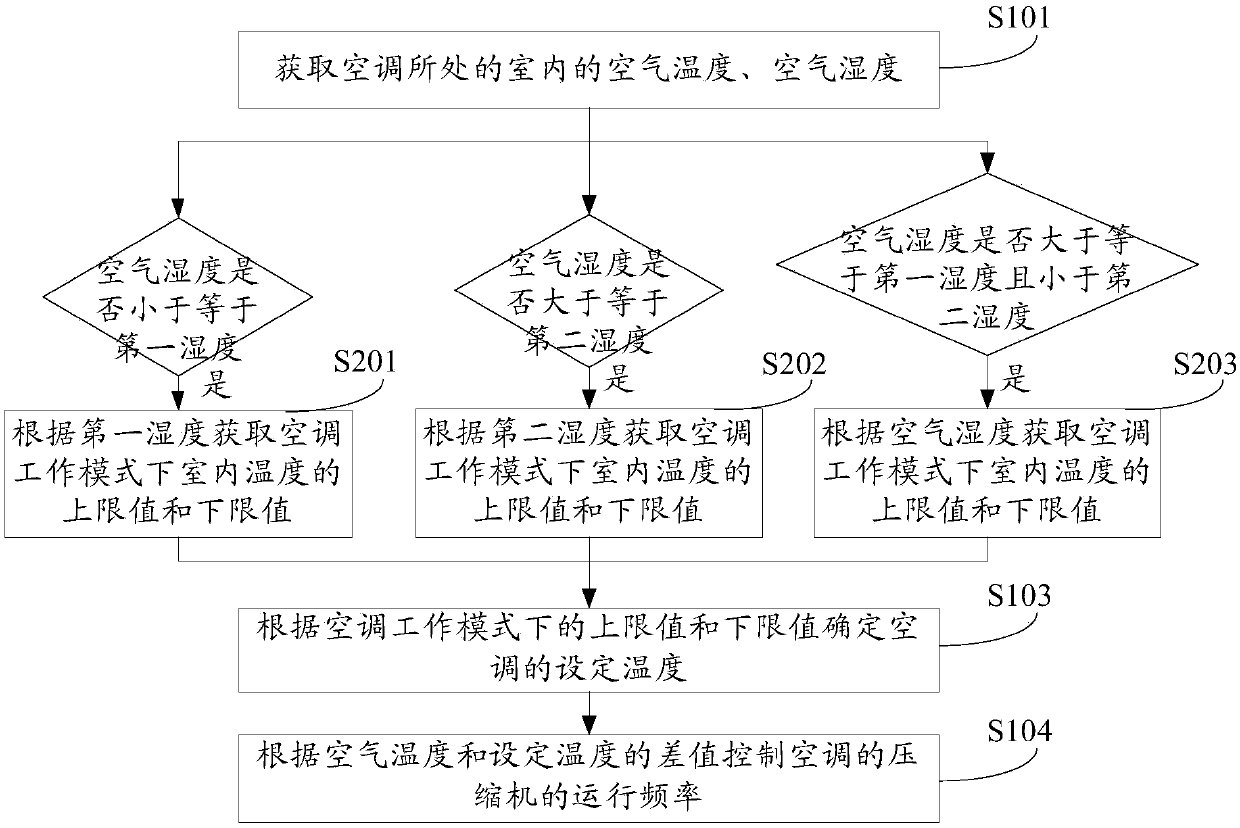

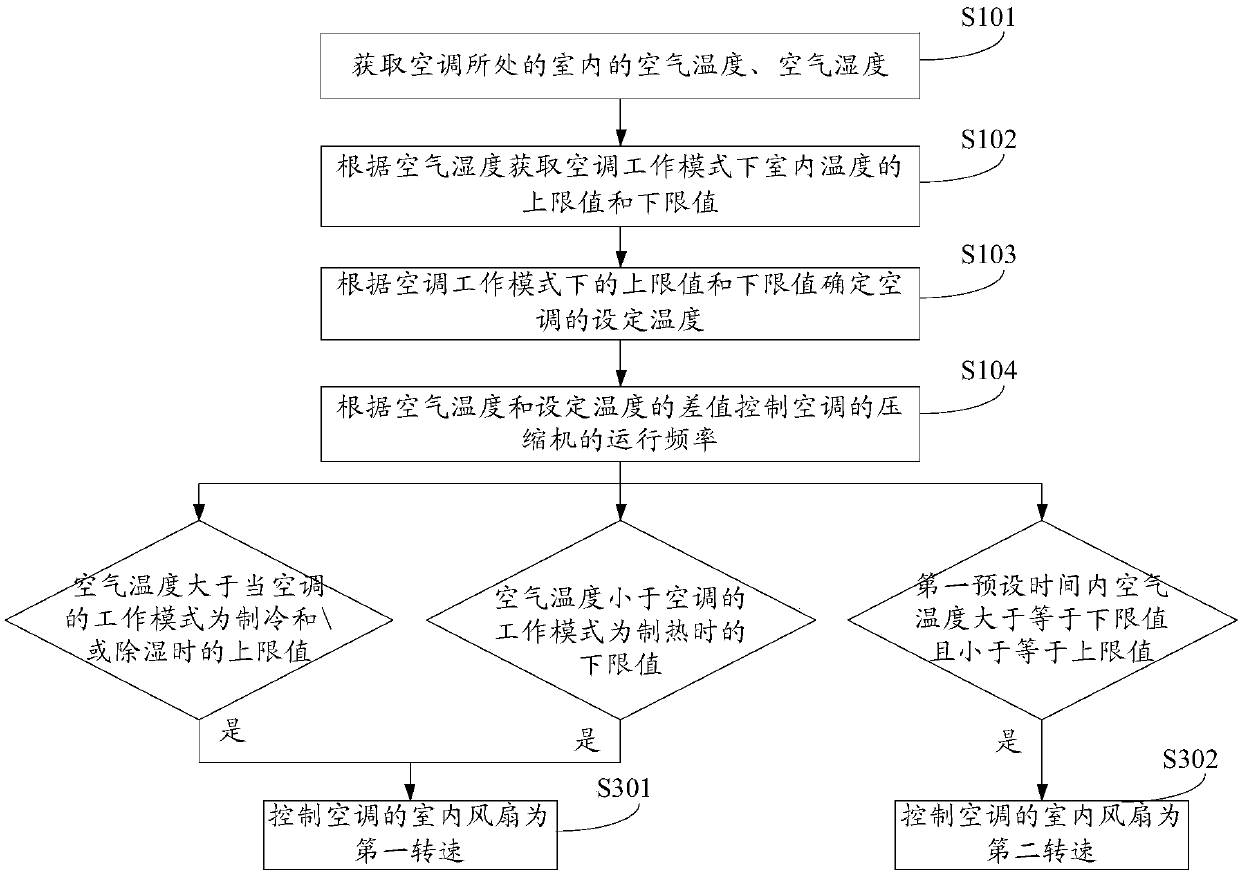

Method and device for controlling air conditioner

InactiveCN109539462ASimple control algorithmMeet computing needsMechanical apparatusSpace heating and ventilation safety systemsLower limitLimit value

The invention discloses a method and device for controlling an air conditioner, and relates to the technical field of household appliances. The method and device are used for solving the problem thata conventional air conditioner comfort control algorithm is complex. The method includes the steps that the air temperature and relative humidity in a room where the air conditioner is located are acquired; the upper limit value and the lower limit value of the indoor temperature in an air conditioner working mode are acquired according to the relative humidity; the setting temperature of the airconditioner is determined according to the upper limit value and the lower limit value in the air conditioner working mode; and the operating frequency of a compressor of the air conditioner is controlled according to the difference value of the air temperature and the setting temperature. The method and device are applied to controlling the comfort of the air conditioner.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

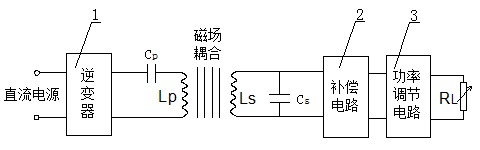

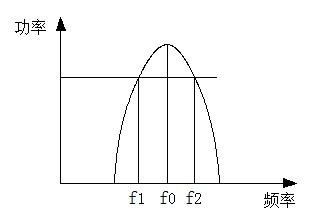

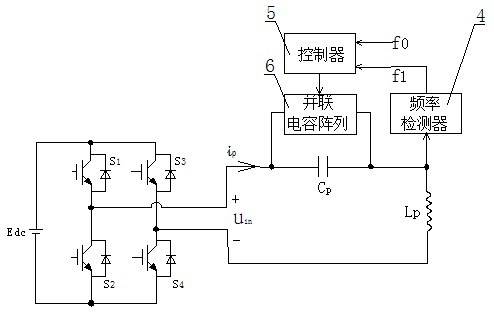

A frequency stabilization circuit for non-contact energy transmission system

InactiveCN102290873ASimple structureSimple control algorithmElectromagnetic wave systemCircuit arrangementsFrequency stabilizationHemt circuits

The invention discloses a frequency stabilization circuit for a non-contact energy transmission system, which includes an inverter, a primary side resonance circuit, a secondary side resonance circuit and a power adjustment circuit; it is characterized in that: the primary side resonance circuit is connected with a frequency detection circuit The input end of the frequency detector is connected between the primary side resonant capacitor and the excitation coil, and its output end outputs the primary side resonant frequency value f1 to the first input end of the controller, and the second input end of the controller is input to the system setting The resonant frequency value f0 is fixed, the output control terminal of the controller is connected with the parallel capacitor array, and the parallel capacitor array is connected in parallel with the primary side resonant capacitor, and the controller controls the capacitance value of the parallel capacitor array according to f1 and f0. Its remarkable effect is: the circuit structure is simple, the control algorithm is easy to implement, the system has good dynamic response speed, stability and anti-interference, and the frequency stability can be guaranteed during the load change process to realize the maximum energy transmission of the system.

Owner:CHONGQING UNIV

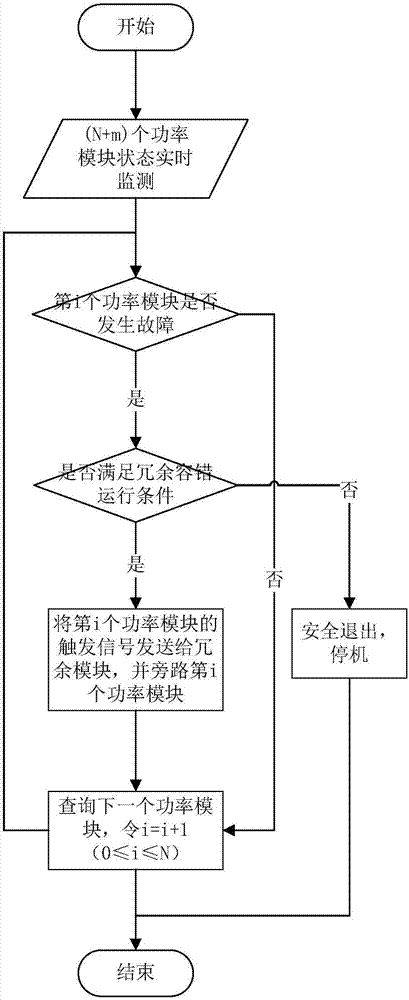

Cascaded power module redundancy fault-tolerant control method of power electronic transformer

ActiveCN107546844ASimple control algorithmRealize redundant switchingDc-dc conversionElectric variable regulationTransformerComputer module

The invention discloses a cascaded power module redundancy fault-tolerant control method of a power electronic transformer. The method is suitable for a cascaded H bridge type power electronic transformer; when the cascaded power module is in fault, the fault power module is bypassed under the situation that the fault-tolerant running condition is satisfied, and a switch device trigger signal of the fault power module is redistributed to a redundancy module, so that the power electronic transformer is smooth in redundancy switching, and the non-intermittent and accuracy of the redundancy switching are realized.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

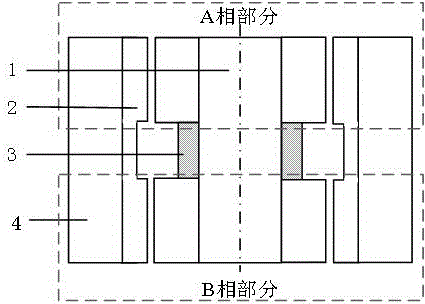

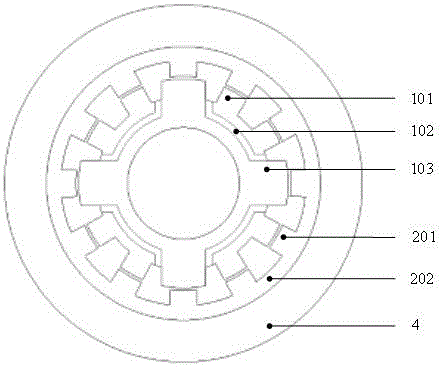

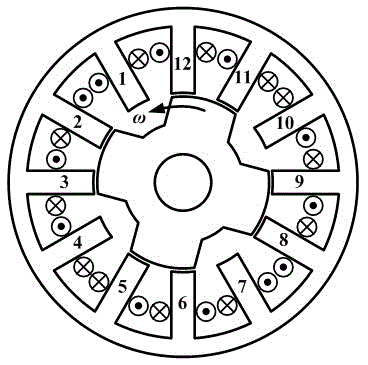

Axial split-phase internal stator permanent magnet biased magnetic suspension switched reluctance flywheel motor

ActiveCN106385203AIncrease the critical speedReduce lossMagnetic circuit stationary partsMechanical energy handlingFreewheelMagnetic poles

The invention provides an axial split-phase internal stator permanent magnet biased magnetic suspension switched reluctance flywheel motor comprising an external rotor, a flywheel and an internal stator. The external rotor is packaged at the internal side of the flywheel in a laminating way. An internal stator iron core and an external rotor iron core are divided into m segments along the axis according to the phase number. The internal side of each segment of external rotor is equidistantly provided with 12 rotor poles along the circumference. The internal stator iron core is provided with 8 narrow tooth main magnetic poles and 4 wide tooth suspension poles. Main pole control coils and suspension control coils are respectively wound on the narrow tooth main magnetic poles and the wide tooth suspension poles. The coils on each narrow tooth main magnetic pole are interconnected in series to form a main pole winding. Every two of the control coils on each segment of wide tooth suspension pole are connected in series so as to form two sets of suspension windings in an orthogonal direction. The size of the system can be reduced and the critical speed of rotation can be enhanced; the suspension supporting loss can be reduced and the operation efficiency can be enhanced; and the stator poles are separately provided with the suspension poles, the main magnetic poles and magnetic isolating rings so that the control algorithm can be simplified and the suspension performance and the decoupling effect can be enhanced.

Owner:NANJING INST OF TECH

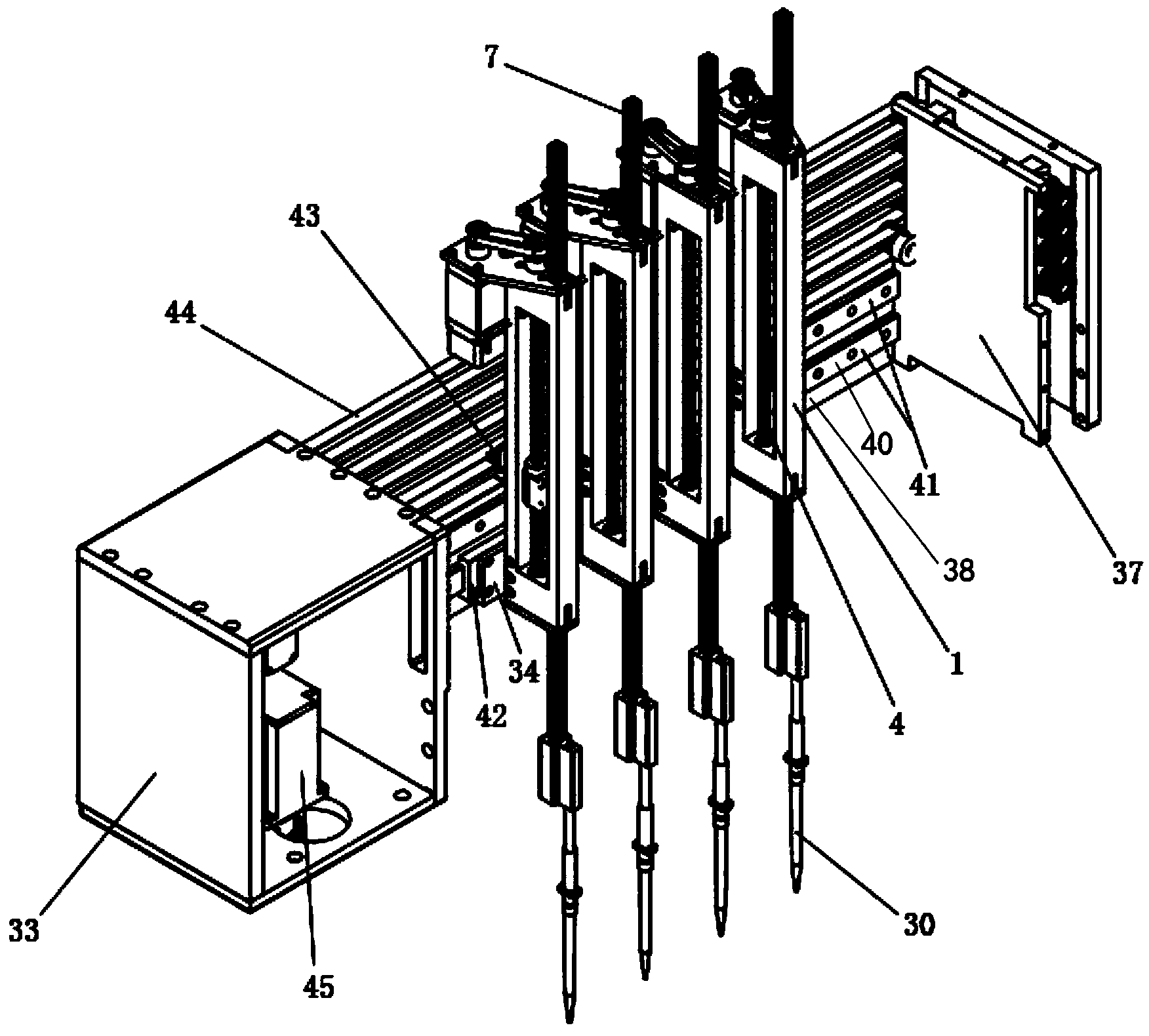

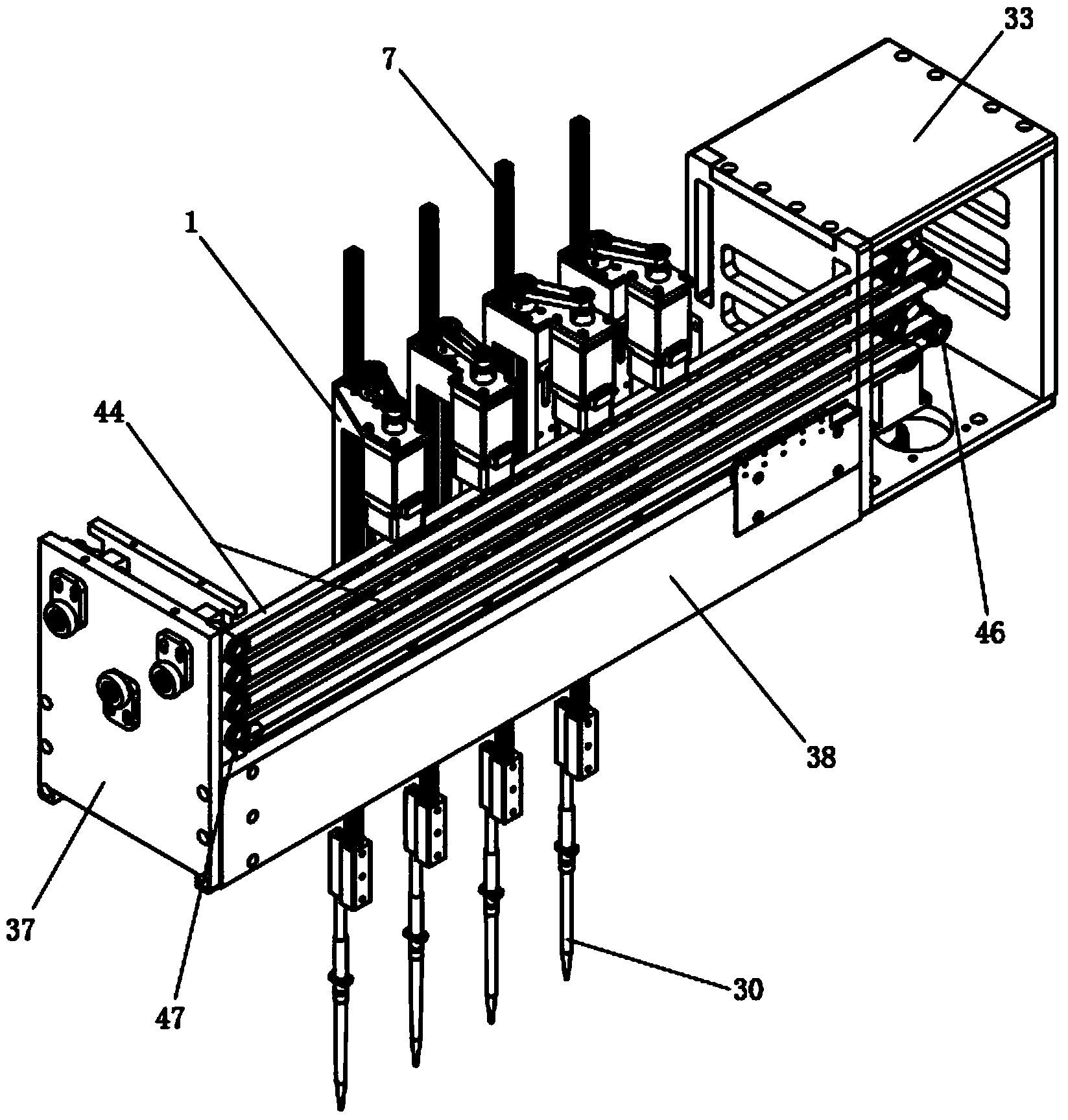

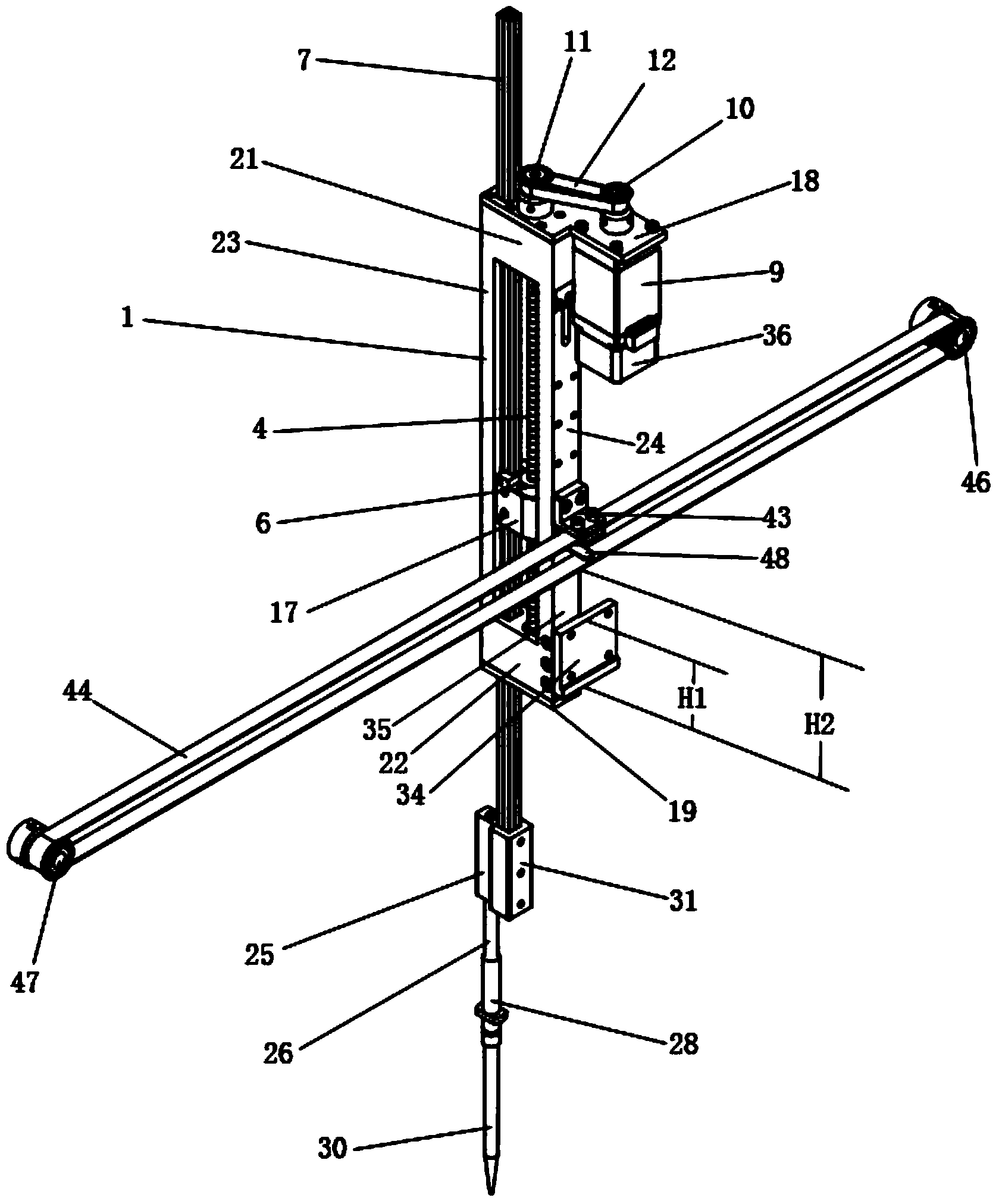

Full-automatic pipetting station and application thereof

InactiveCN103846114AReasonable layoutSmooth structureWithdrawing sample devicesBurettes/pipettesMechanical pipetteControl theory

The invention provides a full-automatic pipetting station comprising a pipetting mechanism support and a plurality of pipetting mechanisms. Each pipetting mechanism comprises a moving base, a moving rod, a moving rod driving mechanism, a linear guide rail fixing seat and a pipetting head, wherein the moving rod is movably assembled on the moving base, and the pipetting head is arranged at the lower end of the moving rod. The invention also provides an application of the pipetting station in the aspects of liquid sample injection, liquid transfer and the like. The pipetting station provided by the invention is capable of greatly buffering impact and vibration generated in an operation process, low in driving noise and stable and reliable in driving so that the pipetting mechanisms in the station can more flexibly operate and the pipetting head can operate to more plate positions.

Owner:GENMAG BIOTECH

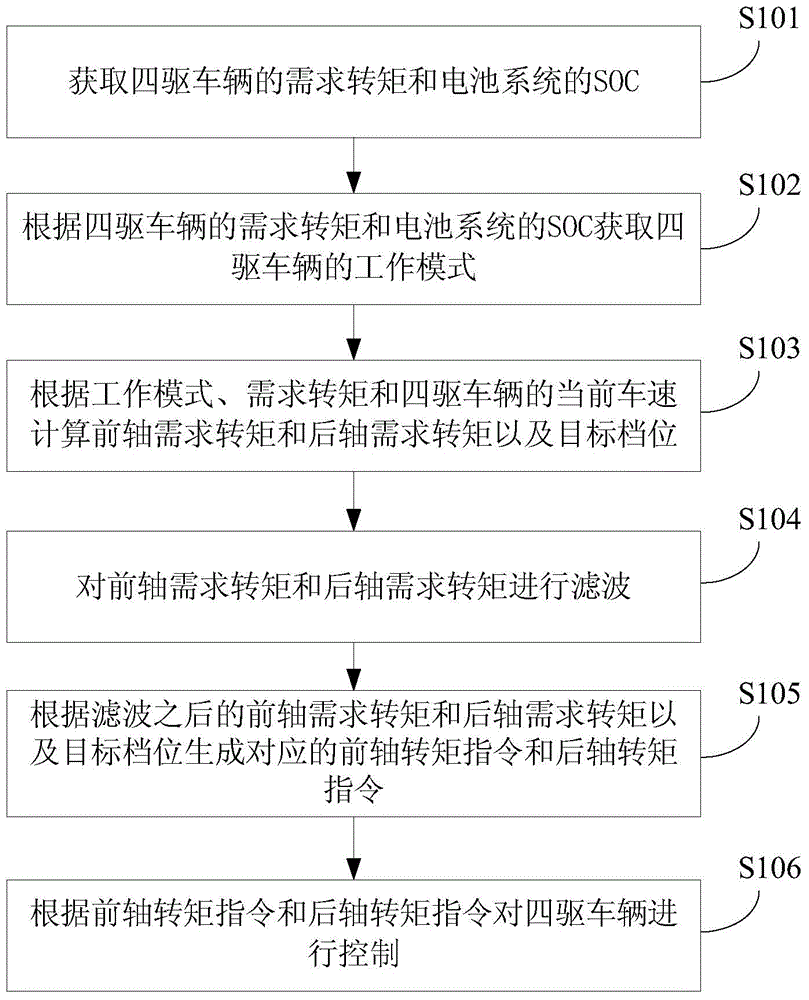

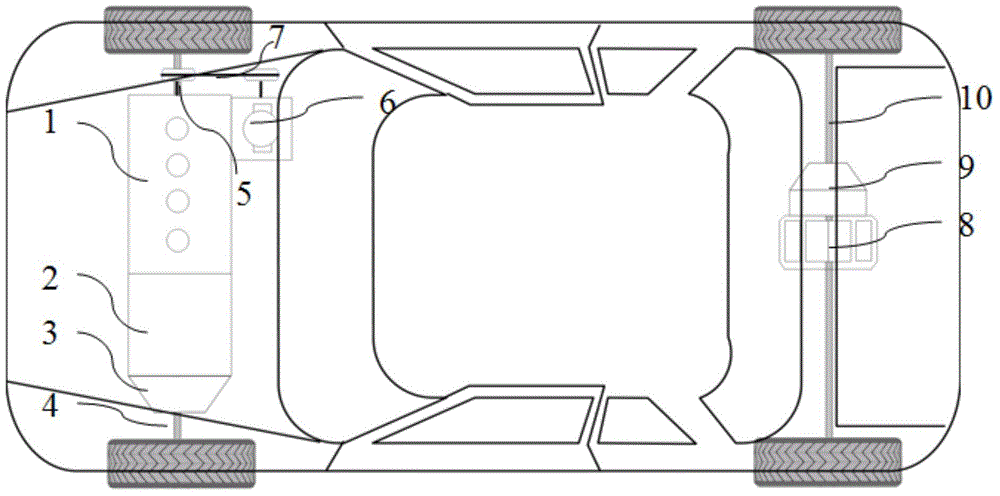

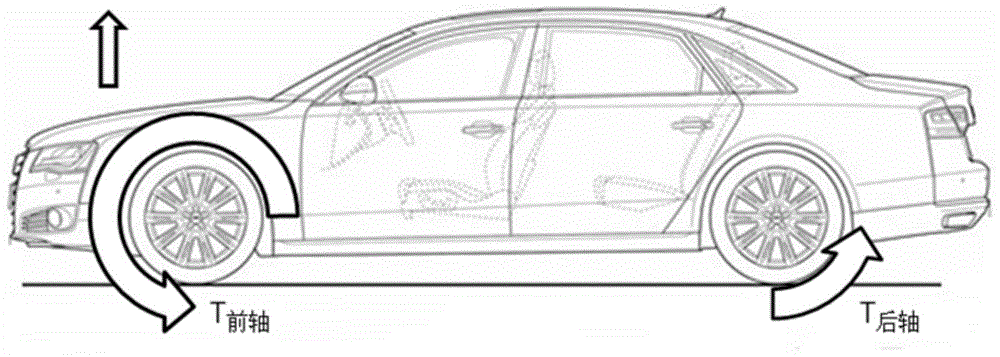

Front and rear axle driving force adjusting control method and system of four-wheel drive vehicle, and four-wheel drive vehicle

InactiveCN104828087ASimple control algorithmImprove comfortHybrid vehiclesControl systemState of charge

The invention discloses a front and rear axle driving force adjusting control method and a front and rear axle driving force adjusting control system of a four-wheel drive vehicle, and the four-wheel drive vehicle. The method comprises the steps of obtaining required torque of the four-wheel drive vehicle and SOC (state of charging) of a battery system; obtaining a working mode of the four-wheel drive vehicle according to the required torque of the four-wheel drive vehicle and the SOC of the battery system; calculating required torque of a front axle, required torque of a rear axle and a target gear according to the working mode, the required torque and a current speed of the four-wheel drive vehicle; performing filtering on the required torque of the front axle and the required torque of the rear axle; generating a corresponding front axle torque instruction and a corresponding rear axle torque instruction according to the required torque of the front axle and the required torque of the rear axle after filtering and the target gear; and performing control over the four-wheel drive vehicle according to the front axle torque instruction and the rear axle torque instruction. By applying the method disclosed by the embodiment of the invention, the control algorithm of the four-wheel drive vehicle provided with an active suspension can be simplified, and comfort of the four-wheel drive vehicle provided with an inactive suspension can also be improved, so that the user experience is improved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

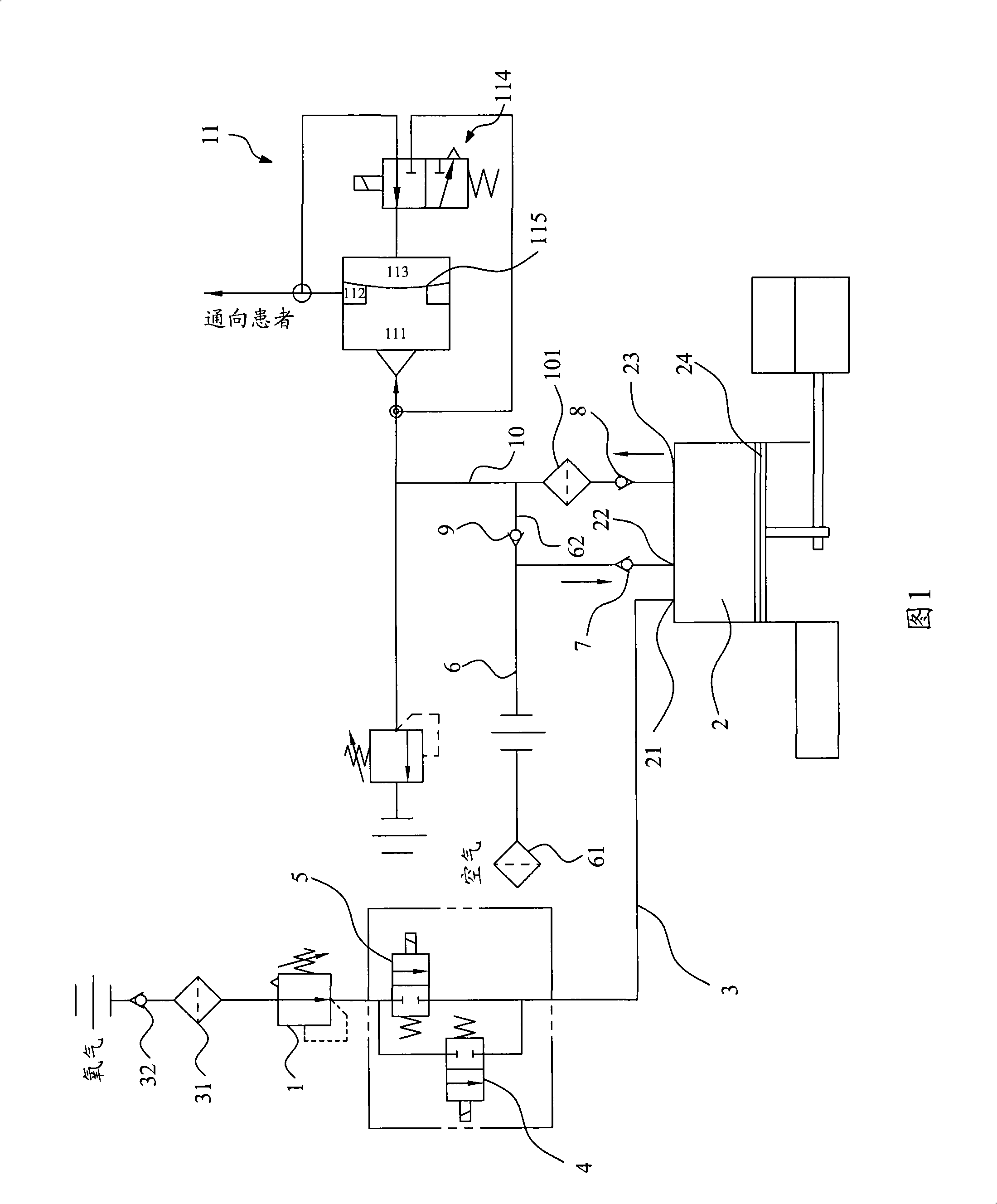

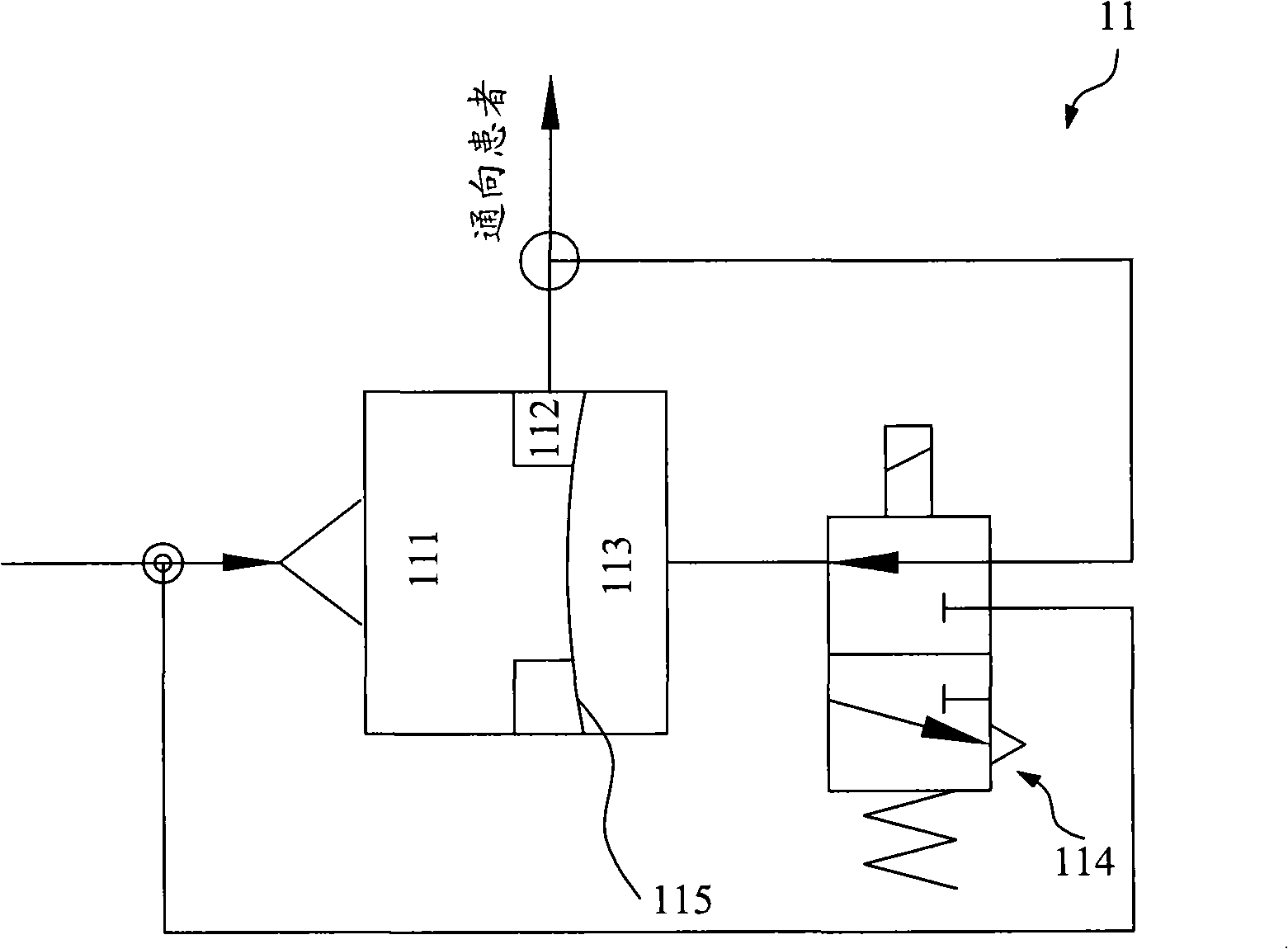

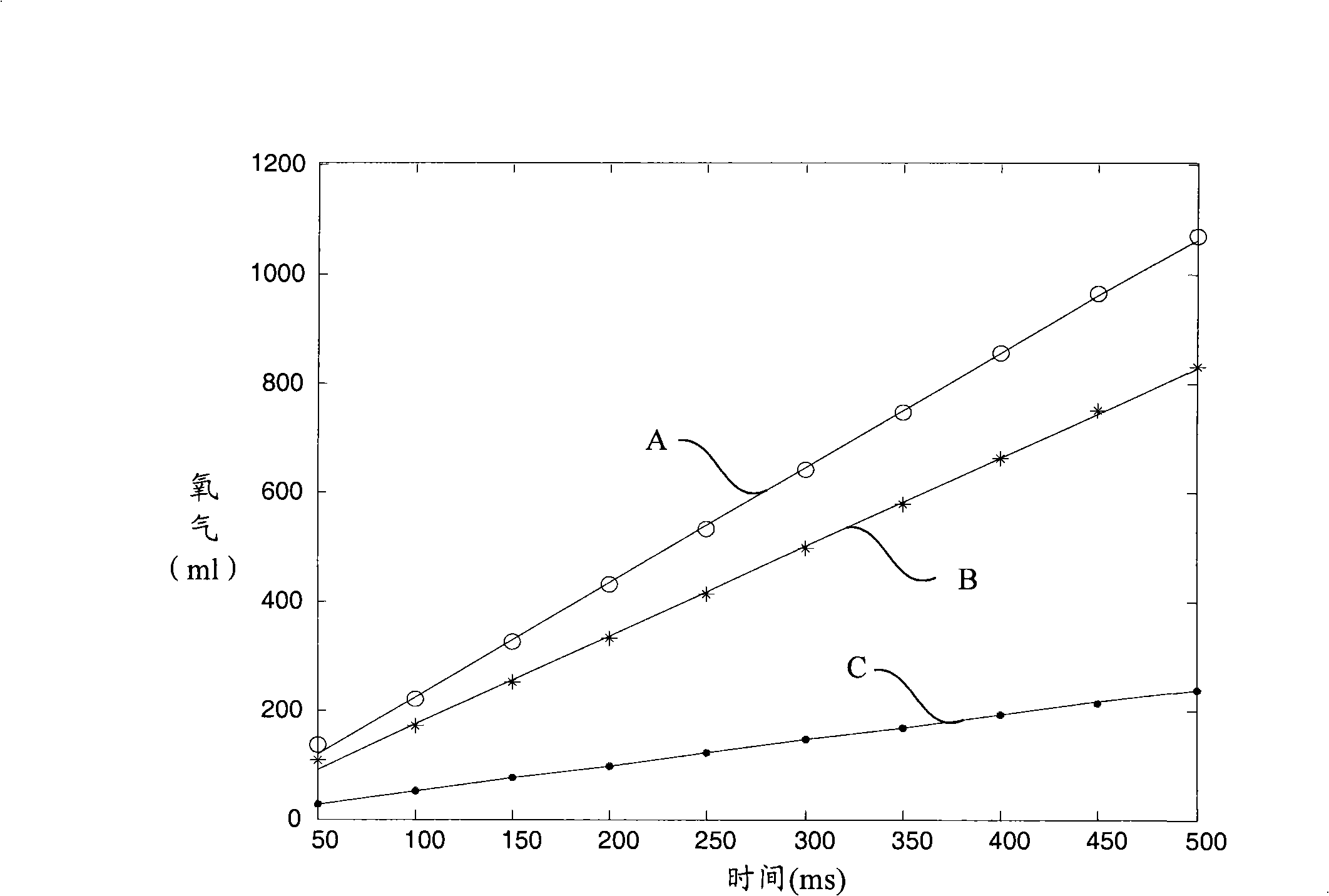

Oxygen concentration adjusting device and method thereof

ActiveCN101310786ASimple control algorithmSimplify complexityRespiratorsPneumatic cylinderProduct gas

The invention relates to an oxygen concentration regulating device, in particular to the oxygen concentration regulating device in an electric pulmotor, the oxygen concentration regulating device comprises: a pressure stabilizing valve; a pneumatic cylinder; an oxygen feed pipeline; the pressure stabilizing valve and the pneumatic cylinder are connected with each other by utilizing the oxygen feed pipeline; an air feed pipeline is connected with the pneumatic cylinder; one end of an air-oxygen mixed gas discharge pipeline is connected with the pneumatic cylinder, and the other end is introduced to a patient; wherein, at least two electromagnetic valves which are connected in parallel are arranged between the pressure stabilizing valve and the pneumatic cylinder, and the electromagnetic valves are used for regulating the oxygen feed amount. In addition, the invention further relates to an oxygen concentration regulating method.

Owner:BEIJING AEONMED

Intercepting voice over IP communications and other data communications

ActiveUS8422507B2Facilitates profileSimple control algorithmSpecial service for subscribersSupervisory/monitoring/testing arrangementsTelecommunicationsVoice over IP

Methods and apparatus for intercepting communications in an Internet Protocol (IP) network involve maintaining dialing profiles for respective subscribers to the IP network, each dialing profile including a username associated with the corresponding subscriber, and associating intercept information with the dialing profile of a subscriber whose communications are to be monitored. Intercept information will include determination information for determining whether to intercept a communication involving the subscriber, and destination information identifying a device to which intercepted communications involving the subscriber are to be sent. When the determination information meets intercept criteria communications are established with a media relay through which communications involving the subscriber will be conducted or are being conducted to cause the media relay to send a copy of the communications involving the subscriber to a mediation device specified by the destination information.

Owner:VOIP PAL COM INC

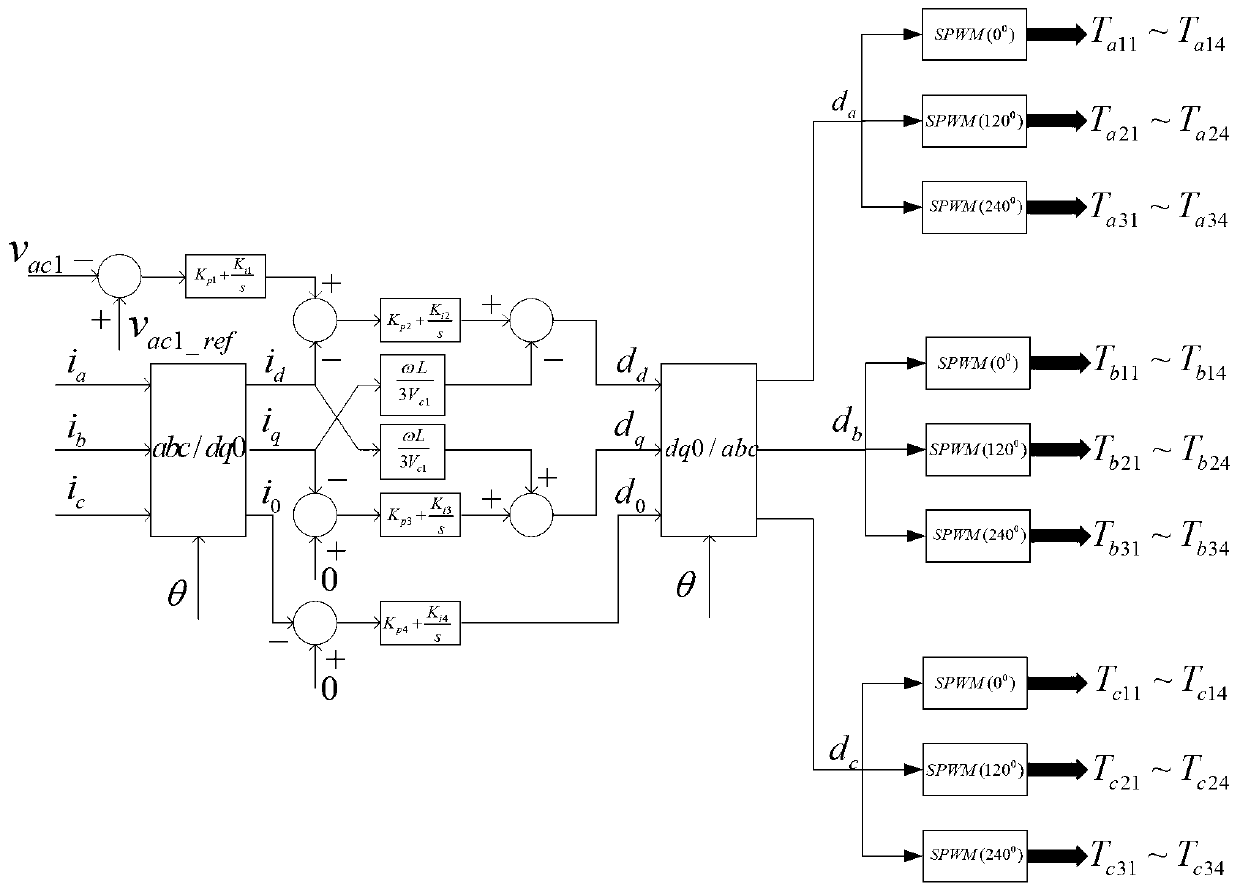

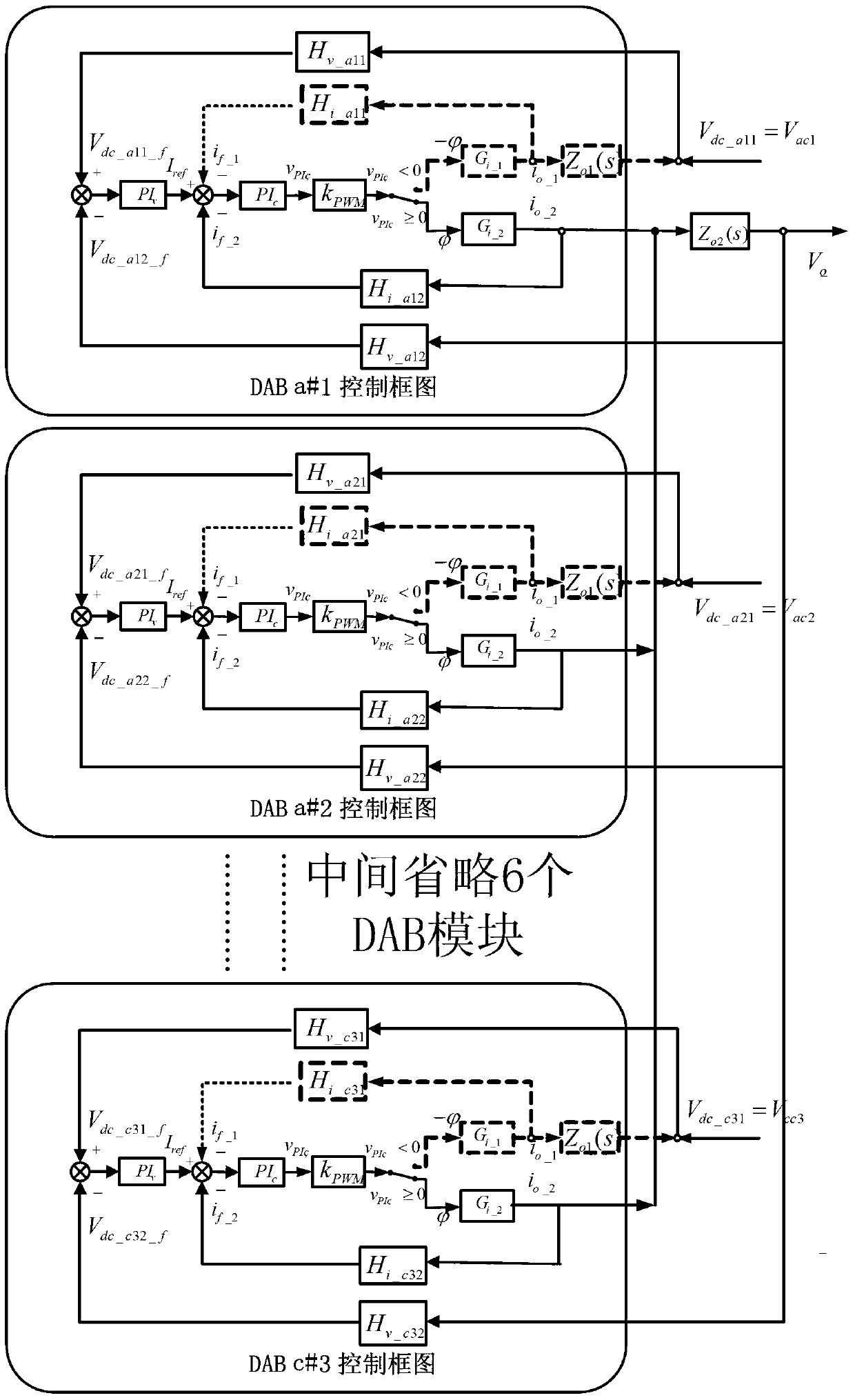

Voltage-equalizing and power-equalizing control method for three-phase multi-module cascade solid-state transformer

InactiveCN103280987AAchieve pressure equalizationAchieve powerAc-dc conversionDc-dc conversionPower factorEqualization

The invention discloses a voltage-equalizing and power-equalizing control method for a three-phase multi-module cascade solid-state transformer. A three-phase SST system power main circuit part applied in the method comprises an input stage, an intermediate stage and an output stage, wherein a control policy based on three-phase d-q-0 vector control is adopted in the input stage, a common duty ratio control policy is adopted in modules in the same phase so as to achieve the unit power factor of an input end of an electric network; a control policy based on voltage feedforward and voltage feedback is introduced for each module in the intermediate stage, the voltage feedforward is used as a reference of the voltage feedback, and an error between the voltage feedforward and the voltage feedback is used as a reference of an inner current loop of each module after being output by a voltage PI adjuster. The two control policies of the front stage and the intermediate stage interact so as to achieve the functions of voltage and power equalization of each SST module, electrical network side unit power factor, high electrical network current sine degree, low switching tube voltage stress and the like.

Owner:ZHEJIANG UNIV

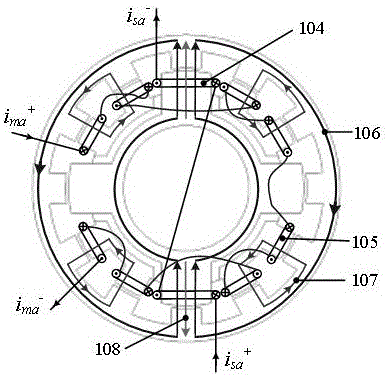

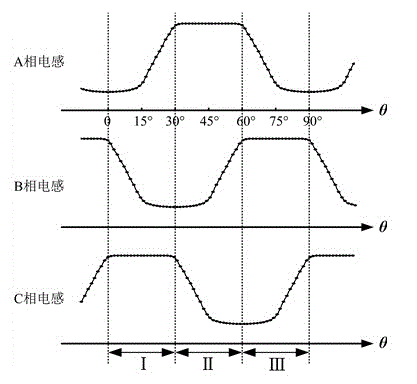

12/4 pole single winding bearingless switch reluctance motor and control method thereof

ActiveCN103337938ASolve decouplingPracticalAC motor controlSynchronous machinesElectricityMotor drive

The invention discloses a 12 / 4 pole single winding bearingless switch reluctance motor and a control method thereof. The motor comprises a stator with 12 gear poles and a rotor with 4 gear poles; each pole of the stator winds a set of excitation windings; the rotor winds no winding; the rotor gear is wider than the stator gear by 30 degrees to enable each inductance to have a maximum induction flat-top area with 1 / 3 period. When the motor is in motor-driven operation, if the two phases in an inductance rising area and an inductance flat-top area are communicated simultaneously, the phase in the inductance rising area can produce a torque, and the phase in the inductance flat-top area can produce a suspension force; when the motor is in motor-driven operation, if only the phase in the inductance flat-top area is communicated, four windings of the phase are individually controlled to produce the suspension force and to provide excitation for the electricity generation stage, and later to generate electricity in an inductance drop area with follow current. The method controls the suspension force and the torque regionally, realizes the decoupling of the suspension force and the torque, simplifies the control algorithm, improves the radial bearing capacity and the high-speed adaptability of the motor, has generality and popularization in structure, and enables the field of the bearingless switch reluctance motor to gain a new development.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

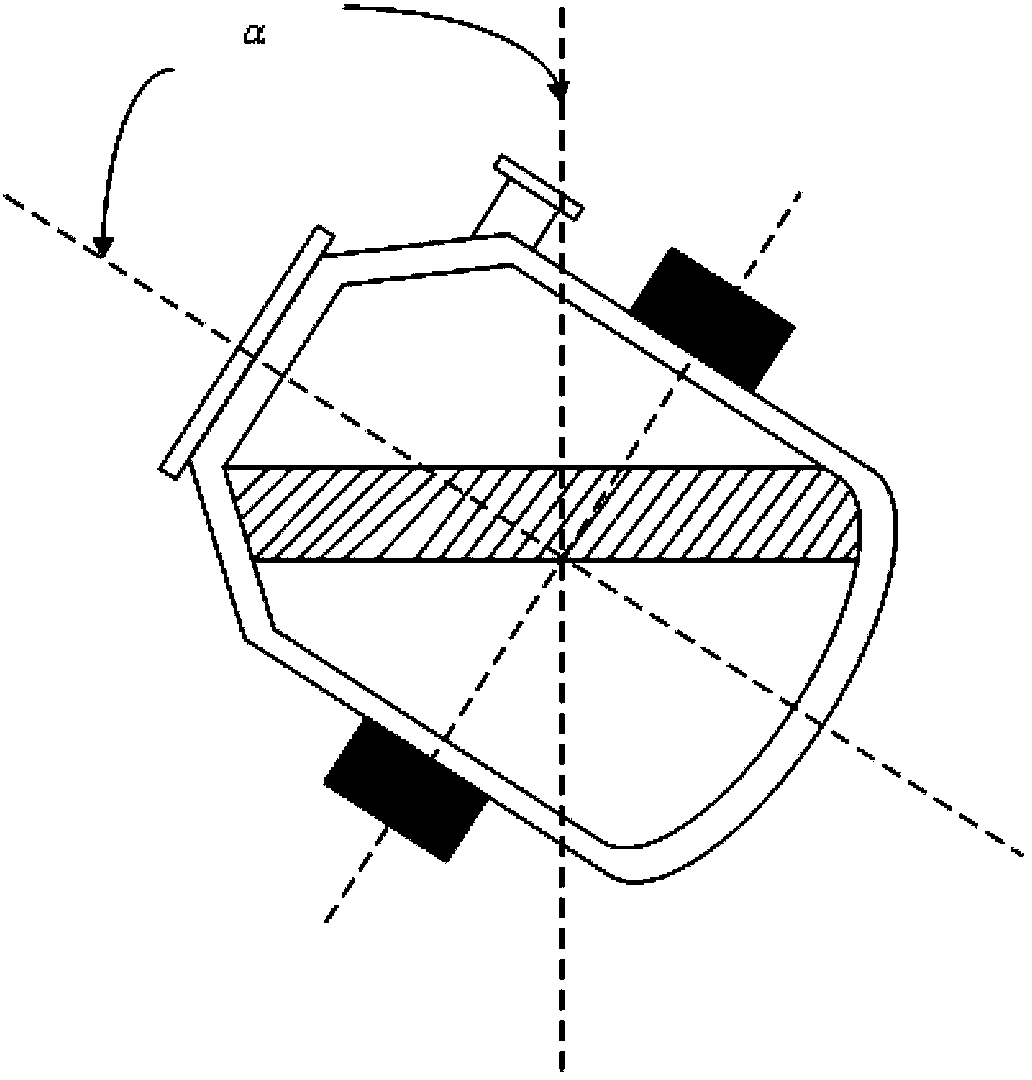

Method for calculating residual slag amount of converter in accordance with tilting angle of converter

ActiveCN103397134ASimple control algorithmEasy to implementManufacturing convertersProcess efficiency improvementMaterial balanceSlag

The invention provides a method for calculating the residual slag amount of a converter in accordance with a tilting angle of the converter. The method comprises the following steps of: after blowing is finished, recording a critical angle alpha when slag in the converter needs to flow out and does flow out in a slag pouring process to obtain a total volume V1 of a molten body in the converter; then, determining the height of a molten steel liquid surface by a secondary gun to obtain the volume Vsteel of molten steel of the converter; recording a converter tilting angle beta after the slag is poured to obtain a total volume V2 of the residual molten body; finally, combining furnace lining corrosion data provided by a furnace lining measurement system to calculate the total volume of the molten body in the converter before the slag is poured out and the volume of the poured slag, wherein the difference between the total volume and the volume is the volume of the residual slag in the converter; calculating the total slag amount by material balance; obtaining the residual slag amount in the converter according to a direct proportion of the mass to the quality. According to the method provided by the invention, detection equipment and weighing equipment do not need to be additionally arranged, so that the method is simple and feasible.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

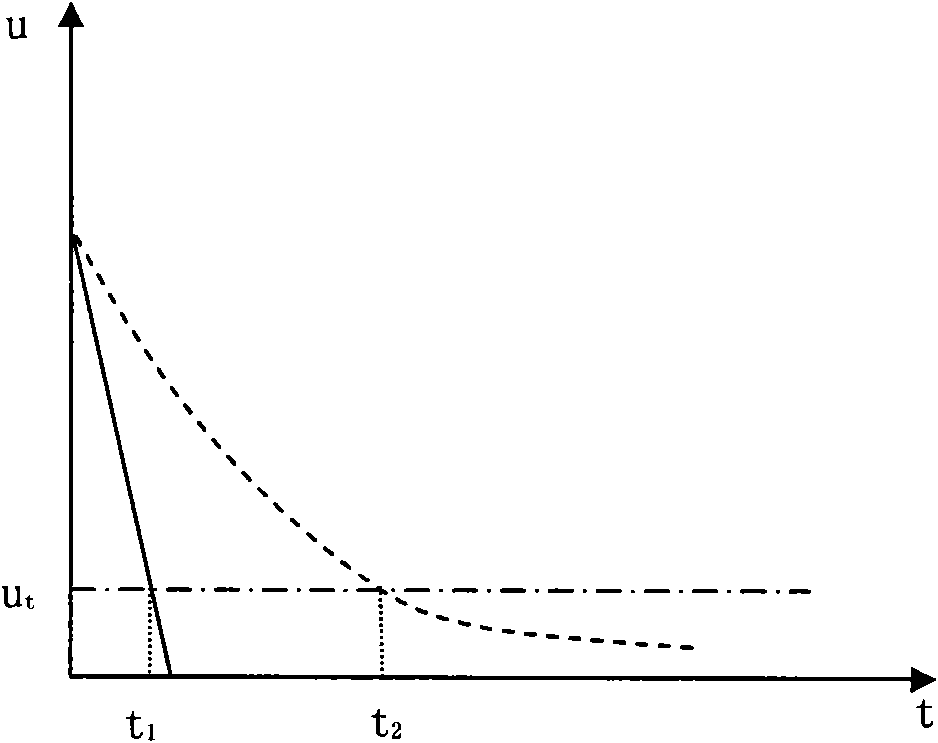

Method for quickly discharging for automobile high-voltage DC bus

ActiveCN101944755ALow costSimple control algorithmBatteries circuit arrangementsDc motor stoppersCapacitanceCapacitor voltage

The invention discloses a method for quickly discharging for an automobile high-voltage DC bus, comprising a main motor system and a plurality of electro-subsystems, wherein the main motor system is connected with the DC bus, the electro-subsystems are also connected with the DC bus and are connected with the main motor system in parallel, and each subsystem is driven by the motor. The invention also comprises a discharge resistor connected with the DC bus in parallel. The method comprises the following steps: (1) when the DC bus is in outage, the main motor serves as a first motor for controlling; a first motor controller sends a signal to the first motor; the first motor generates current to cause a motor winding to heat to dissipate capacitor voltage on the DC bus; and (2) when the first motor can not normally operate, the discharge resistor dissipates the capacitor voltage on the DC bus. On the premise of not influencing the automobile running state, the invention only uses motor winding loss to quickly dissipate electricity energy stored in each subsystem filter capacitor on the high-voltage DC bus; and no discharge resistor is required to be connected in parallel in each subsystem controller, thus improving system efficiency and lowering part cost. The invention can quickly discharge to capacitors connected on the high-voltage DC bus in parallel after cutting off high voltage; then, strong electricity and week electricity are almost synchronous during parking so as to simplify finished automobile control algorithm; and specially, passenger safety can be effectively ensured during emergency failure.

Owner:SAIC MOTOR

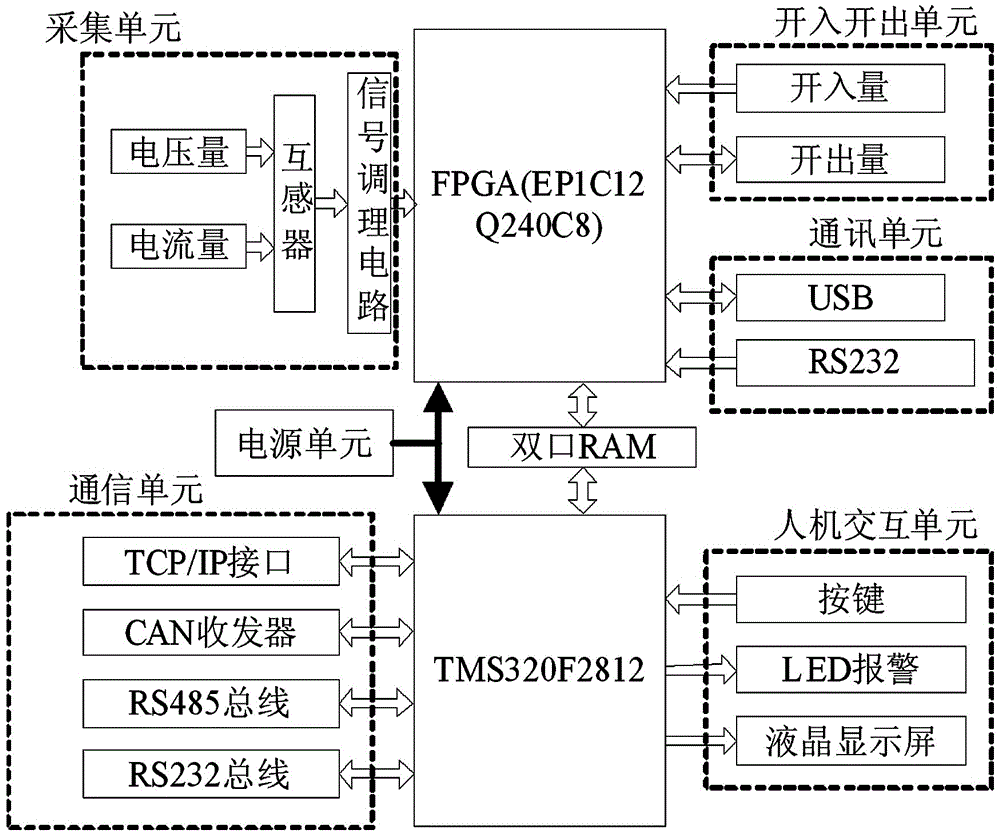

Reactive power compensation controller for power

InactiveCN105490283ASimple control algorithmImprove power factorEmergency protective circuit arrangementsReactive power adjustment/elimination/compensationLiquid-crystal displayPower equipment

The invention belongs to the technical field of power equipment, and particularly relates to a reactive power compensation controller for power, in particular to a device of the reactive power compensation controller applied to an electric power line. The reactive power compensation controller for power is a design of the reactive power compensation controller on the basis of an FPGA and DSP unit, and comprises a power supply unit, the FPGA and DSP unit, a key input unit, a liquid crystal display unit, a communication unit and a control unit. Automatic tracking compensation is carried out according to the change condition of a reactive power and a voltage of the line, so that the power factor is improved; the voltage quality is improved; the reactive power transmission flow of a power distribution line is reduced; the reactive power transmission distance of the power distribution line is shortened; and the reactive power compensation controller also has significant characteristics of high reliability, small size, easiness in installation, powerful function and low cost.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com