Voltage-equalizing and power-equalizing control method for three-phase multi-module cascade solid-state transformer

A solid-state transformer and control method technology, applied in control/regulation systems, output power conversion devices, DC power input conversion to DC power output and other directions, can solve problems such as voltage and power imbalance, and achieve low voltage stress on switching tubes. , to achieve the effect of unit power factor and accelerated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

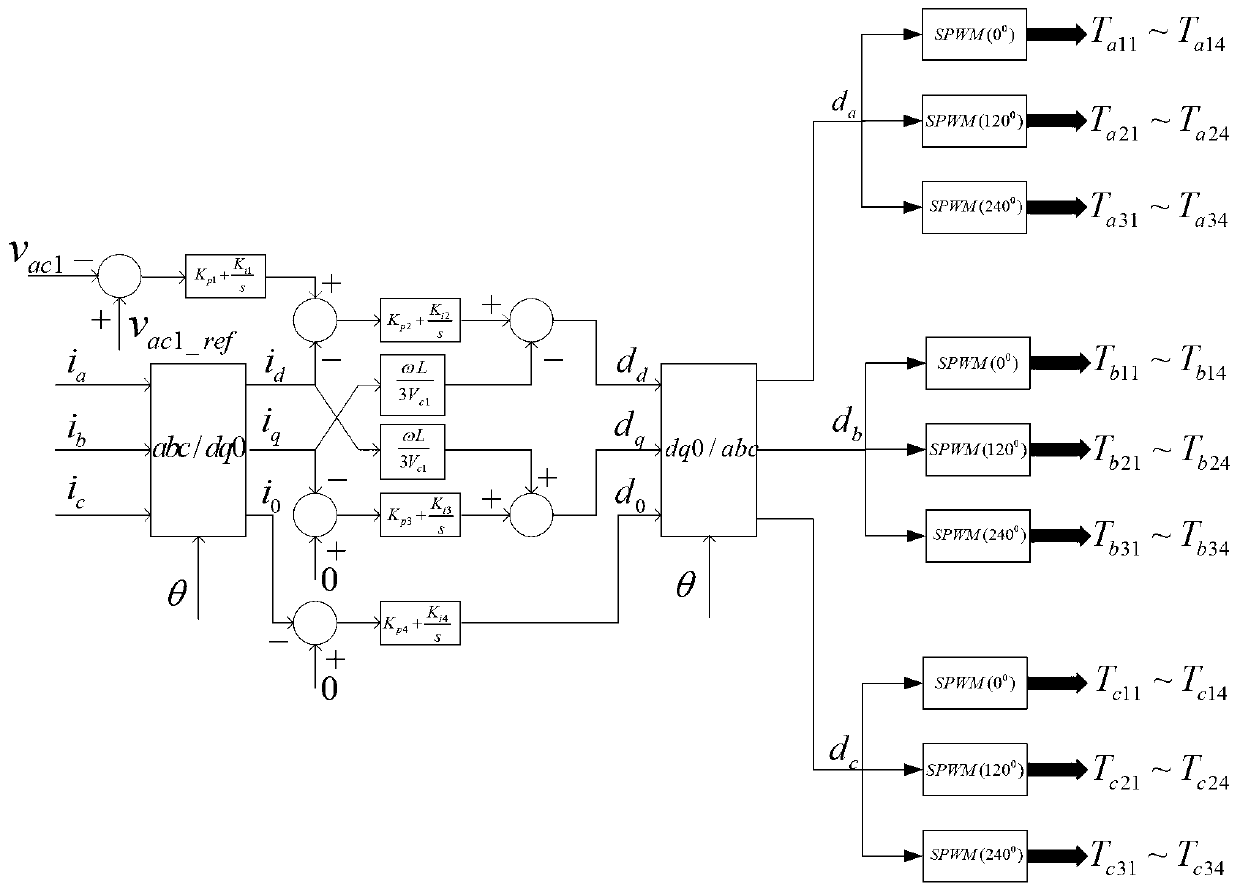

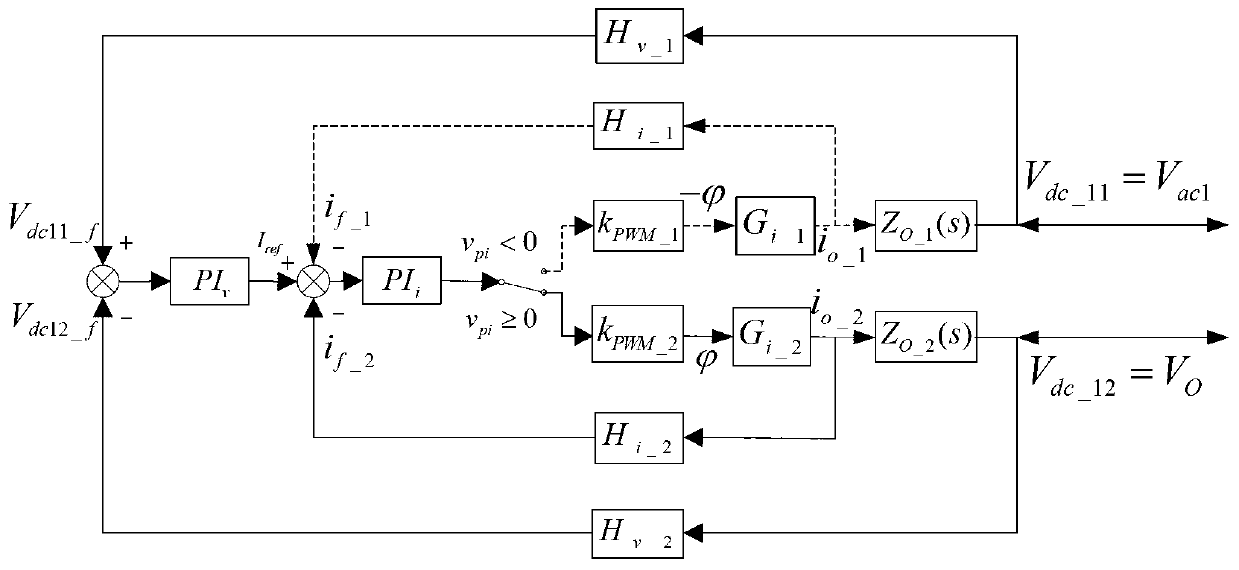

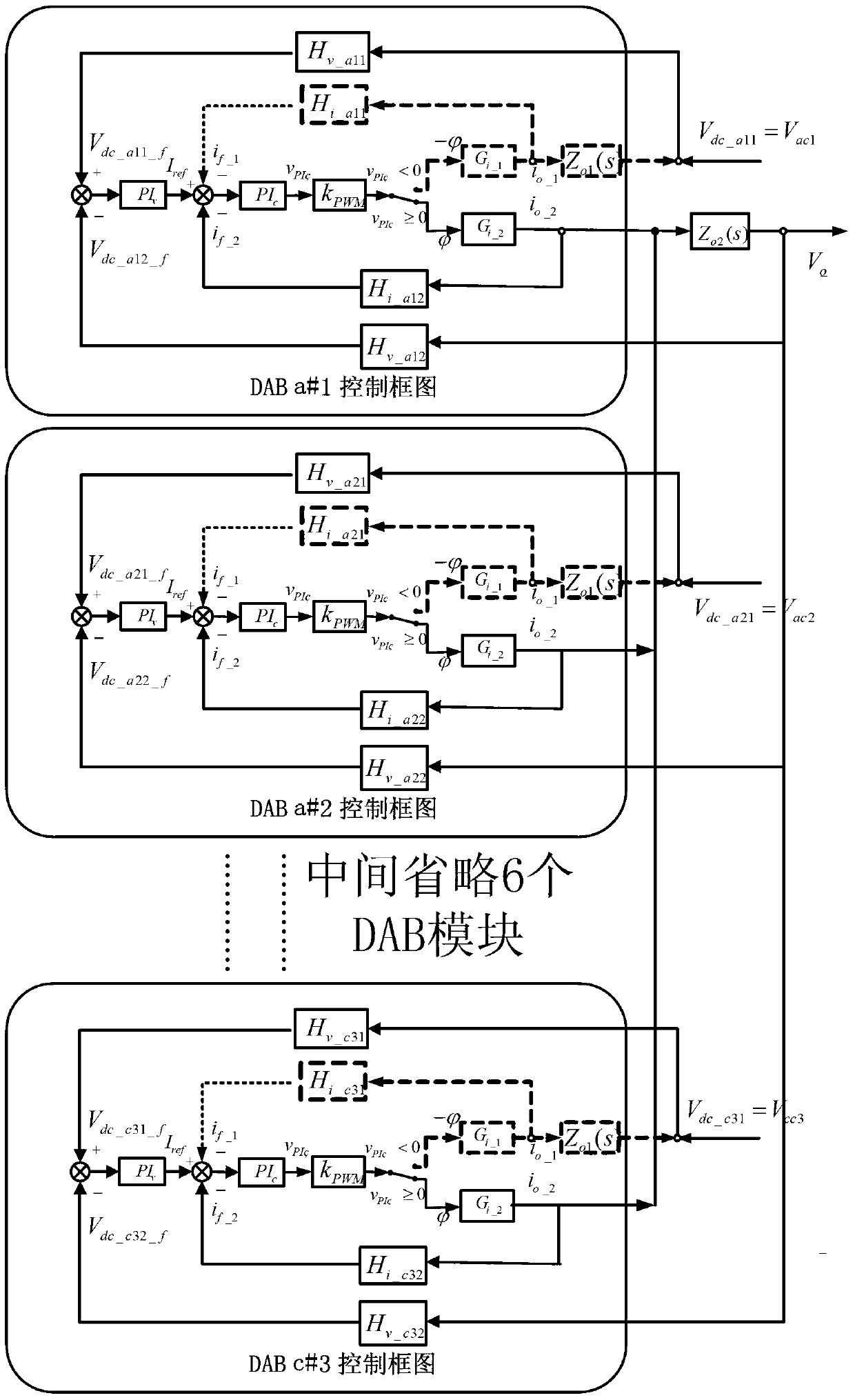

[0024] The three-phase SST system power main circuit part of the three-phase multi-module cascaded solid-state transformer voltage equalization power control method of the present invention is composed of three stages: the input stage is a high-frequency active three-phase AC / DC rectifier, and the intermediate stage is a high-frequency Isolated DC / DC converter, the output stage is a high frequency DC / AC inverter. In order to meet the requirements of high voltage and high power level, each phase of the AC side of the input stage adopts multi-module series connection, the high-voltage DC output terminals of each module of the input stage are connected to the input terminals of each module of the intermediate stage, and the output terminals of each module of the intermediate stage are connected in parallel to output 400 volts DC, the output stage high-frequency inverter converts 400 volts of direct current into output 220 volts / 50 Hz of alternating current. Power can flow in both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com