Reactor grading ring

A technology of equalizing rings and reactors, applied in circuits, electrical components, preventing/reducing unwanted electric/magnetic influences, etc., can solve problems such as inconsistent field strength, poor voltage equalizing effect, and equipment insulation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

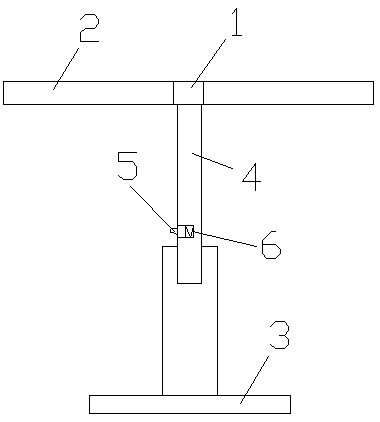

[0013] A pressure equalizing ring for a reactor, which is provided with a separation rod 1, a pressure equalization ring 2 is provided on both sides of the separation rod 1, a base 3 is provided at the lower end of the separation rod 1, and a The telescopic rod 4 is provided with a depressing tongue 5 on the telescopic rod 4, a chamber is provided on the rear side of the depressing tongue 5, and a compression spring 6 is arranged in the chamber, and the depressing tongue 5 and the compression spring 6 are connected to each other .

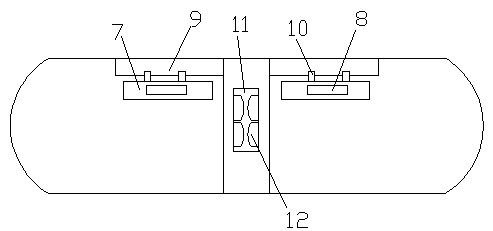

[0014] A connecting groove 7 is arranged inside the pressure equalizing ring 2 , and a pressure equalizing plate 8 is arranged in the connecting groove 7 .

[0015] A suspension rod 9 is arranged between the connection groove 7 and the pressure equalizing ring 2 , and a bite mouth 10 is arranged outside the connection groove 7 .

[0016] The bite mouth 10 on the outside of the connecting groove 7 and the suspension rod 9 are engaged with each othe...

Embodiment 2

[0018] A pressure equalizing ring for a reactor, which is provided with a separation rod 1, a pressure equalization ring 2 is provided on both sides of the separation rod 1, a base 3 is provided at the lower end of the separation rod 1, and a The telescopic rod 4 is provided with a depressing tongue 5 on the telescopic rod 4, and a cavity is provided on the rear side of the depressing tongue 5, and a compression spring 6 is arranged in the cavity, and the depressing tongue 5 and the compression spring 6 are connected to each other .

[0019] A connecting groove 7 is arranged inside the pressure equalizing ring 2 , and a pressure equalizing plate 8 is arranged in the connecting groove 7 .

[0020] A suspension rod 9 is arranged between the connection groove 7 and the pressure equalizing ring 2 , and a bite mouth 10 is arranged outside the connection groove 7 .

[0021] The bite mouth 10 on the outside of the connecting groove 7 and the suspension rod 9 are engaged with each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com