Method for quickly discharging for automobile high-voltage DC bus

A high-voltage DC and DC bus technology, applied in the field of automobile control, can solve the problems of reducing power system efficiency, long discharge time, loss, etc., and achieve the effect of simplifying the vehicle control algorithm, reducing component costs, and improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

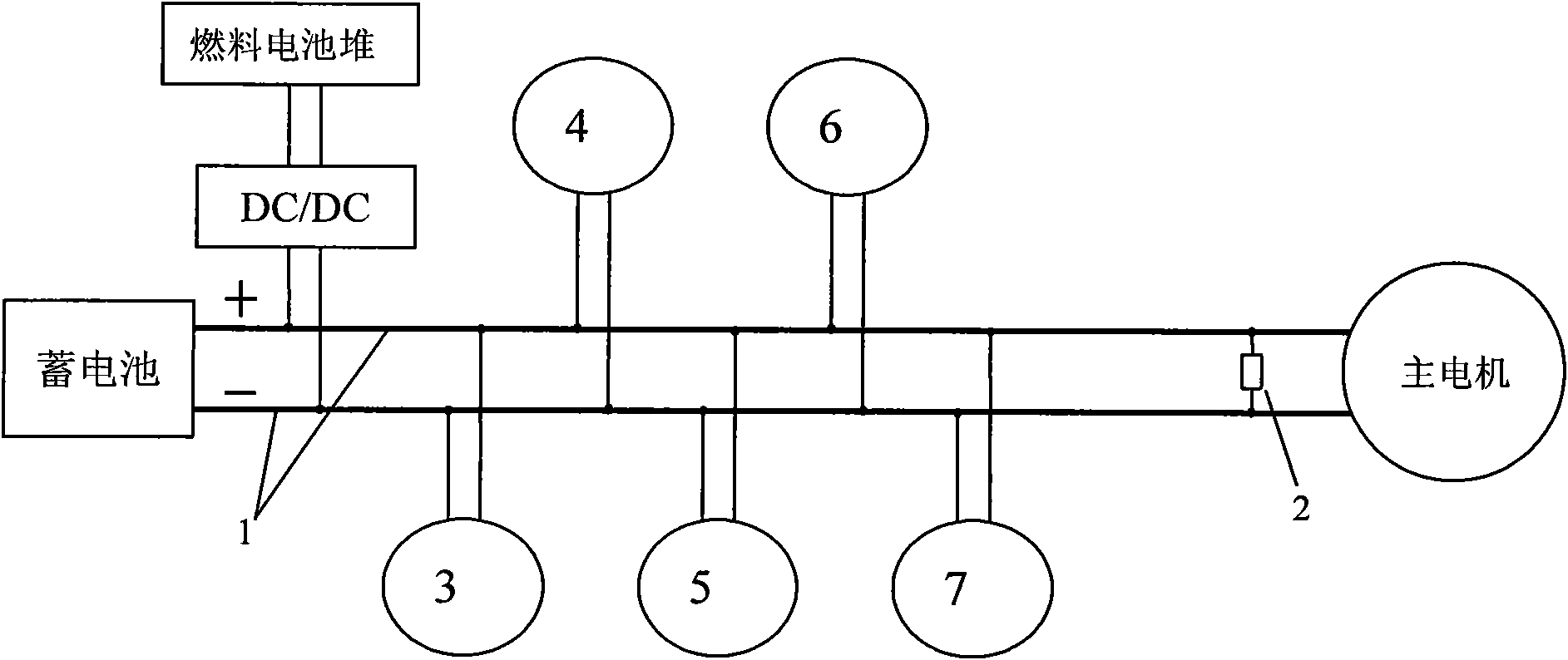

[0015] Such as figure 1 Shown is an embodiment of the fuel cell vehicle power system using the present invention. In this system, the high-voltage DC bus 1 is connected to the power battery, the fuel cell stack (FCS) is connected in parallel with the power battery through a unidirectional DC / DC module, the main motor is connected in parallel to the high-voltage DC bus, and the high-voltage DC bus is also connected to other The high-voltage power consumption system, as shown in the figure, includes two electric water pumps 3, 4, two high-voltage electric fans 5, 6, electric air-conditioning compressor 7, etc., each subsystem is driven by a motor, and the motor in each subsystem is sub motor.

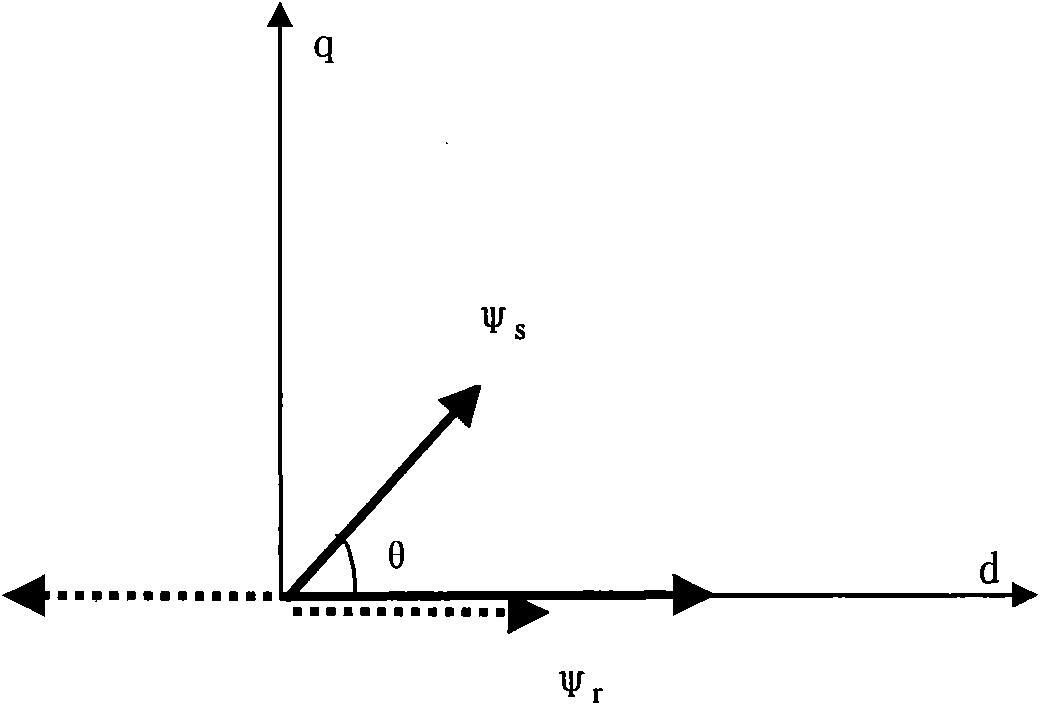

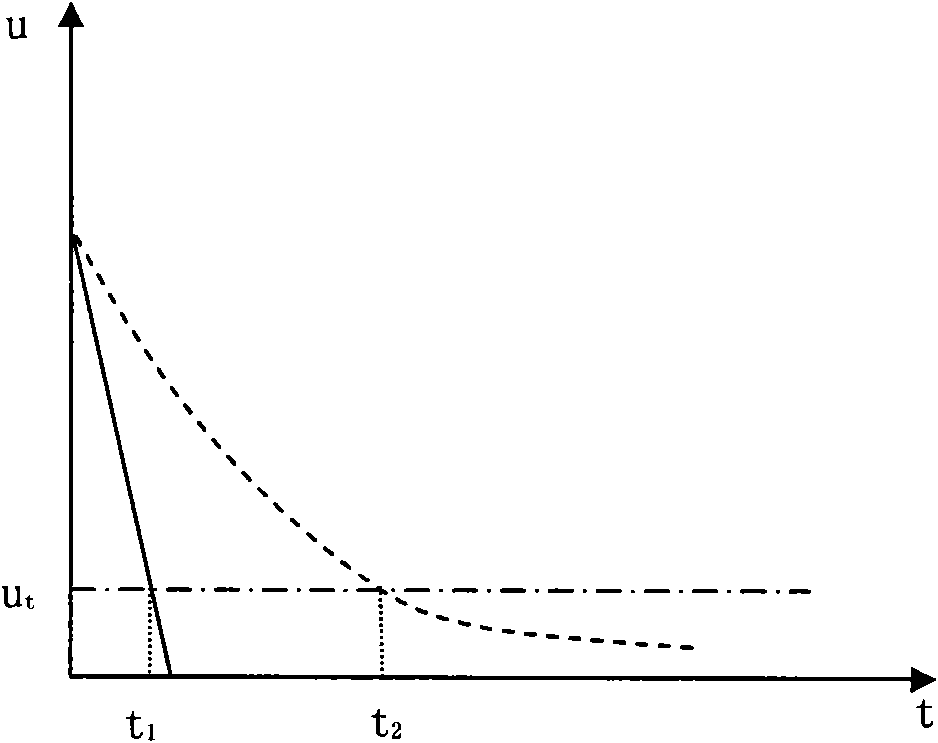

[0016] Such as figure 2 As shown, the output torque of the motor is determined by the rotor flux linkage ψ r and stator flux linkage ψ s It is generated by interaction, and its size is related to the angle θ between the two: the torque is the largest when θ=90°, and the torque is zer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com